Plugging device and processing and plugging construction method for reserved hole of cast-in-place slab pipeline

A plugging device and construction method technology, applied to building components, building insulation materials, etc., can solve the problems of uncompacted concrete, low construction work, high construction and maintenance costs, and achieve convenient processing, disassembly and assembly, and easy operation , The effect of low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

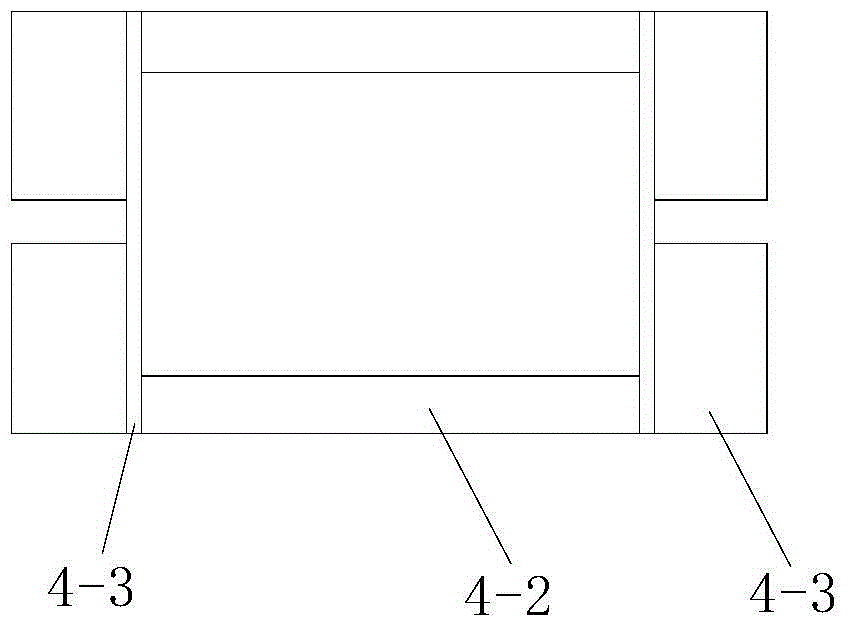

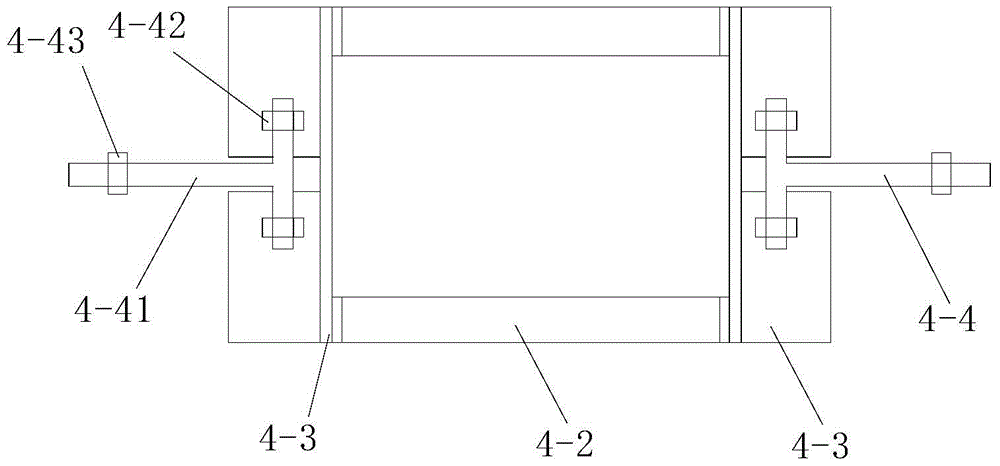

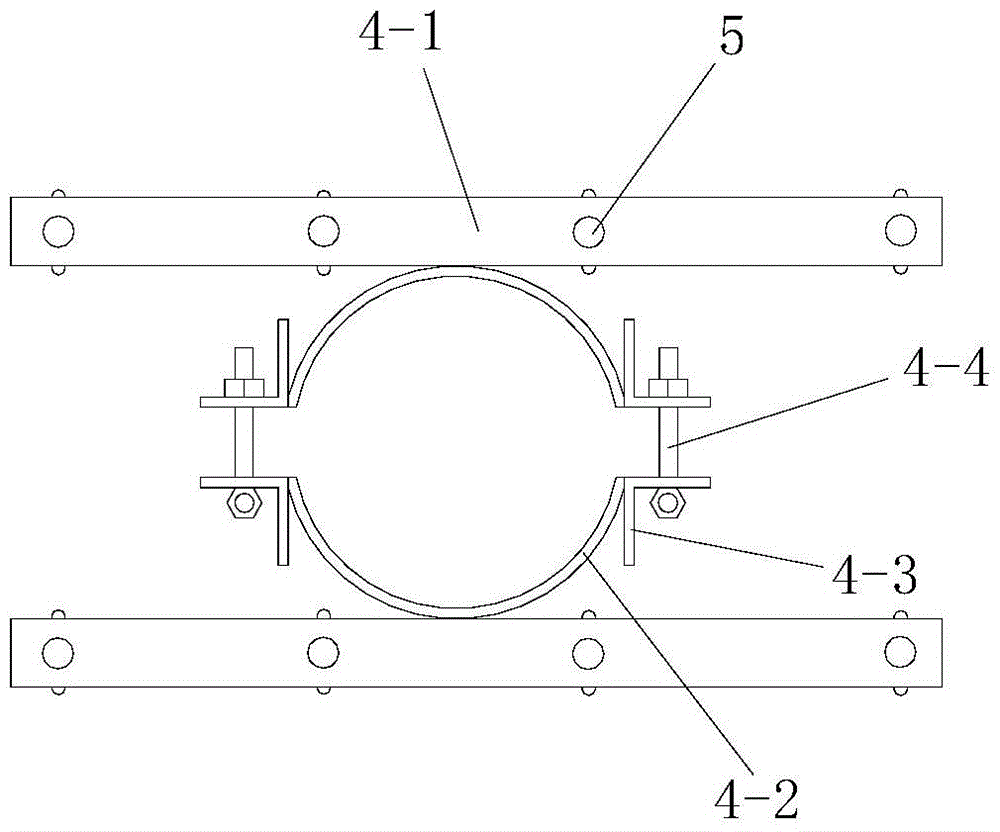

[0062] Such as image 3 , Figure 4 and Figure 7 A plugging device for a reserved hole in a cast-in-place slab pipeline is shown, including a plugging template 2 for plugging the bottom of the hole to be plugged between the pipeline 1 and the reserved hole and a template for stably supporting the plugging template 2 The supporting device 4, the reserved hole is the hole opened on the cast-in-place plate 3 for the installation of the pipeline 1 . The blocking formwork 2 is located below the cast-in-place slab 3 and is supported on the formwork supporting device 4. The blocking formwork 2 is a spliced formwork formed by splicing a plurality of flat plates arranged on the same plane. A pipe installation hole for the installation of the pipe 1 is provided on the blocking template 2 . The template supporting device 4 is installed on the pipeline 1 and is located below the blocking template 2. The template supporting device 4 includes a hoop that is set on the pipeline 1 and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com