Piston rod flat square end finish-milling forming cutter and positioning tool and method

A technology for forming tools and positioning tooling, applied in the field of metal cutting processing, can solve the problems of low processing efficiency, difficult direct processing, inconvenient operation, etc., and achieve the effects of low tool consumption cost, low manufacturing cost, and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

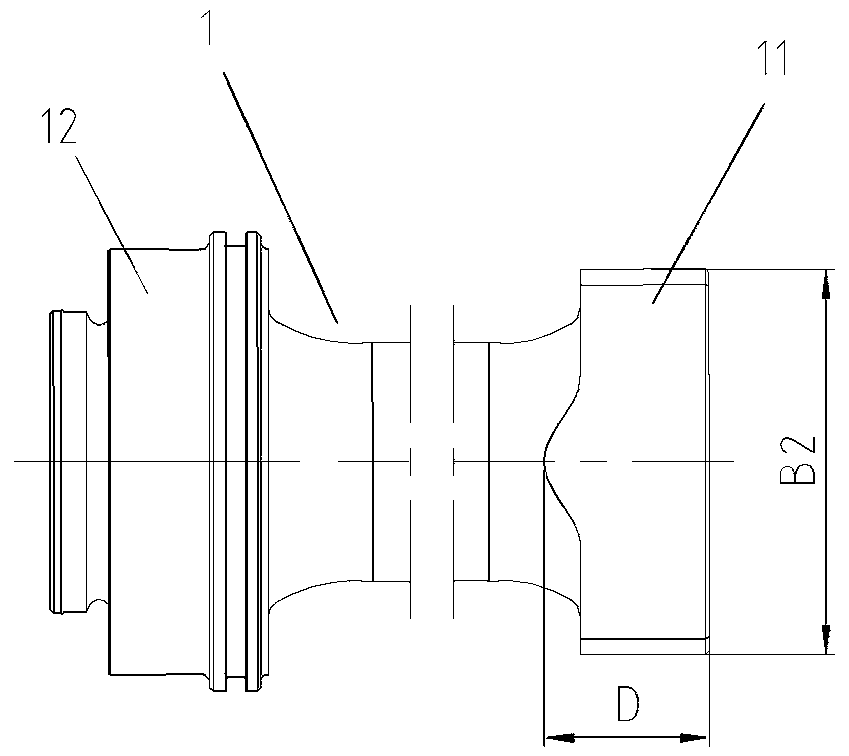

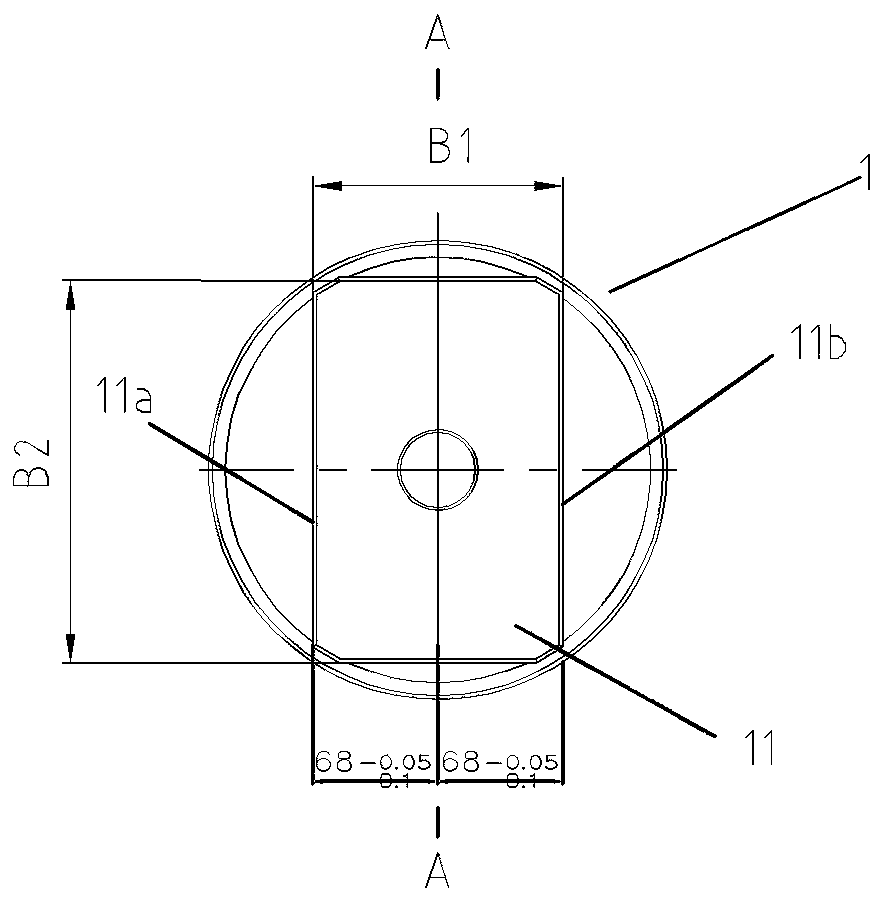

[0032] In the following, the present invention will be further described with reference to the accompanying drawings and an embodiment of a flat square end precision milling of a certain type of marine low-speed diesel engine piston rod with a single side allowance of 0.5 mm.

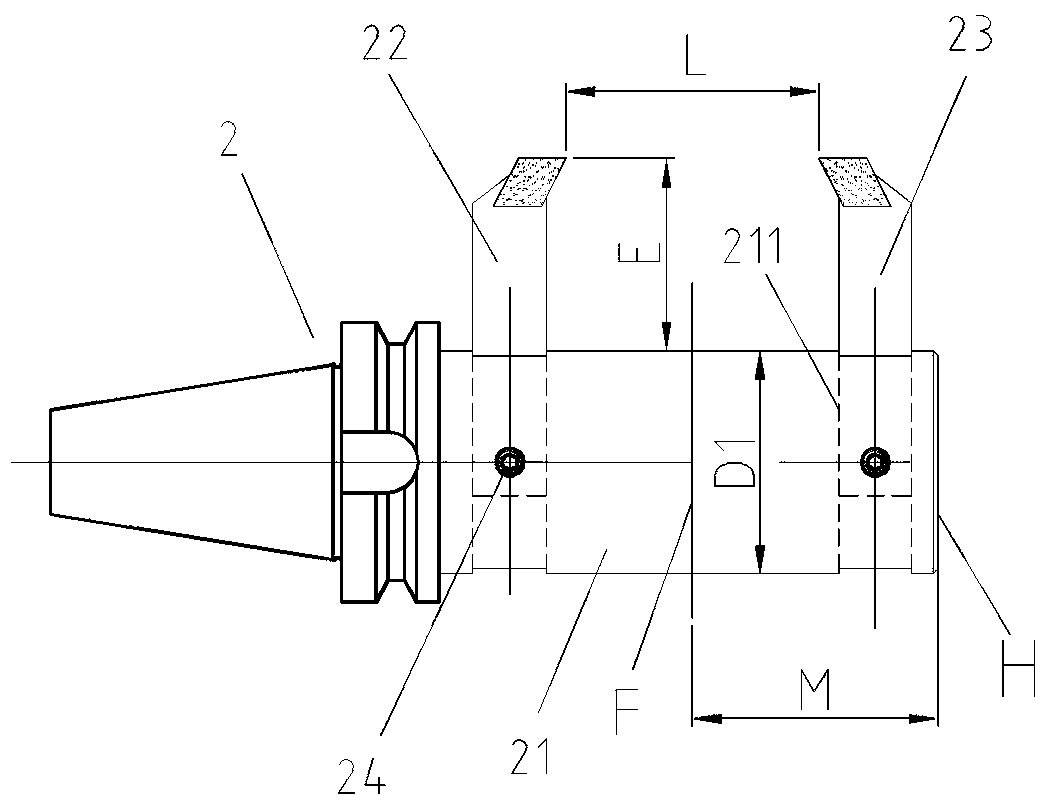

[0033] Such as image 3 As shown, the precision milling forming tool 2 for the flat square end of the piston rod of this embodiment includes a tool bar 21, a left offset knife 22, and a right offset knife 23. The lower end of the left offset knife 22 and the lower end of the right offset knife 23 are perpendicular to each other through a set screw 24. Fixed in the rectangular horizontal holes 211 spaced apart in the middle of the cutter bar 21, the left and right side cutters 22 and 23 have the upper edge of the cutting edge opposite to each other, and the distance L between the two cutting edges is opposite to the left and right sides of the flat square end 11 of the piston rod. The relational expression o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com