Patents

Literature

42results about How to "No quality defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for efficiently preparing graphene-reinforcing copper-based composite brazing filler metal at low temperature

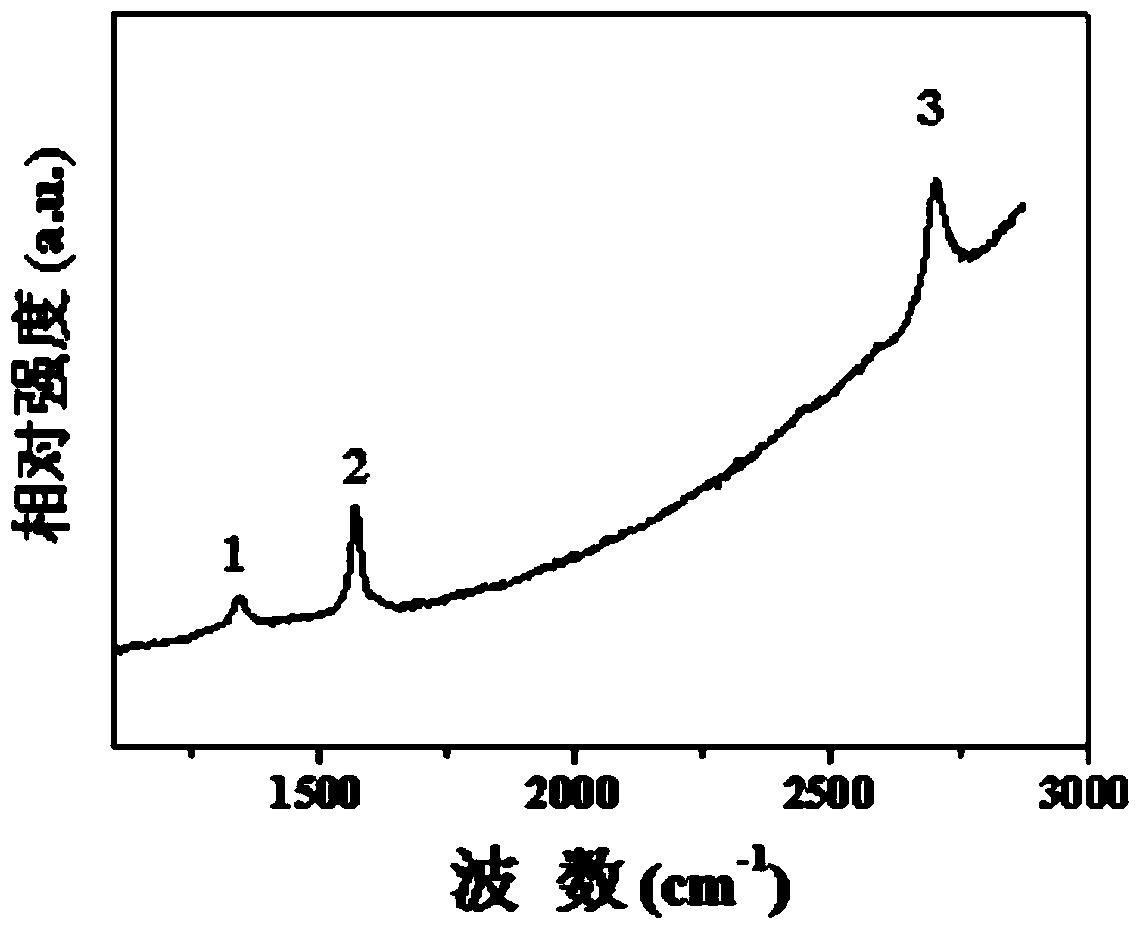

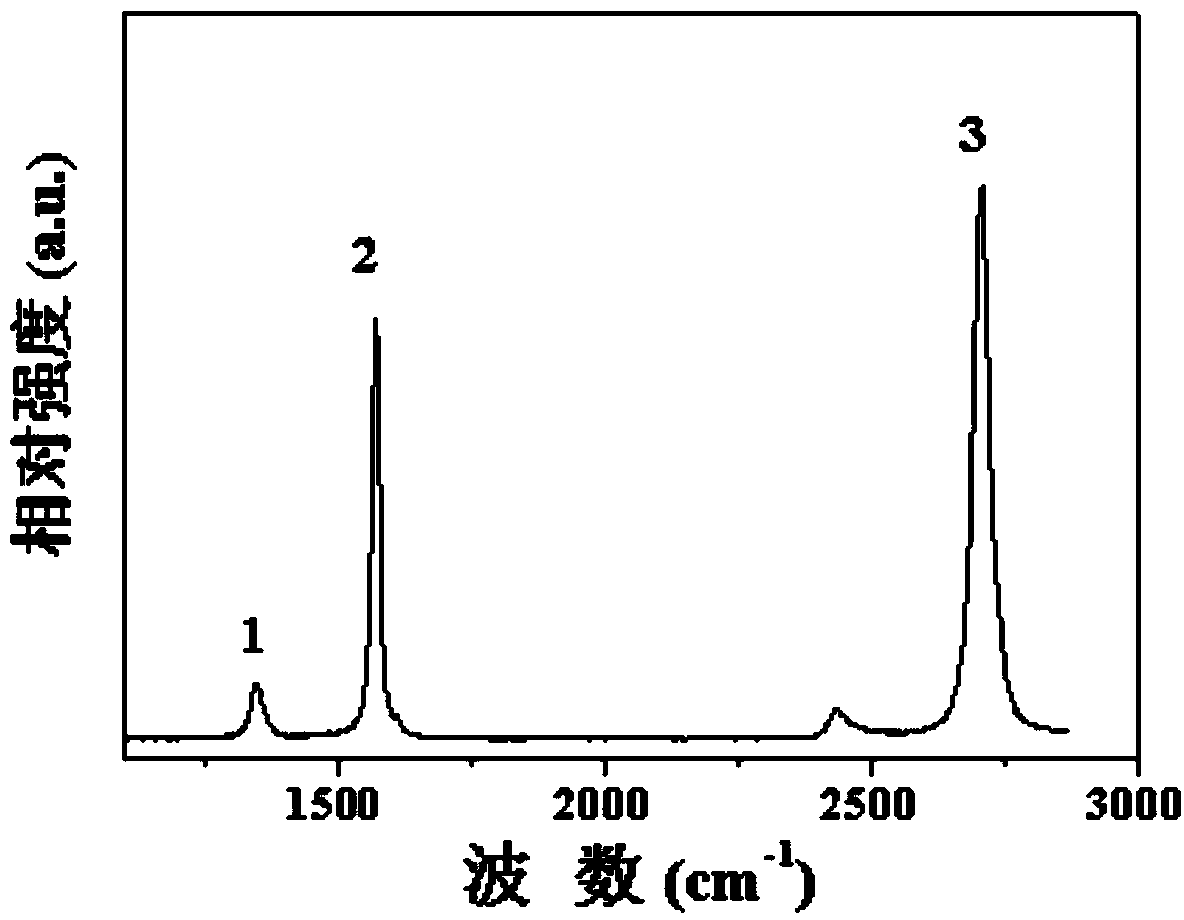

ActiveCN103817466AImprove decomposition efficiencyLow preparation temperatureWelding/cutting media/materialsChemical vapor deposition coatingCvd grapheneCarbon source

Owner:HARBIN INST OF TECH

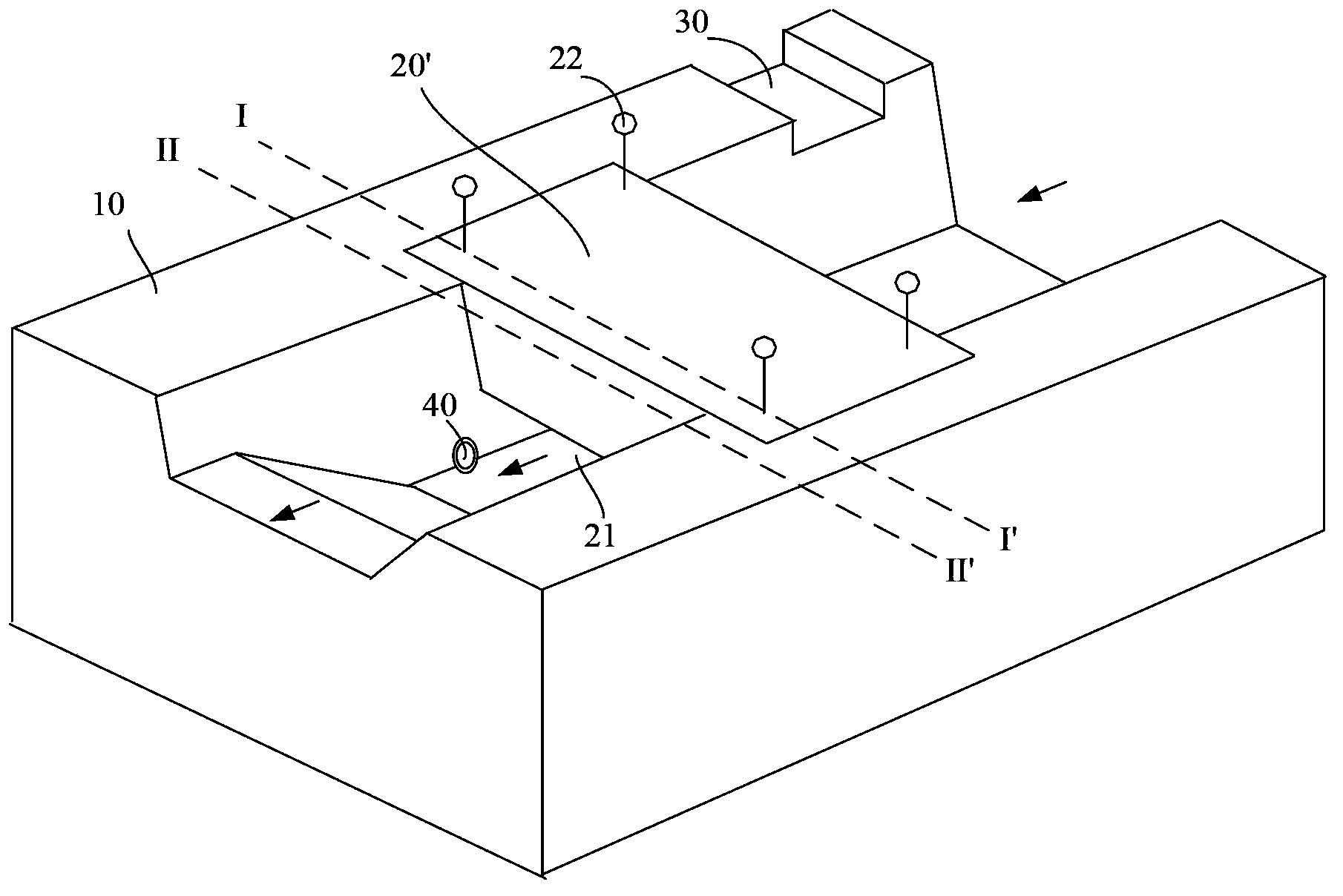

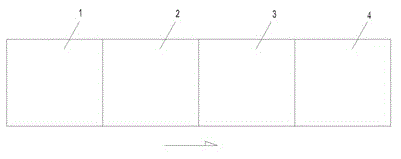

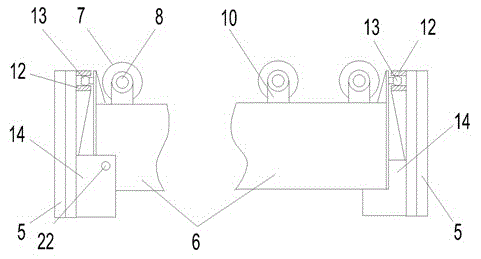

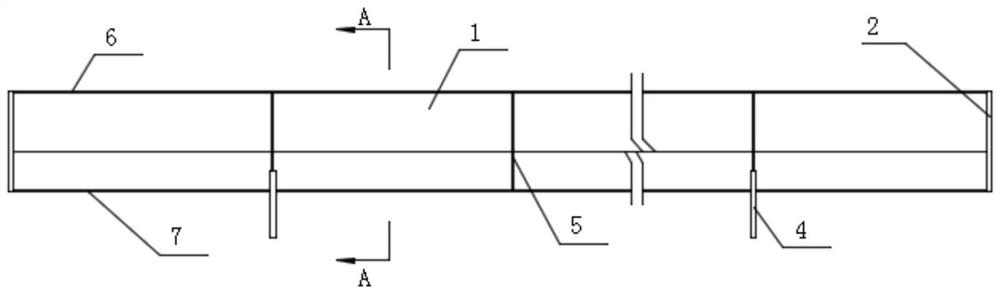

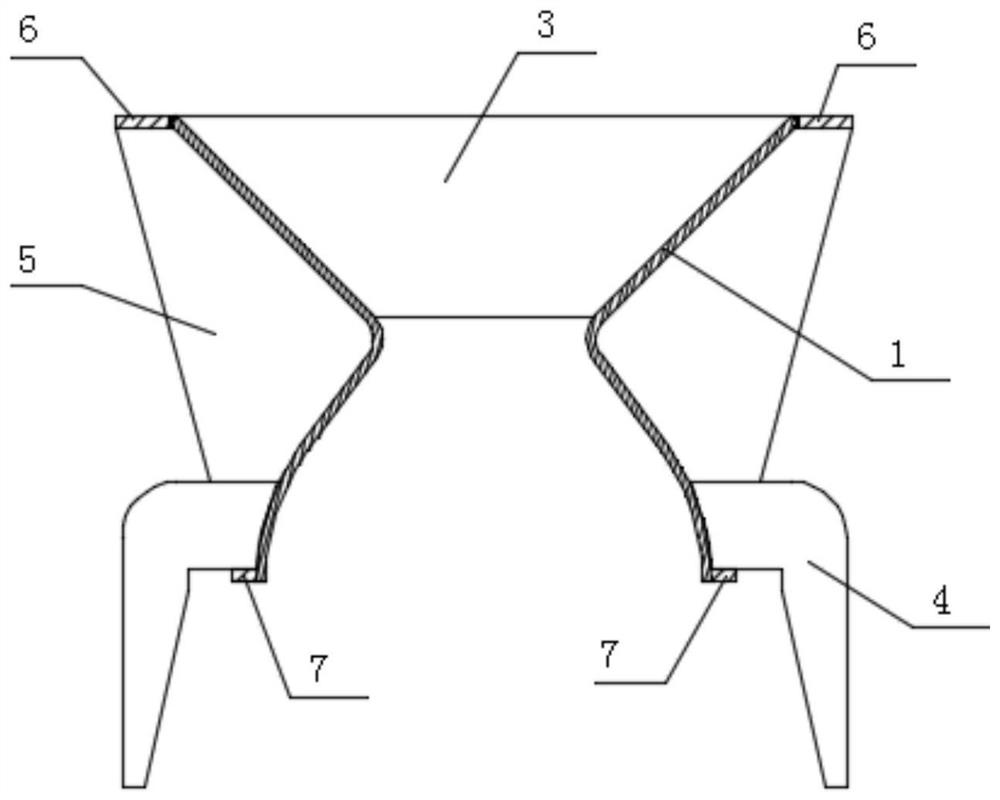

Gradually-moulding bent tempered glass radian-changing device

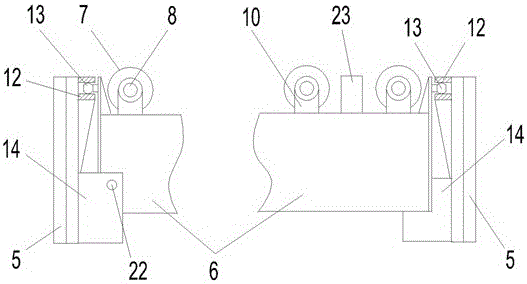

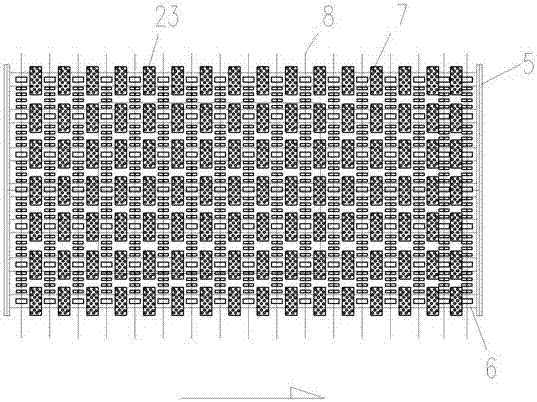

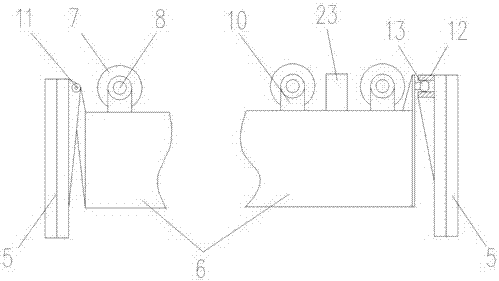

ActiveCN104973759AShorten production timeNo quality defectsGlass reforming apparatusGlass tempering apparatusEngineeringStructural engineering

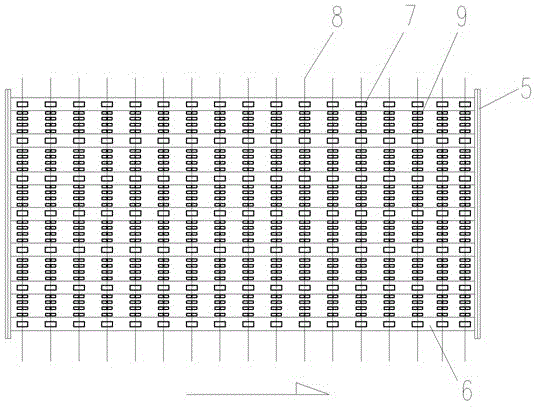

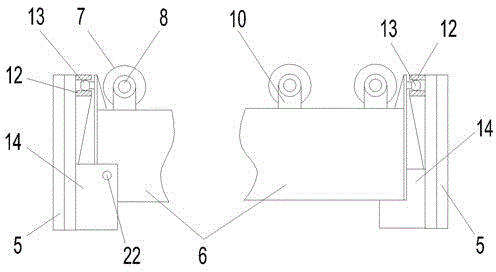

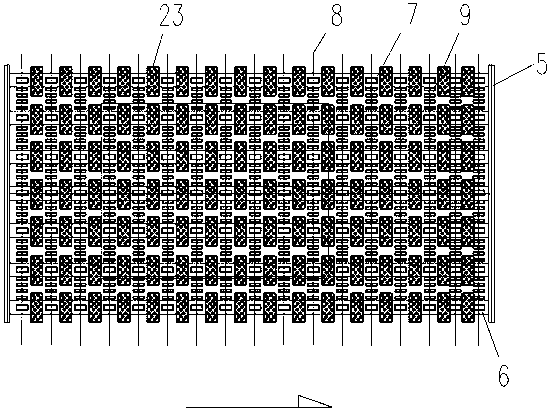

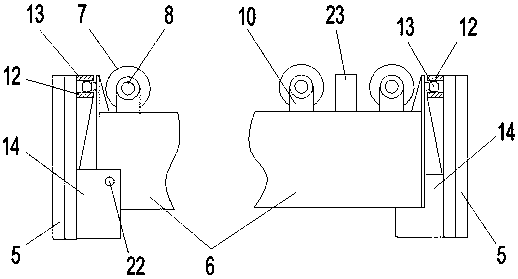

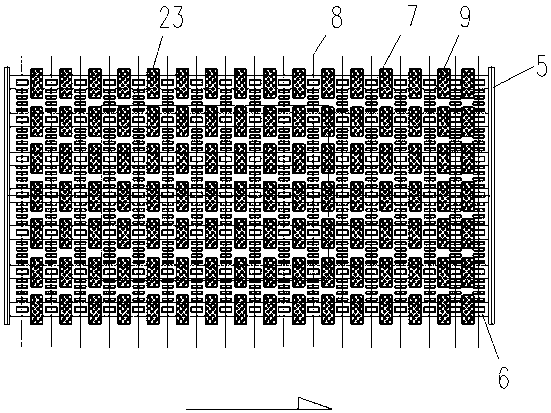

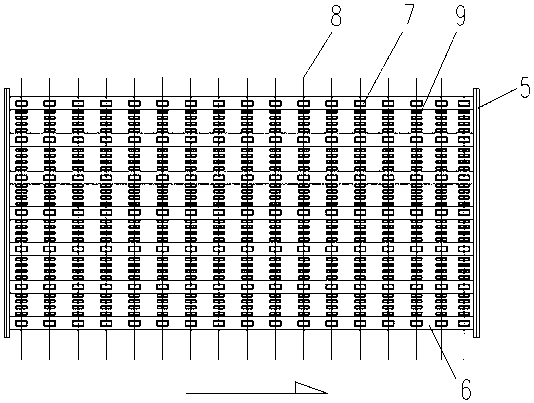

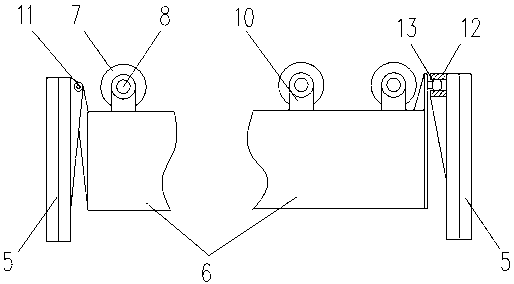

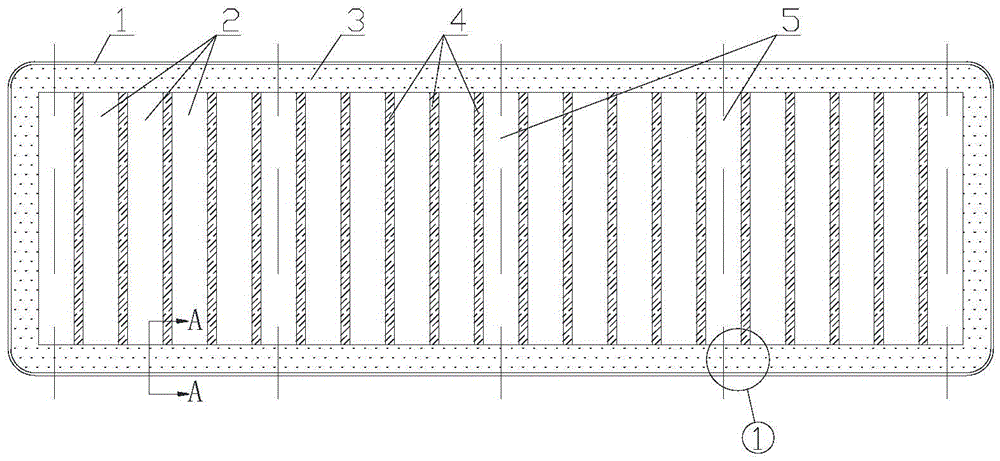

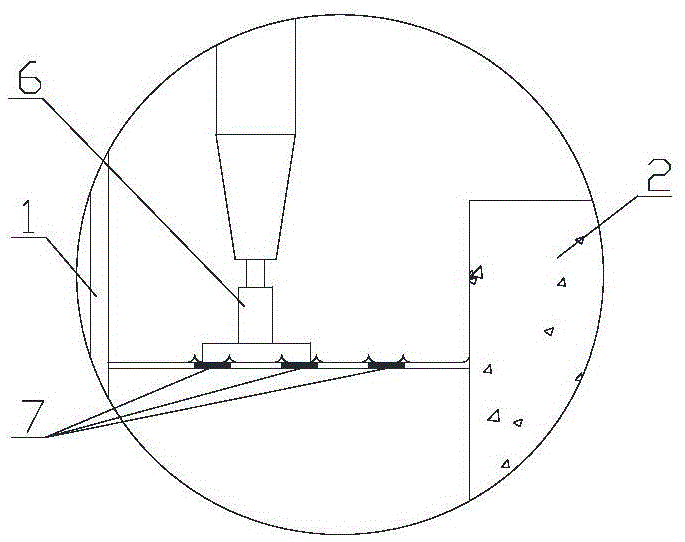

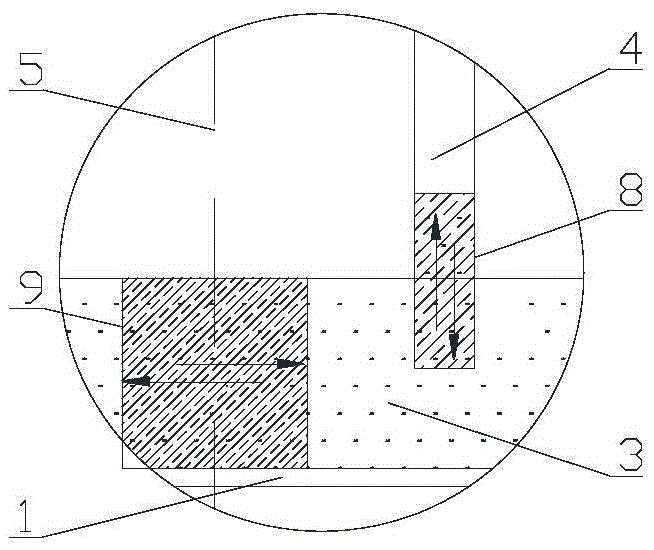

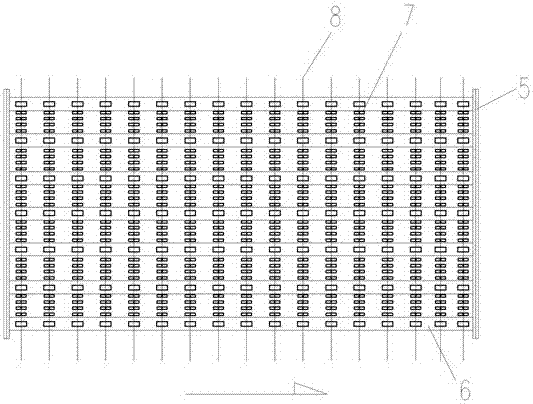

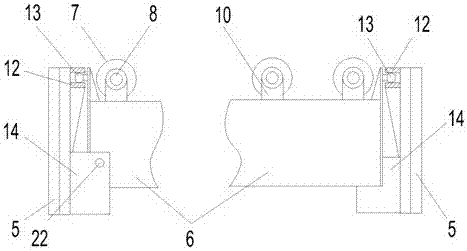

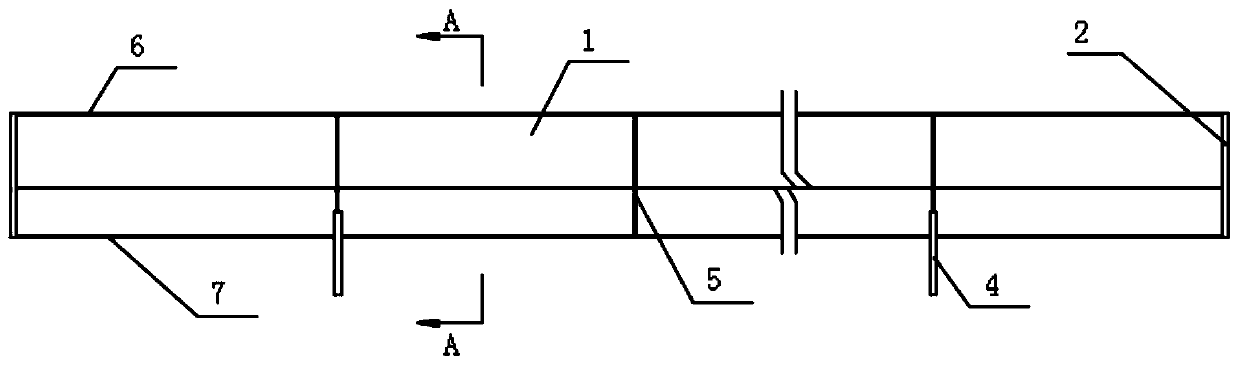

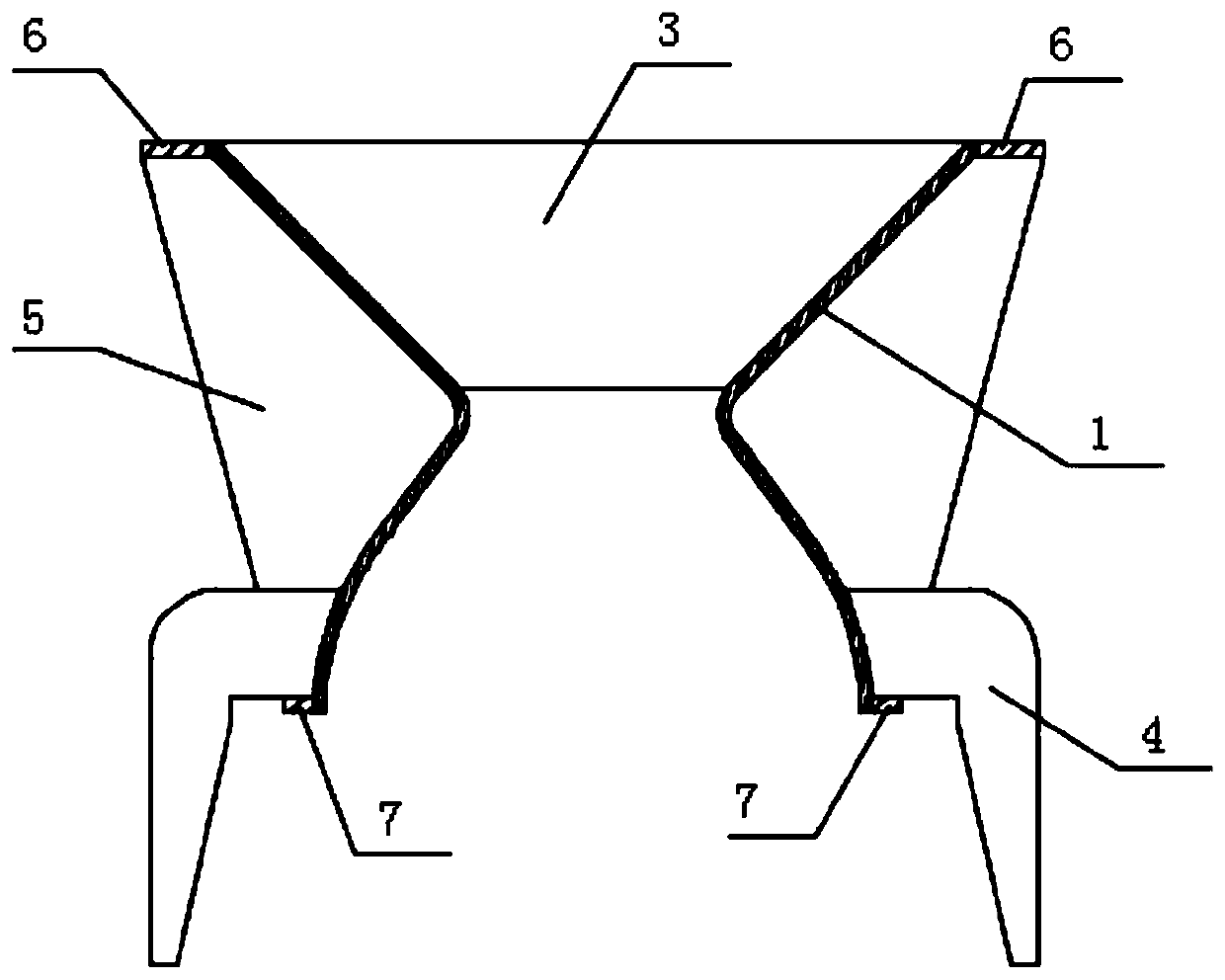

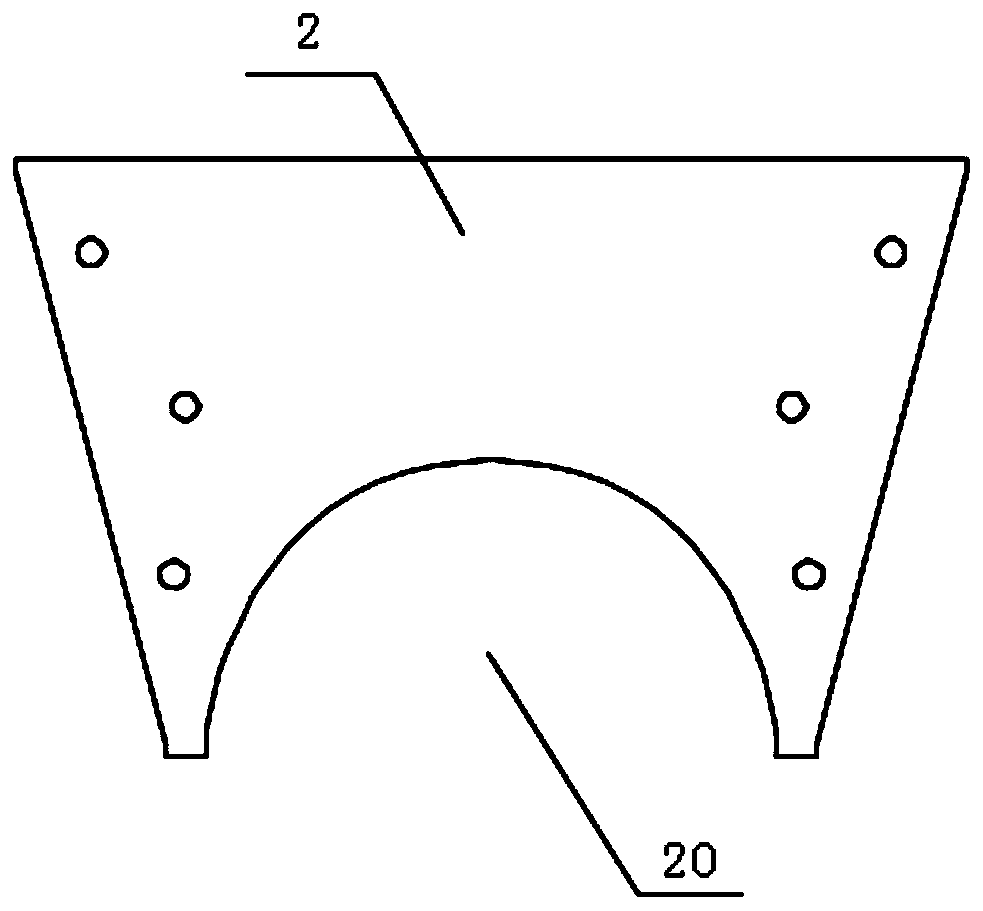

The invention discloses a gradually-moulding bent tempered glass radian-changing device, which includes a plurality of supporting beams which are extended longitudinally and arranged transversally at intervals. A plurality of support roll wheels are arranged on the supporting beams longitudinally at intervals. The two ends of each supporting beam are respectively connected to two transversally radian-changing mechanisms through a universal spherical pair. The two transversally radian-changing mechanisms can change the radian according to the radian-changing positions respectively. By means of the device, glass can be discharged and bent at the same time, so that it is unnecessary to wait the glass to be discharged completely, thereby saving production time. When a long bent tempered glass needs to process, the device can avoid the quality defect due to different temperature at the head and the tail of the glass during bending. By means of independent control on the transversally radian-changing mechanisms, special-shaped glass of which the radian is not constant can be processed on the device.

Owner:LUOYANG LANDGLASS TECH CO LTD

Blast-furnace casting runner

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

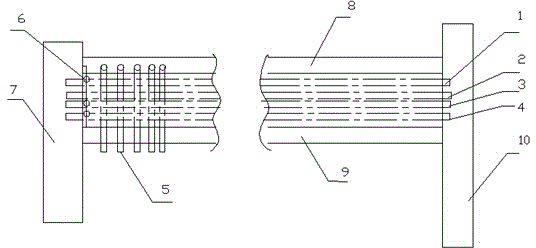

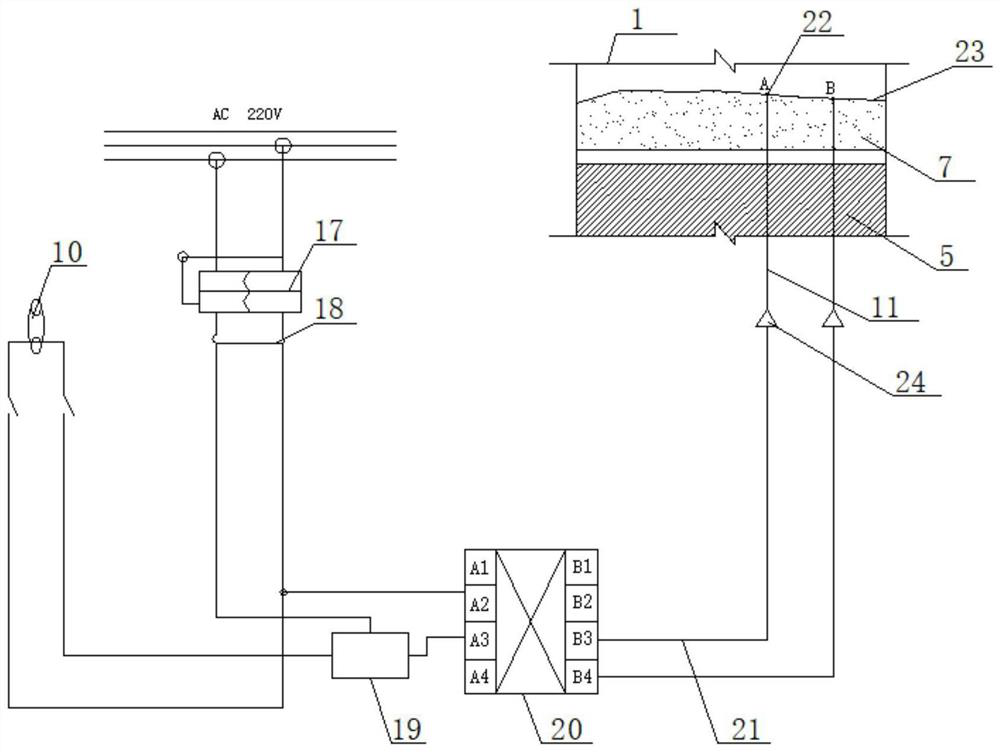

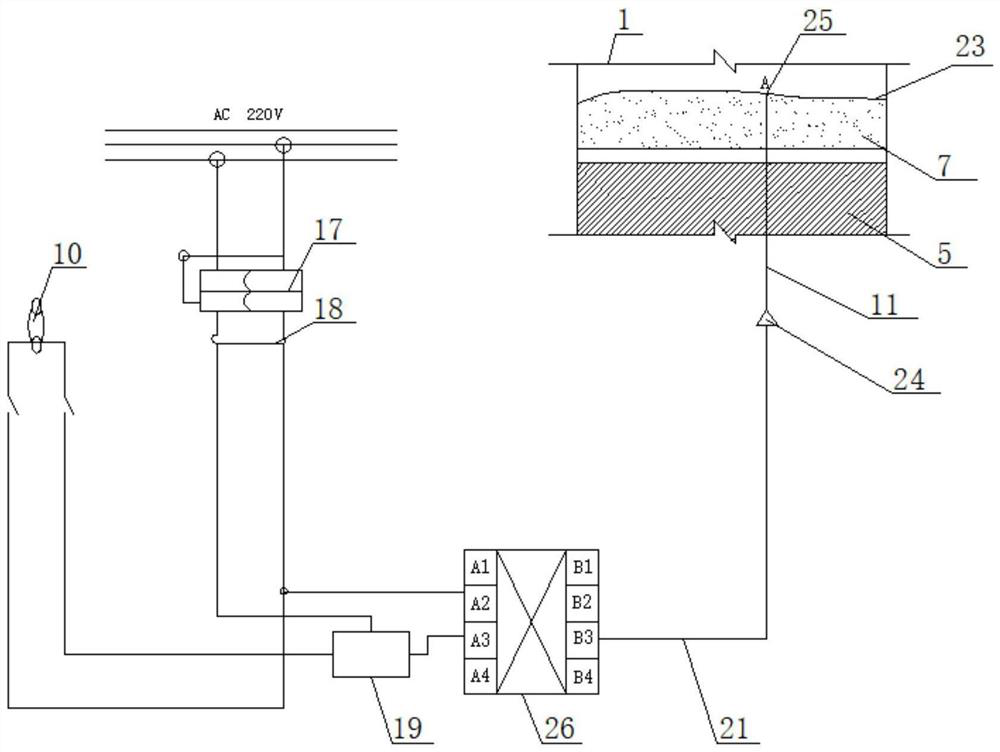

Intelligent control system for spun yarn forming

The invention relates to an intelligent control system for spun yarn forming. The intelligent control system comprises a signal acquisition unit, a control unit and an execution unit. The signal acquisition unit is used for collecting signals indicating whether a steel collar plate reaches an initial position, a yarn middle pull position, a pullback position and the highest position; the control unit is used for receiving the signals collected by the signal acquisition unit and outputting control signals after the collected signals are compared with set signals and judged; the execution unit is used for receiving the control signals output by the control unit and controlling ascending and descending of the steel collar plate according to the received control signals. According to the intelligent control system, whether the steel collar plate reaches the initial position, the yarn middle pull position, the pullback position and the highest position accurately can be precisely detected, it is guaranteed that each movement is precisely in place, and the defects brought by inaccurate positions are overcome.

Owner:YIBIN HUIMEI WORSTED TECH +1

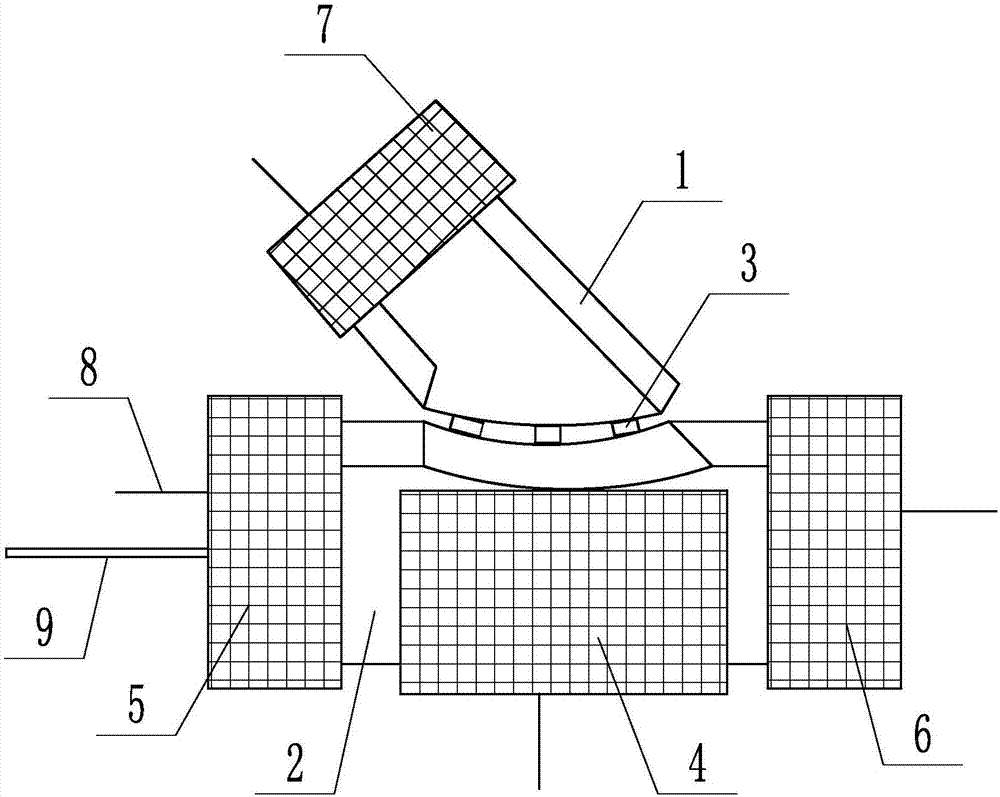

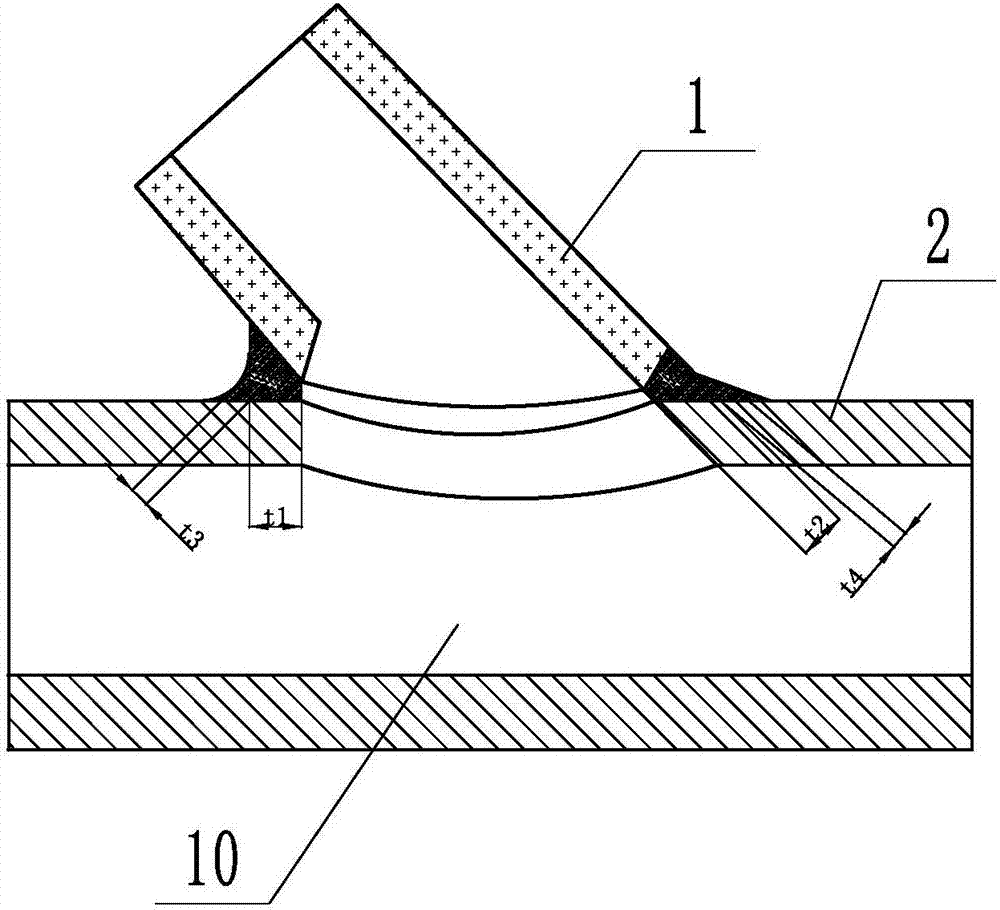

Novel manufacturing method of a large-diameter inclined tee joint

The invention discloses a novel manufacturing method of a large-diameter inclined tee joint. The novel manufacturing method comprises the following specific steps of A, manufacturing forming of an inclined tee joint pipe fitting, B, positioning welding of the inclined tee joint pipe fitting, C, preheating of an inclined tee joint fitting tee joint inclined branch pipe and a tee joint straight main pipe, D, joint first layer welding of the inclined tee joint fitting tee joint inclined branch pipe and the tee joint straight main pipe, E, joint bottoming welding of the inclined tee joint fitting tee joint inclined branch pipe and the tee joint straight main pipe, F, joint secondary preheating of the inclined tee joint fitting tee joint inclined branch pipe and the tee joint straight main pipe, G, joint welding of the inclined tee joint fitting tee joint inclined branch pipe and the tee joint straight main pipe, H, inclined tee joint fitting low-temperature protecting, and I, inclined tee joint fitting heat treatment. The novel manufacturing method of the large-diameter inclined tee joint is simple in manufacturing process, low in cost and capable of solving the quality flaw problem probably existing in the large-diameter inclined tee joint.

Owner:山东海阳丰汇设备技术有限公司

Gradually-moulding bended tempered glass radian-changing device

ActiveCN104973753ABending stabilityShorten production timeGlass reforming apparatusGlass tempering apparatusStructural engineeringToughened glass

The invention discloses a gradually-moulding bended tempered glass radian-changing device, which includes a plurality of supporting beams which are extended longitudinally and are arranged transversally at intervals. A plurality of soft shafts, which are extended longitudinally and are arranged transversally at intervals, are arranged on the supporting beams. The soft shafts are hinged to the supporting beams, wherein a plurality of support roller wheels sleeve the soft shafts. The two ends of the supporting beams are connected to two transversal radian-changing mechanisms respectively through universal ball pairs. The two transversally radian-changing mechanisms can change the radian according to the radian-changing settings respectively. By means of the device, glass can be bent when the glass is discharged from a furnace, so that it is unnecessary to wait the glass to be discharged completely, thereby saving production time. When long bent tempered glass needs to be processed, the device can avoid the quality defect caused by different temperature at the head and the tail of the glass during bending. By means of independent control on the transversally radian-changing mechanisms, special-shaped glass of which the bending radian is not constant can be processed on the device.

Owner:LUOYANG LANDGLASS TECH CO LTD

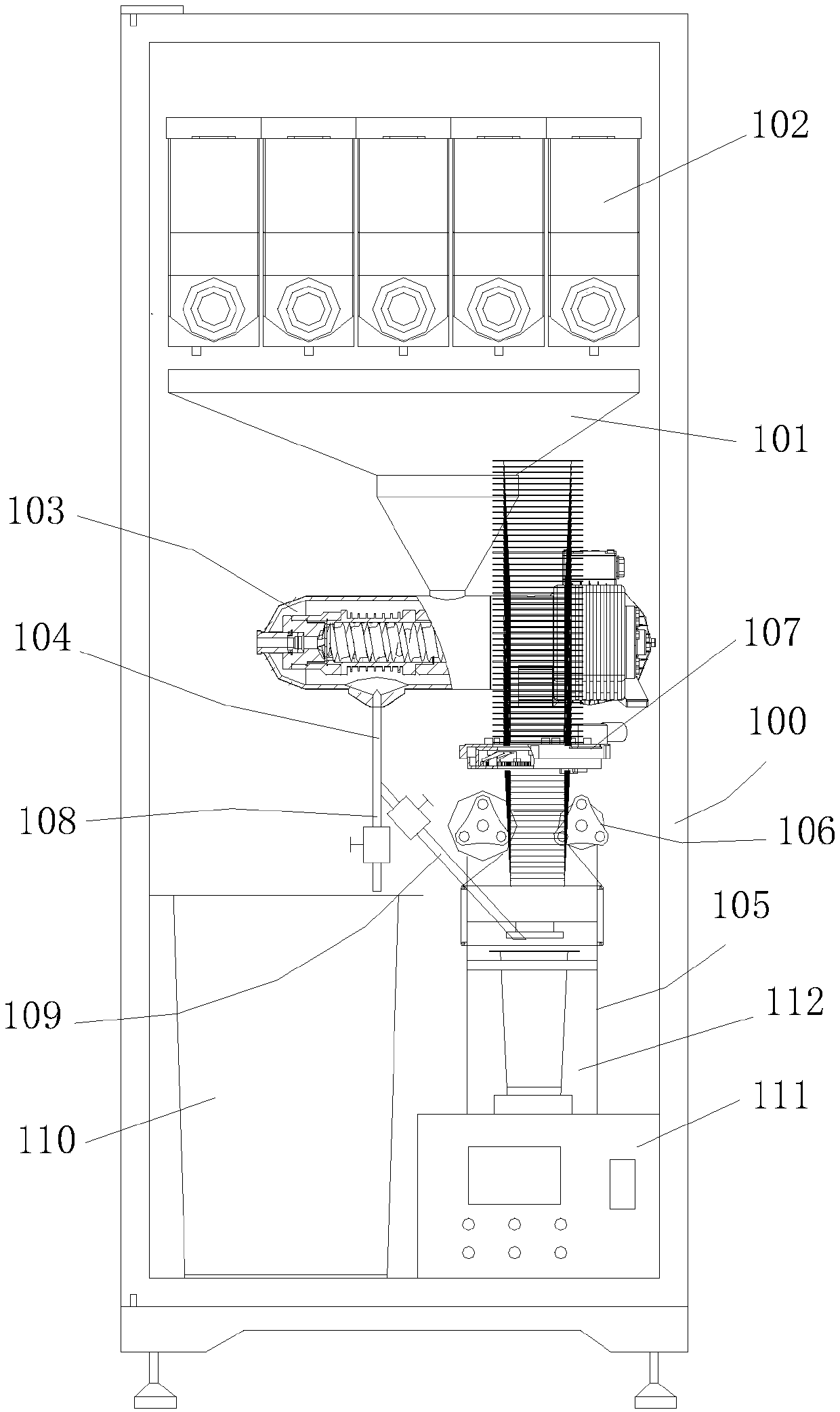

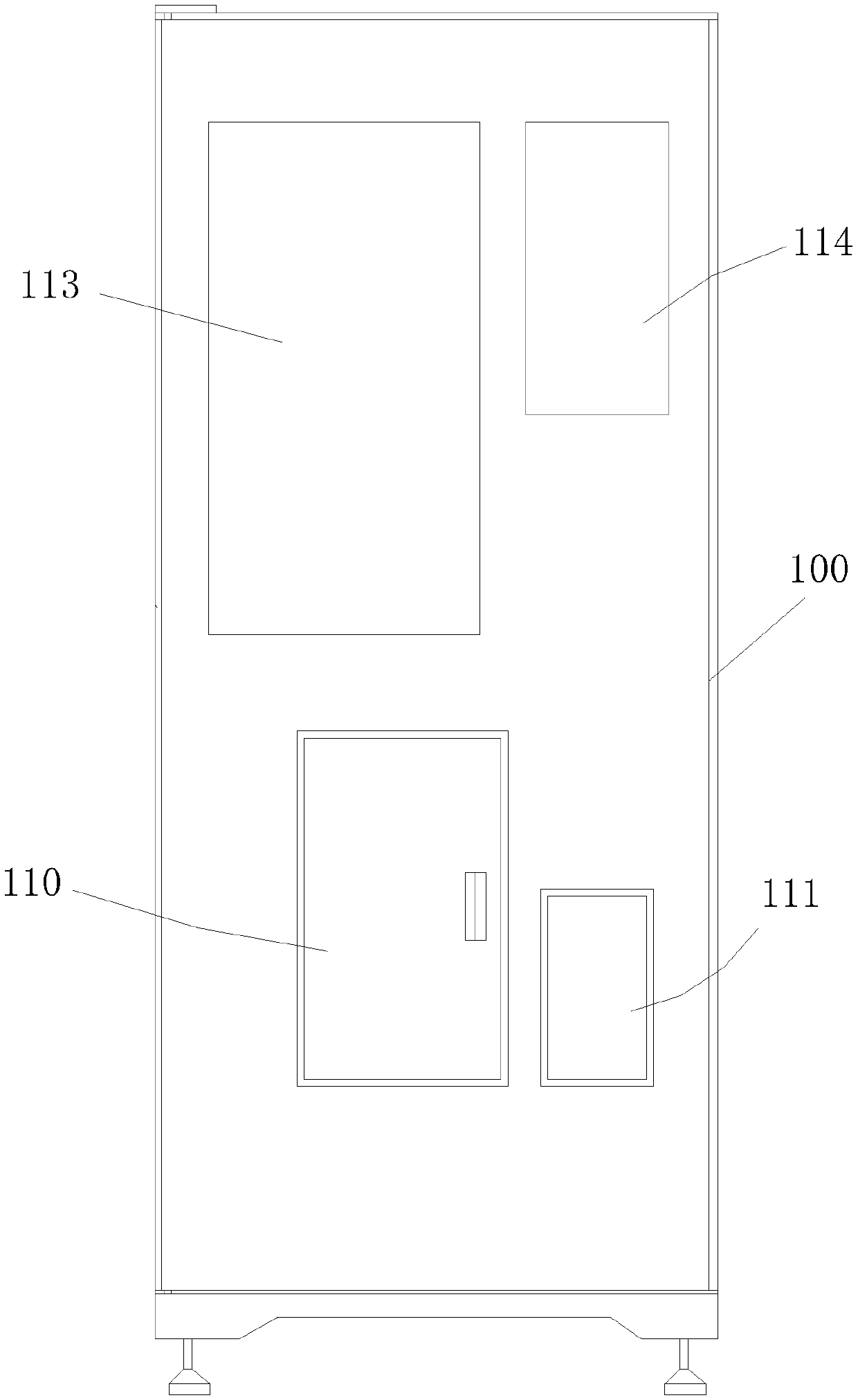

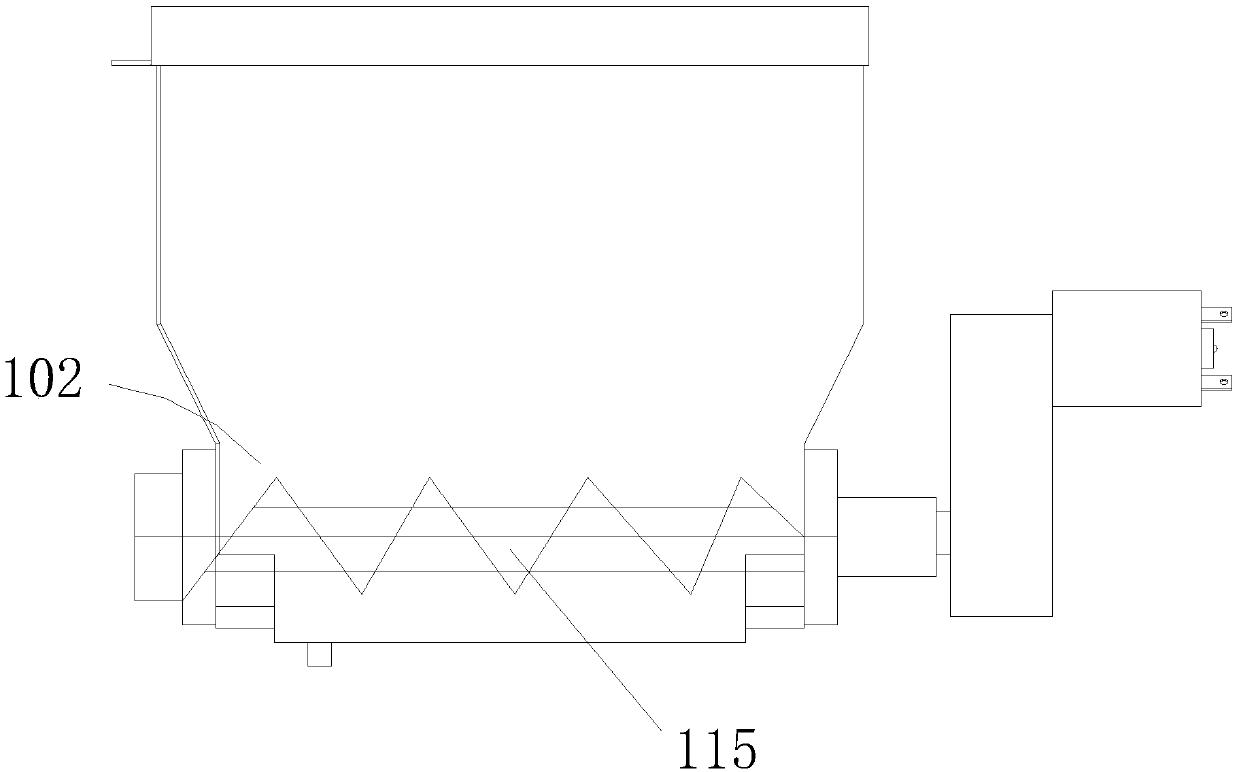

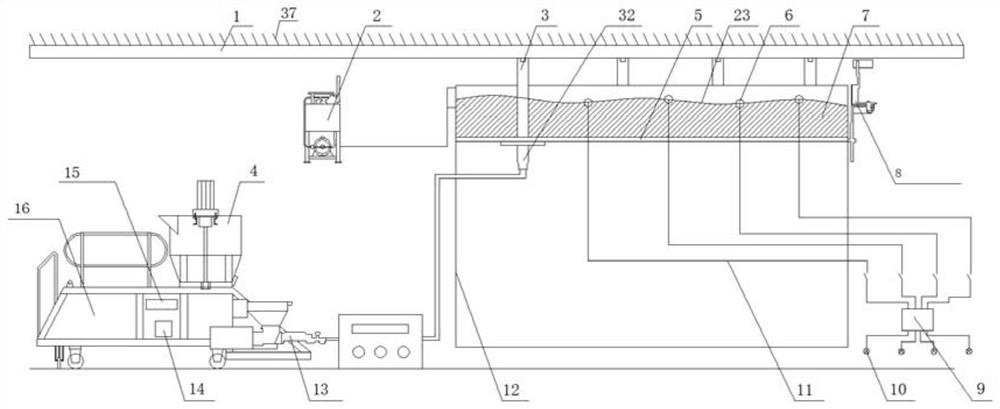

Self-service freshly squeezed edible oil vending equipment

PendingCN109685989AGuarantee food qualityNo quality defectsApparatus for dispensing fluids/granular materialsPressesCommunity orPublic place

The invention relates to the technical field of vending equipment, and discloses self-service freshly squeezed edible oil vending equipment. The self-service freshly squeezed edible oil vending equipment includes a material conveying channel, an oil squeezing machine, a cup dropping device and a cup sealing device, wherein the material conveying channel is used for conveying oil squeezing raw materials, and the oil squeezing machine adopts the oil squeezing raw materials to squeeze oil; the material conveying channel is provided with a material inlet for the oil squeezing raw materials to enter and a material outlet, the oil squeezing machine is provided with an oil squeezing inlet and an edible oil outlet, the oil squeezing raw materials enter the oil squeezing machine through the oil squeezing inlet to be subjected to oil squeezing, and edible oil obtained after squeezing is discharged through the edible oil outlet; the material outlet of the material conveying channel is communicated with the oil squeezing inlet of the oil squeezing machine, a cup dropped from the cup dropping device contains the edible oil discharged through the edible oil outlet, and the cup sealing device isused for sealing the opening of the cup. The self-service freshly squeezed edible oil vending equipment can be directly placed in communities or public places, the edible oil obtained after squeezingcan be directly eaten, no long production period is needed, no other substances need to be added into the edible oil, the edible quality of the edible oil is ensured, and no quality defects exist.

Owner:周胜全

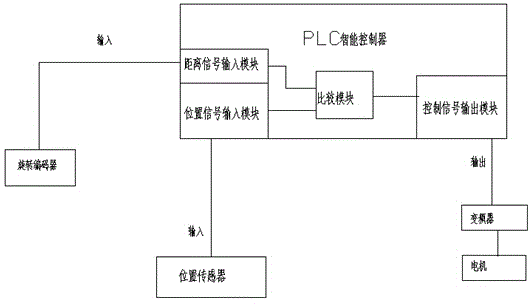

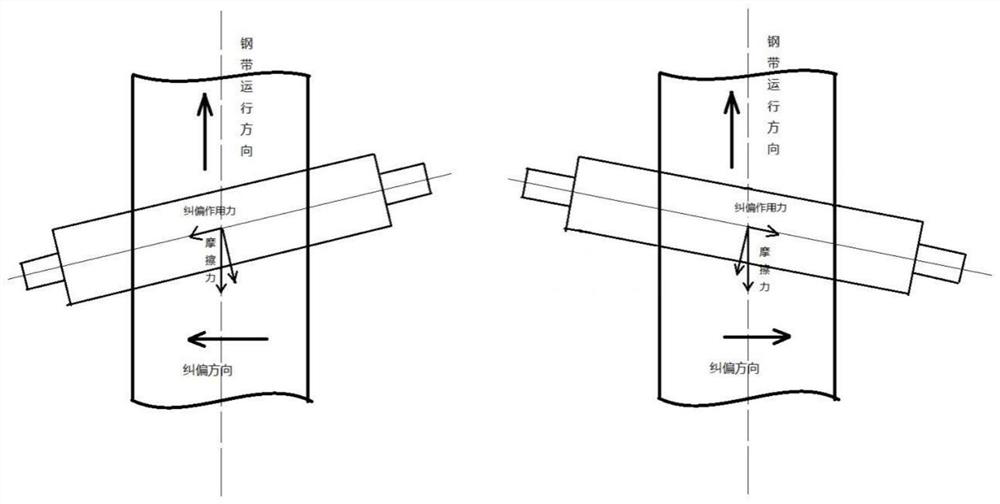

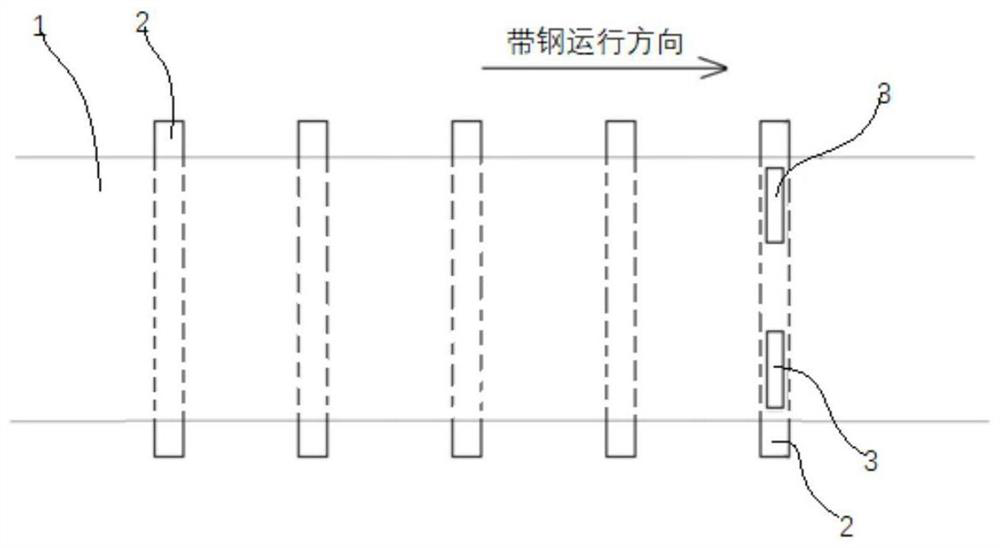

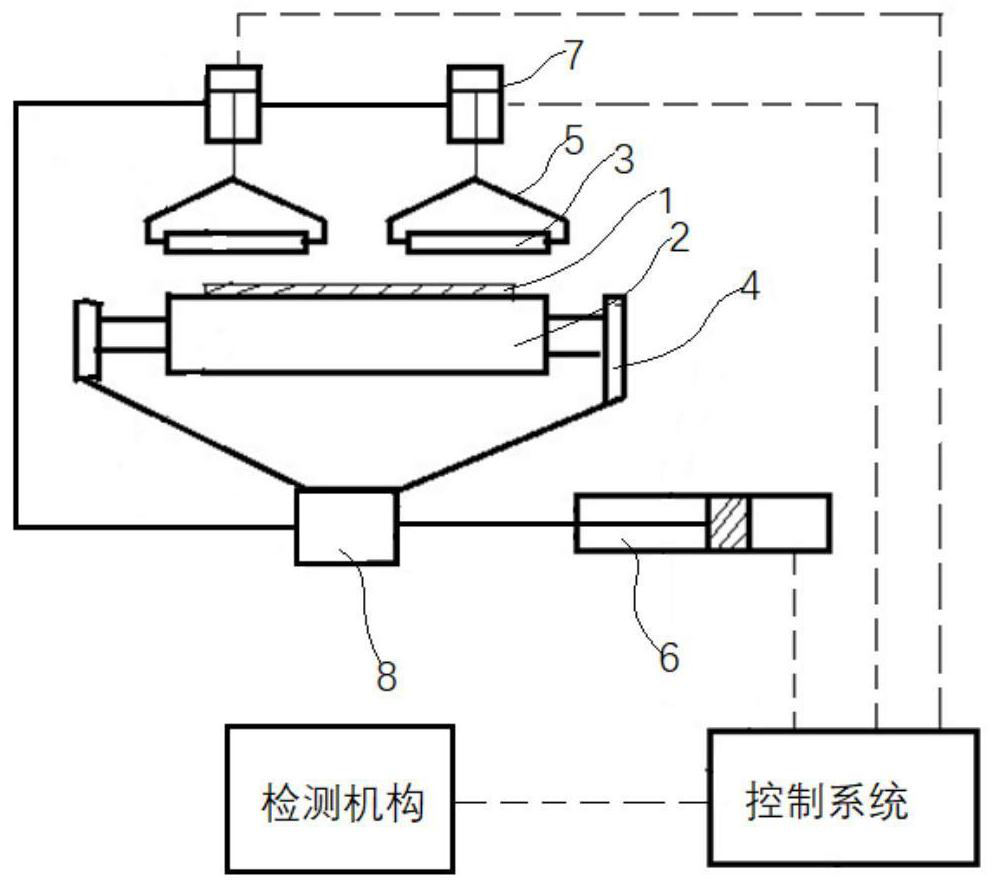

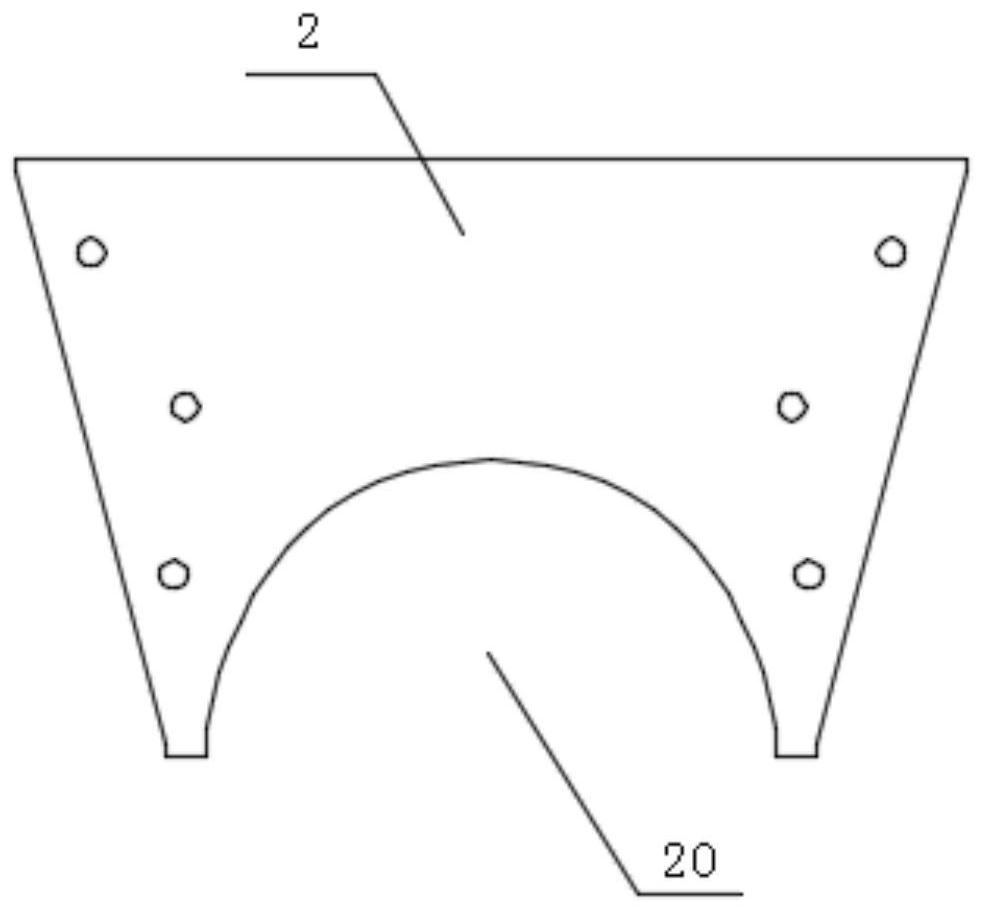

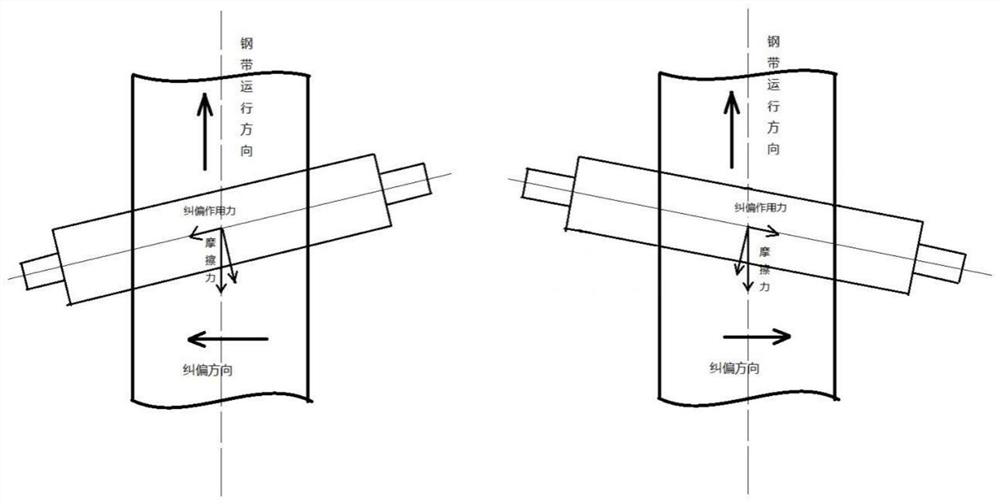

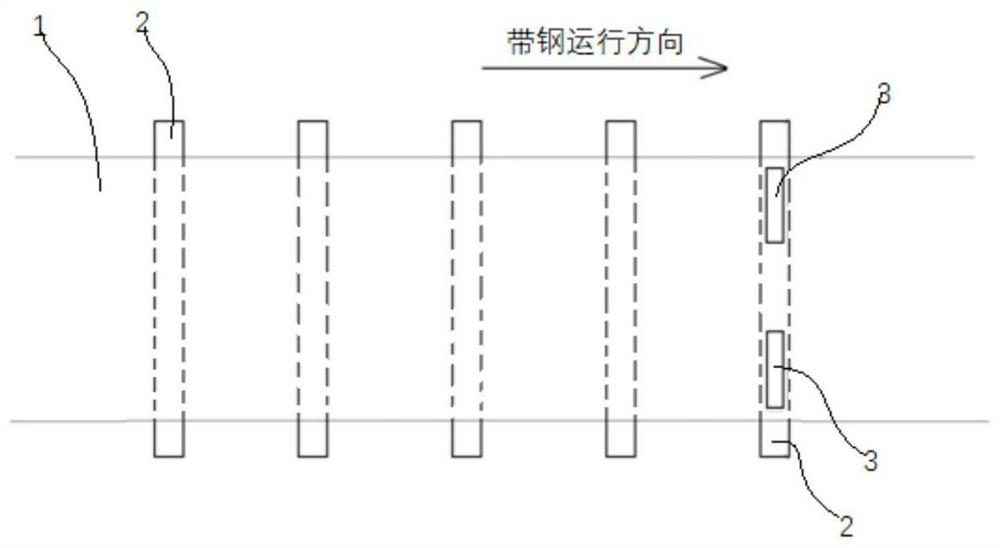

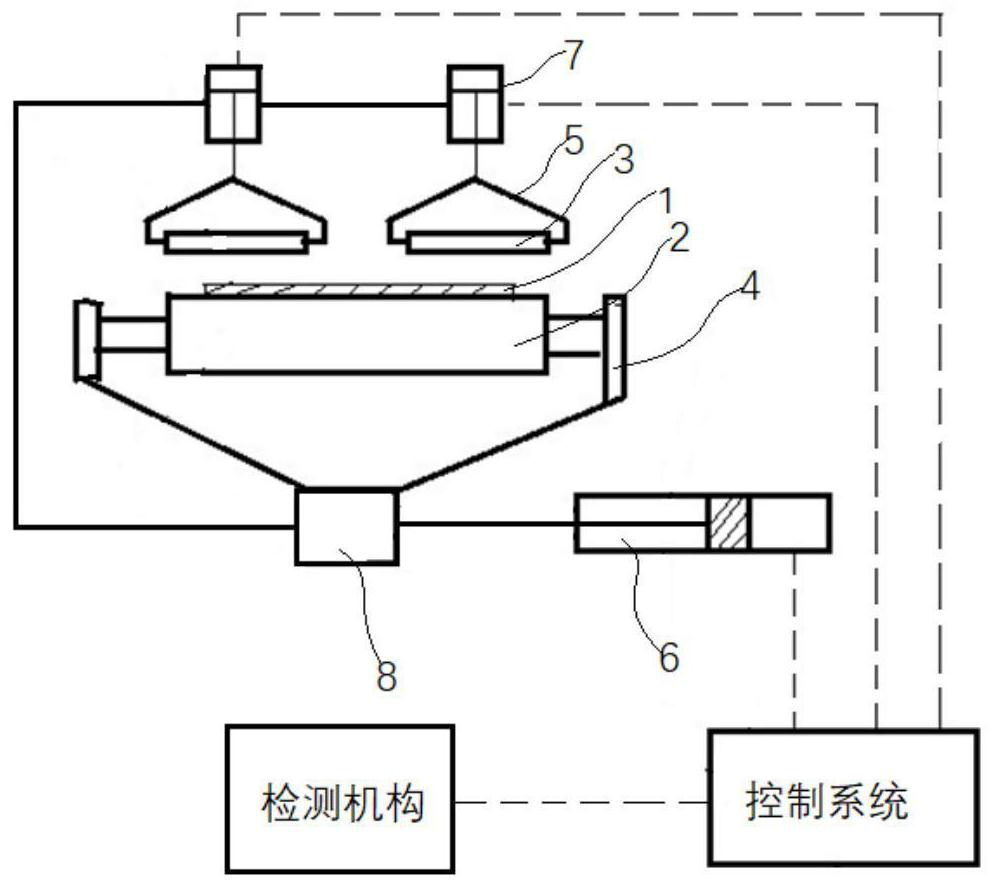

Cold-rolled silicon steel thin strip continuous annealing production line deviation rectifying device and method

ActiveCN112063830AIncrease frictionPowerfulFurnace typesHeat treatment furnacesProduction lineControl system

The invention discloses a cold-rolled silicon steel thin strip continuous annealing production line deviation rectifying device and method. The device comprises a control system and a plurality of deviation rectifying units. Each deviation rectifying unit comprises a detection mechanism used for detecting the current deviation amount of strip steel at the position, a deviation rectifying roller located below the strip steel and used for applying deviation rectifying force to the strip steel, and a swing mechanism capable of driving the deviation rectifying roller to swing leftwards and rightwards relative to the strip steel on the horizontal plane. The most downstream deviation rectifying unit further comprises clamping rollers distributed on the working side and the transmission side above the strip steel and pressing mechanisms capable of driving the clamping rollers in one-to-one correspondence to press the strip steel downwards, the pressing mechanisms can be driven by the swing mechanism to swing synchronously with the deviation rectifying rollers, and the clamping rollers are parallel to the deviation rectifying rollers. The control system is connected with all the detectionmechanisms, the swing mechanisms and the pressing mechanisms and used for controlling the swing direction and angle of the deviation rectifying rollers and the pressing force of the clamping rollers according to the current deviation amount. According to the cold-rolled silicon steel thin strip continuous annealing production line deviation rectifying device and method, continuous deviation rectification can be achieved, the deviation rectification range is large, the retentivity is good, and no quality defect is generated for a continuously-operating cold-rolled silicon steel thin strip.

Owner:武汉钢铁有限公司

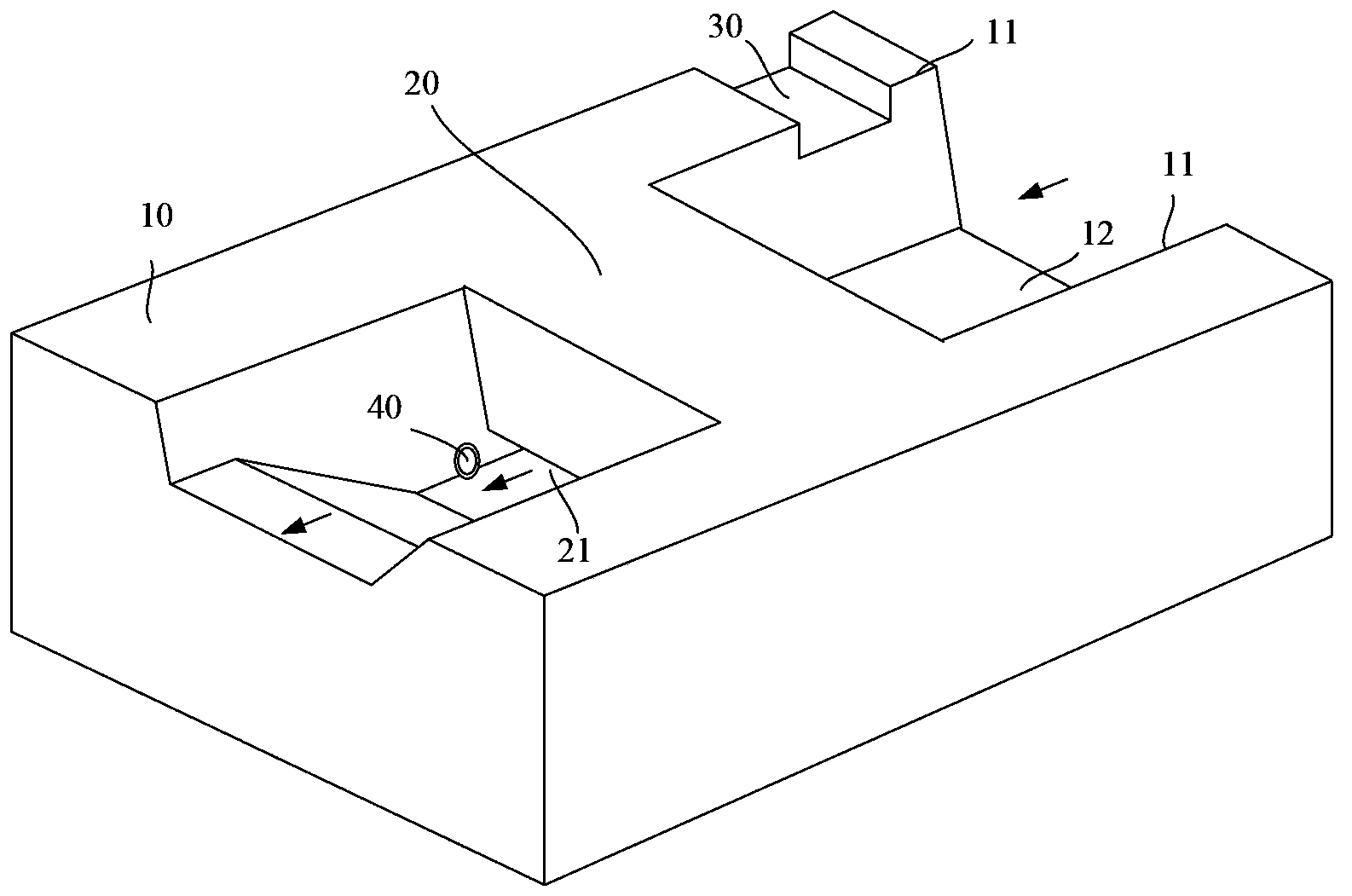

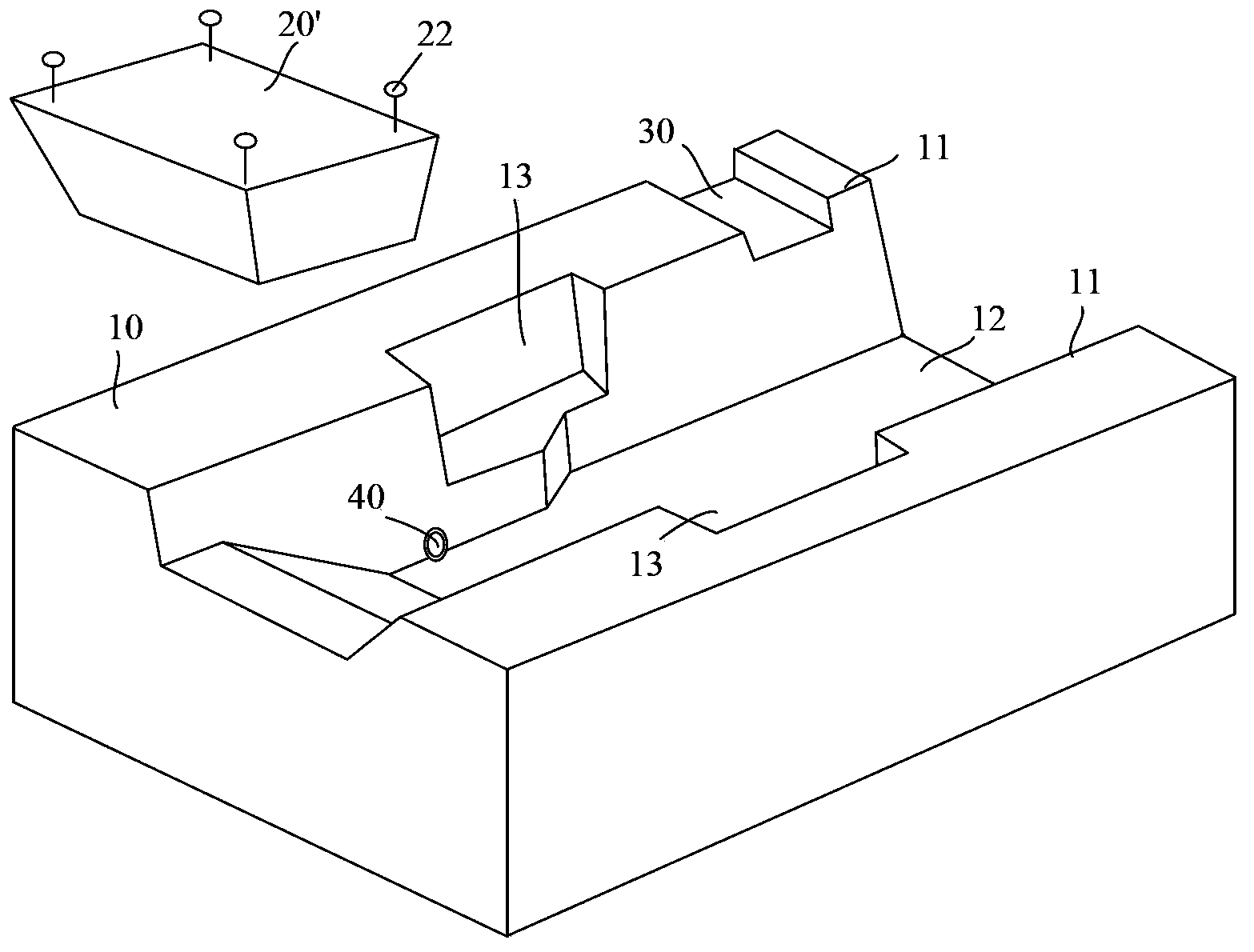

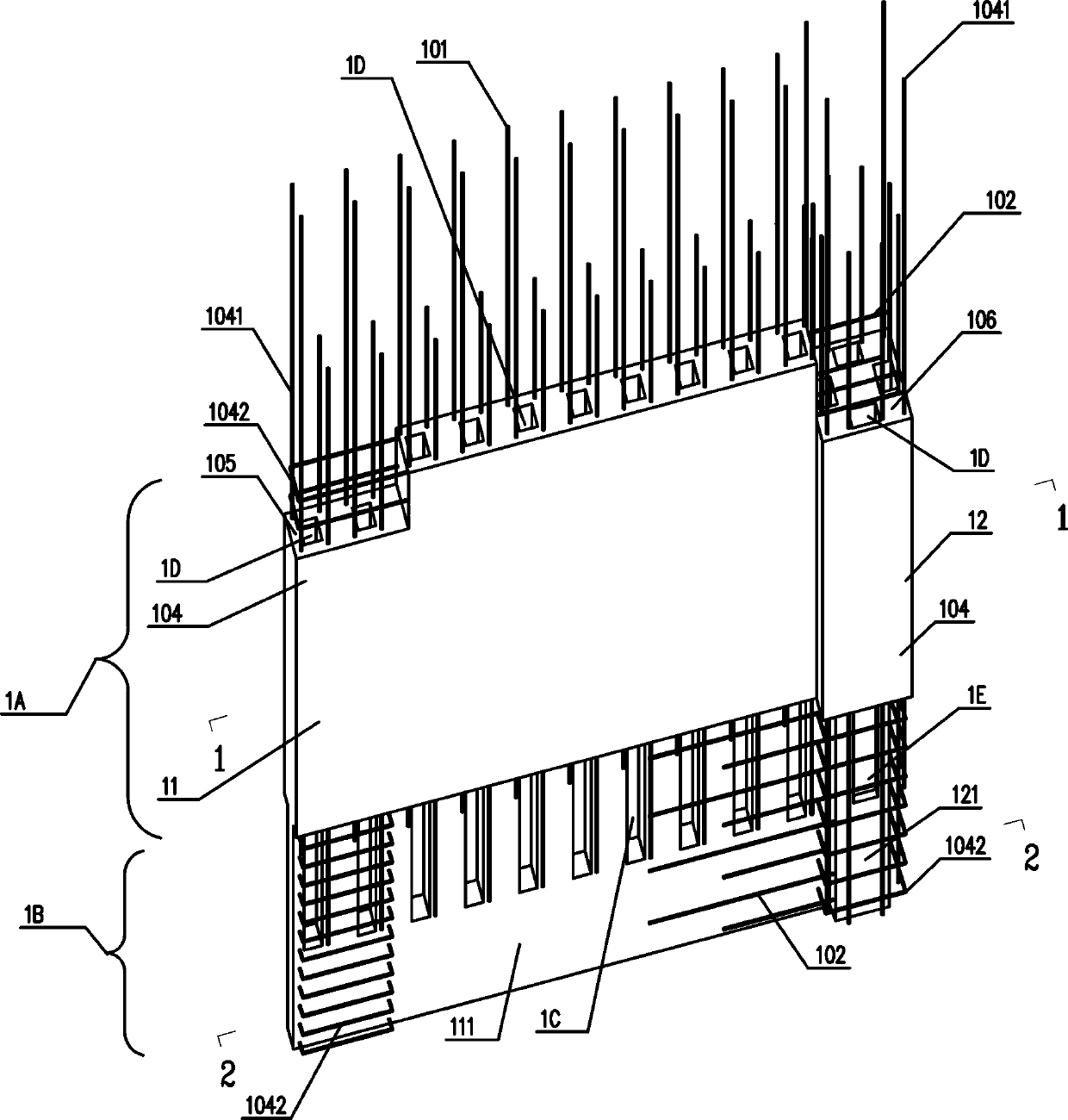

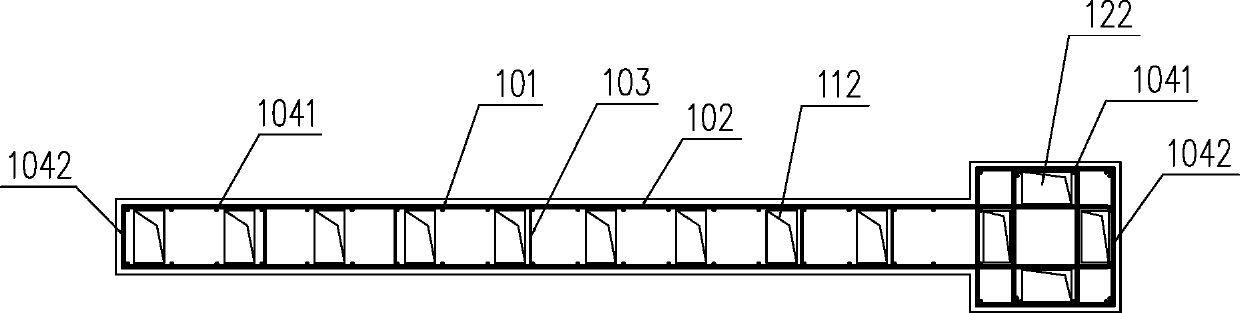

Fabricated concrete variable-section end-column-type shear wall member and construction method thereof

PendingCN107762001AResolve connectionConvenient welding operationWallsMould auxillary partsArchitectural engineeringRebar

The invention belongs to the technical field of building materials and building construction and particularly relates to a fabricated concrete variable-section end-column-type shear wall member and amanufacturing mould and construction method thereof. The fabricated concrete variable-section end-column-type shear wall member comprises a shear wall limb (11) and an end column (12), and the end column (12) is directly connected with one side end of the shear wall limb (11). Through the variable section, steel bar joints (1F) of vertical steel bars (101) on the two sides of the lower section (1B) of the member and edge member vertical steel bars (1041) are exposed. The problem of unstable connection between the vertical steel bars (101) and the edge member vertical steel bars (1041) of the end-column-type shear wall member is conveniently solved through a welding connecting method. Through an overall prefabricated mode, the problem of connection of horizontal steel bars (102) and the problem that various steel bars cannot be mutually connected to form a steel bar framework are solved. By forming a shear wall limb vertical hole channel (112) and an end column vertical hole channel (122) which are special for cast-in-place concrete (32), the cast-in-place concrete (32) is easy to pour, vibrate and compact, the quality defect is avoided, and detection and acceptance are facilitated.By arranging an L-shaped connecting beam support (105) or a connecting beam support platform (106), connecting beams or frame beams are conveniently mounted.

Owner:姚伟华 +1

Tunnel vault anti-void early warning device and concrete real-time monitoring method thereof

PendingCN114658444AThere is no blocking problemNo quality defectsMining devicesUnderground chambersArchitectural engineeringEngineering

The invention discloses a tunnel vault anti-void early warning device which comprises a grouting vehicle and a primary building trolley end mold, and the grouting vehicle is provided with a sewage treatment system, a monitor and an effect evaluation system. According to the tunnel vault anti-void early warning device and the concrete real-time monitoring method and the real-time observation process thereof, the tunnel lining arch self-alarm anti-void construction technology based on the cloud video technology is adopted, in the construction process, the secondary lining procedure and the grouting procedure basically belong to parallel procedures, grouting can be completed immediately while secondary lining is completed, and the construction efficiency is improved. The problem of grouting pipe blocking does not exist, meanwhile, the secondary lining pouring and filling grouting conditions are observed in real time through the cloud video technology, the tunnel vault disengaging prevention early warning is utilized, the tunnel vault concrete pouring compactness condition is checked, an alarm is given in time, vault disengaging is effectively prevented, the tunnel lining construction quality is improved, the lining construction defects are overcome at a time, and the construction efficiency is improved. The method has obvious comprehensive economic benefits, and can greatly save later-stage cost.

Owner:赵立财

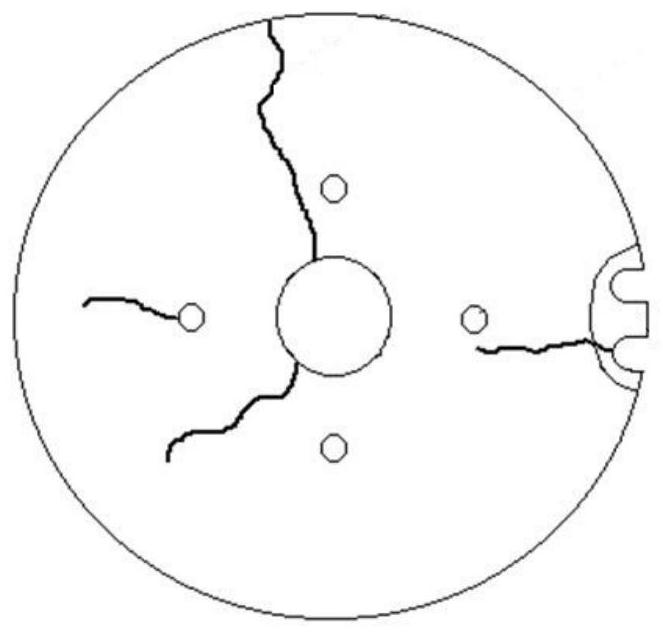

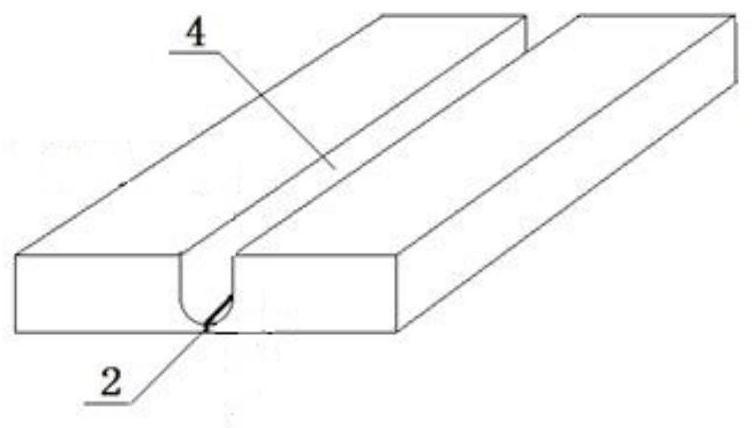

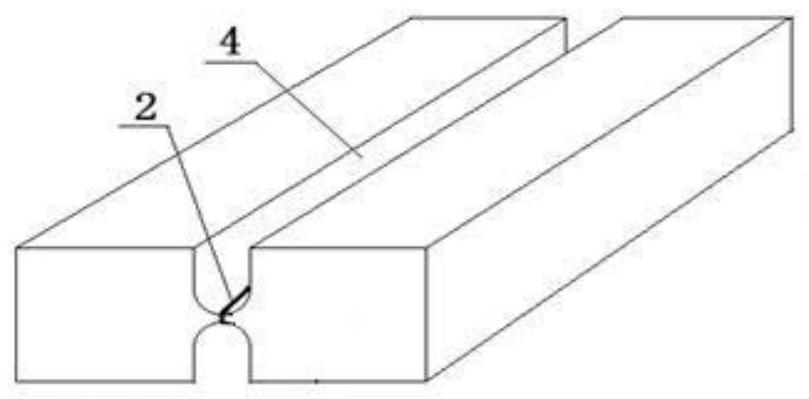

Method for repairing cracks of circular saw blade through welding

InactiveCN112676678AEasy and flexible operationEasy to operateArc welding apparatusSawing tools dressing arrangementsCircular sawEconomic benefits

The invention discloses a method for repairing cracks of a circular saw blade through welding, and particularly provides a manual arc welding process method capable of repairing crack defects of the circular saw blade at a lower preheating temperature. The method is characterized in that a welding material is a flat welding electrode capable of realizing narrow-direction strip conveying method welding and wide-direction strip conveying method welding; narrow and small grooves are welded; weld joint stress is eliminated through vibration impact; a bottoming weld joint and a filling weld joint are welded through a narrow-direction strip conveying method, and a cap weld joint is welded through a wide-direction strip conveying method; and the preheating temperature of the circular saw blade is 100 DEG C, and the welding repair temperature is kept at 80-100 DEG C. According to the method, the problem that the welding preheating temperature is too high is effectively solved, meanwhile, the welding operation is as simple, convenient and feasible as common welding, effective welding repair of the cracks on the circular saw web can be achieved, and the method has very high practical value and economic benefits.

Owner:日照唐晟锯业有限公司

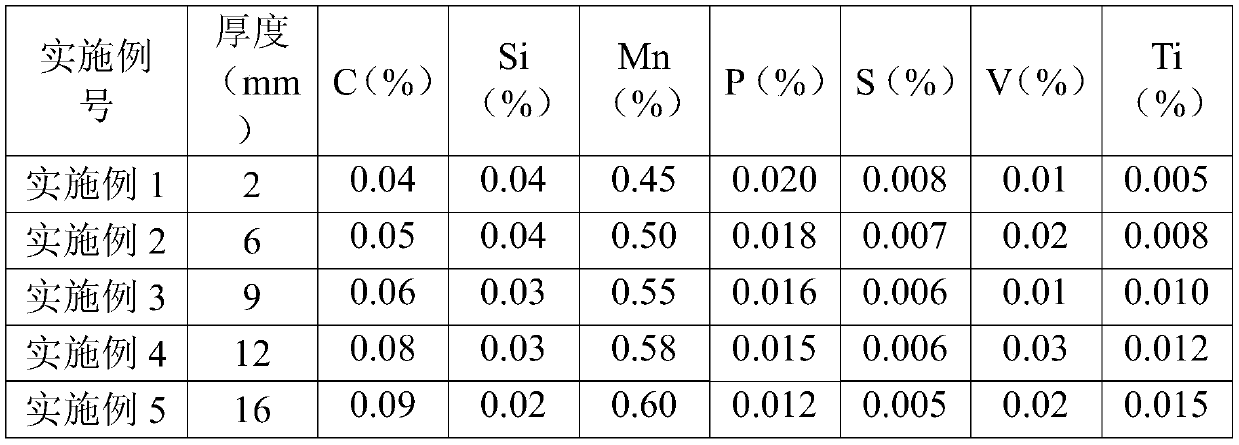

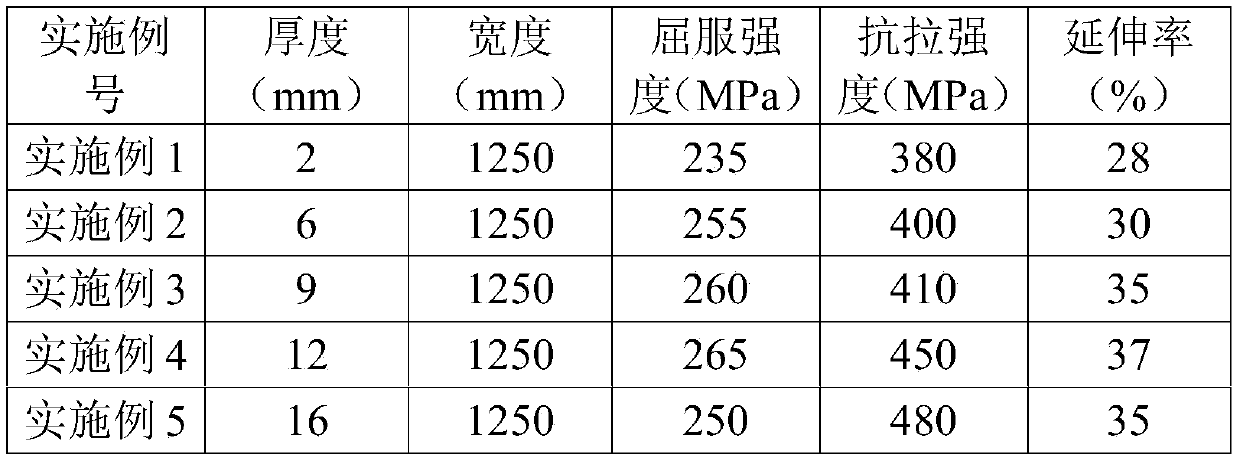

380 MPa grade automobile wheel steel hot rolling acid pickling plate and production method thereof

InactiveCN111057951AImprove welding effectMeet performance needsTemperature control deviceMetal rolling arrangementsHigh pressure waterHeating furnace

The invention provides a 380 MPa grade automobile wheel steel hot rolling acid pickling plate and a production method thereof and belongs to the technical field of steel rolling. The 380 MPa grade automobile wheel steel hot rolling acid pickling plate comprises the following components in percentage by weight: 0.04-0.09% of C, equal to or less than 0.04% of Si, 0.45-0.60% of Mn, equal to or less than 0.020% of P, equal to or less than 0.008% of S, 0.005-0.015% of Ti, 0.01-0.03% of V and the balance of Fe and unavoidable impurities. The production method comprises the following steps: preparinga plate slab, putting the plate slab in a heating furnace to be heated, then, adopting high pressure water to remove phosphorus, and then, carrying out rolling, cooling and coiling on the plate slab.According to the 380 MPa grade automobile wheel steel hot rolling acid pickling plate, vanadium and titanium are added in steel to improve the strength, so that the performance demand of automobile wheel steel is met, generation of an oxide scale is reduced, and the surface quality after acid pickling is high.

Owner:HEBEI IRON AND STEEL

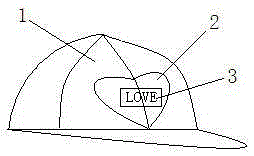

Cap printing and embroidering pattern covering process

The invention discloses a cap printing and embroidering pattern covering process. In a printing pattern deformation printing process, an embroidering pattern position which is not deformed on a printing pattern is remained; under the precondition that the pattern is not deformed after a cap subjected to separated printing and whole embroidering is spliced, the embroidered embroidering pattern has no paste; a covered printing and embroidering pattern is clean and beautiful and has no quality defects.

Owner:SIYANG JIEFENG CAP IND

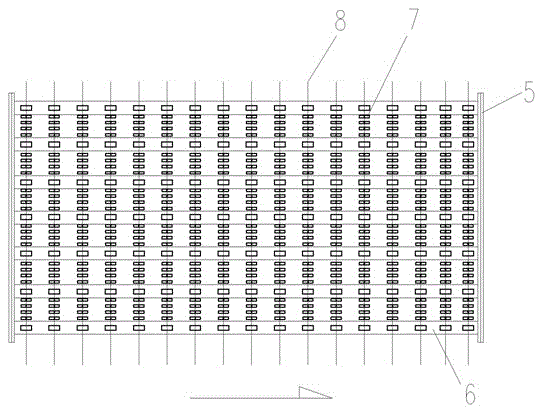

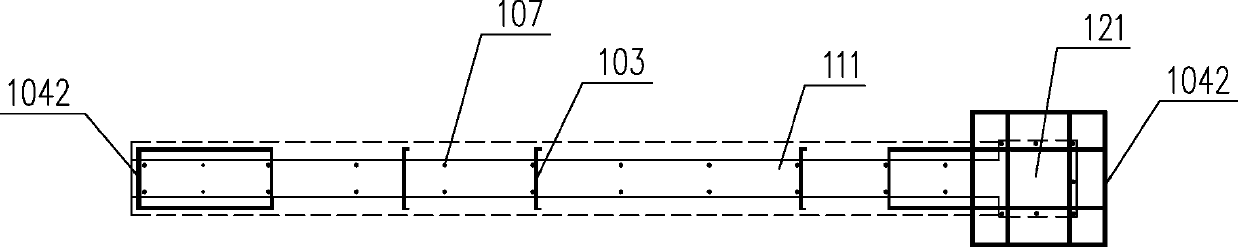

A Gradual Bending Tempered Glass Arc Changing Equipment

ActiveCN103951178BBending stabilityShorten production timeGlass reforming apparatusGlass tempering apparatusEngineeringToughened glass

The invention discloses a gradually shaped curved tempered glass arc changing device, which comprises a plurality of support beams extending longitudinally and arranged at intervals in the transverse direction. The support beams are provided with a plurality of cooling air grids at intervals in the longitudinal direction and several extending transversely and longitudinally. The flexible shafts arranged at intervals, the flexible shafts are hinged on the support beam, and a plurality of support rollers are sleeved on the flexible shaft; the two ends of the support beam are respectively connected to two transverse arc-changing mechanisms through universal ball pairs, The two transverse arc-changing mechanisms can perform arc-changing according to their respective arc-changing settings. The invention can realize that the glass can be bent as soon as it comes out of the furnace, and there is no need to wait for all the glass to be out of the furnace before starting to bend, which saves production time; when processing longer curved tempered glass, there will be no quality problems caused by the temperature difference between the end and the end of the glass during bending Defects; independent control of the horizontal variable arc unit, it can also process special-shaped glass with non-uniform curvature.

Owner:LUOYANG LANDGLASS TECH CO LTD

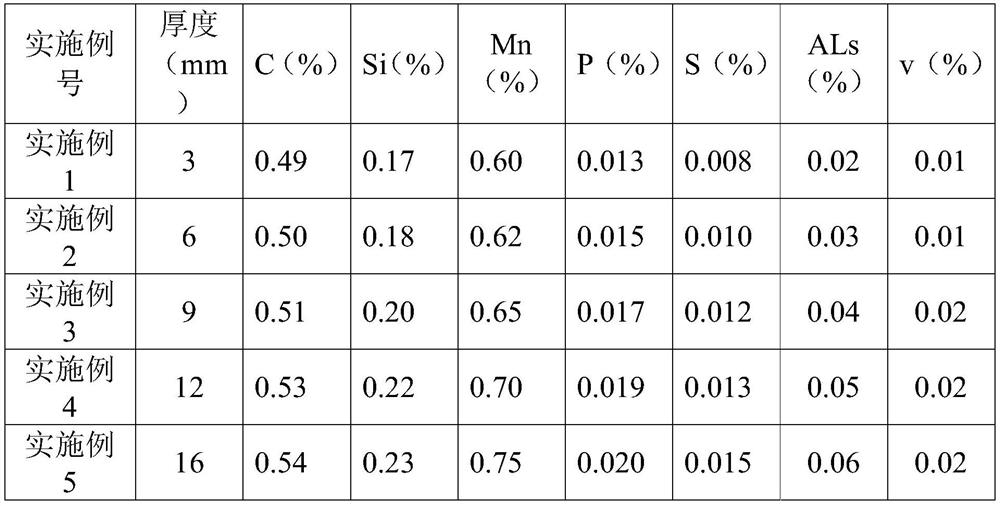

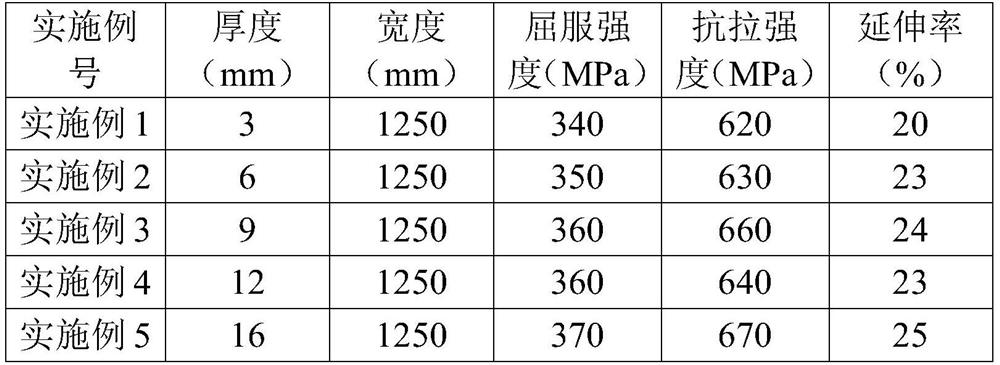

A kind of carbon steel 45mn hot-rolled pickling plate and production method thereof

ActiveCN111172455BReduce silicon contentMeet production requirementsHigh pressure waterHeating furnace

The invention provides a carbon steel 45Mn hot-rolled pickled plate and a production method thereof, belonging to the technical field of steel rolling. The components of the carbon steel 45Mn hot-rolled pickled plate include: C: 0.49% to 0.54%, Si : 0.17% ~ 0.23%, Mn: 0.60% ~ 0.75%, P≤0.020%, S≤0.015%, ALs: 0.02% ~ 0.06%, V: 0.02% ~ 0.05%, the rest is iron and unavoidable impurities; The production method comprises the following steps: preparing a slab, heating the slab in a heating furnace, dephosphorizing with high-pressure water, rolling, cooling and coiling the slab. A carbon steel 45Mn hot-rolled pickling plate of the present invention adds vanadium to the steel to increase the strength, reduces the silicon content in the steel, and reduces the generation of scale by controlling the temperature. After pickling, the surface quality is good and meets the requirements of the pickling plate. Production requirements.

Owner:HEBEI IRON AND STEEL

A Gradual Bending Tempered Glass Arc Changing Equipment

ActiveCN104973760BUniform windShorten production timeGlass reforming apparatusGlass tempering apparatusTemperature differenceToughened glass

The invention discloses a gradually shaped curved tempered glass arc changing device. The arc changing device includes several support beams extending longitudinally and arranged at intervals in the transverse direction. The support beams are provided with several cooling air grids and supporting rollers at intervals along the longitudinal direction. The two ends of the support beam are respectively connected to the two transverse arc-changing mechanisms through the universal ball pair; the two transverse arc-changing mechanisms can change the arc according to their respective arc-changing settings, and thus can transfer the The longitudinal ends of the glass plate are bent according to different curvatures; the longitudinal direction is the glass movement direction, and the transverse direction is the vertical glass movement direction. The invention can realize that the glass can be bent as soon as it comes out of the furnace, and there is no need to wait for all the glass to be out of the furnace before starting to bend, which saves production time; when processing longer curved tempered glass, there will be no quality problems caused by the temperature difference between the end and the end of the glass during bending Defects; independent control of the horizontal variable arc unit, it can also process special-shaped glass with non-uniform curvature.

Owner:LUOYANG LANDGLASS TECH CO LTD

A Gradual Bending Tempered Glass Arc Changing Equipment

ActiveCN104973761BUniform windShorten production timeGlass reforming apparatusGlass tempering apparatusEngineeringElectrical and Electronics engineering

The invention discloses an arc-changing equipment for curved tempered glass with a gradual shape, which comprises several support beams extending longitudinally and arranged at intervals in the transverse direction. The support beams are provided with several cooling air grids and support rollers at intervals along the longitudinal direction. One end is connected to a transverse arc-changing mechanism through a universal ball pair, and the other end of the support beam is hinged to another transverse arc-changing mechanism through a pin shaft extending horizontally; the two transverse arc-changing mechanisms can be set according to their respective arc changes to change the arc. The invention can realize that the glass can be bent as soon as it comes out of the furnace, and there is no need to wait for the glass to be completely out of the furnace before starting to bend, which saves production time; when processing longer curved tempered glass, there will be no quality problems caused by the temperature difference between the head and the tail of the glass during bending Defects; independent control of the horizontal variable arc unit can also process special-shaped glass with non-uniform curvature.

Owner:LUOYANG LANDGLASS TECH CO LTD

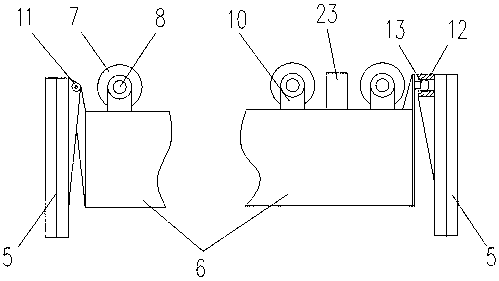

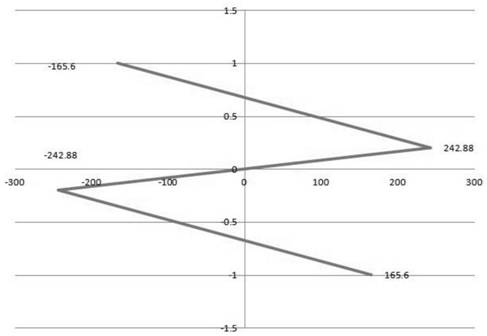

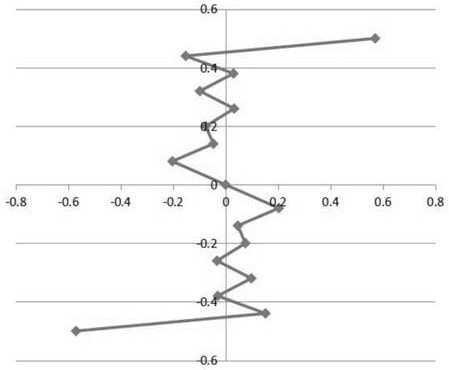

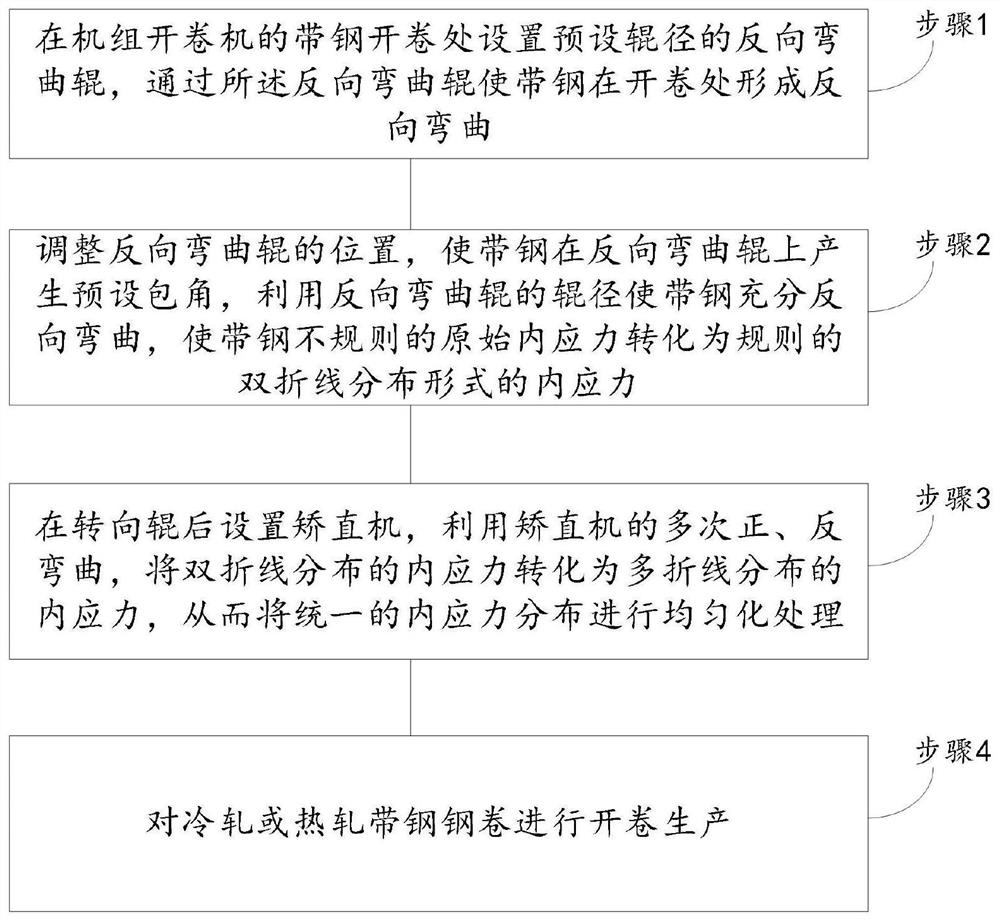

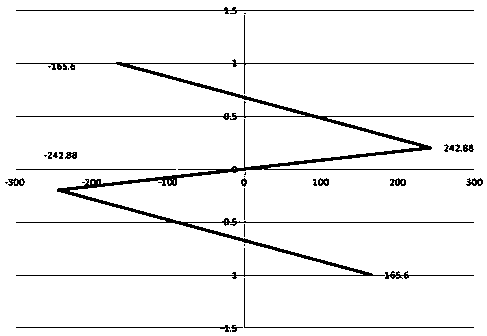

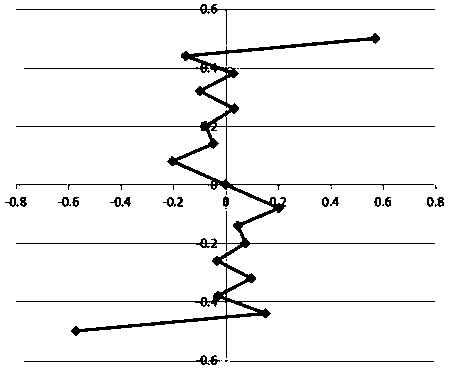

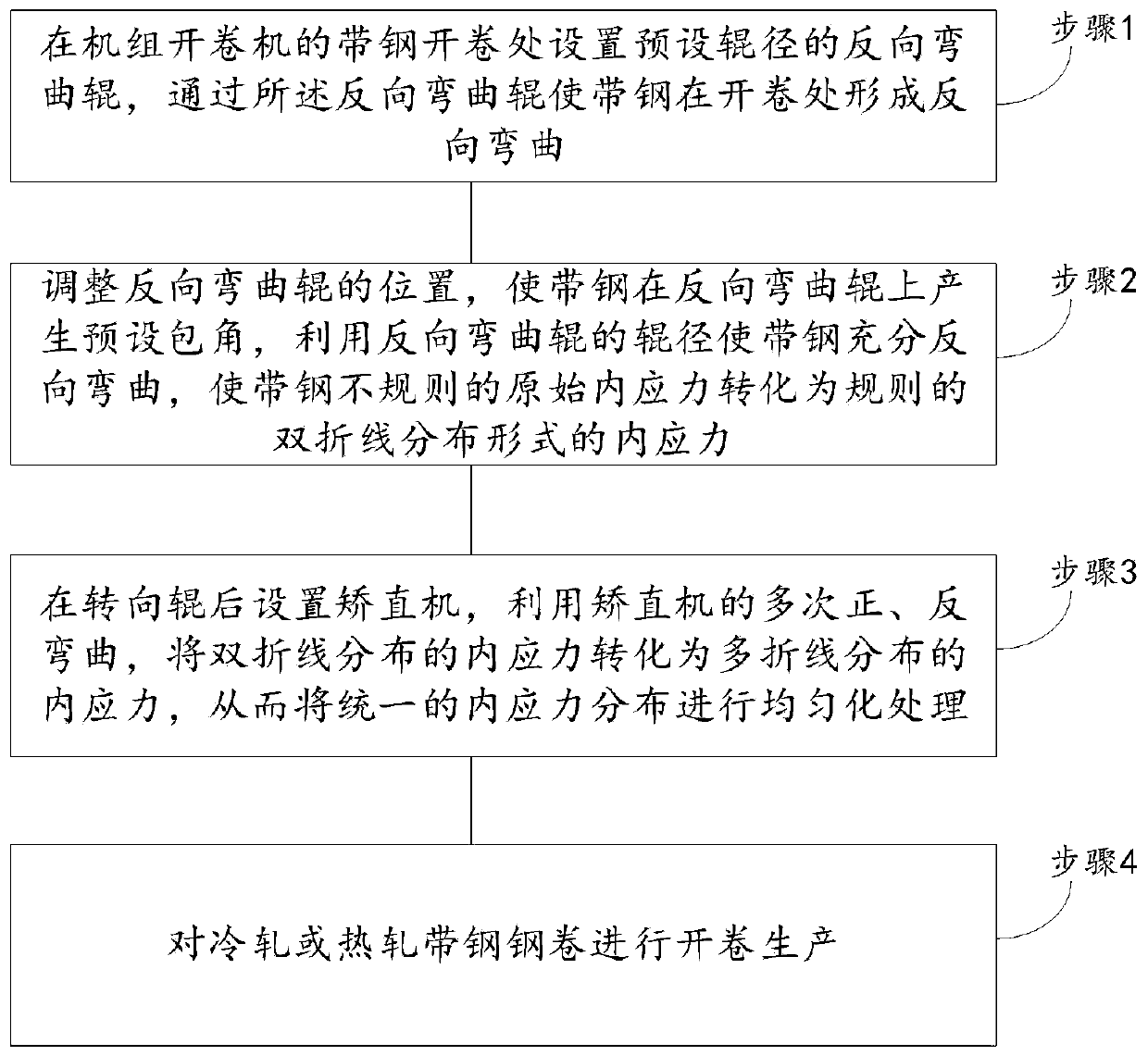

A method and device for improving the internal stress distribution of strip steel

ActiveCN111254265BStable wrap angleDistribution reduction and homogenizationStress distributionStructural engineering

A method and device for improving the internal stress distribution of strip steel. The method includes: setting a reverse bending roll with a preset roll diameter at the strip uncoiling position of the uncoiler of the unit, and forming the strip steel at the uncoiling position through the reverse bending roll. Reverse bending; adjust the position of the reverse bending roller to make the strip produce a preset wrap angle on the reverse bending roller, use the roll diameter of the reverse bending roller to make the strip fully reverse bend, and make the irregular original shape of the strip steel Internal stress is transformed into internal stress in the form of regular double-broken line distribution; a straightening machine is installed behind the steering roller, and the strip is bent forward and reverse for many times by using the straightener, so that the internal stress distributed by double-broken lines is transformed into that of multi-broken line distribution. Internal stress, so as to homogenize the uniform internal stress distribution; uncoil production of cold-rolled or hot-rolled strip steel coils. Through the invention, the effect of improving the internal stress distribution of the steel strip is achieved, and many quality defects due to the release of internal stress will not occur in subsequent processing.

Owner:WISDRI ENG & RES INC LTD

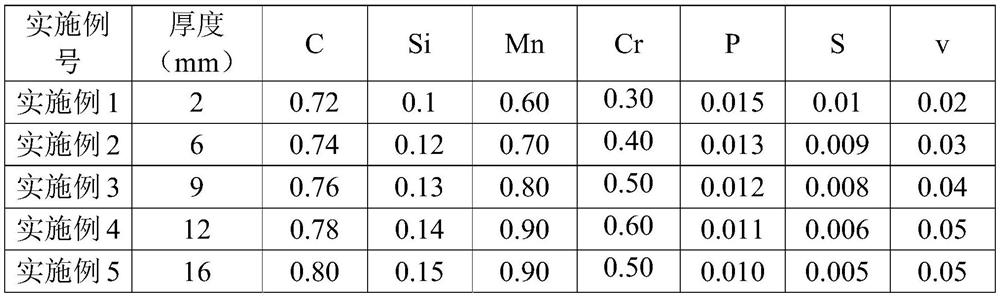

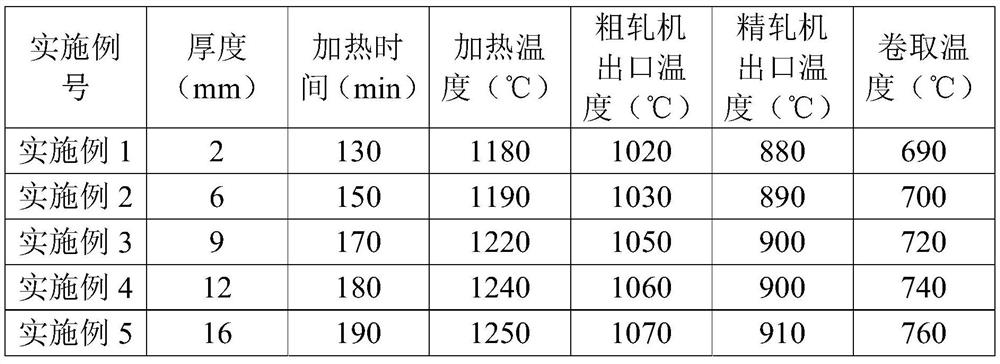

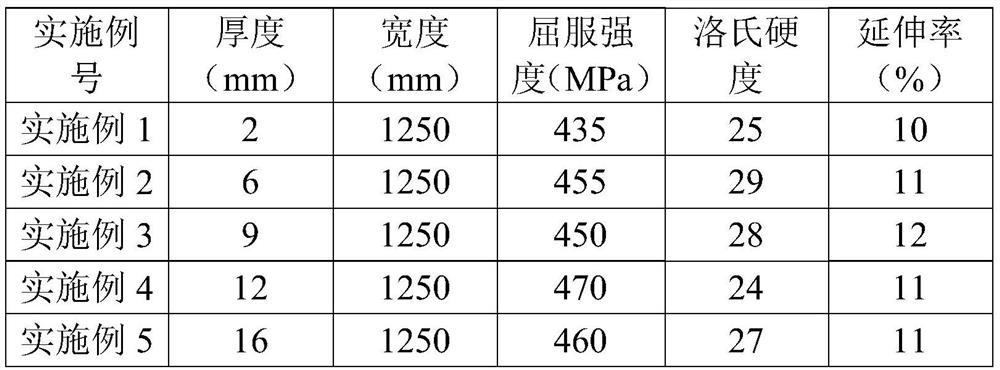

A kind of medium and high carbon steel 75cr hot-rolled pickling plate and its production method

ActiveCN111057962BReduce silicon contentMeet production requirementsHigh pressure waterHeating furnace

The invention provides a medium-high carbon steel 75Cr hot-rolled pickled plate and a production method thereof, which belong to the technical field of steel rolling. The components of the medium-high carbon steel 75Cr hot-rolled pickled plate include: C: 0.72-0.80%, Si : 0.1~0.15%, Mn: 0.60~90%, Cr: 0.30~0.60%, P≤0.015%, S≤0.010%, V: 0.02~0.05%, the rest is iron and unavoidable impurities; its production method includes The following steps are as follows: preparing a slab and placing the slab in a heating furnace for heating, then performing high-pressure water dephosphorization, and then performing rolling, cooling, coiling and slow cooling on the slab. In the present invention, a medium-high carbon steel 75Cr hot-rolled pickling plate adds vanadium to the steel to increase the strength, reduces the silicon content in the steel, and reduces the generation of scale through the control of temperature and time. After pickling, the surface quality is good and the surface is not rough. There are quality defects, which meet the production requirements of pickling boards.

Owner:HEBEI IRON AND STEEL

A Gradual Bending Tempered Glass Arc Changing Equipment

ActiveCN104973758BShorten production timeNo quality defectsGlass reforming apparatusGlass tempering apparatusTemperature differenceElectrical and Electronics engineering

The invention discloses a gradually shaped curved tempered glass arc-changing device. The arc-changing device includes several support beams extending longitudinally and arranged at intervals in the transverse direction. The support beams are provided with several support rollers at intervals along the longitudinal direction. One end of the support beam is connected to a transverse arc-changing mechanism through a universal ball pair, and the other end of the support beam is hinged to another transverse arc-changing mechanism through a pin shaft extending transversely of the axis; the two transverse arc-changing mechanisms can press The respective variable arc settings are used to change the arc. The invention can realize that the glass can be bent as soon as it comes out of the furnace, and there is no need to wait for the glass to be completely out of the furnace before starting to bend, which saves production time; when processing longer curved tempered glass, there will be no quality problems caused by the temperature difference between the head and the tail of the glass during bending Defects; independent control of the horizontal variable arc unit, it can also process special-shaped glass with non-uniform curvature.

Owner:LUOYANG LANDGLASS TECH CO LTD

Parallel type synchronous tamping technology for thickener of aluminum cell lining

A parallel type synchronous tamping technology for thickener of an aluminum cell lining comprises the following steps that firstly, a thickener tamping area of the cell lining is divided into a cell peripheral thickener tamping area and a cathode carbon block gap thickener tamping area which are two parallel tamping areas; secondly, the two parallel tamping areas are divided into a plurality of fixed tamping working planes according to working area dividing lines, and the tamping work is conducted in each working plane at the same time; thirdly, split tamping is needed in the cell periphery thickener tamping area, and when a combined tamping head conducts compression joint on every two adjacent tamping areas, the requirement for the compression joint width of an overlapping area of every two adjacent tamping areas in the cell peripheral thickener tamping area needs to be met; fourthly, at the tamping joint part of the cell peripheral thickener tamping area and the cathode carbon block gap thickener tamping area, the crossed lap joint tamping is conducted in the manner that the respective tamping ranges of the cell peripheral thickener tamping area and the cathode carbon block gap thickener tamping area need to be exceeded by a certain width; and fifthly, at the joint position of every two adjacent tamping working areas, tamped according to working areas, in the groove periphery thickener tamping area, the tamping width of the mutual crossed lap joint needs to meet the tamping requirement. According to the technology, the tamping quality is guaranteed, and the construction progress is improved.

Owner:MCC TIANGONG GROUP

A Gradual Bending Tempered Glass Arc Changing Equipment

ActiveCN104973753BBending stabilityShorten production timeGlass reforming apparatusGlass tempering apparatusGlass furnaceEngineering

The invention discloses a gradually shaped curved tempered glass changing arc device. The arc changing device includes several support beams extending longitudinally and arranged at intervals in the transverse direction. Flexible shaft, the flexible shaft is hinged on the supporting beam, and a plurality of supporting rollers are sleeved on the flexible shaft, and the two ends of the supporting beam are respectively connected to two transverse arc-changing mechanisms through universal ball pairs; The arc can be changed according to the respective arc setting. The invention can realize that the glass can be bent as soon as it comes out of the furnace, and there is no need to wait for the glass to be completely out of the furnace before starting to bend, which saves production time; when processing longer curved tempered glass, there will be no quality problems caused by the temperature difference between the head and the tail of the glass during bending Defects; independent control of the horizontal variable arc unit can also process special-shaped glass with non-uniform curvature.

Owner:LUOYANG LANDGLASS TECH CO LTD

Raw skin hair saving and removing method using neutral protease and chemical substances

ActiveCN103773907BReduce dosageShort duration of actionPre-tanning chemical treatmentNeutral proteaseProteinase activity

The invention discloses a raw skin hair saving and removing method using neutral protease and chemical substances. The method is characterized by comprising the following steps: firstly treating raw skin for 25-55 minutes at the pH of 7.0-8.5 by using the neutral protease so as to damage and remove the surface skin; increasing the pH of bath foam to be over 12 by using lime, and inactivating the neutral protease, so that the risk of damaging the skin collagen through the protease is eliminated, the hair is protected, and finally the aim of protecting and removing the hair is achieved by using a small amount of sulfides. According to the method, the technical problems that the hair is incompletely removed in the conventional enzyme unhairing method, the grain side is damaged or loosened due to the enzyme unhairing method and enzyme-sulfide cooperative unhairing method, the hair is easily removed excessively in a chemical hair protecting and removing method and the surface skin is difficultly removed in a sulfur chemical hair protecting and removing method can be solved. Compared with a limed alkali method, the method has the advantages that the grain side on unhaired naked skin is clean and smooth, the sulfides, suspended solids and organic pollutants in wastewater are greatly reduced, and the method is a raw skin hair removing method which is easily controlled in operation, economical and practical and can ensure the product quality safety.

Owner:SICHUAN UNIV

Method and device for improving internal stress distribution of strip steel

ActiveCN111254265AStable wrap angleDistribution reduction and homogenizationStress distributionStructural engineering

The invention discloses a method and a device for improving internal stress distribution of strip steel. The method includes the following steps that a reverse bending roller having the preset rollerdiameter is arranged in the strip steel uncoiling position of a unit uncoiling machine, and the strip steel is bent reversely in the uncoiling position by the aid of the reverse bending roller; the position of the reverse bending roller is adjusted, the strip steel produces a preset wrap angle on the reverse bending roller, the strip steel is bent sufficiently reversely by the aid of the roller diameter of the reverse bending roller, and the irregular original internal stress of the strip steel is converted into the regular internal stress in the double-broken-line distribution form; a straightening machine is arranged behind a turning roller, repeated forward and reverse bending is performed on the strip steel by the aid of the straightening machine, the internal stress in double-broken-line distribution is converted into the internal stress in multiple-broken-line distribution, and thus homogenization treatment is performed on the unified internal stress distribution; and uncoiling production is performed on a cold-rolled or hot-rolled strip steel coil. By the aid of the method and the device, the effect of improving the internal stress distribution of the strip steel is achieved, and multiple quality defects caused by internal stress release can be avoided during subsequent processing.

Owner:WISDRI ENG & RES INC LTD

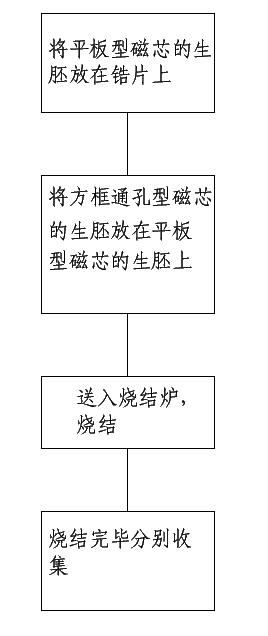

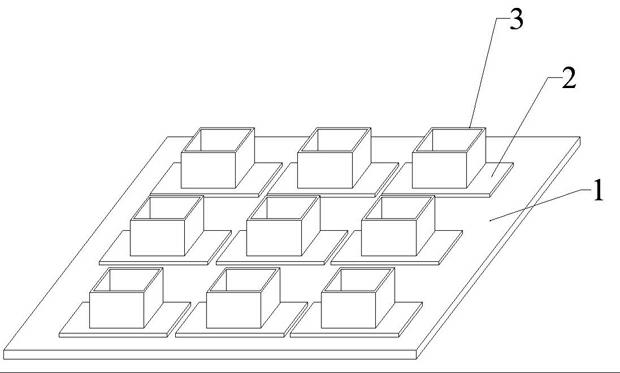

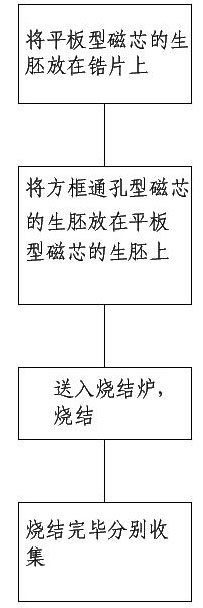

Method for improving yield of sintered square frame through hole type magnetic cores

InactiveCN102161096ANo quality defectsInductances/transformers/magnets manufactureShrinkage rateNanotechnology

The invention discloses a method for improving the yield of sintered square frame through hole type magnetic cores. The method comprises the following steps of: tidily stacking crude blanks of flat plate type magnetic cores to be sintered on a zirconium sheet used for loading, wherein the material of the crude blanks of the flat plate type magnetic cores is the same as that of the crude blanks of the square frame through hole type magnetic cores to be sintered; tidily stacking the crude blanks of the square frame through hole type magnetic cores to be sintered on the crude blanks of the flat plate type magnetic cores to be sintered; sending the stacked crude blanks of the square frame through hole type magnetic cores and the crude blanks of the flat plate type magnetic cores into a sintering furnace through the zirconium sheet for loading to sinter the crude blanks; and collecting the sintered square frame through hole type magnetic cores and the sintered flat plate type magnetic cores respectively. The method has the advantages that: a quality defect caused by uneven shrinkage caused by friction is not generated at a contact face of the sintered square frame through hole type magnetic cores, because the crude blanks of the flat plate type magnetic cores are placed on the crude blanks of the flat plate type magnetic cores which are made of the same material as the flat plate type magnetic cores to be sintered together, and the principle that the shrinkage rate is the same is adopted.

Owner:ACME ELECTRONICS KUNSHAN

A production process of centrifugal slurry-free piles and supporting material introduction molds and vibrating distribution vehicles

ActiveCN111015931BHigh strengthNo quality defectsMouldsShaping reinforcementsPre stressCentrifugation

The invention belongs to the technical field of concrete pile production, and in particular relates to a production process of centrifugal slurry-free piles, a supporting material introduction mold and a vibrating distribution vehicle; the production process of centrifugal slurry-free piles includes the following production steps: step A, preparing materials and Compile the reinforcement cage and assemble it into shape; step B, prepare dry hard concrete material; step C, hang the bottom mold of the production mold on the vibrating distribution vehicle, and use the lead mold to distribute the material: step D, combine the cover mold of the production mold with the Clamp the bottom mold and tighten the clamping bolts to tension the prestressed steel bars; step E, place the production mold on a centrifuge for centrifugation, and then enter the curing pool for maintenance; finally demould and leave the warehouse; and the production mold Auxiliary devices used in conjunction with the process include a vibrating material distribution vehicle and a material introduction mold; the invention solves several problems in the mold opening material distribution process and the mold closing pump material process on product quality, environmental pollution, cost consumption, production efficiency, and resource waste.

Owner:TIANJIN BAOFENG BUILDING MATERIALS CO LTD

Deviation correcting device and method for continuous annealing production line of cold-rolled silicon steel thin strip

ActiveCN112063830BIncrease frictionPowerfulFurnace typesHeat treatment furnacesControl systemStructural engineering

Owner:武汉钢铁有限公司

A method for pcb chemical nickel gold

ActiveCN107815669BNo black nickel quality issuesImprove the activation effectLiquid/solution decomposition chemical coatingResistElectroless nickel

The invention relates to a method for chemical nickel plating and gold immersing of a printed circuit board (PCB). The method comprises the following steps that the PCB is pretreated; then full-boardelectroless chemical nickel plating is conducted; and the PCB subjected to nickel plating is subjected to solder resist ink treatment and then gold chemical replacement. Solder resist ink treatment isconducted after chemical nickel plating, during chemical nickel plating, a plating starting agent is not used, any sulfur-containing additive does not exist, and thus the black nickel quality problemcannot be generated; the influence of a solder resist ink layer is avoided, the activation performance of the copper surface is improved, the uniformity of a nickel coating is greatly improved, the quality problems of skip plating or plating leakage, step plating, thin shoulder and the like are avoided, and the quality defects, caused by solder resist method residual, of chemical nickel plating are also avoided; and meanwhile, the attack of an electroless nickel groove on solder resisting is eliminated, the method is suitable for industrial production, and good application prospects are achieved.

Owner:GUANGDONG SKYCHEM TECH LTD

Centrifugal slurry-free pile rod production process, and material guiding mold and vibration material distribution vehicle matched with production process

ActiveCN111015931AHigh strengthNo quality defectsMouldsShaping reinforcementsPre stressProcess engineering

The invention belongs to the technical field of concrete pile rod production, and particularly relates to a centrifugal slurry-free pile rod production process, and a material guiding mold and a vibration material distribution vehicle matched with the process. The centrifugal slurry-free pile rod production process comprises the following production steps that A, materials are prepared, and a reinforcement cage is woven and assembled, b, a dry hard concrete material is prepared, c, a bottom die of a production die is hung on a vibration material distribution vehicle, and the material guiding mold is used in cooperation for material distribution, D, a cover die and the bottom die of the production die are closed, die assembling bolts are screwed down, and prestressed steel bars are tensioned, and E, the production die is placed on a centrifugal machine to be subjected to centrifugal operation, then enters a maintenance pool to be maintained, and finally is demolded and delivered. The auxiliary device used in cooperation with the production process comprises the vibration material distribution vehicle and the material guide mold. According to the invention, the problems of product quality, environmental pollution, cost consumption, production efficiency and resource waste in a mold opening and material distributing process and a mold closing and material pumping process are solved.

Owner:TIANJIN BAOFENG BUILDING MATERIALS CO LTD

A Gradual Bending Tempered Glass Arc Changing Equipment

ActiveCN104973754BBending stabilityShorten production timeGlass reforming apparatusGlass tempering apparatusGlass furnaceEngineering

The invention discloses a gradually shaped curved tempered glass arc changing device, which comprises a plurality of support beams extending longitudinally and arranged at intervals in the transverse direction. The support beams are provided with a plurality of cooling air grids at intervals in the longitudinal direction and several extending transversely and longitudinally. The flexible shafts arranged at intervals are hinged on the support beam, and a plurality of support rollers are sleeved on the flexible shaft; one end of the support beam is connected to a transverse arc-changing mechanism through a universal ball pair, and the other end of the support beam The pin shaft extending laterally through the axis is hinged on another transverse arc changing mechanism; the two transverse arc changing mechanisms can perform arc changing according to their respective arc changing settings. The invention can realize that the glass can be bent as soon as it comes out of the furnace, and there is no need to wait for all the glass to be out of the furnace before starting to bend, which saves production time; when processing longer curved tempered glass, there will be no quality problems caused by the temperature difference between the end and the end of the glass during bending Defects; independent control of the horizontal variable arc unit, it can also process special-shaped glass with non-uniform curvature.

Owner:LUOYANG LANDGLASS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com