Method for preparing stable nano-silver

A nano-silver and stable technology, applied in the direction of nanotechnology, can solve the problems of reducing agent or additive toxicity, uneven particle size, slow preparation speed, etc., and achieve uniform and stable size, simple preparation process and fast preparation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

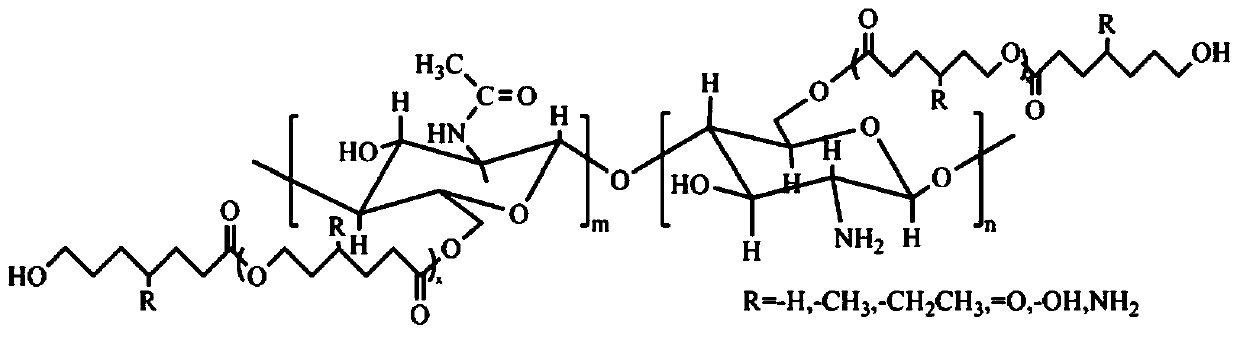

[0033] Take the preparation of chitosan-grafted polycaprolactone copolymer micelle aqueous solution as a stabilizer for nano-silver particles as an example. First, 10 mg of chitosan-g-poly(ε-caprolactone) graft copolymer (source? Molecular weight of chitosan and poly(ε-caprolactone) before and after grafting? Grafting rate? Self-made , mentioned above; the molecular weight of chitosan before grafting is 1.03×10 5 , the molecular weight of polycaprolactone is 2000, and the grafting rate is 29%. The same parameters are used for the copolymers and their derivative micelles mentioned later) into 10mL deionized water, and ultrasonic 3 times at 300W power, each 30 seconds each time, with an interval of 30 seconds, to form copolymer micelles with a concentration of 1 mg / mL. Then the copolymer micelles were compounded with silver nitrate aqueous solution, the compounding molar ratio was 1:1, and the radiation time was 20 minutes as an example. Quickly add silver nitrate aqueous solu...

Embodiment 2

[0036] Take the preparation of chitosan-grafted polycaprolactone copolymer micelle aqueous solution as a stabilizer for nano-silver particles as an example. First, 10 mg of chitosan-g-poly(ε-caprolactone) graft copolymer was dissolved in tetrahydrofuran solvent, and after being dissolved, it was slowly added dropwise to 10 mL of deionized water, and evaporated overnight to form a copolymer with a concentration of 1 mg / mL. micelles. Then the copolymer micelles were compounded with silver nitrate aqueous solution at a compounding ratio of 2:1. Silver nitrate aqueous solution (10mg / mL, dosage: 50μL) was quickly added dropwise to the copolymer micelle solution, and after a period of rapid stirring, it was irradiated under a mercury lamp (500W) with a wavelength of 365nm ultraviolet light for 15 minutes to complete the nano-silver solution. preparation.

Embodiment 3

[0038] Take the preparation of chitosan-grafted polycaprolactone copolymer micelle aqueous solution as a stabilizer for nano-silver particles as an example. First, 10 mg of chitosan-g-poly(ε-caprolactone) graft copolymer was dissolved in dimethyl sulfoxide solvent, and after dissolving, it was slowly added dropwise to 10 mL of deionized water, and after dialysis, it was mixed with silver nitrate Aqueous solution composite, composite ratio 1:2. Silver nitrate aqueous solution (10 mg / mL, dosage: 200 μL) was quickly added dropwise to the copolymer micelle solution, and then stirred rapidly for a period of time, and then irradiated under a mercury lamp (500 W) with a wavelength of 365 nm ultraviolet light for 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com