Screening device for metallurgical furnace burdens

A metallurgical furnace and material screen technology, which is applied in the field of iron and steel smelting equipment, can solve the problems affecting the quality of steelmaking and the size of metallurgical furnace materials, and achieve the effects of uniform and stable size, improved quality, and full reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

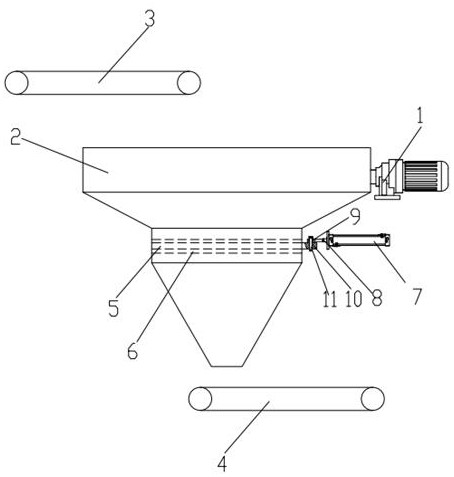

[0016] Such as figure 1 As shown, the present invention discloses a screening device for metallurgical charge, comprising a charge pulverizer 1, a conical crushing bin 2, a feed conveyor belt 3 and a discharge conveyor belt 4, specifically, in order to ensure the scrap metal in the metallurgical charge , pig iron, etc., the furnace material crusher 1 is a gear crusher with large bite crushing capacity, the furnace material crusher 1 is set in the middle of the conical crushing bin 2, the feed conveyor belt 3 and the upper end of the conical crushing bin 2 The inlet is connected, and the discharge conveyor belt 4 is connected to the outlet at the lower end of the conical crushing bin 2. A drawer-type vibrating screen 5 is arranged in the conical crus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com