Rub screening machine structure for producing wafer cutter raw materials

A raw material and wafer technology, which is applied in the field of wafer knife production, can solve problems such as waste, unguaranteed product metallographic appearance, and large product deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

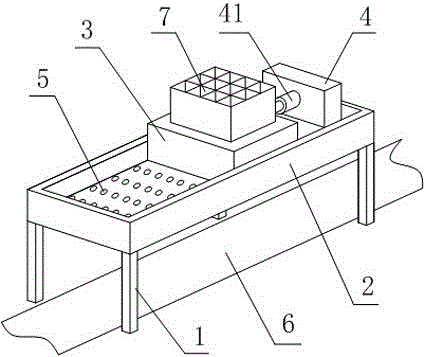

[0016] Such as figure 1 The structure of a screen cleaning machine for producing disc knife raw materials shown includes a bracket 1, a trough 2 is fixed above the bracket 1, the trough 2 is rectangular, and the surface of the trough 2 is evenly distributed with several diameters of 0.18 mm. The circular through hole 5 of mm, the distance between the centers of circles between two adjacent circular through holes 5 is 1mm; The sliding material pushing block 3 that matches with the material trough 2 is arranged in the described material trough 2, and described sliding material pushing away The width of the block 3 is consistent with the internal width of the chute 2, and the material storage box 7 is fixed on the sliding pushing block 3, the upper part of the storage box 7 is open, and the lower part is welded on the sliding pushing block 3; the chute 2 One end is fixed to the driving device 4, and the driving end 41 of the driving device 4 is connected with the sliding pushing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com