Overflowing fanning strip for strengthening cooling of motor stator

A motor stator and sector-shaped technology, which is applied to the shape/style/structure of the magnetic circuit and the static parts of the magnetic circuit, etc., can solve the problems affecting the reliability of the service life of the motor, the small radial size of the unit, and the high thermal load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

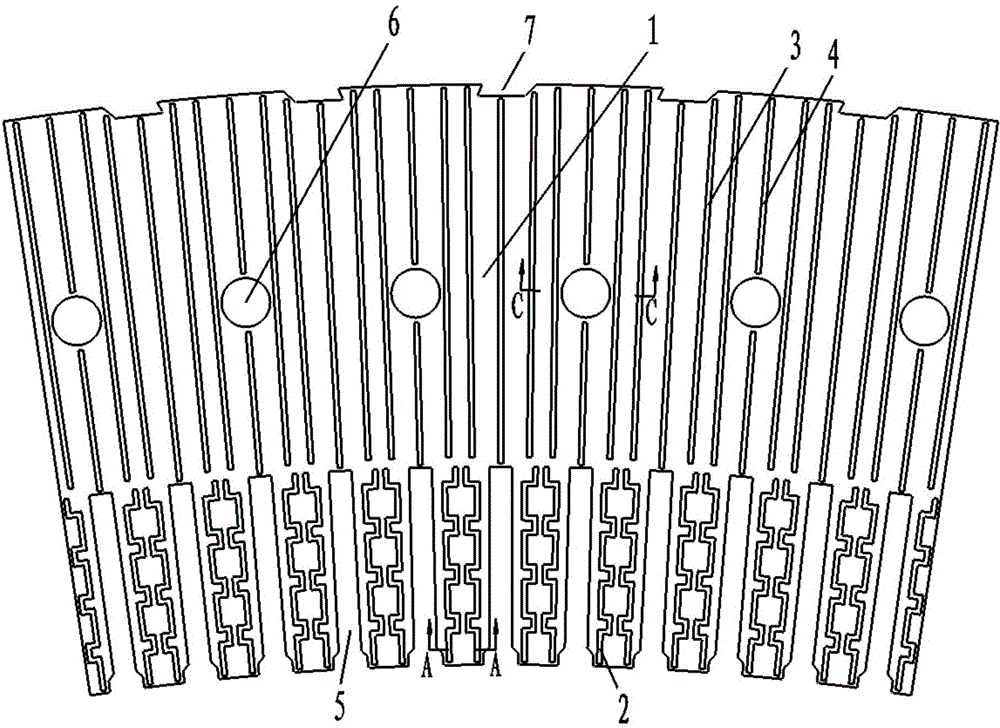

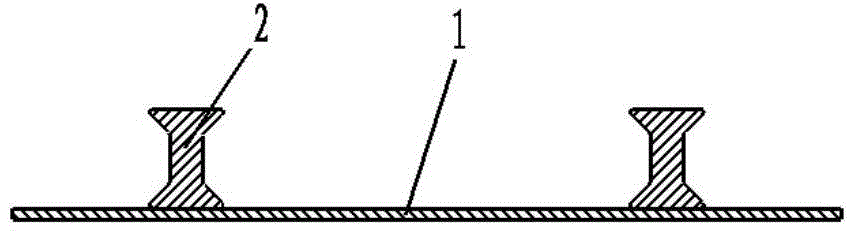

[0012] Such as figure 1 , 2 , shown in 3, a kind of overcurrent fan-shaped piece that strengthens the cooling of the motor stator is composed of fan-shaped piece 1, several broken line flow channel steels 2, several long straight line flow channel steels 3 and several short straight line flow channel steels 4 Composition, broken line flow channel steel 2, long straight line flow channel steel 3 and short straight line flow channel steel 4 are all fixed on the fan-shaped piece 1 by laser spot welding; they are arranged in a full circle between the stator core segments The stator ventilation ditch is formed between them as a fluid passage, and the fluid flowing through the passage can cool the stator coil and the stator core.

[0013] The sector piece 1 is processed by silicon steel sheet with a thickness of 0.65 mm, and a whole number of sector pieces 1 are connected to form a ring.

[0014] Several uniformly distributed slots 5 are processed on the inner circle of the secto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com