Purification method for deep silica removal of ammonium metavanadate

A technology of ammonium metavanadate and purification method, which is applied in the field of high-purity vanadium, can solve the problems of low silicon content, etc., and achieve the effects of high production efficiency, large feeding concentration and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

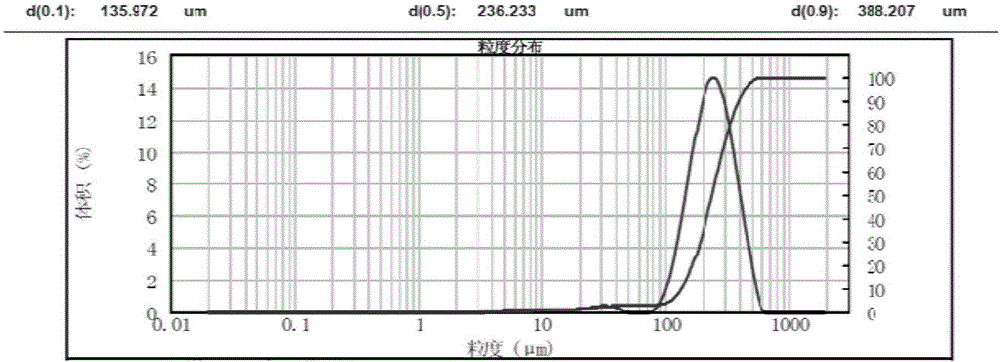

[0028] The crude ammonium metavanadate has a silicon content of 150ppm and other impurities not exceeding 150ppm. Granularity report see figure 1 .

[0029] Take 300g of the above-mentioned ammonium metavanadate, put it into 800ml water, stir and heat to 70°C, add 92.5% sulfuric acid, adjust the pH to 2.5, add acid for 10min, continue stirring for 30min, filter, the filtrate is ammonium sulfate solution, and the solid is polyvanadate Ammonium filter cake, containing 15% moisture;

[0030] Stir, add the ammonium polyvanadate filter cake to ammonia water, control the end point pH to 8, continue to stir for 30min, filter, the filtrate contains V 2 o 5 3g / L, used as a solution for converting crude ammonium metavanadate into ammonium polyvanadate; the filter cake was dried to obtain ammonium metavanadate A296g, the extraction rate of vanadium was 98.7%, and the silicon content was 35ppm.

Embodiment 2

[0037] Crude product ammonium metavanadate, with embodiment 1, silicon content is 150ppm, and other impurity is no more than 150ppm.

[0038] Take 300g of the above-mentioned ammonium metavanadate, put it into 800ml of water, stir and heat to 80°C, add 92.5% sulfuric acid, adjust the pH to 2.5, add acid for 120min, continue stirring for 5h, filter, the filtrate is ammonium sulfate solution, and the solid is polyvanadate Ammonium filter cake, containing 60% moisture;

[0039] Stir, add the ammonium polyvanadate filter cake to ammonia water, control the end point pH to 8, continue to stir for 30min, filter, the filtrate contains V 2 o 5 3.1g / L, the filter cake was dried to obtain ammonium metavanadate B with a silicon content of 20ppm.

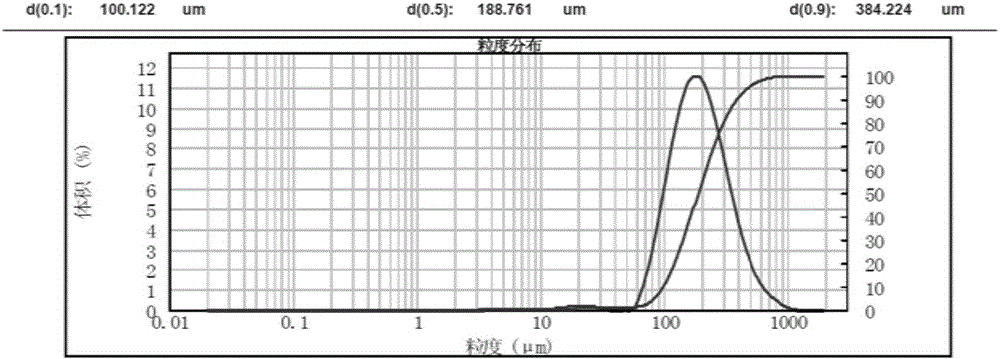

[0040] The difference between embodiment 2 and embodiment 1 is the time of adding acid and the stirring time after adding acid, here will contrast the influence of adding time of acid on ammonium metavanadate. Moisture analysis shows that th...

Embodiment 3

[0042] Crude product ammonium metavanadate, with embodiment 1, silicon content is 150ppm, and other impurity is no more than 150ppm.

[0043] Take 500g of the above-mentioned ammonium metavanadate, put it into 800ml of water, stir and heat to 90°C, add 60% sulfuric acid, adjust the pH to 2.5, add acid for 120min, continue stirring for 5h, filter, the filtrate is ammonium sulfate solution, and the solid is polyvanadate Ammonium filter cake;

[0044] Stir, add the ammonium polyvanadate filter cake to ammonia water, control the end point pH to 8, continue to stir for 30min, filter, the filtrate contains V 2 o 5 1.7g / L, the filter cake was dried to obtain ammonium metavanadate C with a silicon content of 47ppm.

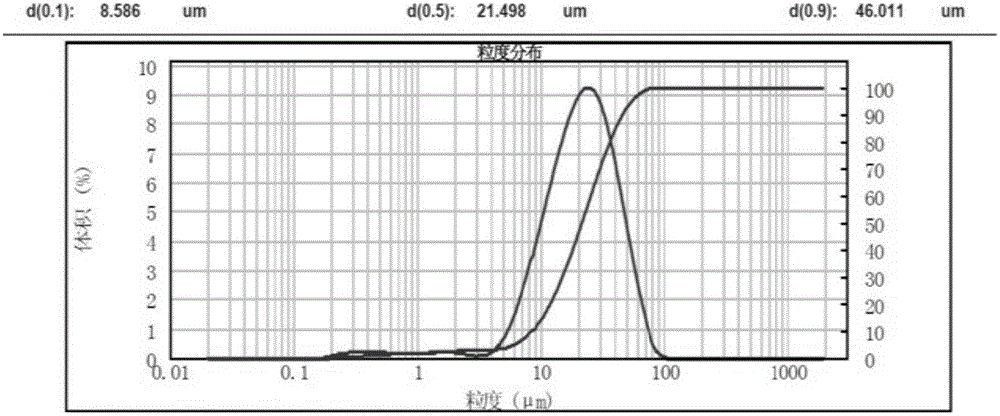

[0045] The difference between embodiment 3 and embodiment 2 is that the feeding amount of ammonium metavanadate is increased from 300g to 500g, and the silicon content of the product is higher than that of embodiment 2. This shows that the amount of feed will affect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com