Double-helix stepped forced vortex type liquid cooling radiator and processing method thereof

A technology of forced eddy current and double helix, which is applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of semiconductor device power increase, reduce thermal resistance, improve service life and safety, and enhance The effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

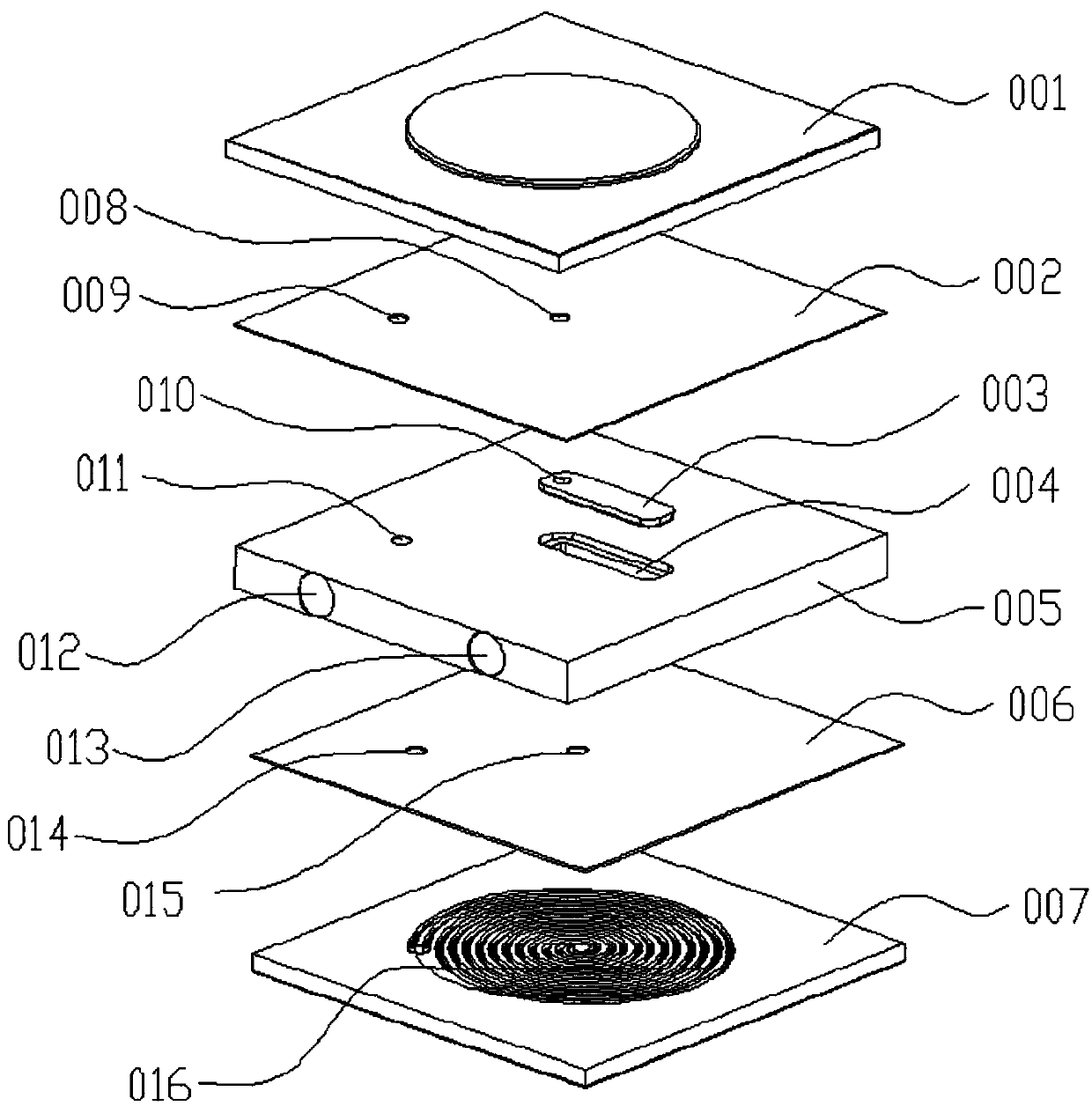

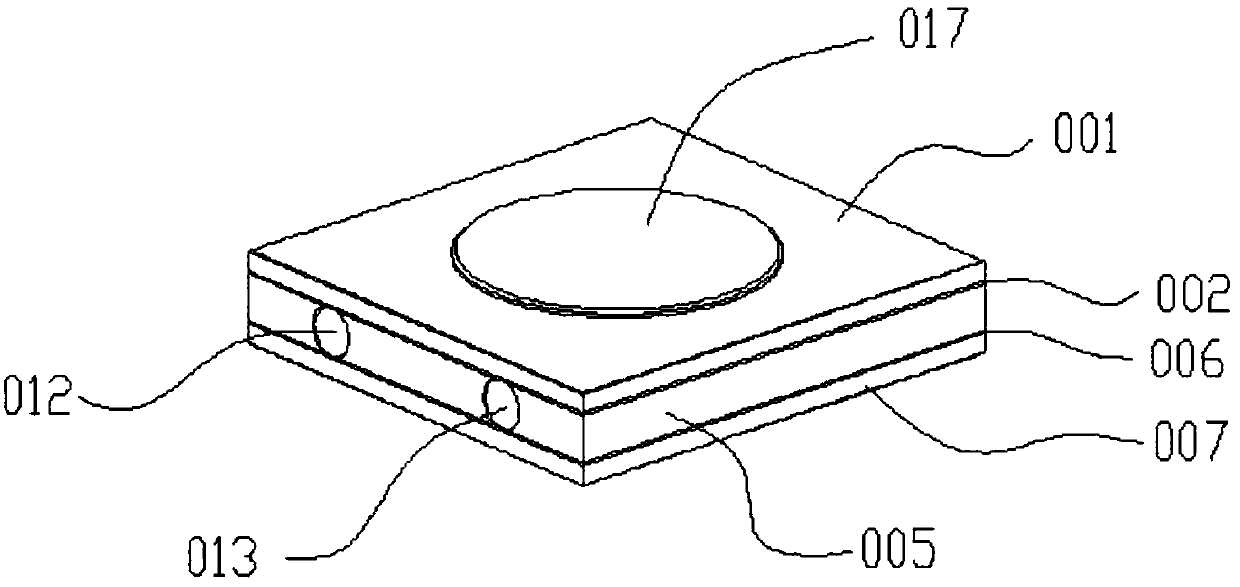

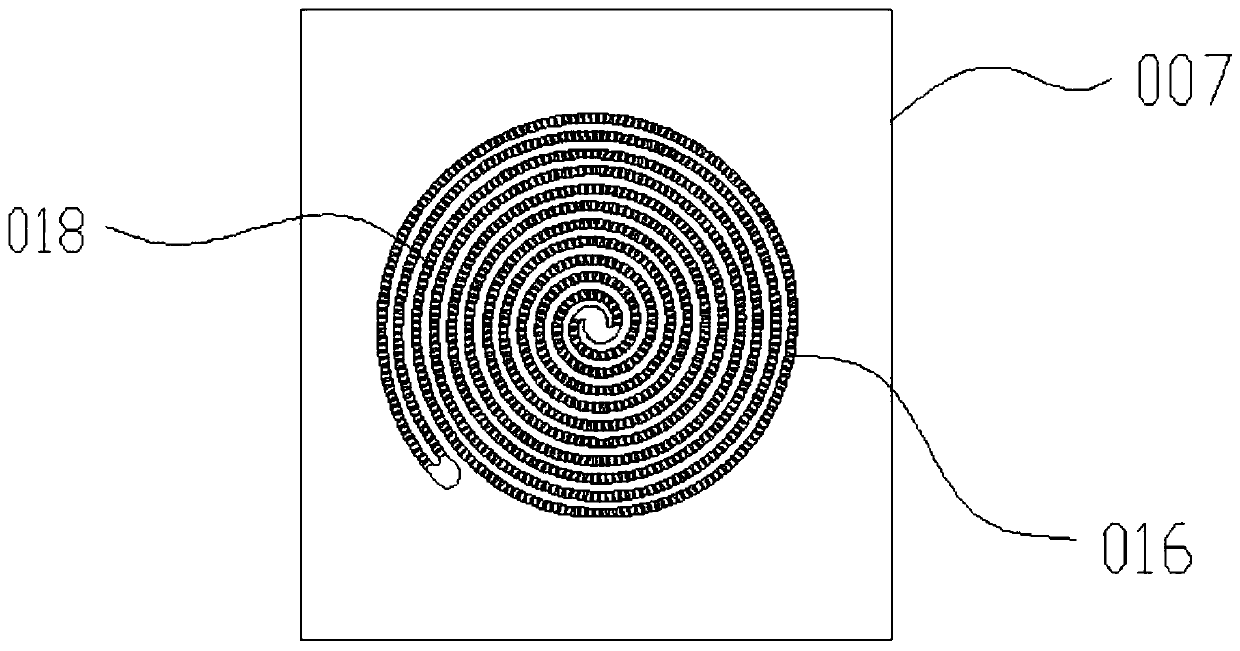

[0040] Figure 1 to Figure 4 It shows a preferred embodiment of the double-helix stepped forced vortex type liquid cooling radiator of the present invention, which includes an upper cover plate 001, a base plate 005 and a lower cover plate 007 fixed in sequence; the upper cover plate 001 and the lower cover plate 007 At least one of them is provided with a double-helix stepped groove 018, so that when the coolant flows through the double-helical stepped groove 018, it flows along a helical route and generates a forced vortex, forming one or two double-helical stepped forced vortex flow channels 016 One side of the substrate 005 is provided with a liquid flow inlet 013 and a liquid flow outlet 012, and a liquid return diversion hole 011 that runs through the top and bottom and communicates with the liquid flow outlet 012; the top and bottom of the substrate 005 are provided with The diversion groove 004 connected with the liquid inlet 013, the diversion groove 004 is sealed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com