380 MPa grade automobile wheel steel hot rolling acid pickling plate and production method thereof

A hot-rolled pickling and production method technology, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of excessive surface scale, poor quality, low qualified rate of finished products, etc., and achieve good surface quality, The effect of reducing the generation of iron oxide scale and improving the welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0037] As a specific embodiment of the production method of a 380MPa grade automotive wheel steel hot-rolled pickled plate provided by the present invention, the rolling includes: rolling the slab that has been dephosphorized by high-pressure water through a rough rolling mill and a finish rolling mill. system.

[0038]In this embodiment, the slab dephosphorized by high-pressure water is sequentially subjected to rough rolling, hot coil box and finish rolling to obtain a hot-rolled plate.

[0039] As a specific embodiment of the production method of a 380MPa grade automotive wheel steel hot-rolled pickled plate provided by the present invention, the outlet temperature of the rough rolling mill is 1020-1080°C, and the outlet temperature of the finishing mill is 840-890°C.

[0040] As a specific embodiment of the production method of a 380MPa grade automotive wheel steel hot-rolled pickled plate provided by the present invention, the slab is rolled in five passes in the rough ro...

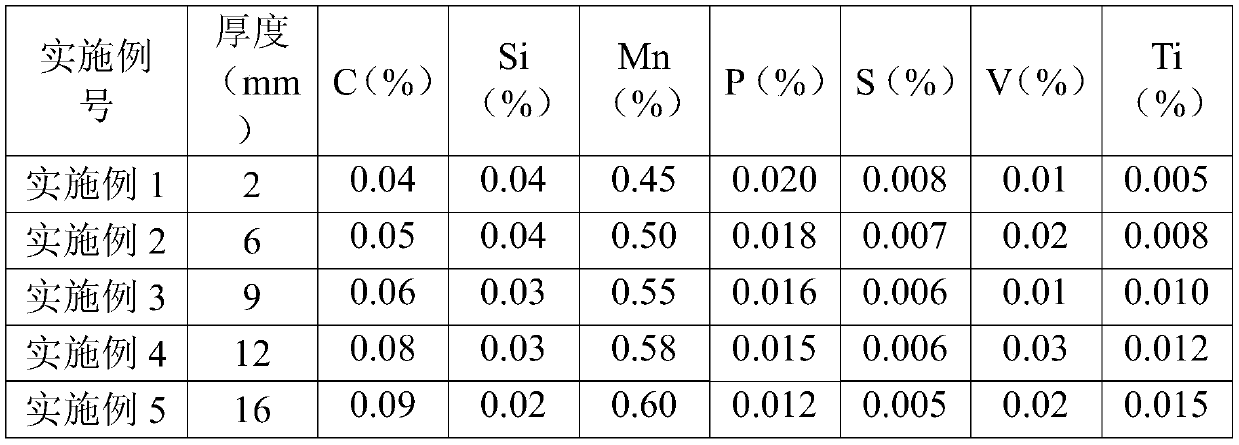

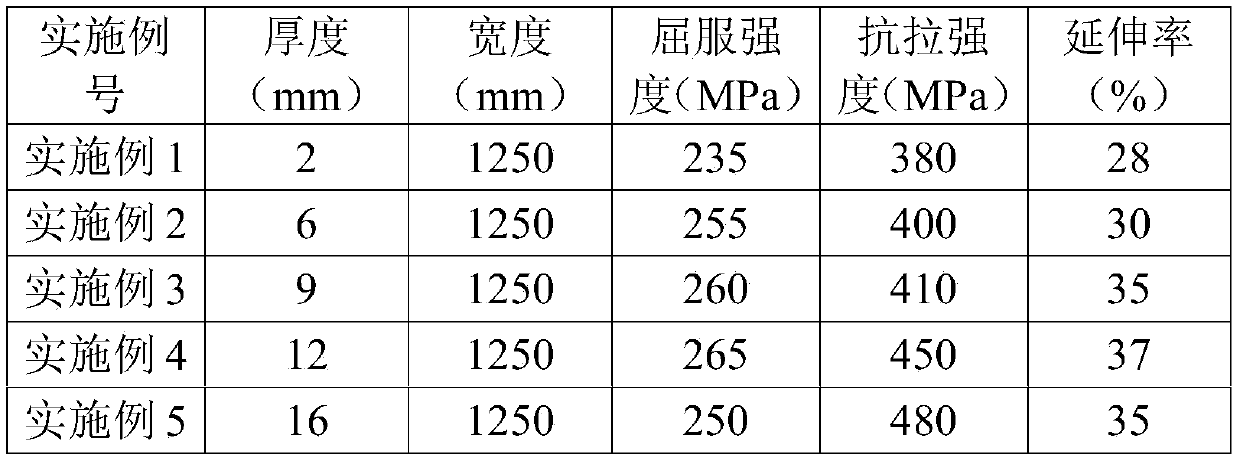

Embodiment 1

[0044] A 380MPa-grade automobile wheel steel hot-rolled pickled plate, in terms of weight percentage, its composition includes: C: 0.04%, Si: 0.04%, Mn: 0.45%, P: 0.020%, S: 0.008%, V: 0.01% , Ti: 0.005%, and the rest are iron and unavoidable impurities; prepare qualified slabs with the above composition and through 150 tons of converter to extract vanadium, 150 tons of converter smelting, LF refining, and slab continuous casting; place the slab Heating in the heating furnace, the heating time is 120 minutes, the heating time is 1180 ° C, and then the slab is taken out of the heating furnace and dephosphorized by high-pressure water. The coil box, after 7 passes of the finishing mill, the outlet temperature is 840°C, after centralized cooling, the coiling temperature is 550°C, and the coiled slab is stacked and cooled in the coil warehouse for 24 hours, and the thickness is 2.0mm. Qualified 380MPa-grade automotive wheel steel hot-rolled pickled plate with a width of 1250mm, a ...

Embodiment 2

[0046] A 380MPa-grade automobile wheel steel hot-rolled pickled plate, in terms of weight percentage, its composition includes: C: 0.05%, Si: 0.04%, Mn: 0.50%, P: 0.018%, S: 0.007%, V: 0.02% , Ti: 0.008%, and the rest are iron and unavoidable impurities; prepare qualified slabs with the above composition and through 150 tons of converter to extract vanadium, 150 tons of converter smelting, LF refining, and slab continuous casting; place the slab Heating in the heating furnace, the heating time is 130 minutes, and the heating time is 1190 ° C. After the slab is taken out of the heating furnace, it is dephosphorized by high-pressure water. The coil box, after 7 passes of the finishing mill, the outlet temperature is 860°C, after centralized cooling, the coiling temperature is 570°C, and the coiled slabs are stacked and cooled in the coil warehouse for 28 hours, and the thickness is 6.0mm. Qualified 380MPa-grade automotive wheel steel hot-rolled pickled plate with a width of 1250...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com