Heat exchanger

A technology of heat exchangers and heat exchange tubes, applied in the direction of heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., which can solve the problems of reduced efficiency of assembly operations, increased number of parts, and high weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

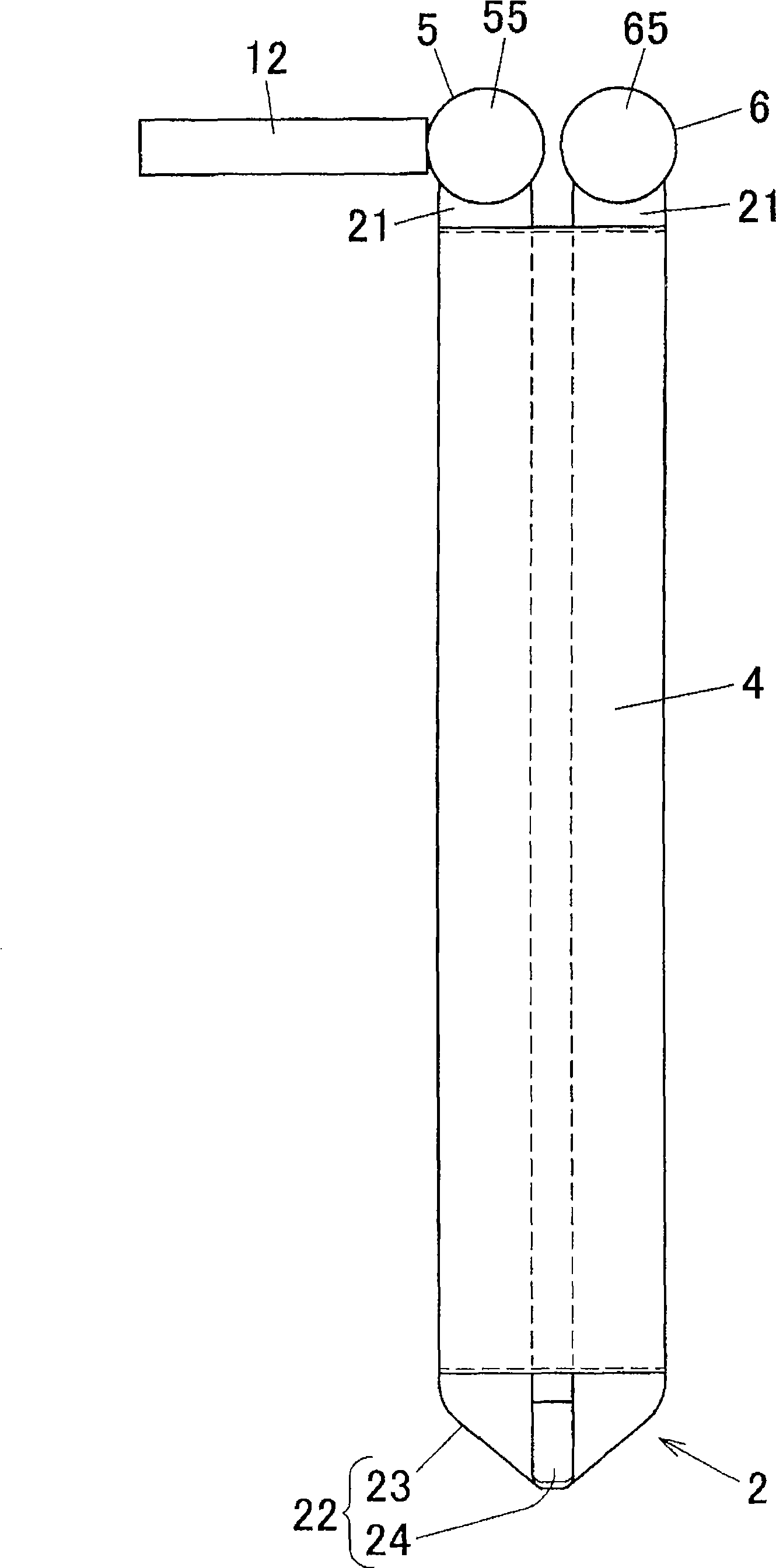

[0239] (Pipe manufacturing apparatus of another embodiment)

[0240] Next, a manufacturing apparatus (manufacturing method) of another embodiment for manufacturing the heat exchange tube 2 described above will be described in detail.

[0241] In addition, in the following description of the pipe manufacturing apparatus, in order to facilitate understanding of the invention, the Figure 17 , the right side is referred to as "front side", the left side is referred to as "rear side", the upper side is referred to as "upper side", the lower side is referred to as "lower side", and the perpendicular direction is referred to as "left-right direction".

[0242] As shown in the figure, this heat exchange tube manufacturing apparatus (bending apparatus for flat tube members) has a pressing die 8 and a bending die 9 on a base frame 70 .

[0243] Such as Figure 17-2 0, the front end (rear end) of the pressing die 8 is provided with a mountain-shaped plate portion 81 that is in the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com