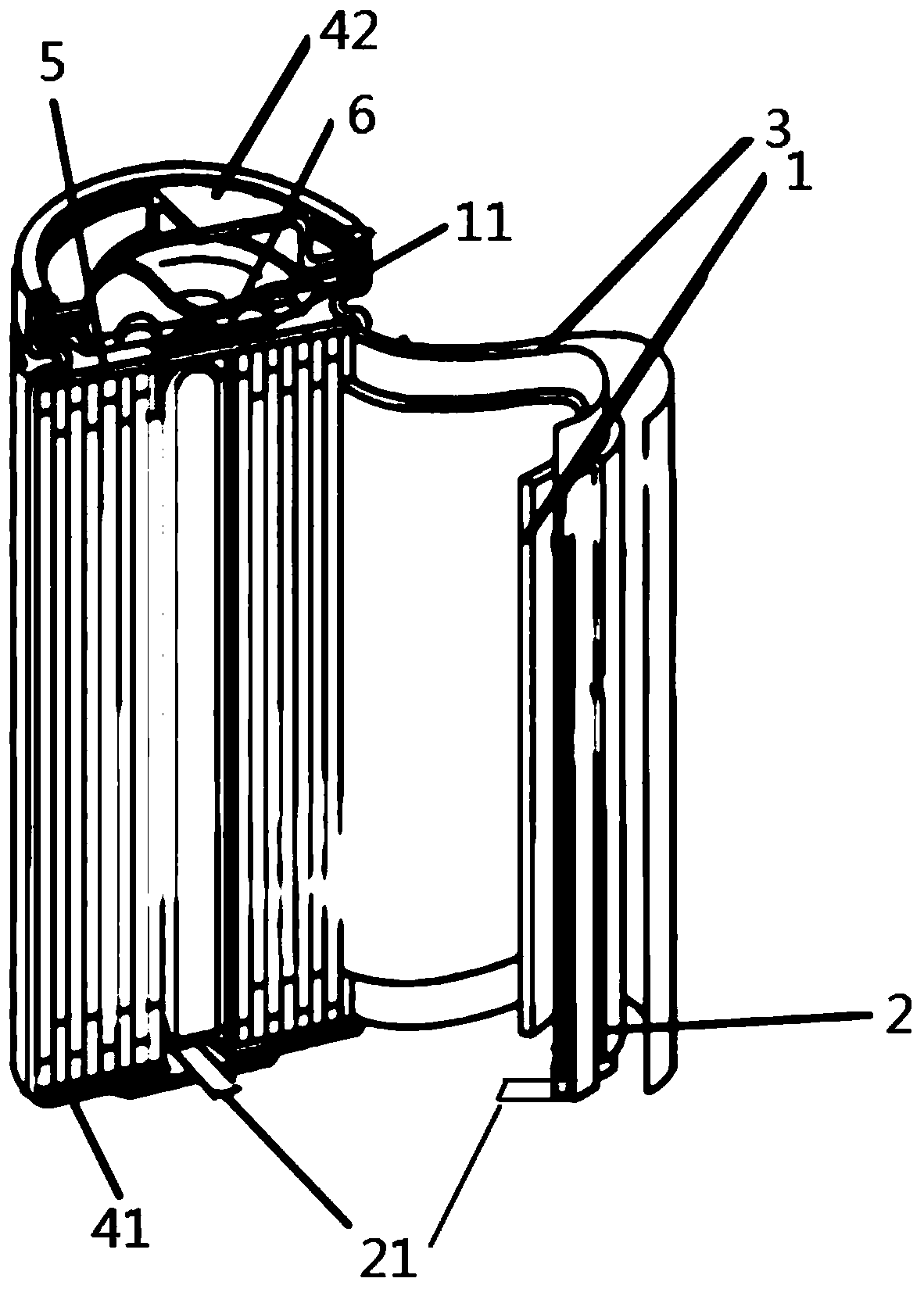

Cylindrical lithium ion battery and preparation method thereof

A lithium-ion battery, cylindrical technology, applied in electrode manufacturing, secondary batteries, battery electrodes, etc., can solve the problems of small lithium ion diffusion coefficient, high production conditions, increased production costs, etc., to reduce lithium ion consumption , Embedding/de-embedding performance is good, and the effect of saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] This embodiment also provides a method for preparing the aforementioned cylindrical lithium-ion battery, including:

[0053] The preparation steps of the positive electrode sheet: mix the positive electrode coating according to the formula amount, add nitrogen-methylpyrrolidone solvent (NMP) and mix to obtain a positive electrode coating with a solid content of 53%, and coat the positive electrode coating on the positive electrode metal foil On the sheet, after drying at 120-150°C, it is rolled and cut into a strip-shaped positive electrode sheet with a width of 56.5±1mm and a thickness of 145-149μm, and the gap metal foil at 1 / 3 of the length direction of the strip-shaped positive electrode sheet The positive electrode ear is welded on the chip to make a positive electrode piece;

[0054] Preparation steps of the negative electrode sheet: mix the negative electrode coating according to the formula, add deionized water and mix to make a negative electrode coating with a...

Embodiment 1

[0062]The preparation of negative plate: mix suspension agent dry powder 1.4%wt (mass fraction), graphite powder 94.8%wt, conductive agent 1.8%wt, binding agent 2.0%wt, then add deionized water and mix evenly to make a solid The negative electrode slurry with a content of 50% is intermittently coated on a metal copper foil with a thickness of 8 μm. After drying at a temperature of 100-130 ° C, it is rolled into a negative electrode sheet with a thickness of about 120 μm, and cut into long strips. The width is 58.0mm. A total of 2pcs negative lugs are welded on the gap foil to make a negative electrode sheet. There are 1pcs tabs at the head and tail of the negative electrode sheet, of which the head is a short tab and the tail is a long tab. .

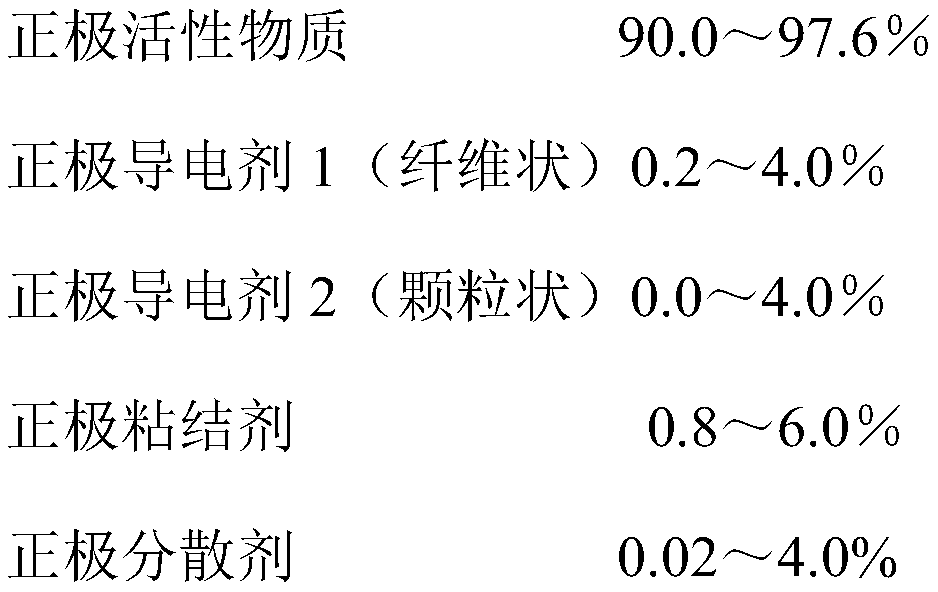

[0063] Preparation of positive electrode sheet: 2.5%wt of binder dry powder, 1.5%wt of conductive agent (wherein, the content of conductive agent 1 is 1%wt, and the content of conductive agent 2 is 0.5%wt), dispersant 0.2%wt, active mat...

Embodiment 2

[0067] Preparation of negative electrode sheet: Mix 1.6%wt of suspending agent dry powder, 94.3%wt of graphite powder, 2.1%wt of conductive agent, and 2.0%wt of binder, then add deionized water and mix evenly to make a solid content of 50%. Negative electrode slurry, intermittently coated on 8μm thick metal copper foil, dried at a temperature of 100-130°C, rolled into a negative electrode sheet with a thickness of about 123μm, cut into long strips, and the width of the electrode sheet is 58.0mm , Weld one long and one short negative tab at the gap foil to make a negative plate. There are 1pcs tabs at the head and tail of the negative plate, of which the head is a short tab and the tail is a long tab.

[0068] Preparation of positive electrode sheet: 2.6%wt of binder dry powder, 1.7%wt of conductive agent (wherein, the content of conductive agent 1 is 1%wt, and the content of conductive agent 2 is 0.7%wt), dispersant 0.3%wt, active material 95.4%wt Mix with an appropriate amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com