Liquid injection device and operating method thereof

A liquid injection device and liquid injection technology, applied in the assembly of battery machines, electrical components, climate sustainability, etc., can solve problems such as inability to adapt, low product quality, low production efficiency, etc., to reduce labor time consumption and optimize injection. Liquid process flow, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

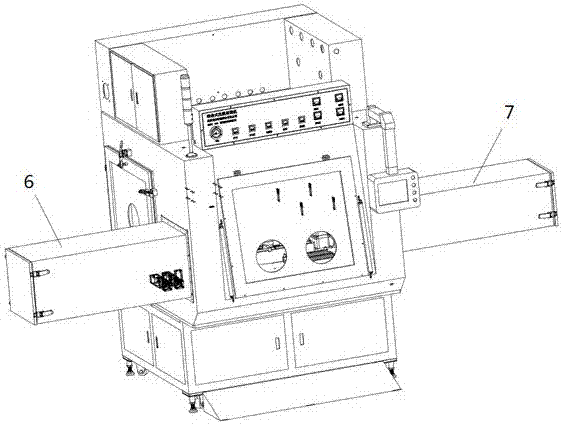

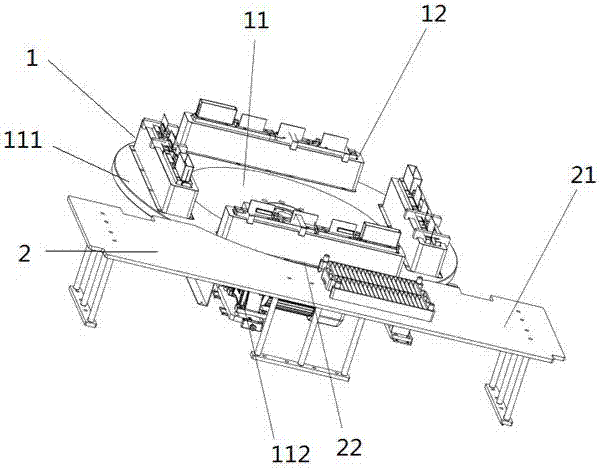

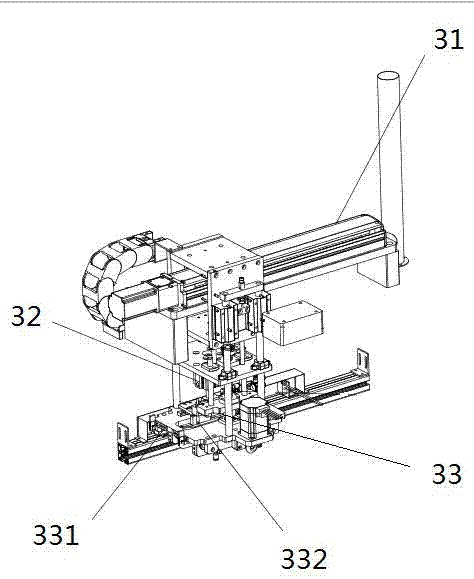

[0030] Such as Figure 1-5 As shown in , the liquid injection device provided by an embodiment of the present invention includes a rotary transmission mechanism 1. The rotary transmission mechanism 1 includes a turntable 11, and a number of jigs 12 are evenly distributed on the surface of the turntable 11. On the turntable 11, there are The process is provided with a loading and unloading mechanism 2, a flaring liquid injection mechanism 3, a vacuum liquid injection mechanism 4, and a vacuum sealing mechanism 5, and the positions of the jigs 12 correspond to each mechanism one by one.

[0031] Further, the turntable 11 includes a disk body 111, a drive motor 112, a transmission assembly and an index assembly, the drive motor 112 is connected to the bottom of the disk body 111 through the transmission assembly, and the index assembly is arranged on the transmission assembly.

[0032] Further, the indexing of the indexing component is set to 90°.

[0033] Further, the loading a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com