Auxiliary rubbing and screening machine for compression production of round-flat slitters

A screen cleaning machine and disc knife technology, which is applied to turbines, mechanical equipment, engine components, etc., can solve problems such as uneven pressing, poor density of semi-finished products, and difficult placement of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

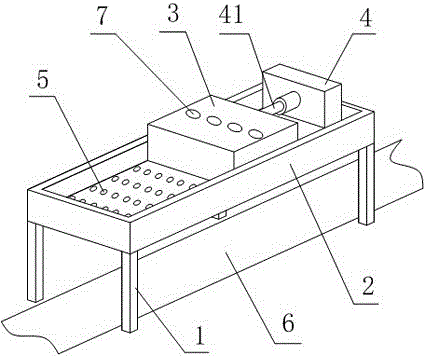

[0016] Such as figure 1 The shown one is used for the auxiliary sieve cleaning machine of disc knife pressing production, comprises support 1, and the trough 2 is fixed above support 1, and described trough 2 is rectangular, and the surface of described trough 2 is evenly distributed with several diameters It is a circular through hole 5 of 0.18 mm, and the distance between the centers of two adjacent circular through holes 5 is 1 mm; a sliding pushing block 3 matching with the trough 2 is arranged in the trough 2, and the sliding The width of the pusher block 3 is consistent with the internal width of the trough 2; the driving device 4 is fixed at one end of the trough 2, and the driving end 41 of the drive device 4 is connected with the sliding pusher block 3; a belt conveyor belt is arranged below the trough 2 6. The belt conveyor belt 6 moves along the long axis of the trough 2, and the belt conveyor belt 6 passes through the bottom of the support 1; the sliding push block...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com