A stirring device for architectural paint

A stirring device and technology for construction, applied in the field of coatings and construction, can solve the problems of unsatisfactory composition and size uniformity, uneven coating, uneven coating particle size, etc., and achieve product uniformity and stability enhancement and strengthening The effect of stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

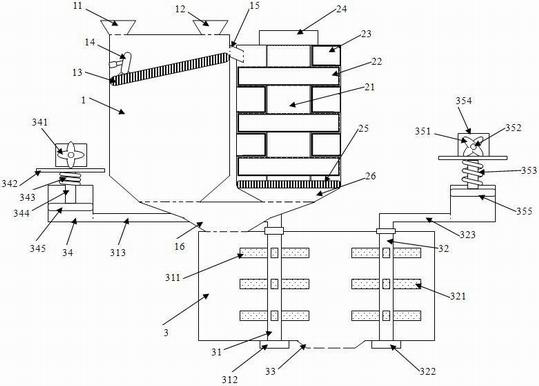

[0031] Such as figure 1 Shown: including filter chamber, grinding chamber, mixing discharge part, stirring chamber, first air piston part and second air piston part.

[0032]The filter chamber includes a filter chamber shell, a filter chamber inlet, a filter chamber water inlet, an inclined filter plate, a broom plate part, a large block discharge port and a small block discharge port; The leftmost side of the top wall of the chamber casing, the water inlet of the filter chamber is set on the right side of the top wall of the filter chamber casing, and a slanted filter plate is arranged inside the filter chamber casing, and the slanted filter plate is set in the form of lower left and higher right. A broom board part is arranged on the upper part of the inclined filter plate, and the broom board part includes a broom board and a thrust extension rod. The filter plate is set at an acute angle (29°), and the rubber strip at the bottom is closely connected to the top of the incl...

Embodiment 2

[0049] A stirring device for architectural paint, comprising a filter chamber, a grinding chamber, a mixing discharge part, a stirring chamber, a first air piston part and a second air piston part.

[0050] The filter chamber includes a filter chamber shell, a filter chamber inlet, a filter chamber water inlet, an inclined filter plate, a broom plate part, a large block discharge port and a small block discharge port; The leftmost side of the top wall of the chamber casing, the water inlet of the filter chamber is set on the right side of the top wall of the filter chamber casing, and a slanted filter plate is arranged inside the filter chamber casing, and the slanted filter plate is set in the form of lower left and higher right. The upper part of the inclined filter plate is provided with a broom board part, and the broom board part includes a broom board and a thrust extension rod, and a plurality of rubber strips are arranged at the bottom of the broom board, and the broom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com