Nano cellulose, and preparation method thereof

A technology of nanocellulose and fiber raw materials, applied in the field of nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of nanocellulose, comprising the following steps:

[0040] (1) Use a blender to crush 2g of cotton fibers;

[0041] (2) Take out the broken cotton fiber, soak it in 100ml distilled water together with 3g sodium chlorite for 15min, then treat it at 70°C for 40min, during this period, use glacial acetic acid to adjust the pH of the solution to keep it at 4, repeat three times to remove the fiber most of the lignin in the raw material to obtain a suspension;

[0042] (3) Place the suspension obtained in step 2 in an ice bath (0°C), and add 250ml of 85% (volume fraction) phosphoric acid to it dropwise within 20 minutes using a dropping funnel. After calculation, the molar concentration of phosphoric acid in the total solution after adding is 10.7mol / L;

[0043] (4) Place the treated suspension in an oil bath at 120°C, stir for 100 minutes, and then quickly cool down to room temperature (20-25°C);

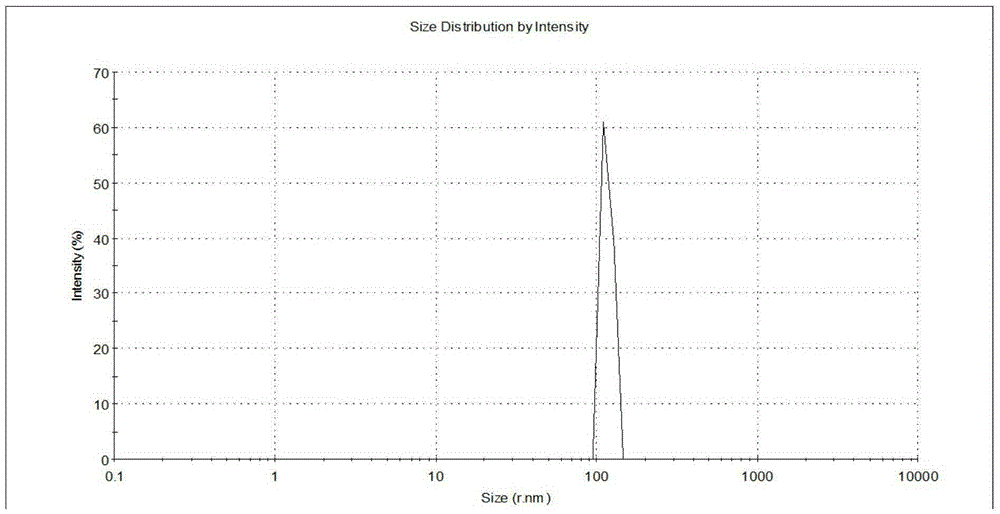

[0044] (5) Centrifuge with a centrifuge at 4000rpm f...

Embodiment 2

[0052] The steps are the same as in Example 1, using phosphoric acid in different proportions (the volume concentration of phosphoric acid is 44%), and other preparation process conditions, parameters, and steps are exactly the same. The yield of the prepared nanocellulose is 60.7%, and the particle size is 600-1000nm, such as Figure 6 shown.

Embodiment 3

[0054] The steps are the same as in Example 1, using phosphoric acid in different proportions (the phosphoric acid volume concentration is 55%), and other preparation process conditions, parameters, and steps are exactly the same. The yield of the prepared nanocellulose is 66.56%, and the particle size is 200-600nm, such as Figure 7 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com