A kind of carbon steel 45mn hot-rolled pickling plate and production method thereof

A technology of hot-rolled pickling and carbon steel, which is applied in the field of steel rolling, can solve the problems of poor quality, low qualified rate of finished products, and many scales on the surface, so as to reduce the generation of scales, have good surface quality, and meet production requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0036] As a specific embodiment of the production method of a hot-rolled carbon steel 45Mn pickling plate provided by the present invention, the rolling includes: rolling the slab that has been dephosphorized by high-pressure water through a rough rolling mill and a finish rolling mill. .

[0037] In this embodiment, the slab dephosphorized by high-pressure water is sequentially subjected to rough rolling, hot coil box and finish rolling to obtain a hot-rolled plate.

[0038]As a specific embodiment of the production method of a hot-rolled carbon steel 45Mn pickling plate provided by the present invention, the outlet temperature of the roughing mill is 1020-1080°C; the outlet temperature of the finishing mill is 860-910°C; After five rolling passes in the roughing mill and seven rolling passes in the finishing mill.

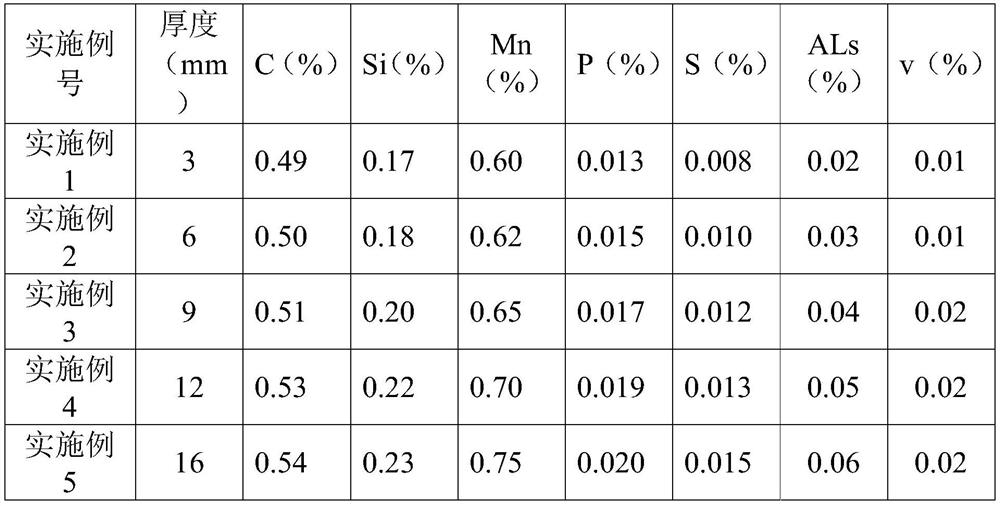

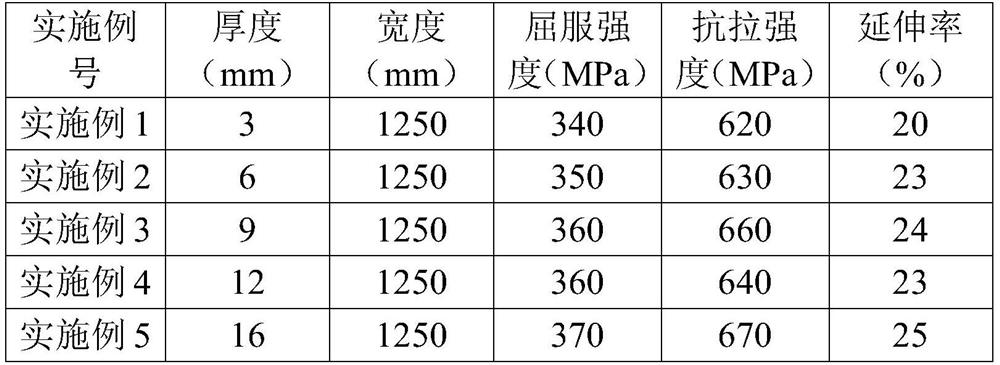

[0039] In order to more specifically illustrate the technical solution of the present invention, the following examples are now used for detailed description. ...

Embodiment 1

[0041] A hot-rolled carbon steel 45Mn pickling plate is calculated by weight percentage, and its composition includes: C: 0.49%, Si: 0.17%, Mn: 0.60%, P: 0.013%, S: 0.008%, V: 0.01%, ALs: 0.02%, the rest is iron and unavoidable impurities; prepare qualified slabs with the above components and go through 150 tons of converter vanadium extraction, 150 tons of converter smelting, LF refining, and continuous casting of slabs; place the slabs in Heating in the heating furnace, the heating time is 120 minutes, and the heating time is 1240 ° C. After the slab is taken out of the heating furnace, it is dephosphorized by high-pressure water. box, and then through the finishing mill for 7 passes, the outlet temperature is 870°C, after dispersive cooling, the coiling temperature is 700°C, the thickness is 3.0mm, the width is 1250mm, the yield strength is 340MPa, the tensile strength is 620MPa, and the elongation The qualified hot-rolled high-quality carbon steel pickling plate with a rat...

Embodiment 2

[0043] A hot-rolled carbon steel 45Mn pickling plate is calculated by weight percentage, and its composition includes: C: 0.50%, Si: 0.18%, Mn: 0.62%, P: 0.015%, S: 0.010%, V: 0.01%, ALs: 0.03%, the rest is iron and unavoidable impurities; prepare qualified slabs with the above components and go through 150 tons of converter vanadium extraction, 150 tons of converter smelting, LF refining, and continuous casting of slabs; place the slabs in Heating in the heating furnace, the heating time is 130 minutes, and the heating time is 1250 ° C. After the slab is released from the heating furnace, it is dephosphorized by high-pressure water. box, and then through the finishing mill for 7 passes, the outlet temperature is 880°C, after dispersion cooling, the coiling temperature is 710°C, the thickness is 6.0mm, the width is 1250mm, the yield strength is 350MPa, the tensile strength is 630MPa, and the elongation The qualified hot-rolled high-quality carbon steel pickling plate with a ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com