Water-cooling pipe, motor housing and manufacturing method thereof

A motor shell and water-cooling tube technology, which is applied in the manufacture of motor shells and motor shells, and in the field of water-cooling tubes, can solve the problems of easy generation of air holes, short service life, low yield rate, etc., to ensure shape stability, high service life, Effect of Yield Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following description is used to disclose the present invention so that those skilled in the art can implement the present invention. The preferred embodiments in the following description are only examples, and those skilled in the art can think of other obvious variations.

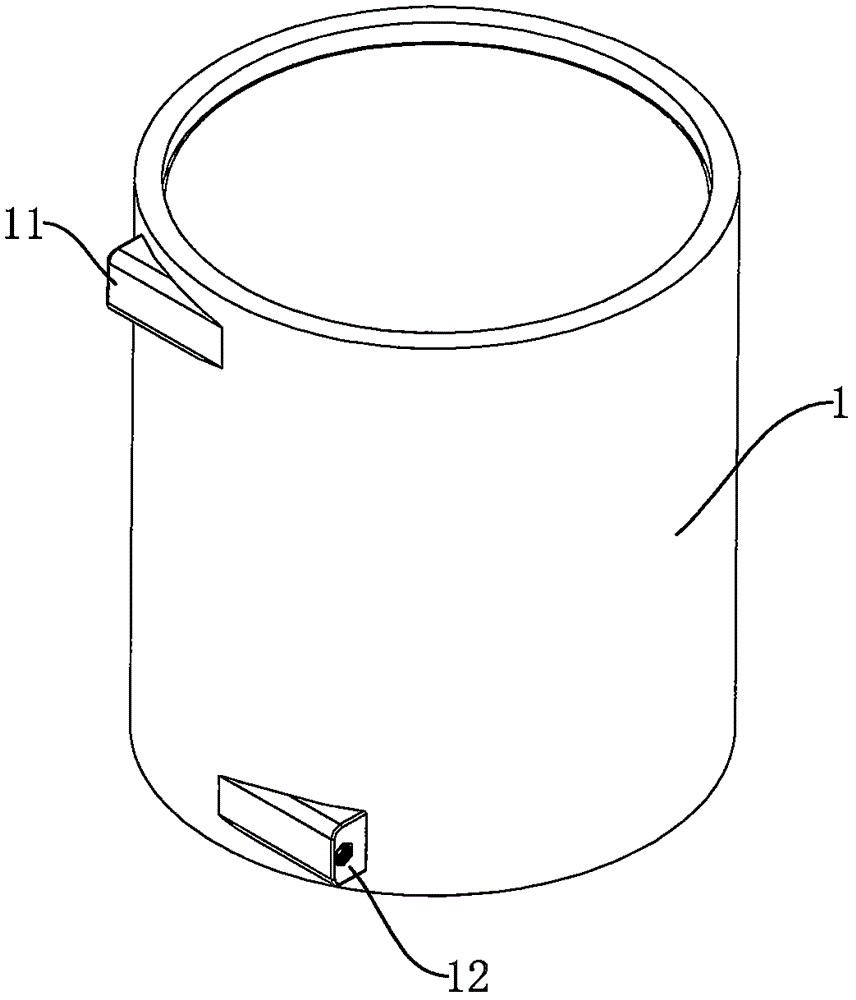

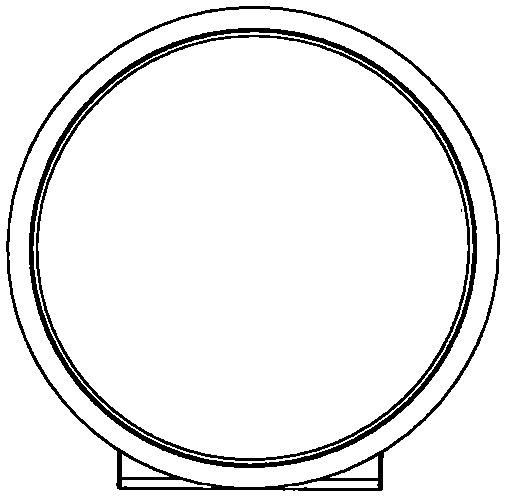

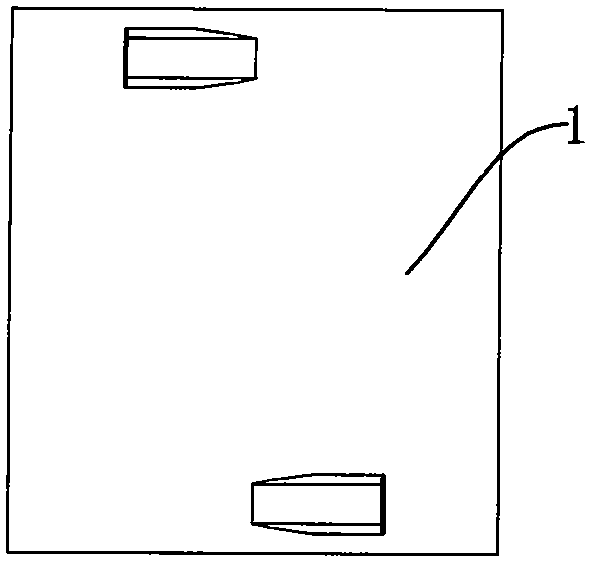

[0034] As shown in FIGS. 1-4, a water-cooled motor housing of the present invention includes a housing body 1, a spiral water-cooling tube 2, two joint sleeves 3, and two joint nuts 4.

[0035] The material of the casing body 1 is an aluminum-silicon alloy with a silicon content of 4% to 13%, in addition to 0.2% to 0.6% of magnesium and a small amount of rare earth elements. This alloy has good casting properties and wear resistance. The coefficient of thermal expansion is small.

[0036] The water cooling pipe 2 is arranged in the housing body 1. Preferably, as figure 2 As shown, the distance L1 between the inner side of the water-cooling pipe 2 and the inner wall of the housing body 1 is 0.5-1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com