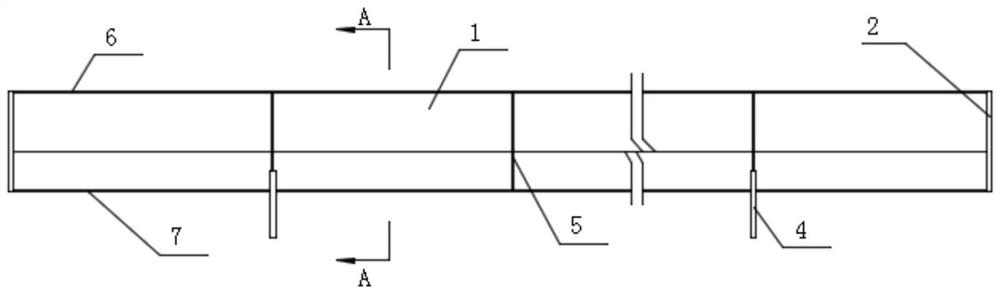

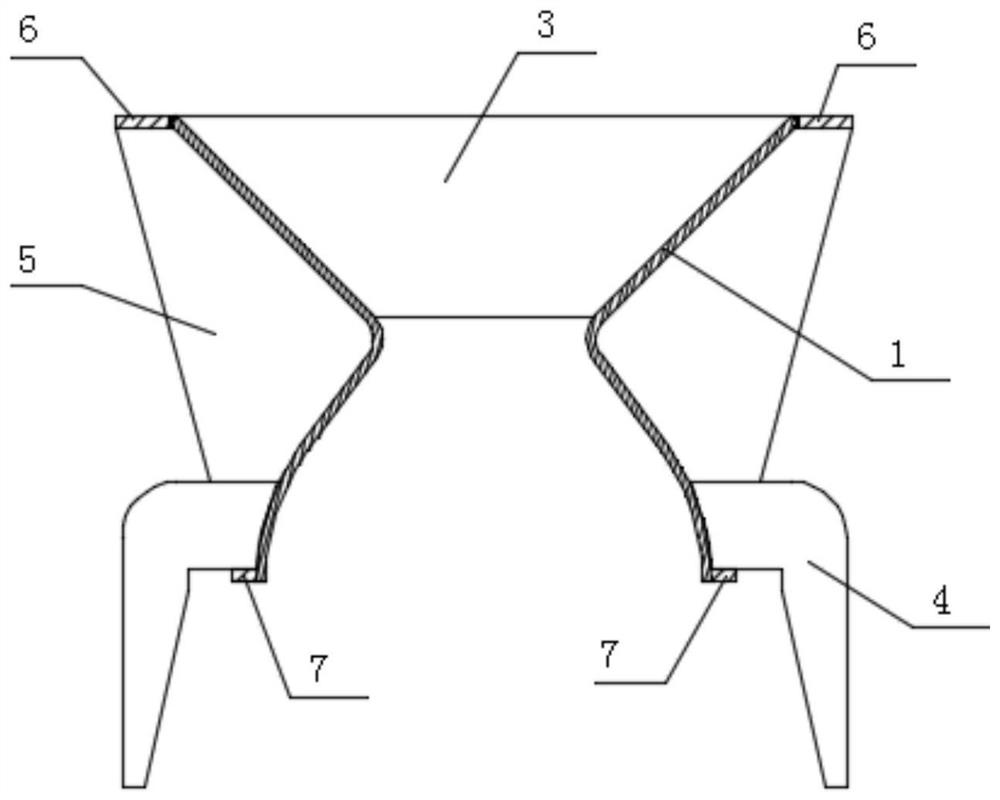

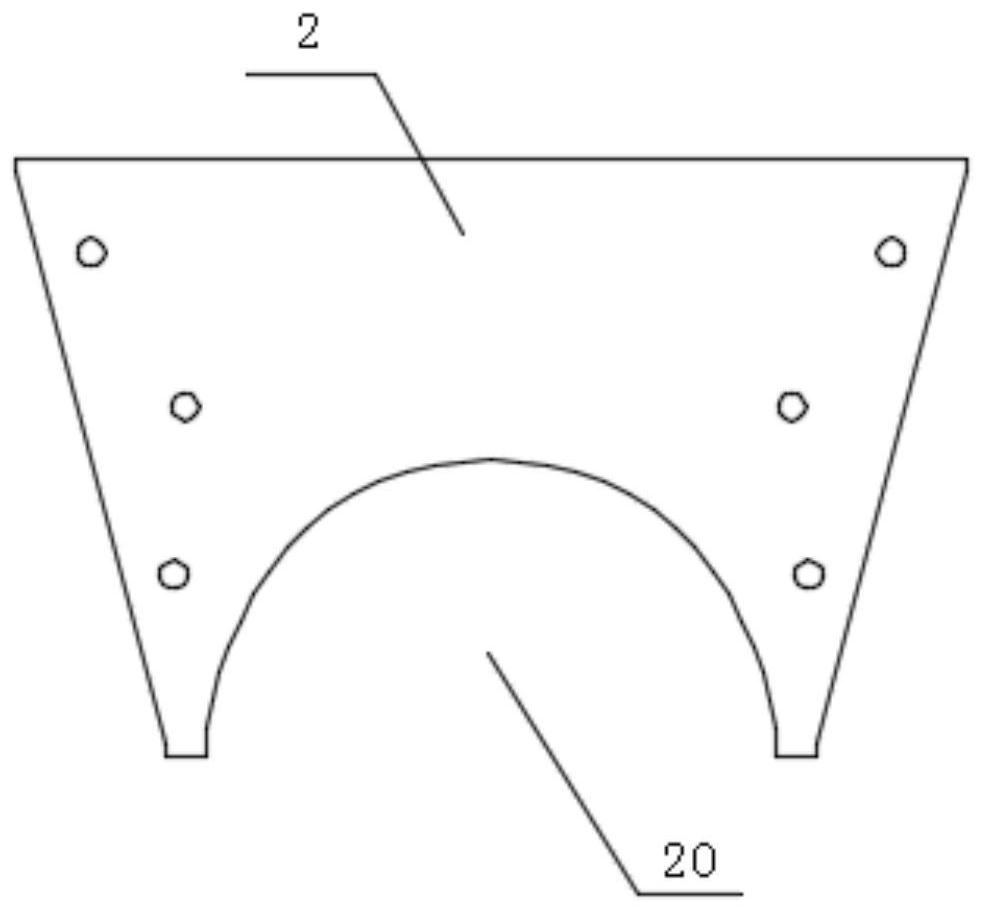

A production process of centrifugal slurry-free piles and supporting material introduction molds and vibrating distribution vehicles

A technology of production process and cloth car, applied in molds, manufacturing tools, reinforced molding, etc., can solve problems such as pollution and waste, achieve the effect of reducing costs and improving concrete strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The composite speed change agent is a combination of water reducer, slump stabilizer, retarder, lubricant, and dispersant.

[0057] The concrete components are: cement 280Kg, admixture 120Kg (wherein, the mass percent of each substance is: slag powder 20%, fly ash 55%, microbead 12%, silica fume 8%, activator 5%,), 690Kg of sand, 1380Kg of crushed stone, 9.5Kg of water reducer, compound quick-change agent (wherein, the mass percent of each substance is: 30% of water reducer, 30% of anti-collapse agent, 30% of retarder, 5% of lubricant, Dispersant 5%) 3Kg, water 80Kg;

[0058] Production process: lead material vibration centrifugal pulpless production process;

[0059] Specifically, the vibration process conditions: the vibration force is at least 150% of its load-bearing (including mould, mold-in-mold pile, mold-bearing platform), the full amplitude, and the vibration time is 160 seconds; centrifugal process conditions: the centrifugal force is 55G gravity acceleration...

Embodiment 2

[0063] The composite speed change agent is a combination of quick setting agent, lubricant and dispersant,

[0064] Concrete components are: cement 280Kg, admixture 130Kg (wherein, the mass percent of each substance is: slag powder 30%, fly ash 45%, microbead 8%, silica fume 12%, exciter 5%,), Sand 670Kg, crushed stone 1380Kg, water reducing agent 8.5Kg, composite quick-change agent (wherein, the mass percentage of each substance is: quick-setting agent 60%, lubricant 20%, dispersant 20%) 4Kg, water 90Kg.

[0065] Production process: lead material vibration centrifugal pulpless production process;

[0066] Specifically, the vibration process conditions: the vibration force is 100% of its load-bearing (including mould, mold-in-mold pile, mold-supporting platform), the moderate amplitude, and the vibration time is 160 seconds; the centrifugal process conditions: the centrifugal force is 45G gravitational acceleration, the centrifugal The time is 720 seconds;

[0067] Experimen...

Embodiment 3

[0070] The compound quick-change agent is a combination of quick-setting agent, water reducing agent and slump-preserving agent,

[0071] The concrete components are: cement 290Kg, admixture 130Kg (wherein, the mass percent of each substance is: slag powder 40%, fly ash 20%, microbead 5%, silica fume 16%, quicklime 5%, gypsum 5% , activator 7%), sand 670Kg, gravel 1380Kg, water reducer 8.2Kg, quick change agent (wherein, the mass percent of each substance is: quick set agent 40%, polyether carboxylic acid water reducer 40%, hair Foaming agent 20%) 4.8Kg, water 90Kg;

[0072] Production process: lead material vibration centrifugal pulpless production process;

[0073] Specifically, the vibration process conditions: the vibration force is 70% of its load-bearing (including mould, in-mold pile, formwork platform), moderate or slight amplitude, and the vibration time is 120 seconds; centrifugal process conditions: the centrifugal force is 37G gravity Acceleration, centrifugation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com