Horizontal dual-mold cold extrusion mechanism and forming production process

An extrusion mechanism and mold cooling technology, applied in the direction of presses, stamping machines, metal extrusion dies, etc., can solve the problems of unstable bottom dimensional accuracy, slow production speed, low production efficiency, etc., to save working hours per piece, High production efficiency and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

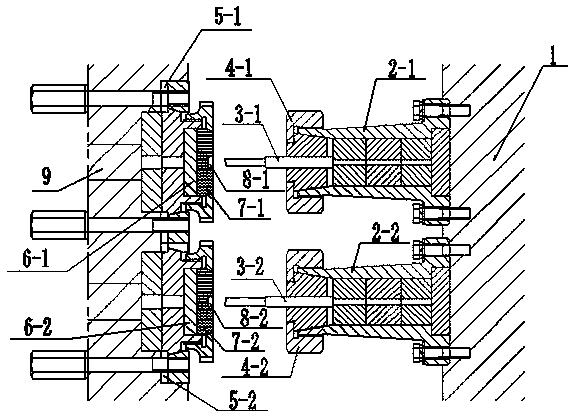

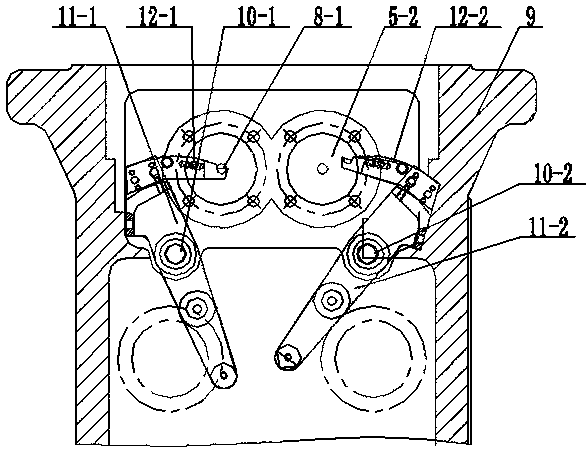

[0018] A horizontal double-mode cold extrusion mechanism, including a multi-link toggle mechanical transmission mechanism, an automatic feeding mechanism and a bed (9), the multi-link toggle mechanical transmission mechanism includes a slider (1), a slider (1) The front end is connected with the punch seat I (2-1) and the punch seat II (2-2), and the punch seat I (2-1) and the punch seat II (2-2) are on the slider (1 ) front ends are horizontally side by side, the front ends of punch seat I (2-1) and punch seat II (2-2) are respectively connected with punch I (3-1) and punch II (3-2), and the punch Die I (3-1) and punch II (3-2) are respectively fixed with punch seat nut I (4-1) and punch seat nut II (4-2).

[0019] The bed (9) is provided with sinking hole I (5-1), sinking hole II (5-2), sinking hole I (5-1), sinking hole II (5-2) parallel in the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com