Parallel type synchronous tamping technology for thickener of aluminum cell lining

A technology for lining paste and aluminum electrolytic cells, which is applied in the field of electrolytic aluminum production, can solve the problems of low interlayer bonding strength, insufficient tamping, and increase construction costs, so as to achieve reasonable control of tamping time and eliminate tamping. Solid or not dense, the effect of ensuring quality and progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A parallel synchronous tamping process for lining paste in an aluminum electrolytic cell, comprising the following steps:

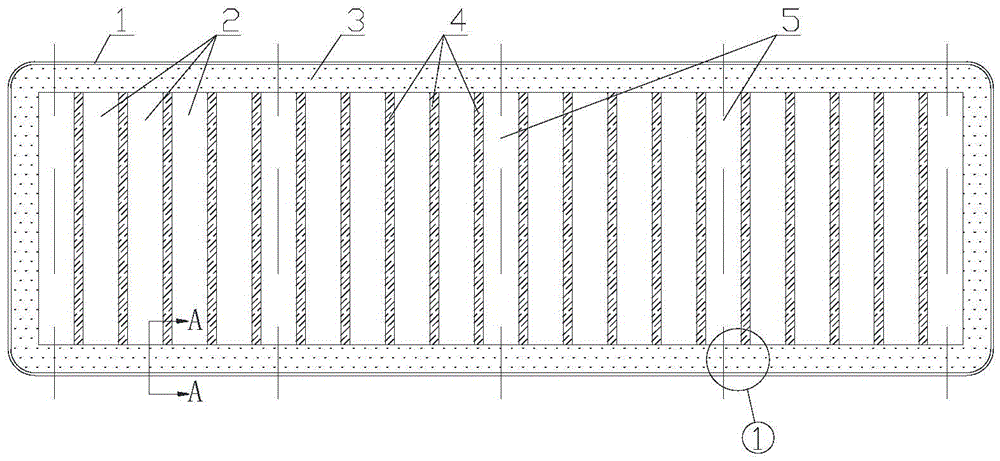

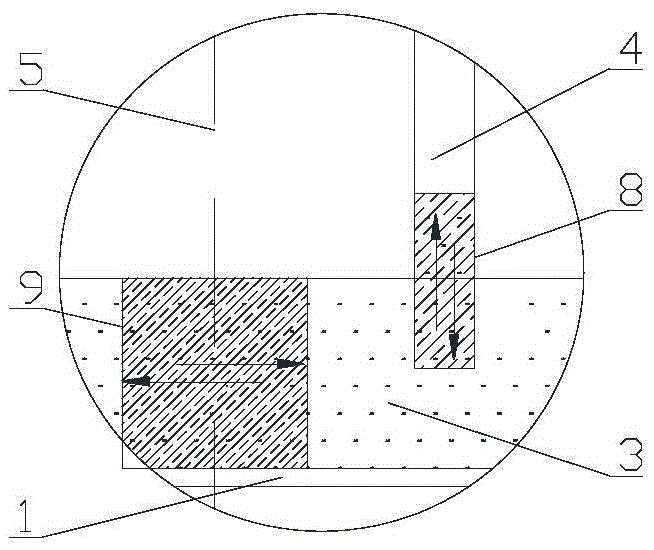

[0024] Step 1: Divide the paste tamping area for the lining of the electrolytic cell into two parts: the paste tamping area around the tank (3) and the paste tamping area (4) between the cathode carbon blocks, to synchronize the operation between the tank and the carbon provide conditions.

[0025] Step 2: Divide the two parallel tamping areas into a number of fixed tamping work surfaces according to the separation line (5) of the work area. 3) and the tamping operation of the cathode carbon block gap paste tamping area (4).

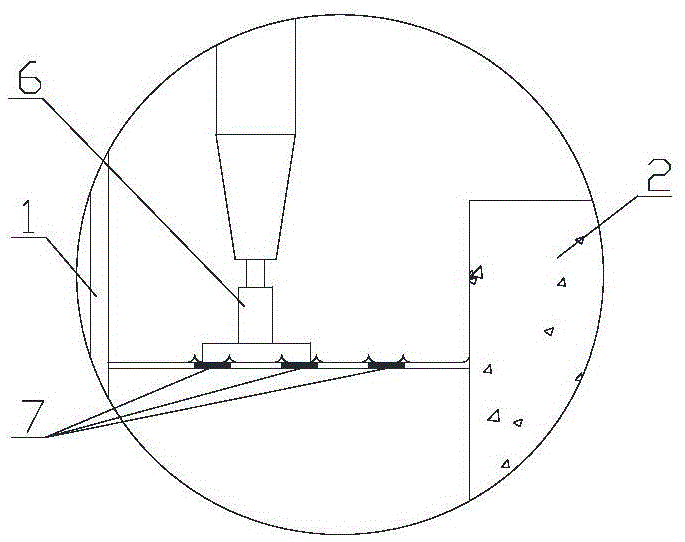

[0026] Step 3: The paste tamping area (3) around the tank cannot be tamped into shape at one time, so the width must meet the requirements and must be divided into multiple sequential operations; when the paste tamping area (3) around the tank is tamped separately, When the combined tamping head (6) is crimping two adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com