Upstream auxiliary tool for round-flat slitter pressing

An auxiliary tooling and upstream technology, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of uneven pressing charging, difficulty in pressing molding, waste, etc., achieve uniform and stable density distribution, improve the first-time success rate, and improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

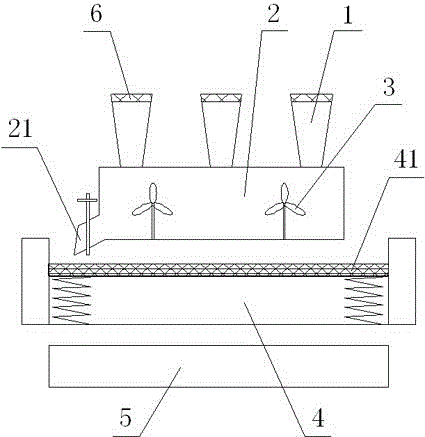

[0018] like figure 1 The upstream auxiliary tooling of a disc knife pressing shown includes a feed port 1, and the feed port 1 is provided with a filter screen 6 with a mesh number of 20, and the feed port 1 is connected to the mixing chamber 2, and the A stirring device 3 is arranged in the stirring chamber 2, and a vibrating screen 4 is arranged below the discharge end 21 of the stirring chamber 2. The vibrating screen 4 has a three-layer screen 41, and the mesh number of the three-layer screen 41 is 40 from top to bottom. Mesh, 60 mesh, and 80 mesh, a material receiving device 5 is arranged below the vibrating screen 4; the material receiving device 5 is a belt conveyor; the vibrating screen 4 is a linear vibrating screen; there are three feeding ports 1, The three feeding ports 1 are all connected to the stirring chamber 2; the stirring device 3 is a stirrer.

[0019] In the present invention, the raw material enters the mixing chamber 2 through the feed port 1, and a 20-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com