Wiping and screening device for raw materials pressing disk cutters

A material receiving device and raw material technology, which is applied in the directions of sieve, solid separation, grid, etc., can solve the problems of difficulty in pressing and forming of disc knives, large deformation of products, and poor density of semi-finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

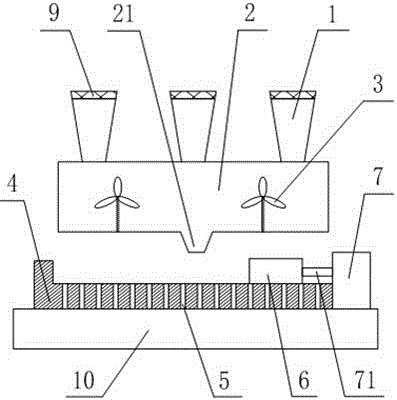

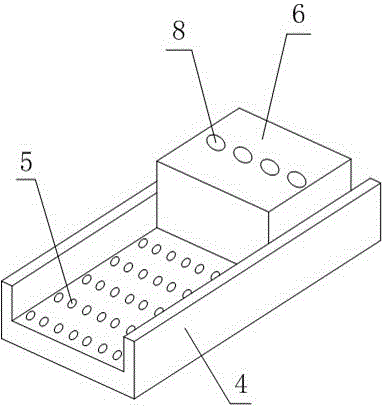

[0019] like figure 1 and figure 2 A kind of sieve wiping device for pressing raw materials with a disc knife as shown includes a feed port 1, and a filter screen 9 with a mesh number of 20 meshes is arranged on the feed port 1, and the feed port 1 is connected to the mixing chamber 2, and the stirring chamber 2 A stirring device 3 is arranged inside, and a rectangular groove 4 is arranged below the discharge end 21 of the stirring chamber 2. Several circular through holes 5 with a diameter of 0.18mm are evenly distributed on the surface of the groove 4, and two adjacent circular through holes 5 are uniformly distributed on the surface of the groove 4. The distance between the centers of the through holes 5 is 1mm; the groove 4 is provided with a sliding push block 6 matching the groove 4, and the width of the slide push block 6 is consistent with the inner width of the groove 4; one end of the groove 4 is provided with a drive Device 7, the driving end 71 of driving device 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com