A Gradual Bending Tempered Glass Arc Changing Equipment

A kind of equipment and glass technology, which is applied in the field of glass bending and arc-changing equipment to achieve the effect of smooth glass bending, saving production time and uniform wind exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

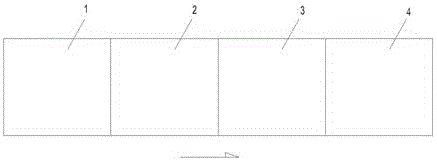

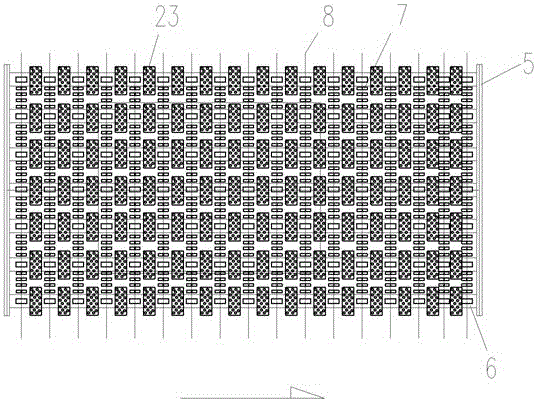

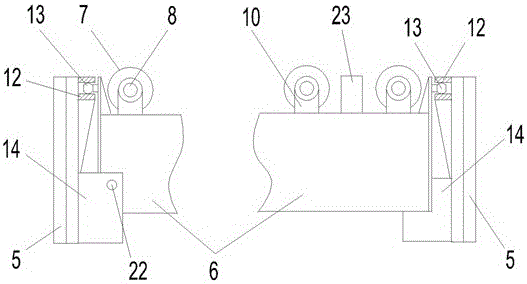

[0027] Such as figure 2 with image 3 Shown is a preferred embodiment of the curved tempered glass arc-changing device of the present invention. The direction of the arrow in the figure is the conveying direction of the glass. The arc-changing equipment includes several support beams 6 extending longitudinally and arranged at intervals in the transverse direction. A number of flexible shafts 8 and cooling air grids 23 are alternately arranged longitudinally. The supporting beam 6 serves as a cooling air duct to supply air to the cooling air grid 23 installed thereon. The two ends of the supporting beam 6 are respectively connected to the On a horizontal arc changing mechanism 5, wherein, the universal ball pair includes a universal ball 13 fixed on the support beam 6 and a card slot 12 fixed on the horizontal arc changing mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com