Bismuthyl iodate nanosheet material and preparation method thereof

A technology of bismuth oxyiodate nanometer and sheet material, applied in the field of materials, can solve the problems of long reaction time, high temperature, uneven product structure, etc., and achieve the effects of short preparation time, improved utilization rate and regular product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

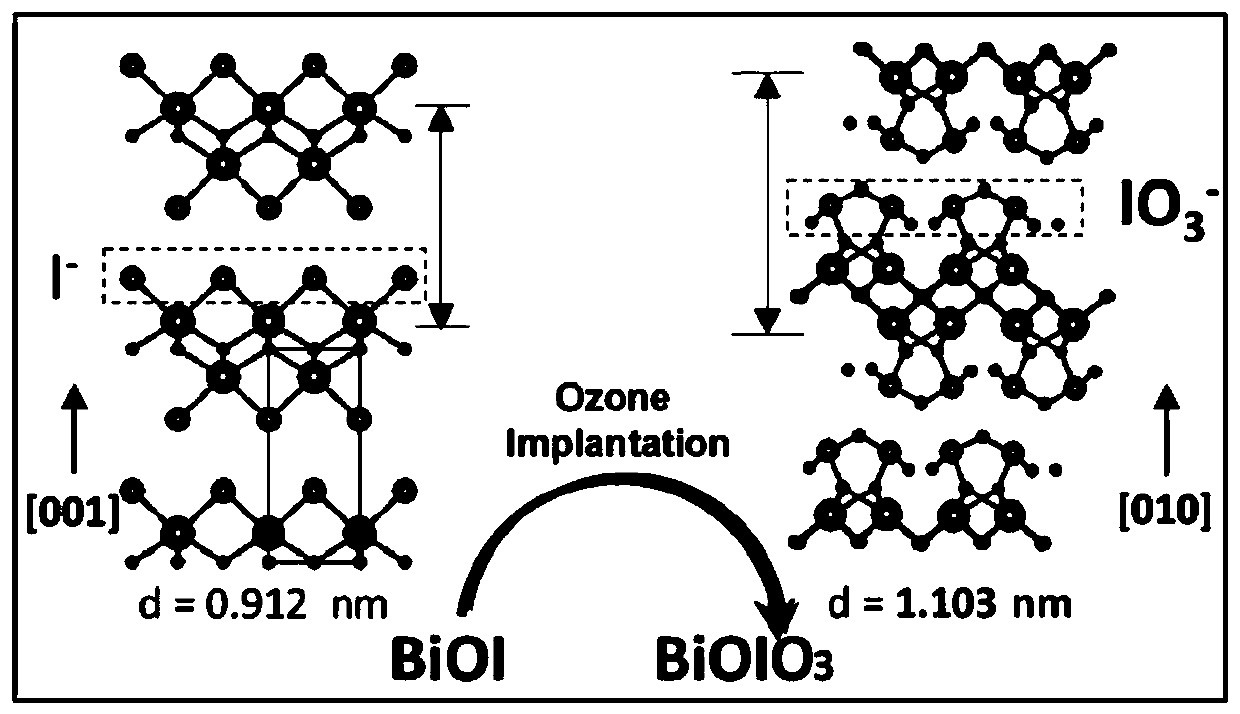

[0024] Example of the present invention provides a kind of preparation method of bismuth oxyiodate nanosheet material, comprises the steps:

[0025] S01. Provide bismuth oxyiodide nanosheet materials;

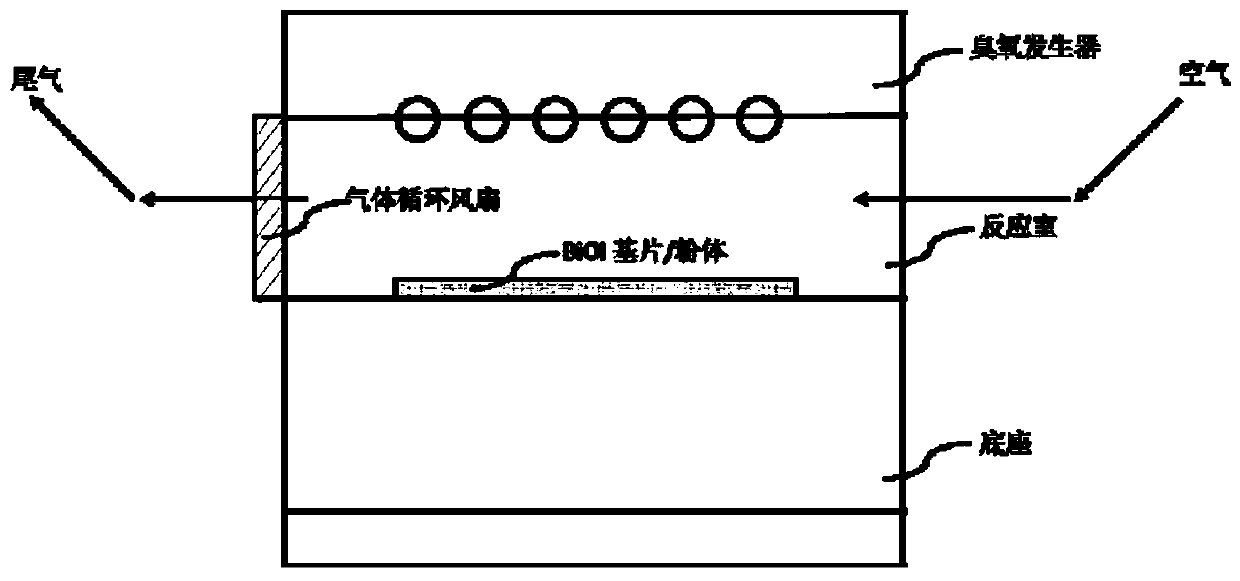

[0026] S02. Place the bismuth oxyiodide nanosheet material in an ozone atmosphere to react for 3-20 hours; the volume content of ozone in the ozone atmosphere is 5%-80%.

[0027] Specifically, in the above step S01, a bismuth oxyiodide nanosheet material is provided, preferably, the bismuth oxyiodide nanosheet material is prepared by an electroplating method or a solvothermal method.

[0028] In a preferred embodiment of the present invention, the electroplating method is used to prepare bismuth oxyiodide nanosheet material, which specifically includes the following steps:

[0029] G01. Provide potassium iodide aqueous solution, add concentrated nitric acid, then add Bi(NO 3 ) 3 ·5H 2 O is dissolved to obtain the first solution;

[0030] G02. Provide a p-benzoquinone alcoh...

Embodiment 1

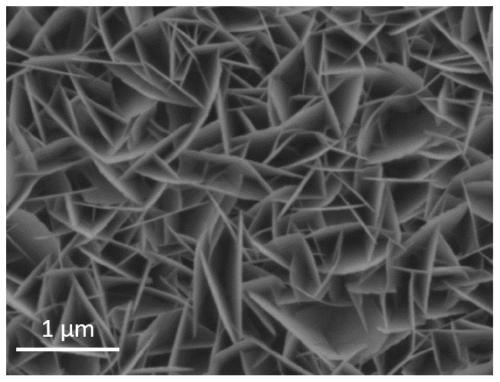

[0065] Preparation of bismuth oxyiodide nanosheets by electroplating and further preparation of bismuth oxyiodate nanosheets

[0066] Add 50mL water to dissolve 3.32g potassium iodide, add 50μL concentrated nitric acid, then add 0.97g Bi(NO 3 ) 3 ·5H 2 O is dissolved to obtain the first solution, which is an orange clear solution;

[0067] Dissolve 0.5g p-benzoquinone in 20mL absolute ethanol to obtain the second solution;

[0068] The first solution and the second solution were mixed, stirred for 5min, transferred to the electrolytic cell, under the three-electrode system, a constant potential of -0.1V (relative to the silver silver chloride reference electrode) was applied for 100 to 200s, and the constant potential was applied. The voltage is maintained for 100 to 200s, and electroplated on the pre-cleaned conductive substrate to obtain the bismuth oxyiodide nanosheet material.

[0069] The above-mentioned bismuth oxyiodide nanosheet material is put into a reaction chambe...

Embodiment 2

[0071] Preparation of bismuth oxyiodide nanosheets by solvothermal method and further preparation of bismuth oxyiodate nanosheet materials

[0072] 1mmol Bi(NO 3 ) 3 ·5H 2 O is dissolved in 20mL ethylene glycol to obtain the third solution;

[0073] 1mmol potassium iodide was dissolved in 20mL methanol to obtain the fourth solution;

[0074] The third solution and the fourth solution were mixed and stirred for 30 minutes, then transferred to a 50mL reaction kettle, and reacted at 180°C for 8h; then cooled to room temperature, centrifuged, washed with water and ethanol several times, and then dried to obtain the iodine The bismuth oxide nanosheet material is a 1.5 micron powder.

[0075] Put the above-mentioned bismuth oxyiodide nanosheet powder material into the reaction chamber, ensure that the ozone content in the ozone reactor is 5%-80%, adjust the oxidation reaction of the ozone generator for 10 hours, the reaction degree can be adjusted, and BiOI / BiOIO 3 Heterojunc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com