Light emitting screen of side light source supplied by AC / DC electricity

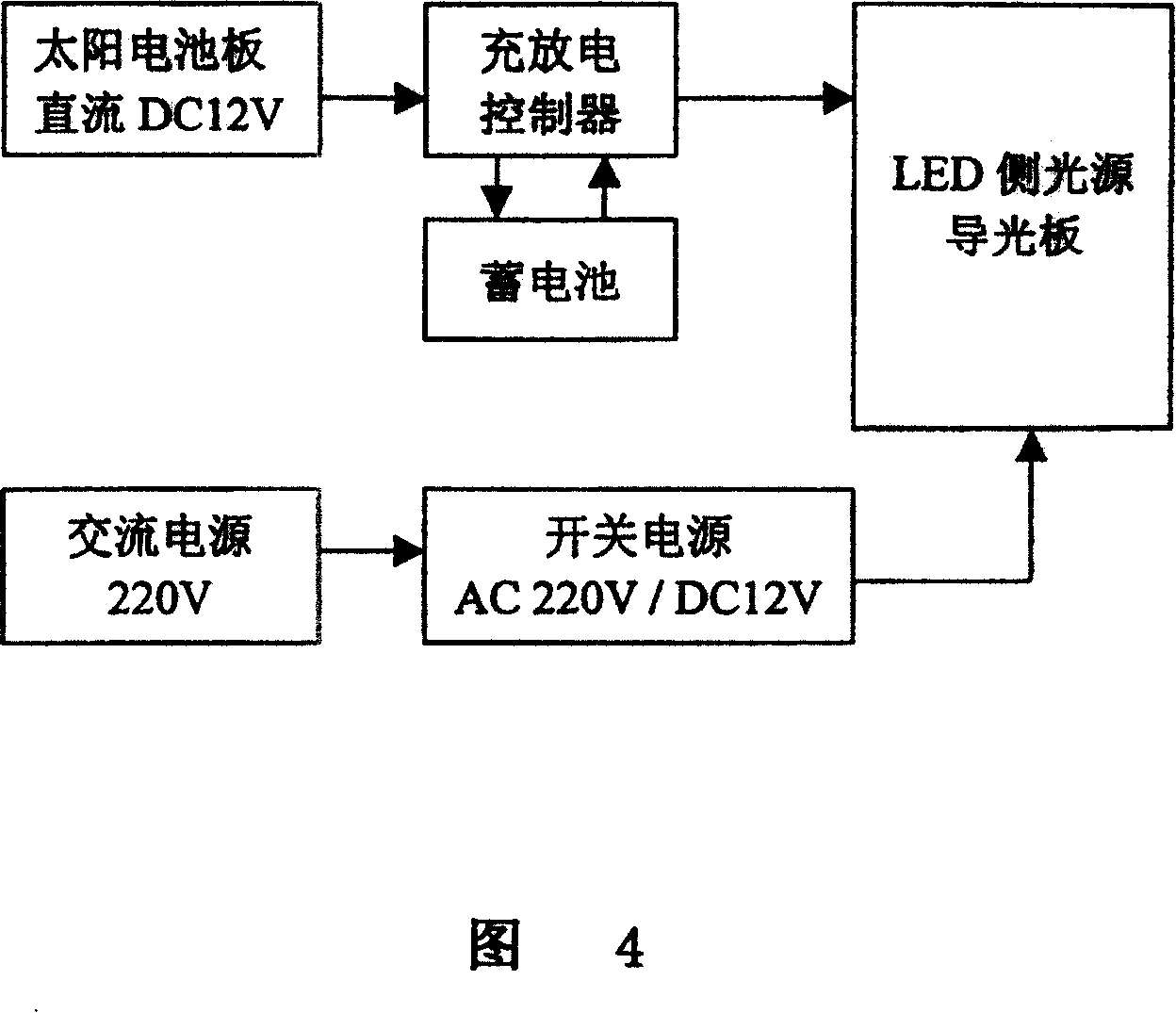

A side light source, AC and DC technology, which is applied in the field of low-power side light source light-emitting panels, can solve the problems of short lamp life, large power consumption, and influence on the overall effect of the display card, so as to improve system reliability, stable and reliable performance, The effect of a good display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A detailed description will be given below in conjunction with preferred embodiments of the present invention and accompanying drawings.

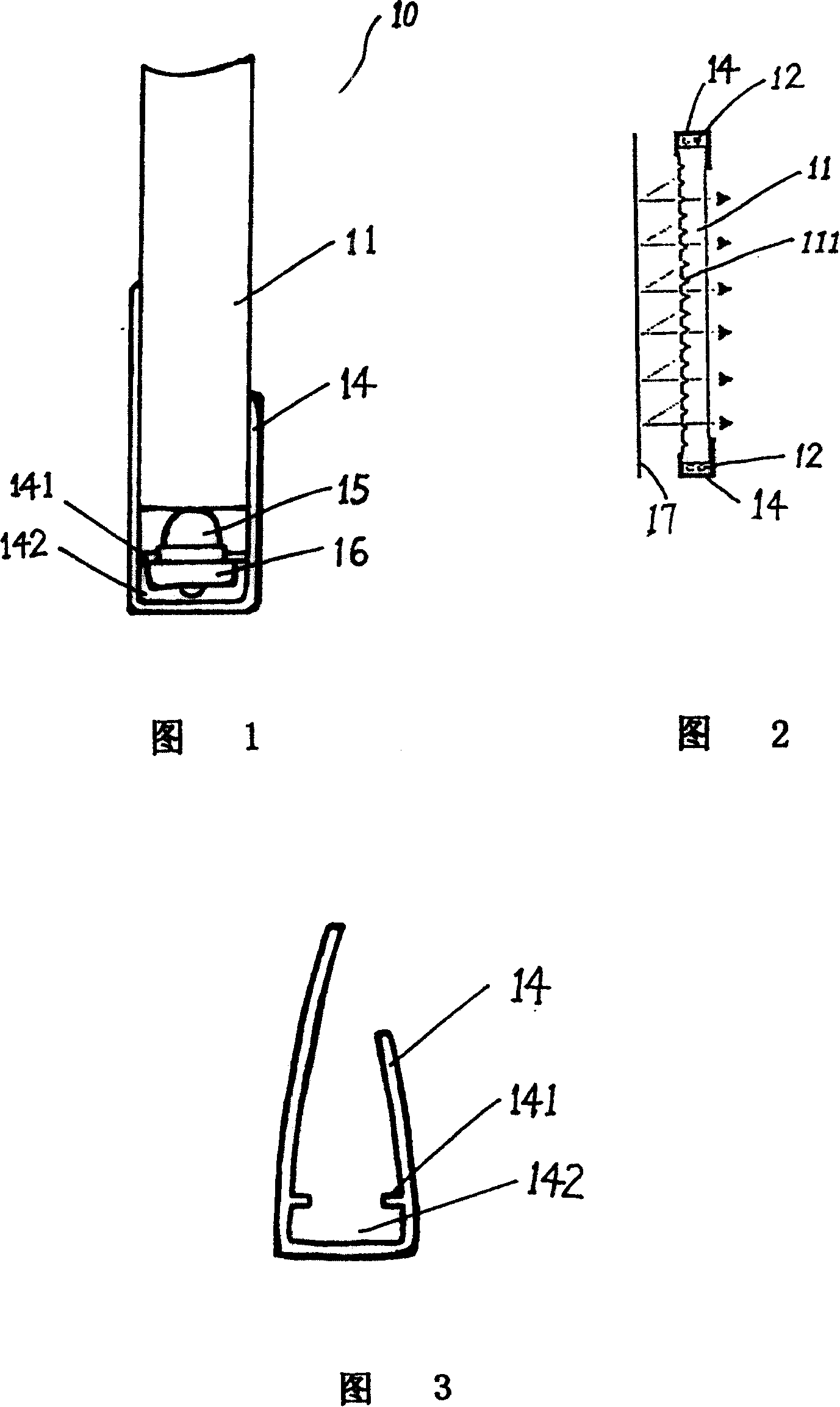

[0019] As shown in Figures 1 to 3, the luminous plate 10 includes a light guide plate 11 and a light source 12. The light guide plate 11 is made of polymethyl methacrylate (Poly Methyl Meth Acrylate), which is an optical grade PMMA light guide plate, which has a certain Thickness, can be made into various shapes. The back of the light guide plate 11 is provided with reticulated refraction grooves 111 made by three-dimensional laser engraving technology. The farther the refraction grooves 111 are from the light source 12, the larger the groove diameter and the sparser the spacing. In this way, the light path closer to the light source is narrower, and the light path farther away is wider, thereby solving the problem of changing a point light source into a surface light source, so that the brightness of the picture displayed by the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com