Screening method for pressing materials of round-flat slitter

A screening method and disc technology, applied in chemical instruments and methods, filtration, solid separation, etc., can solve the problems of uneven pressing, large deformation of products, waste, etc., and achieve uniform and stable density distribution and high first-time success rate Improvement, uniform size and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

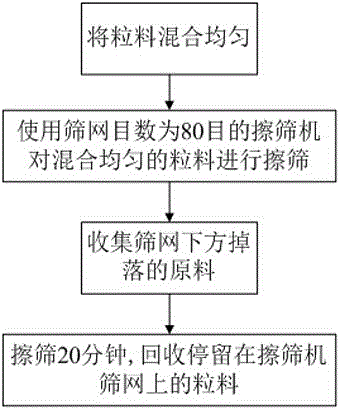

[0019] Such as figure 1 The screening method of a kind of disc knife pressing material shown, comprises the following steps:

[0020] (A) Mix the granules evenly; (B) Sieve the evenly mixed granules with a sieve machine with a mesh number of 80, and collect the raw materials falling from the bottom of the sieve; (C) After sieving for 20 minutes Stop the work of the sieve wiper, and recover the pellets that stay on the sieve of the sieve wiper. The granules in the step (A) are washed and dried before being mixed. The pellets recovered in the step (C) are returned to the furnace.

[0021] The method of the present invention firstly mixes the pellets evenly to ensure that the follow-up process is carried out under the condition of uniform pellets. After that, the uniformly mixed pellets are wiped and screened by a screen wiper with a mesh number of 80. The screen wiper continuously squeezes and crushes the pellets, and finally makes the particle size smaller. drop in the hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com