Method for preparing fibroin nanoparticles taking polyvinyl alcohol as stabilizer

A technology of silk fibroin and nanoparticles, which is applied in the field of preparation of silk fibroin nanoparticles, can solve the problems of difficulty in large-scale production, low yield, and need for special equipment, and achieve low pollution, low energy consumption, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

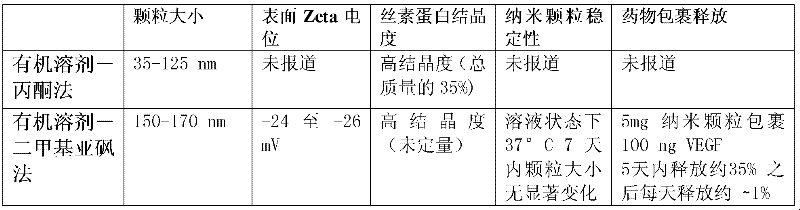

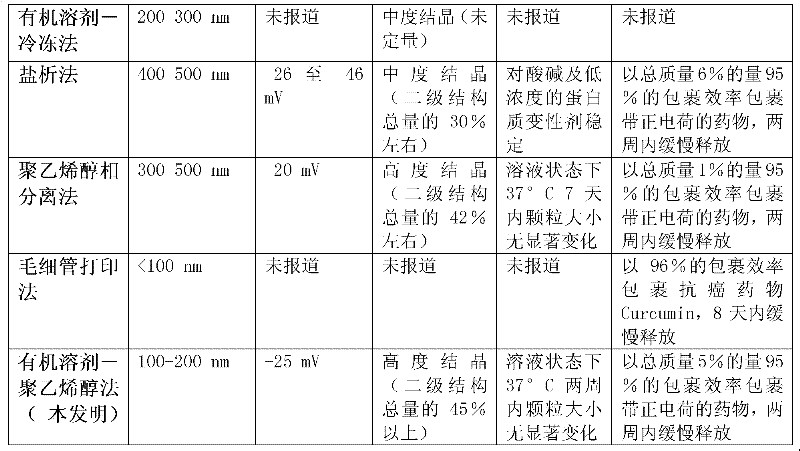

Image

Examples

Embodiment 1

[0043] 1) The silk fibroin protein extracted from silk is made into a silk fibroin protein solution with a weight volume percentage of 5%;

[0044] 2) Add a polyvinyl alcohol solution with a weight ratio of 1:1 to the silk fibroin solution to obtain a blend solution, and the polyvinyl alcohol solution has an average molecular weight of 30,000 Daltons , made by dissolving polyvinyl alcohol with a degree of hydrolysis of 98% in water;

[0045] 3) Add the above blend solution dropwise at a rate of 0.5 ml / min into the methanol solution stirred at a speed of 400 rpm with a volume ratio of 1:4 to the blend solution, and then continue stirring at a speed of 100 rpm for 1 hour to obtain Uniform silk fibroin nanoparticle solution;

[0046] 4) further purifying and enriching the uniform silk fibroin nanoparticle solution obtained above by ammonium sulfate salting out precipitation method or natural volatilization and centrifugation to obtain uniform silk fibroin nanoparticles with a si...

Embodiment 2

[0057] 1) The silk fibroin protein extracted from silk is made into a silk fibroin protein solution with a weight volume percentage of 8%;

[0058] 2) Add a polyvinyl alcohol solution with a weight ratio of 1:5 to the silk fibroin solution to obtain a blend solution, and the polyvinyl alcohol solution has an average molecular weight of 180,000 Daltons , the degree of hydrolysis is 87% polyvinyl alcohol dissolved in water;

[0059] 3) Add the above blend solution dropwise at a rate of 1 ml / min into ethanol stirred at a speed of 600 rpm with a volume ratio of 1:10 to the blend solution, and then continue to stir at a speed of 200 rpm for 6 hours to obtain a uniform The silk fibroin nanoparticle solution;

[0060] 4) further purifying and enriching the uniform silk fibroin nanoparticle solution obtained above by ammonium sulfate salting out precipitation method or natural volatilization and centrifugation to obtain uniform silk fibroin nanoparticles with a size of 200 nanometers...

Embodiment 3

[0071] 1) The silk fibroin protein extracted from silk is made into a silk fibroin protein solution with a weight volume percentage of 7%;

[0072] 2) Add a polyvinyl alcohol solution with a weight ratio of 1:4 to the silk fibroin solution to obtain a blend solution, and the polyvinyl alcohol solution has an average molecular weight of 100,000 Daltons , made by dissolving polyvinyl alcohol with a degree of hydrolysis of 89% in water;

[0073] 3) Add the above-mentioned blend solution dropwise at a rate of 0.8 ml / min to methanol stirred at a speed of 500 rpm with a volume ratio of 1:7 to the blend solution, and then continue to stir at a speed of 150 rpm for 4 hours to obtain a uniform The silk fibroin nanoparticle solution;

[0074] 4) further purifying and enriching the homogeneous silk fibroin nanoparticle solution obtained above by the ammonium sulfate salting out precipitation method or natural volatilization and centrifugation to obtain uniform silk fibroin nanoparticles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com