Patents

Literature

31results about How to "Adjust granularity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Special bacterium-contained organic-inorganic compound fertilizer for tea plants

ActiveCN102372526AHigh activityImprove stress resistanceBio-organic fraction processingOrganic fertiliser preparationPhosphateAlkaloid

The invention discloses a special bacterium-contained organic-inorganic compound fertilizer for tea plants. A fermentation technology comprises the following steps: 1, taking 35% of CMS, 15% of tobacco powder and 30% of a domestic fungal leftover, and uniformly mixing them to obtain a mixture; 2, injecting 0.1% of dry yeast powder and 3% of a mixed Bacillus mucilaginosus and actinomyce solution which is prepared with a compound alkaloid as an bactericide, and composting for 168h; 3, injecting a dissolving solution containing 1% of alum, 0.5% of borax, 0.1% of cooper sulfate and 0.3% of sulfur powder into each 625kg of above fermented material, adding 230kg of urine, 120kg of monoammonium phosphate and 100kg of potassium sulfate, uniformly stirring, and composting for 72h; 4, detecting that whether contents of organic matters, water, nitrogen, phosphor, potassium, effective live bacteria and the like in the fertilizer composted in step 3 satisfy standards shown in the specification; and 5, granulating qualified semi-finished product discs obtained in step 4, and packaging them to prepare finished products after processes of low temperature drying, screening and detection. The fertilizer, which has the effects of soil activation, tea plant root environment improvement, tea strongylid and fusarium inhibition and the like, has important effects on the construction of organic tea gardens and nuisance-free tea gardens.

Owner:漳州美利德生物工程有限公司

Purification method for deep silica removal of ammonium metavanadate

ActiveCN106044853AIncrease productivitySimple methodVanadium compoundsPurification methodsWastewater

The invention discloses a purification method for deep silica removal of ammonium metavanadate. The method comprises the following steps: (1) pouring ammonium metavanadate into water; (2) adding acid for acidification; (3) carrying out solid-liquid separation; (4) adjusting pH to 7-9 by adding ammonia water; and (5) filtering to obtain ammonium metavanadate. According to the method, caustic soda flakes are not used, wastewater is not generated, and the product is high-purity ammonium metavanadate and ammonium sulfate solution and can be recycled.

Owner:DALIAN RONGKE ENERGY STORAGE GRP CO LTD

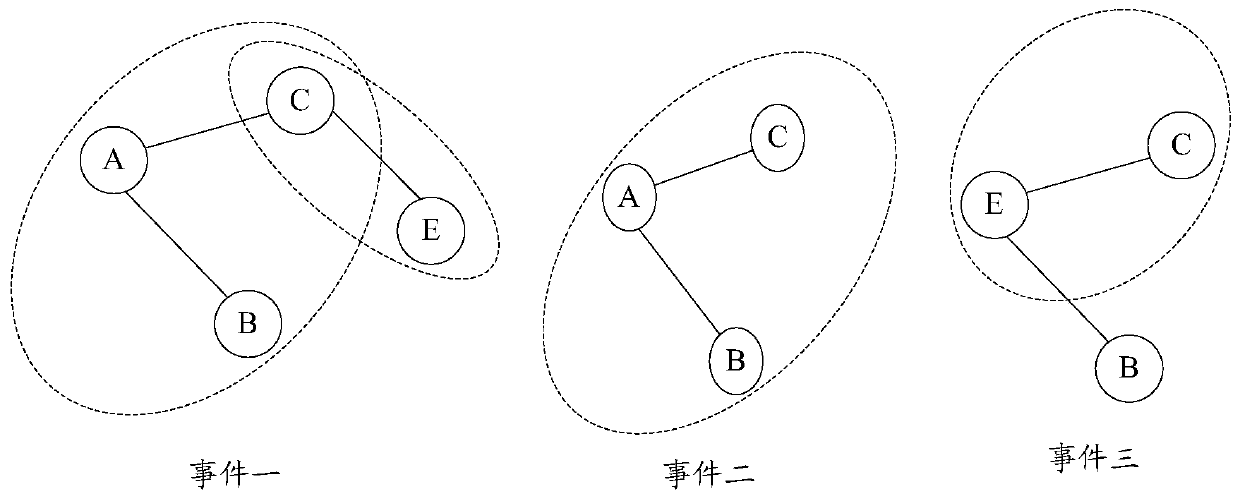

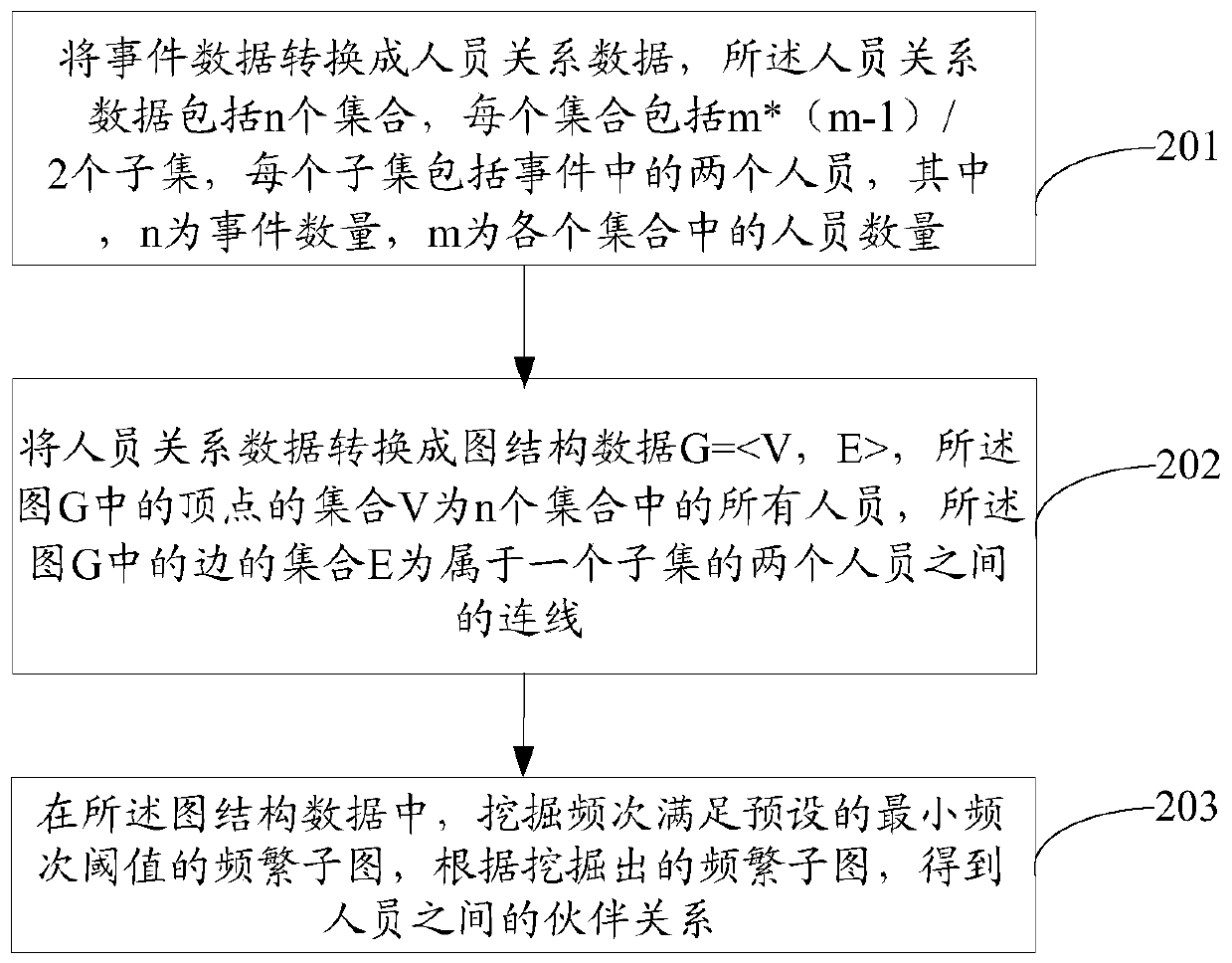

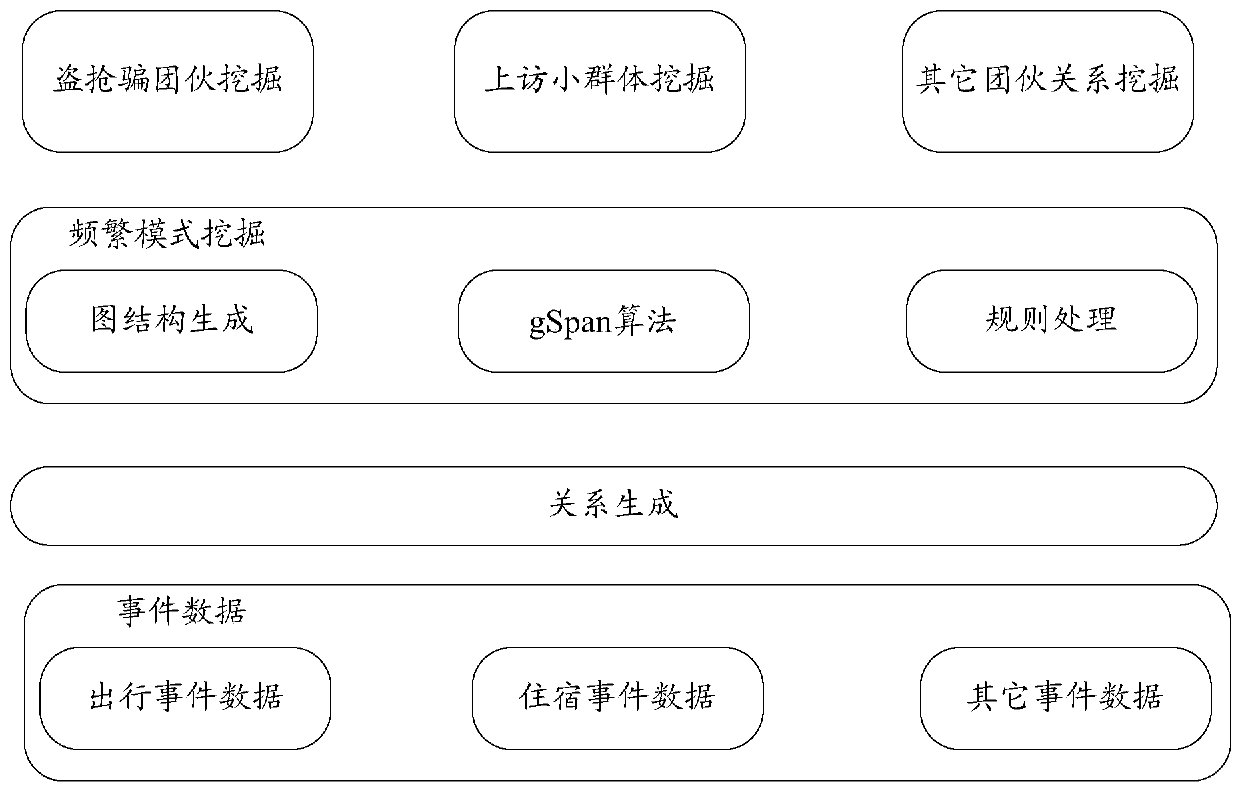

Relationship discovery method and device and computer readable storage medium

InactiveCN109783531AGet implicit relationshipAdjust granularitySpecial data processing applicationsDatabase modelsGraph structured dataGranularity

The invention discloses a relation discovery method and device and a computer readable storage medium, and the method comprises the steps: converting event data into personnel relation data, the personnel relation data comprising n sets, and each set comprising m * (m- 1) / 2 subsets, each subset comprising two persons in an event, n being the number of events, and m being the number of persons in each set; Converting the personnel relationship data into graph structure data G = (V, E), a set V of vertexes in the graph G being all personnel in the n sets, and a set E of sides being a connectionline between two personnel belonging to one subset; And in the graph structure data, mining a frequent subgraph with the frequency meeting a preset minimum frequency threshold value, and obtaining a partner relationship among the personnel according to the mined frequent subgraph. According to the method, the event data is converted into the graph structure data, the frequent subgraphs are mined according to the minimum frequency threshold value, the granularity of relation discovery is better adjusted, and therefore the hidden relation in the event data is more accurately obtained.

Owner:BEIJING MININGLAMP SOFTWARE SYST CO LTD

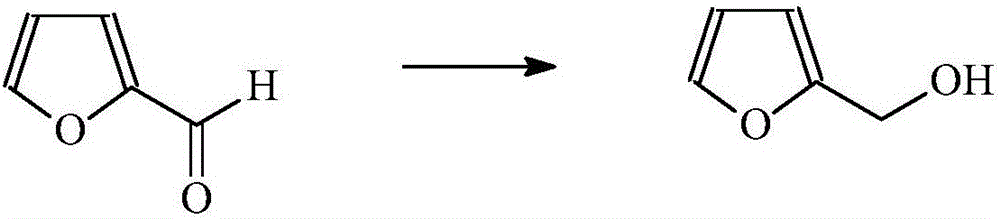

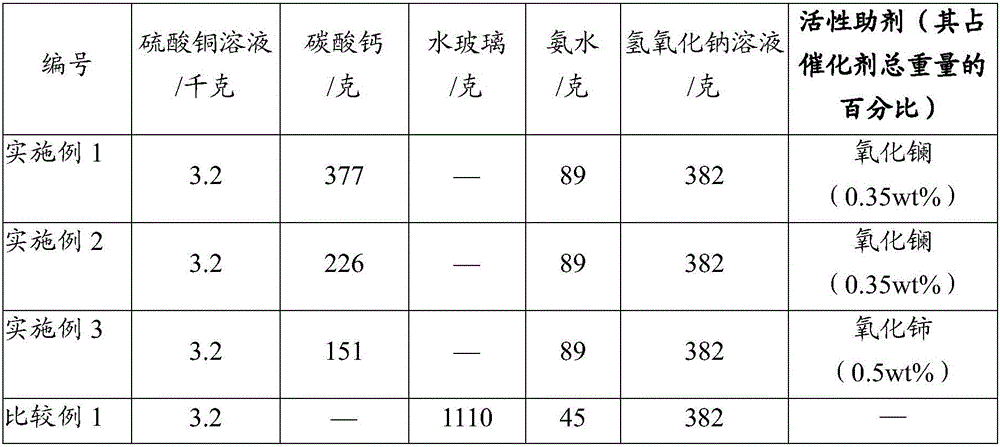

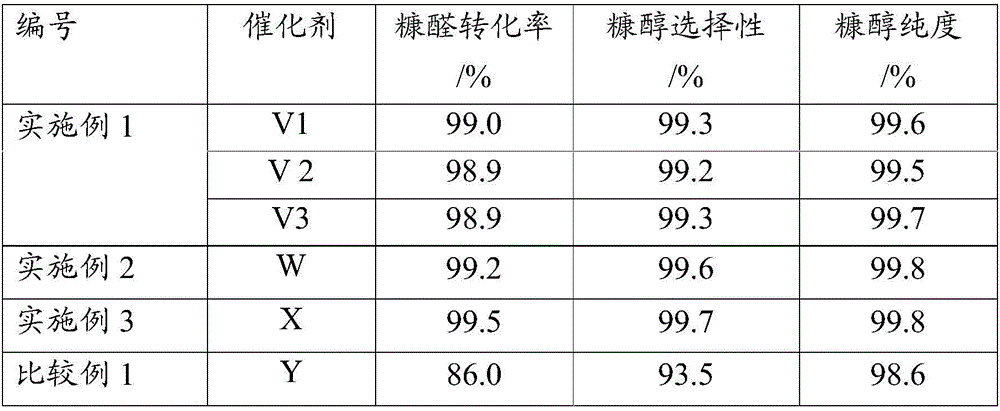

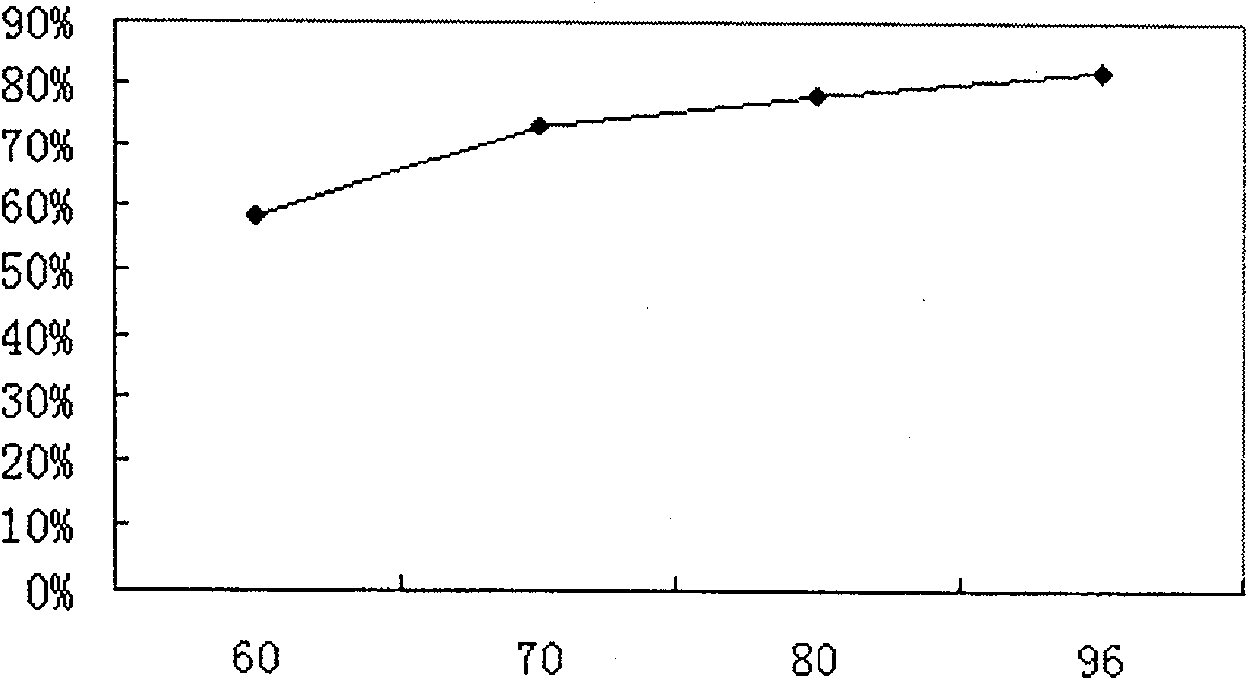

Furfural hydrogenation catalyst containing rare earth elements and preparation method thereof

ActiveCN106732706AAdjust DispersionAdjust granularityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementActive component

The invention discloses a furfural hydrogenation catalyst containing rare earth elements and a preparation method thereof. The catalyst takes calcium carbonate as a carrier, takes copper oxide as an active component and takes a rare earth compound as an active aid; the weight of copper oxide is 28-75wt% of the total weight of the catalyst; the weight of the rear earth compound is 0.1-5wt% of the total weight of the catalyst. According to the furfural hydrogenation catalyst containing rare earth elements and the preparation method thereof, the production cost of the furfural hydrogenation catalyst is effectively controlled; and the furfural hydrogenation catalyst is extremely high in furfural conversion rate and hydrogenation selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +2

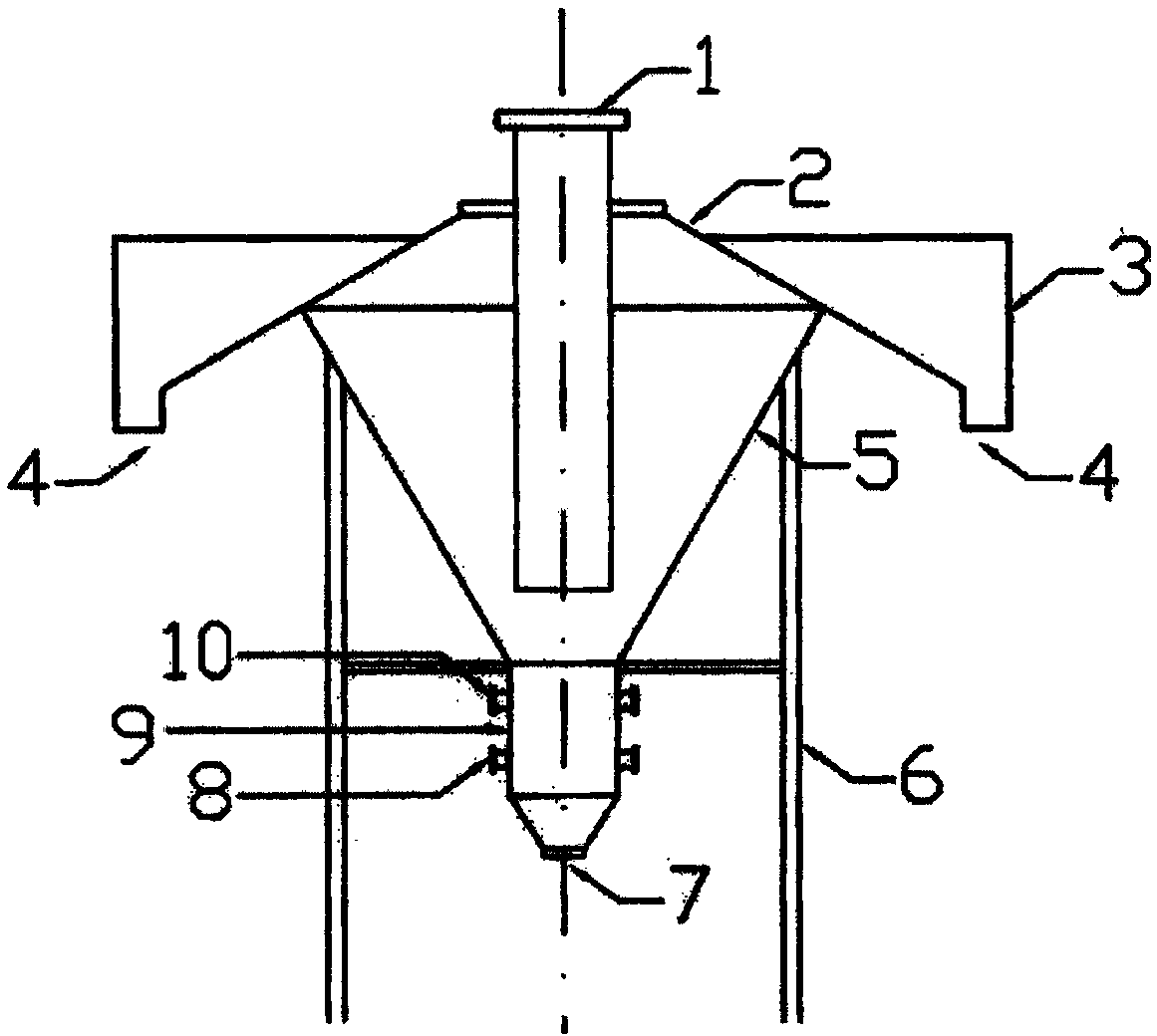

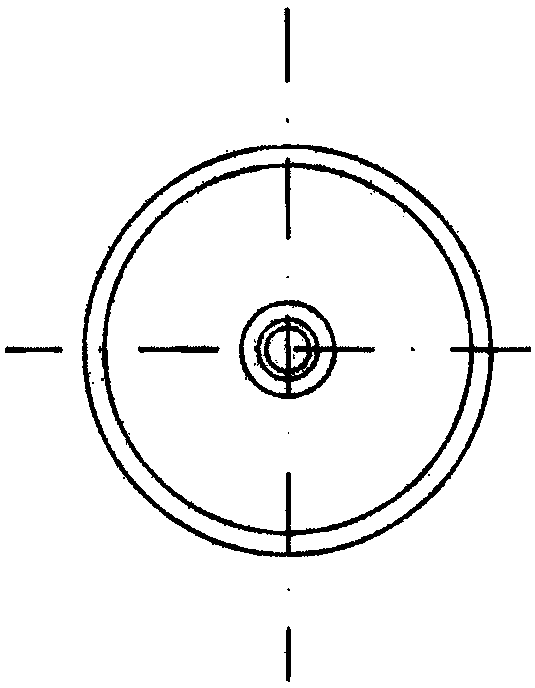

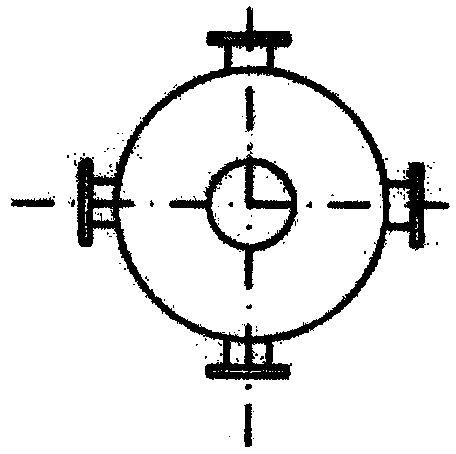

Module type hydraulic classification device with variable cone angle

InactiveCN103433117AAdd adjustment parametersReduce maintenance costsWet separationEngineeringWater pipe

The invention discloses a module type hydraulic classification device with a variable cone angle. The module type hydraulic classification device with the variable cone angle is characterized in that the module type hydraulic classification device with the variable cone angle comprises three modules; the first module is composed of an upper shell body, an overflowing collecting groove and a feeding well, the upper shell body is located on the upper portion and of a conical structure, the overflowing collecting groove is formed around the outer conical surface located below a feeding port of the upper shell body, and the feeding well is arranged in the feeding port of the upper shell body in a penetrating mode through a fixing piece in the mode that the feeding well and a hydraulic classification machine body are coaxial; the second module is composed of a lower shell body, the lower shell body is located in the middle and buckled with the upper shell body, the cone angle of the lower shell body is variable, and the lower shell body is of a reverse-cone structure; the third module is composed of a hollow column section and a conical discharging section, the hollow column section is installed in the position of a discharging port formed in the bottom of the lower shell body and provided with a top water inlet pipe opening, and the conical discharging section is arranged at the bottom of the hollow column section; the upper end of the feeding well is higher than an upper edge opening of the overflowing collection groove, and the lower end of the feeding well is located above the connection portion between the second module and the third module.

Owner:HENAN POLYTECHNIC UNIV

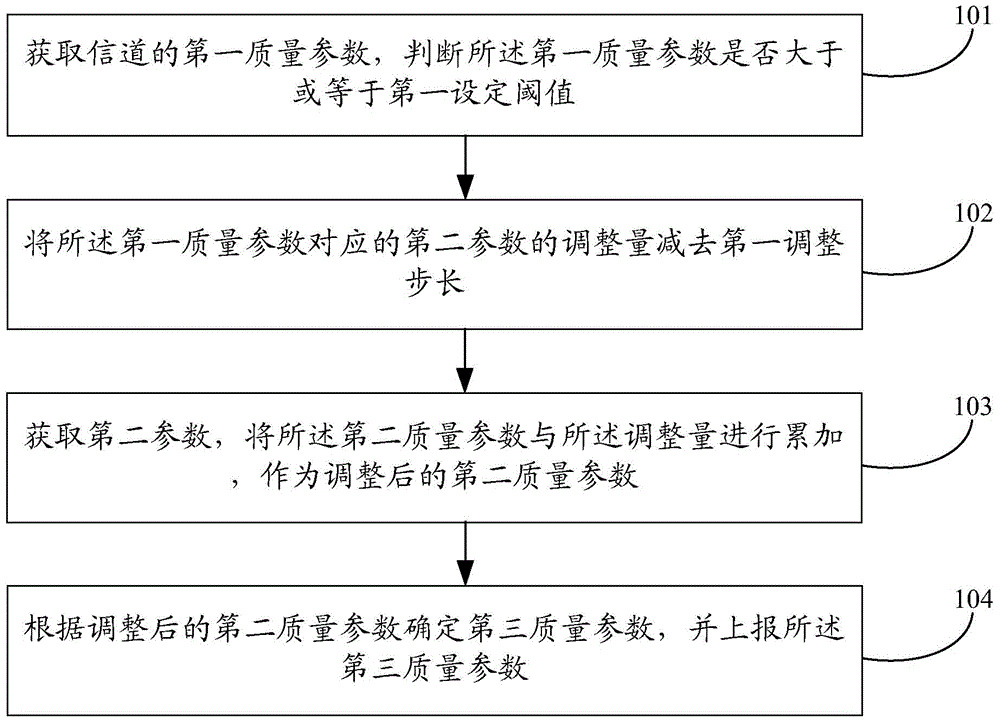

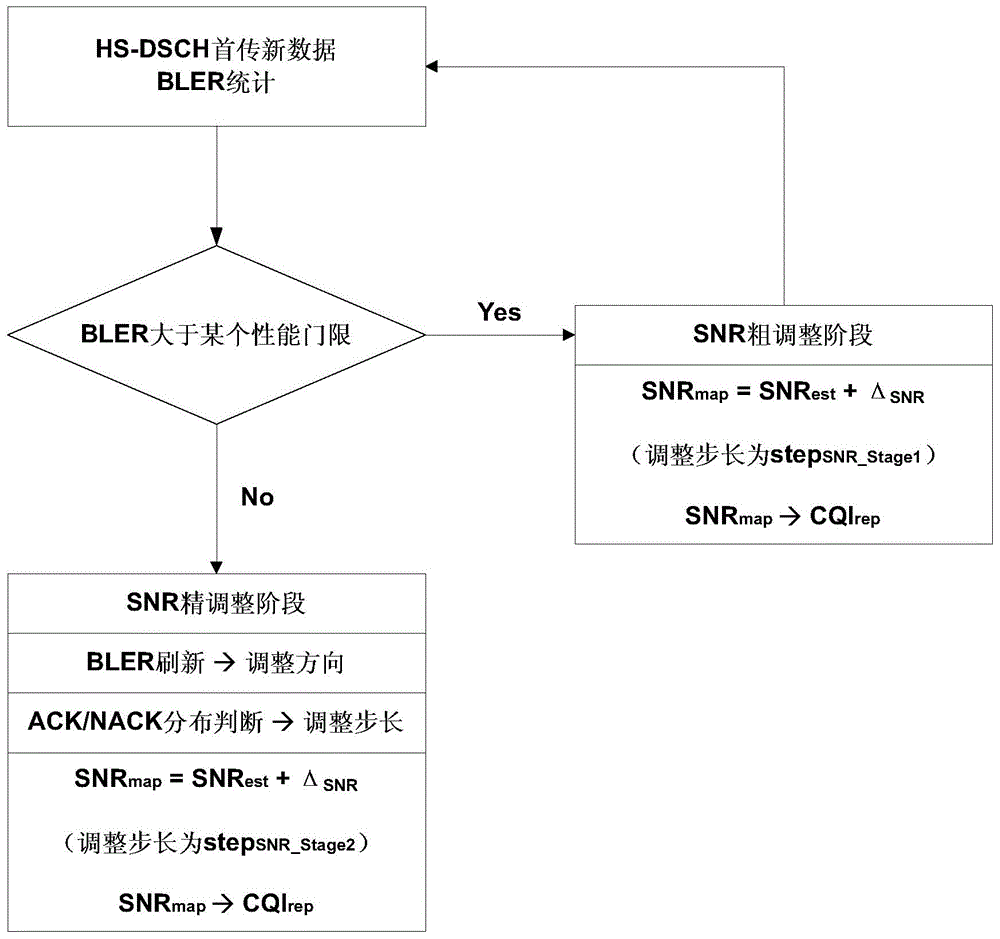

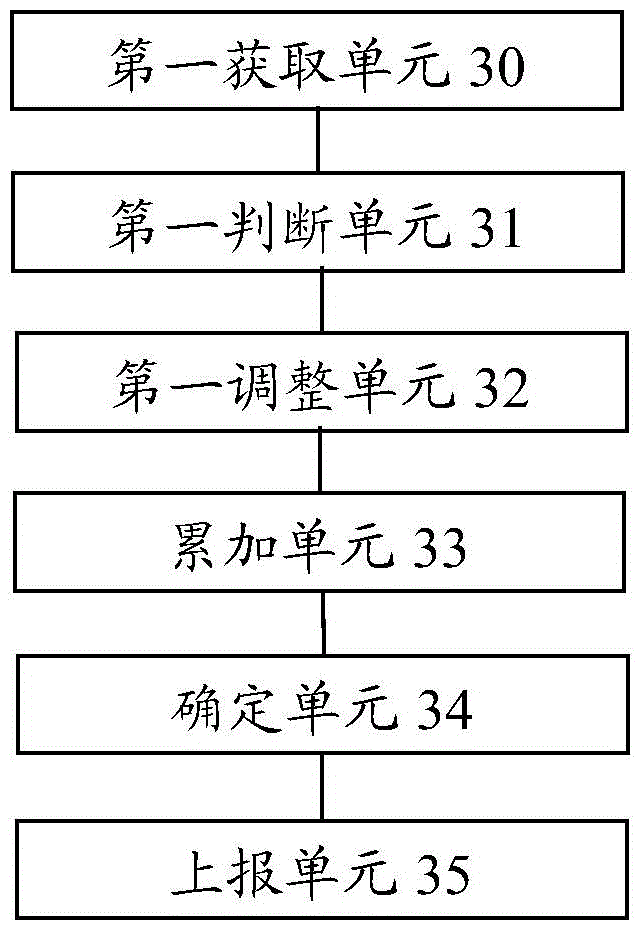

Channel quality indication information adjusting method and device and mobile terminal

InactiveCN104618951AAdjust granularitySmall granularitySignalling characterisationWireless communicationComputer terminalReal-time computing

Owner:SANECHIPS TECH CO LTD

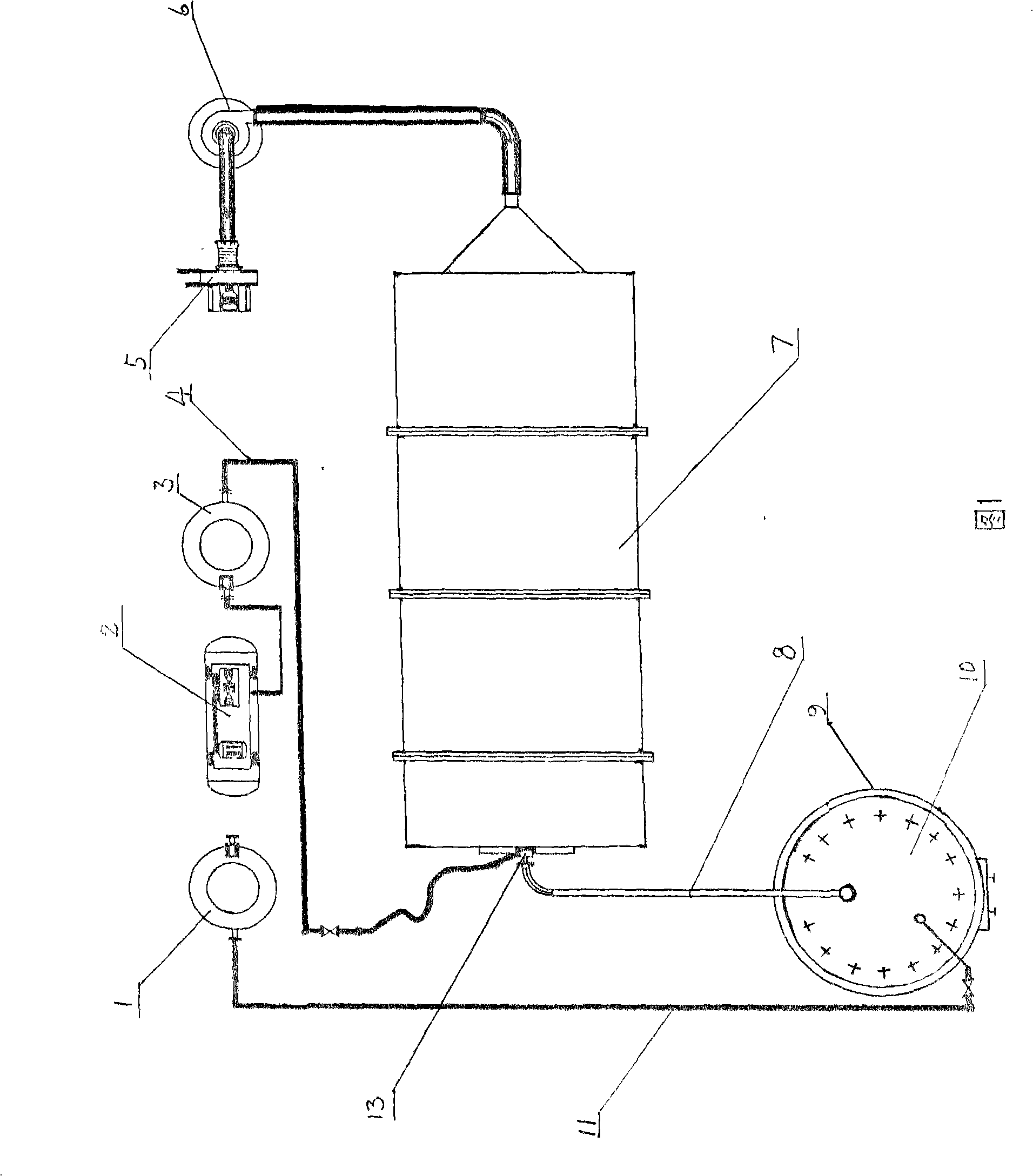

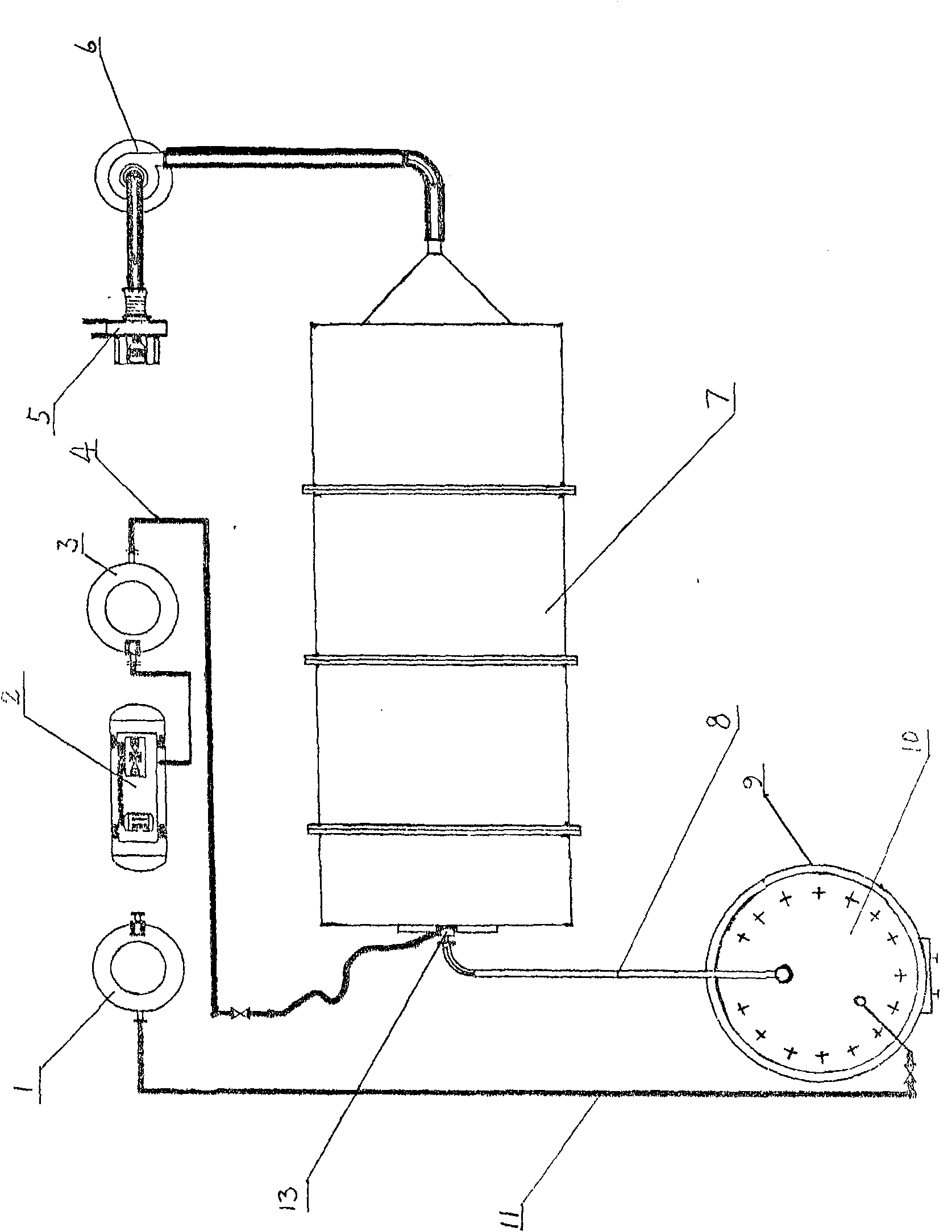

Preparation for anhydrous magnesium chloride

The invention provides a method for the production and a device of anhydrous magnesium chloride powder, the magnesium chloride is melted at a temperature above the melting point of the magnesium chloride, the fused mass of the magnesium chloride is sprayed out by an inert gas and the fusing liquid of the magnesium chloride is atomized by the dry compressed air, and the anhydrous magnesium chloride powder is obtained through condensation. The device comprises a melting furnace, a crucible, a feeding fused mass pipeline, a nozzle, a compressor and a collecting bin; and the method includes following steps of: (1) putting the magnesium chloride into the furnace, (2) melting the magnesium chloride, (3) high-frequency heating to the magnesium chloride feeding pipeline and the nozzle, (4) atomization, and (5) collection and packaging. The atomization of the invention adopts the dried high pressure compressed air to impact the liquid jets of the molten magnesium chloride strongly so as to reach the atomization effect, and the process and operation are simple and convenient, thereby obtaining relative pure anhydrous magnesium chloride powder; the atomized products are spherical and the particle-size distribution is even; and the particle sizes of the products can be adjusted flexibly according to the demands of customers.

Owner:ZUNYI TITANIUM +1

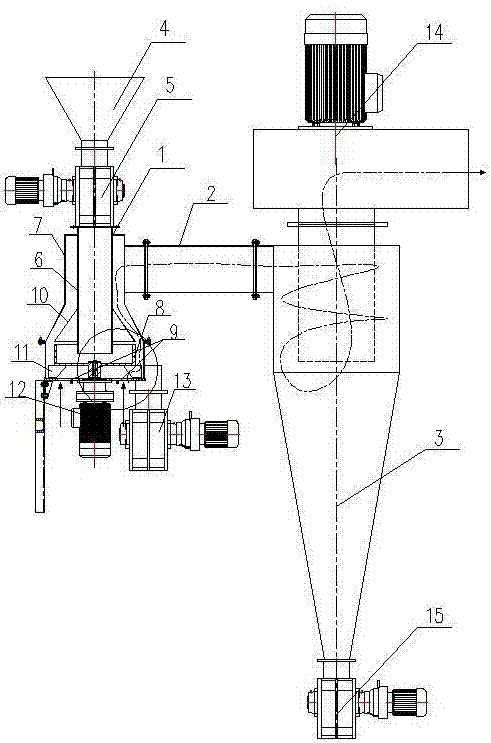

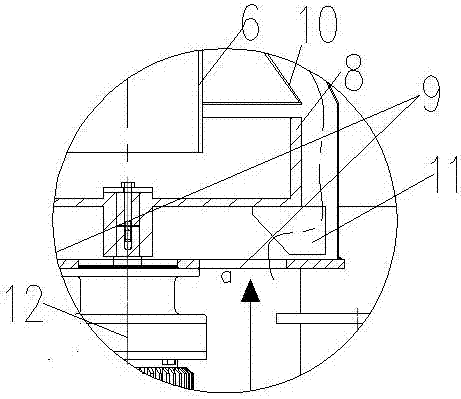

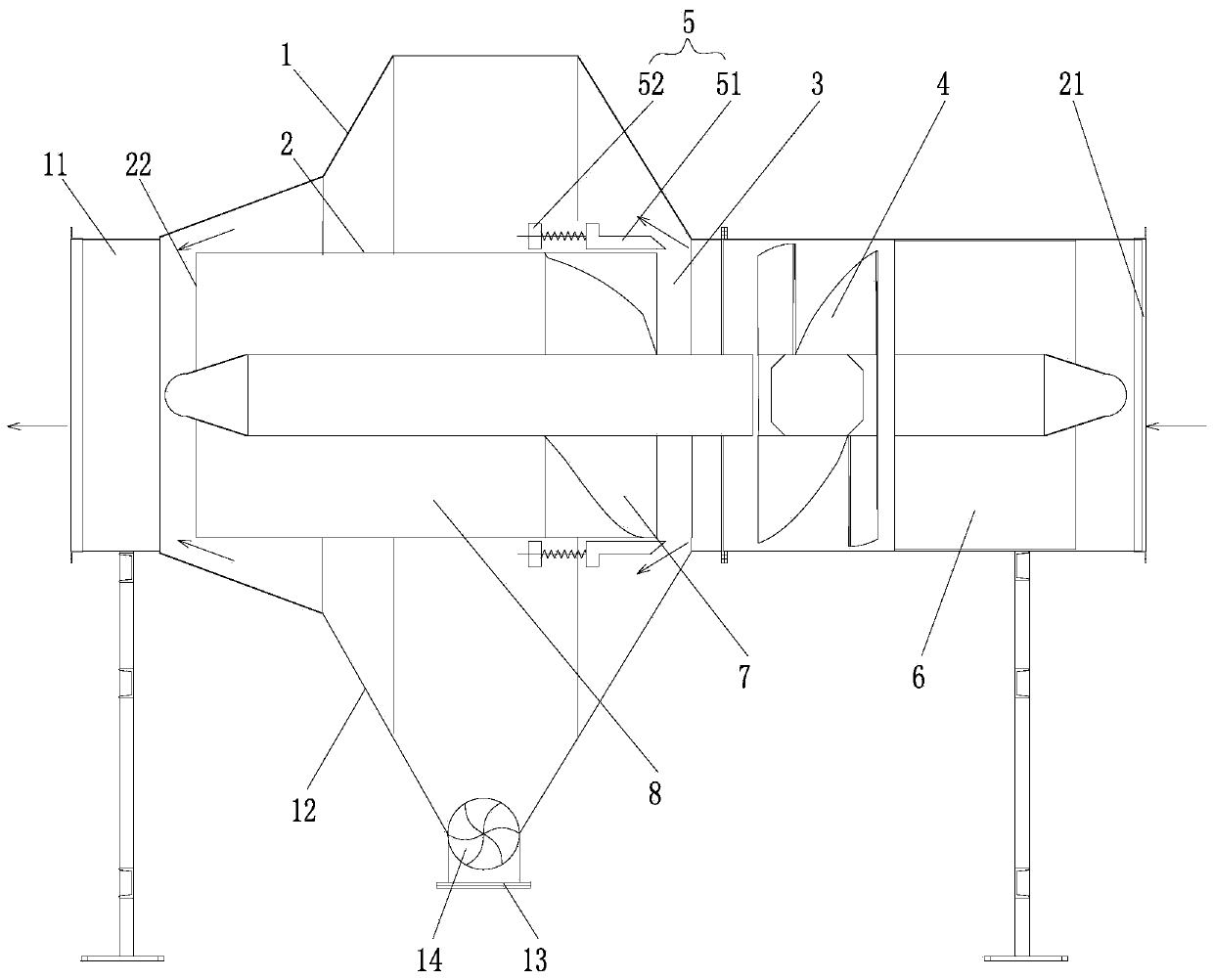

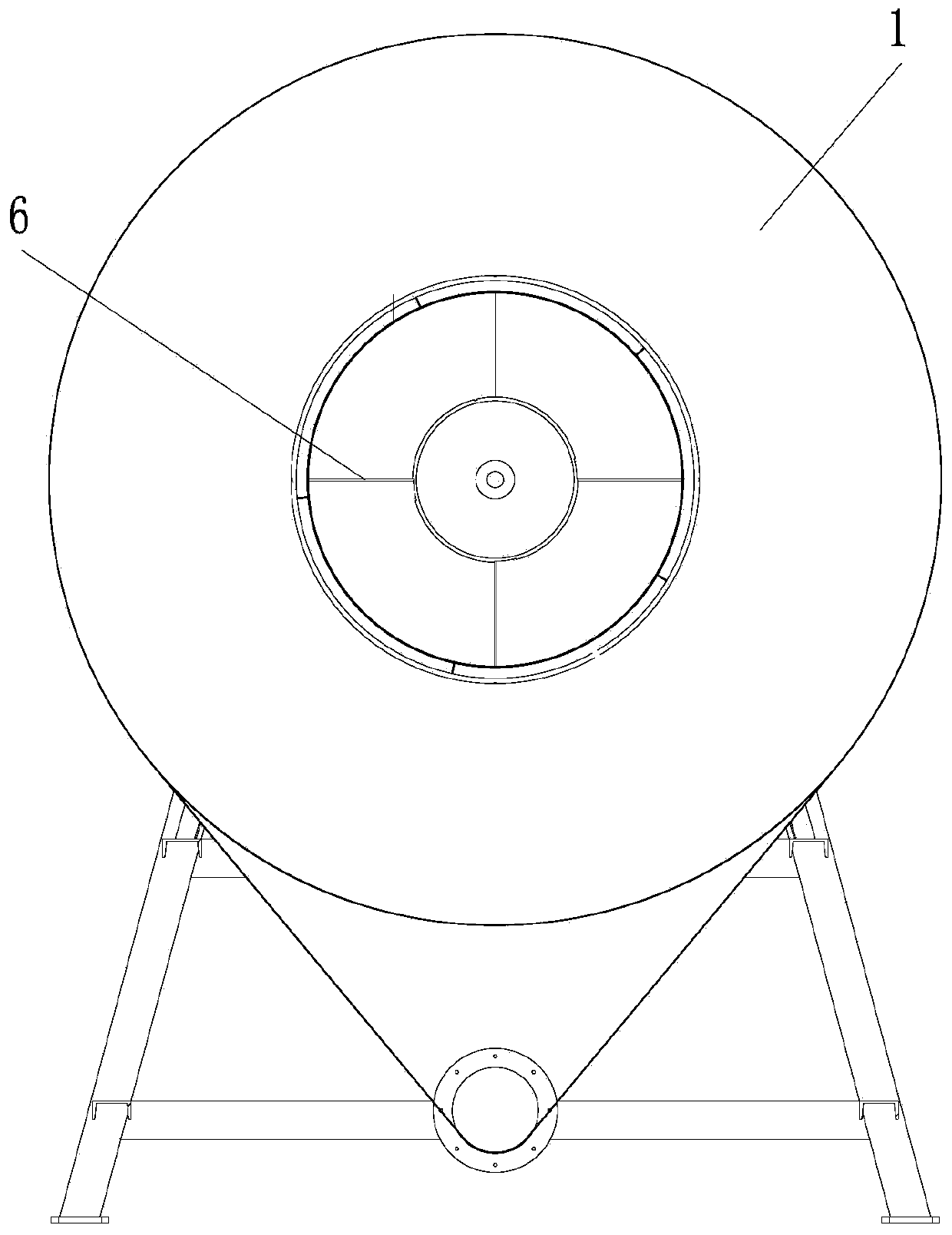

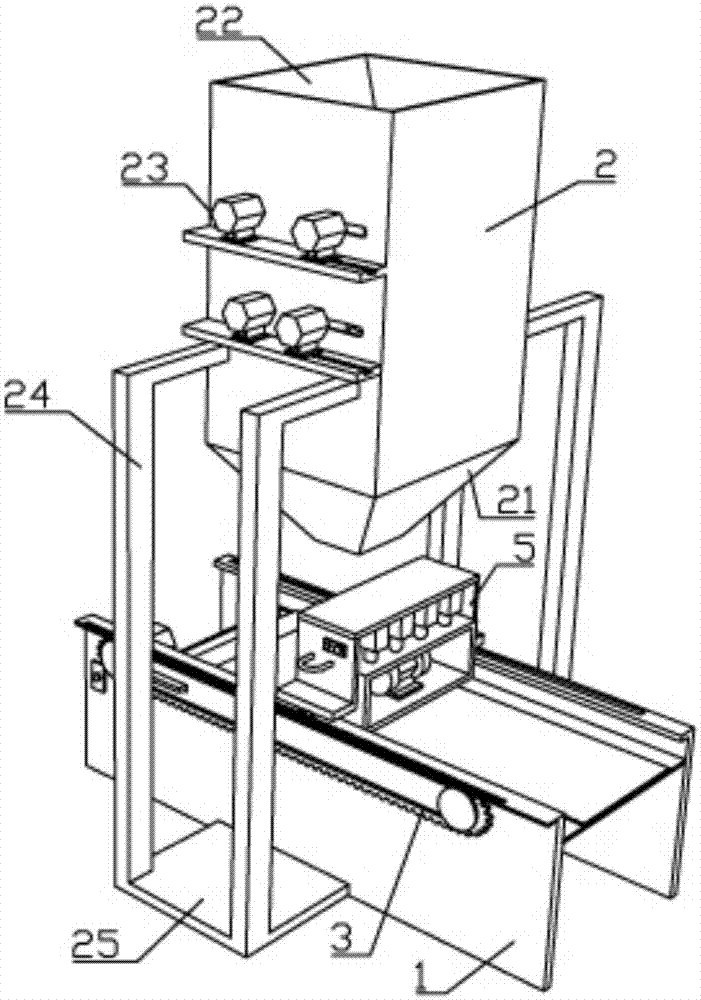

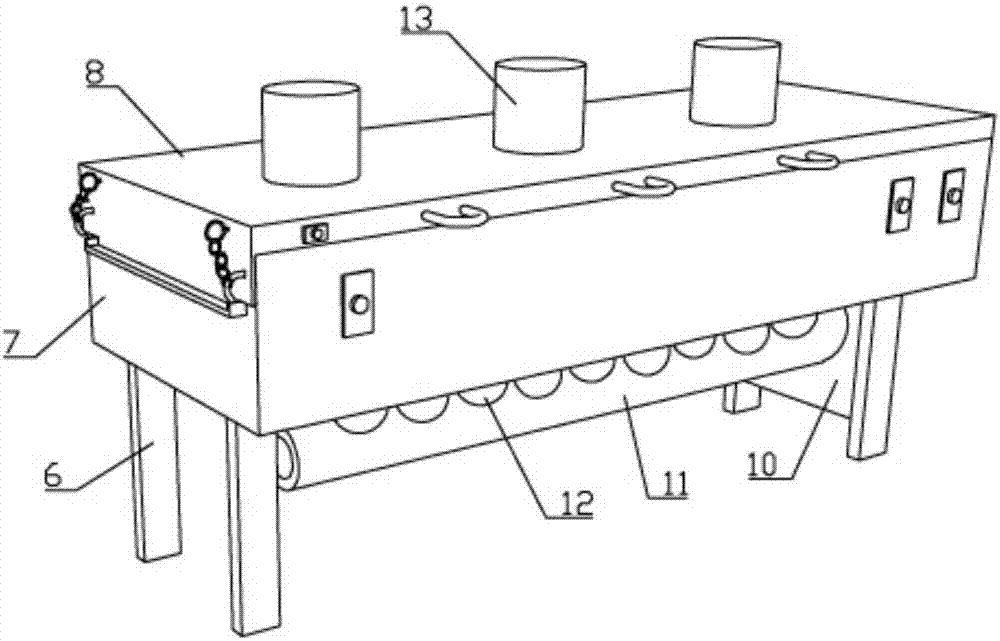

Fine powder winnowing machine

PendingCN107413650AImprove efficiencyReduce energy consumptionGas current separationVortex flow apparatusPulverizerAirflow

The invention discloses a fine powder winnowing machine. The fine powder winnowing machine at least comprises a material passage, a gas passage and a rotating disc, wherein materials go downward in the material passage, air currents rise in the gas passage, and the rotating disc is used for throwing the materials of the material passage to the gas passage. According to the fine powder winnowing machine, the materials are coarsely ground at first, then materials with qualified particles and materials with particles larger than the qualified particles are separated by utilizing the fine powder winnowing machine, fine powder meeting the particle requirement is extracted, and the materials with the particles larger than the qualified particles are ground for the second time, so that the efficiency of a pulverizer is greatly improved and the energy consumption is reduced.

Owner:HENAN LONGCHANG MACHINERY MFG

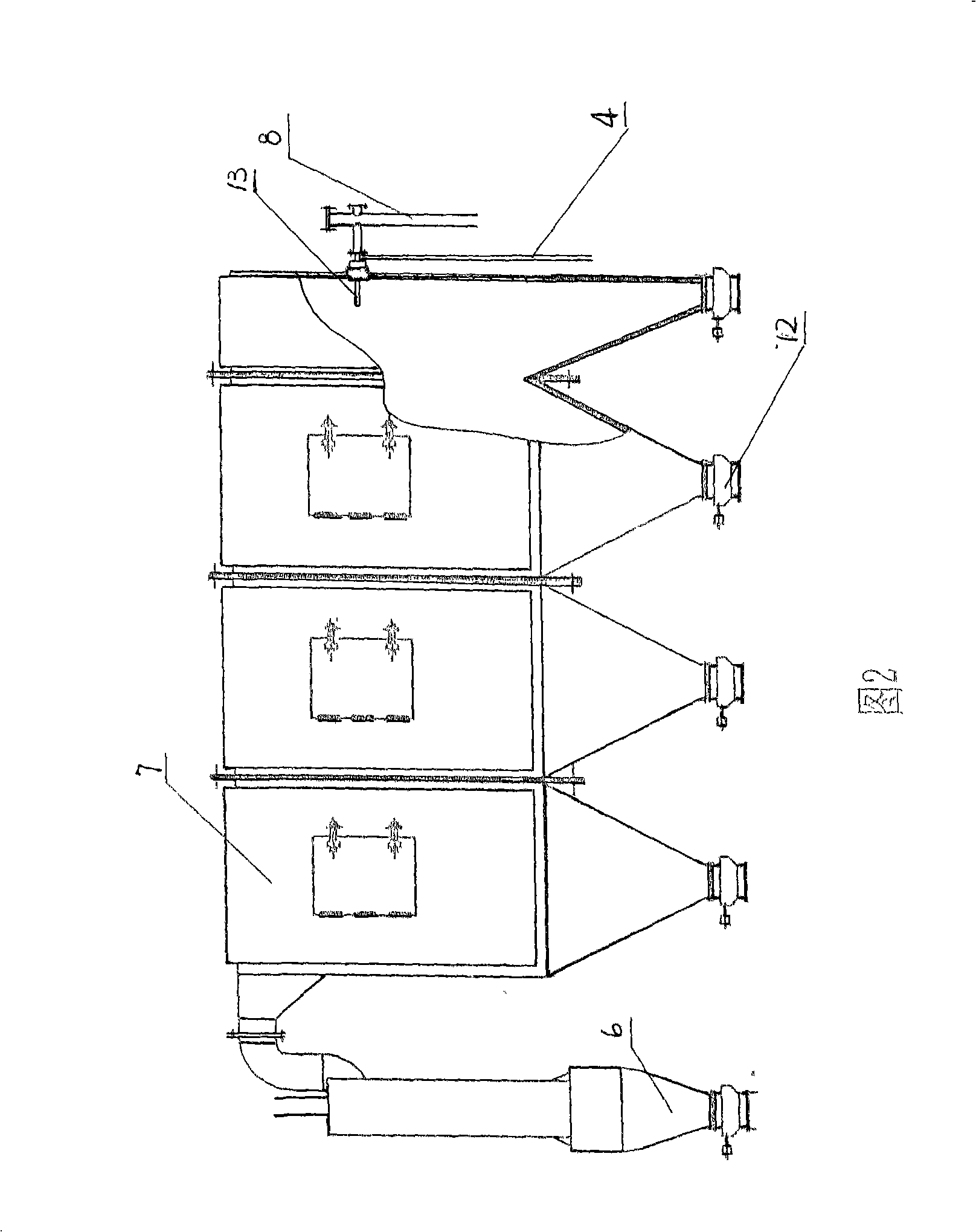

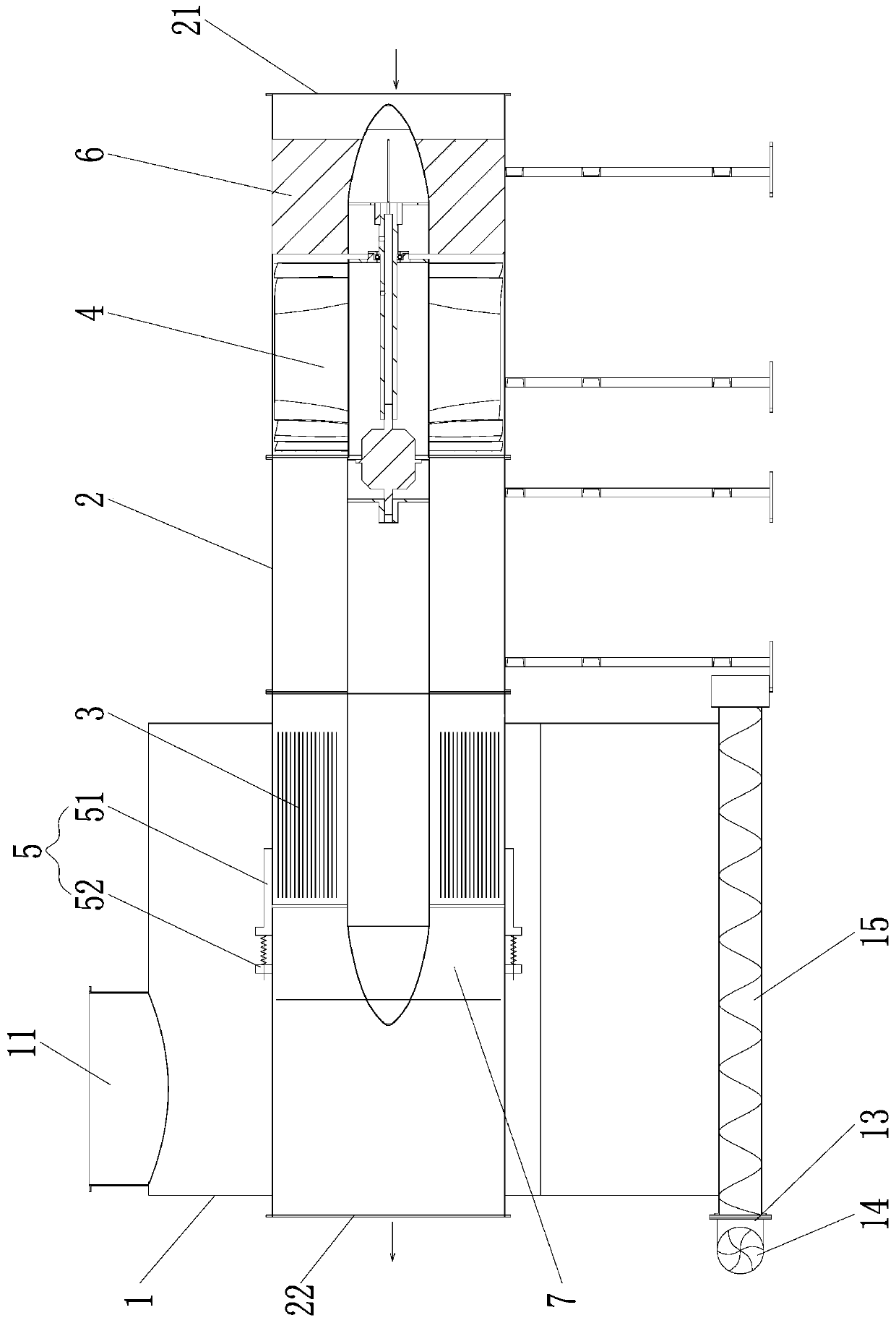

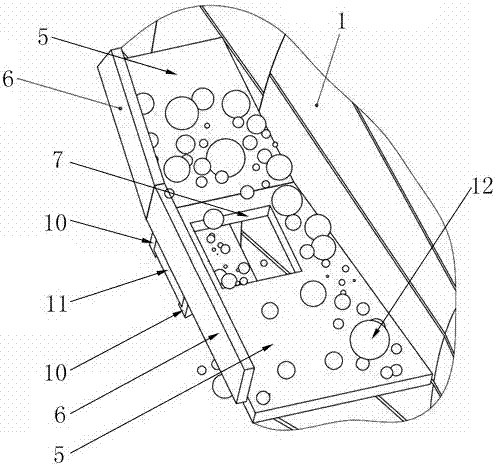

Supergravity dust removal device

PendingCN111330359AReduced operating power consumptionHigh dust separation efficiencyDispersed particle separationMechanical engineeringDust particles

The invention discloses a supergravity dust removal device. The device comprises: a main ventilating duct with one end as an air inlet end and the other end as an air outlet end; a fan arranged in themain ventilating duct and used for enabling gas to do centrifugal motion and do axial motion along the main ventilating duct; a dust outlet flow channel formed in the circumferential wall surface ofthe main ventilating duct and positioned on one side of an air outlet direction of the fan; a sedimentation cavity communicated with the dust outlet flow channel and equipped with a dust outlet and asecondary gas outlet. According to the invention, a mode of first centrifugal separation and then sedimentation dust removal is adopted; the fan is used for conveying dusty gas along the axial direction and centrifuging the dusty gas at a high speed simultaneously, miscellaneous dust particles are gathered in a radial outer area to form high-dust-content gas, the high-dust-content gas enters the sedimentation cavity to be settled, good separation and dust removal effects are achieved, purified gas in a radial middle area is directly exhausted along the main ventilating duct, the pressure lossis small, the operation power consumption of the supergravity dust removal device is reduced, the dust removal separation efficiency is high, and the effect is good.

Owner:成都市珑熙科技有限公司

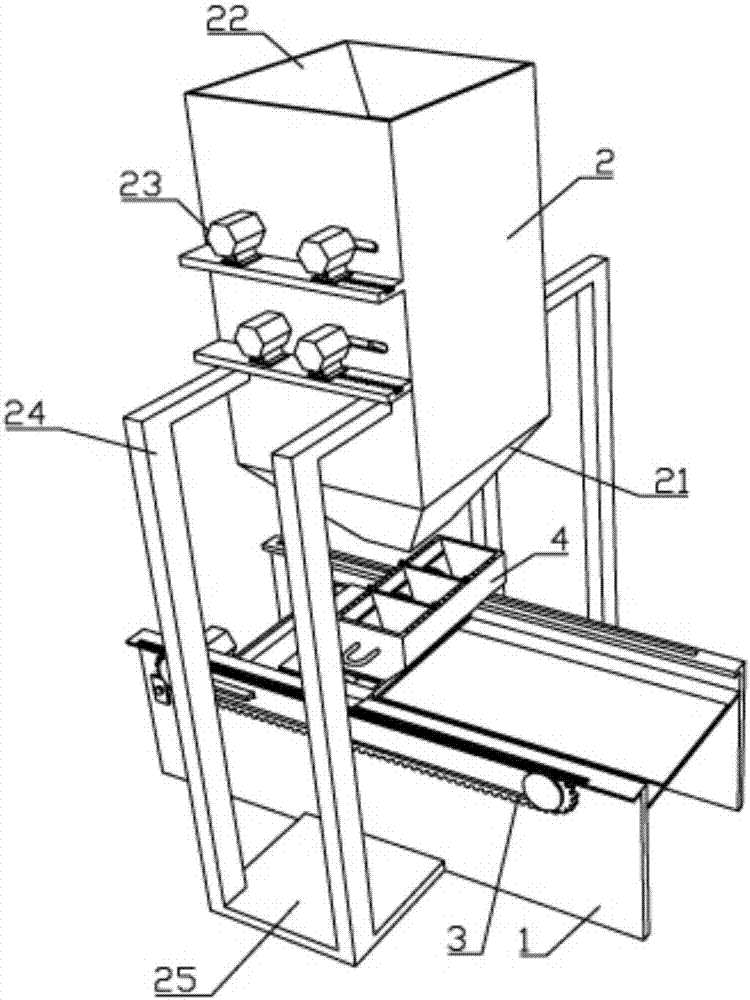

Quartz stone countertop production line

PendingCN107511919AImprove the breaking effectAdjust granularityCeramic shaping plantsFeeding arrangmentsProduction lineMaterial scattering

The invention belongs to the technical field of furniture production, and in particular, relates to a quartz stone countertop production line. The quartz stone countertop production line comprises a scattering device, a distribution and pressing common device, and a heating curing and cooling common device; the scattering device comprises a scattering mechanism and a shell; the scattering mechanism comprises a left upper rotating shaft, a right upper rotating shaft, a left lower rotating shaft and a right lower rotating shaft; the front ends of the left upper rotating shaft and the left lower rotating shaft are in transmission connection with a first motor, and the back ends are fixedly mounted on the back side wall of the shell for rotation; the front ends of the right upper rotating shaft and the right lower rotating shaft are in transmission connection with a second motor, and the back ends are detachably mounted on the back side wall of the shell for rotation; the distribution and pressing common device comprises a distribution mold frame and a power mechanism; and the heating curing and cooling common device comprises a bracket, a sleeve box and a box cover. The quartz stone countertop production line designs the material scattering, the distribution and the pressing in a centralized manner, integrates heating curing and cooling as a whole, and can adjust the material scattering particle size.

Owner:重庆鸿基木业有限公司

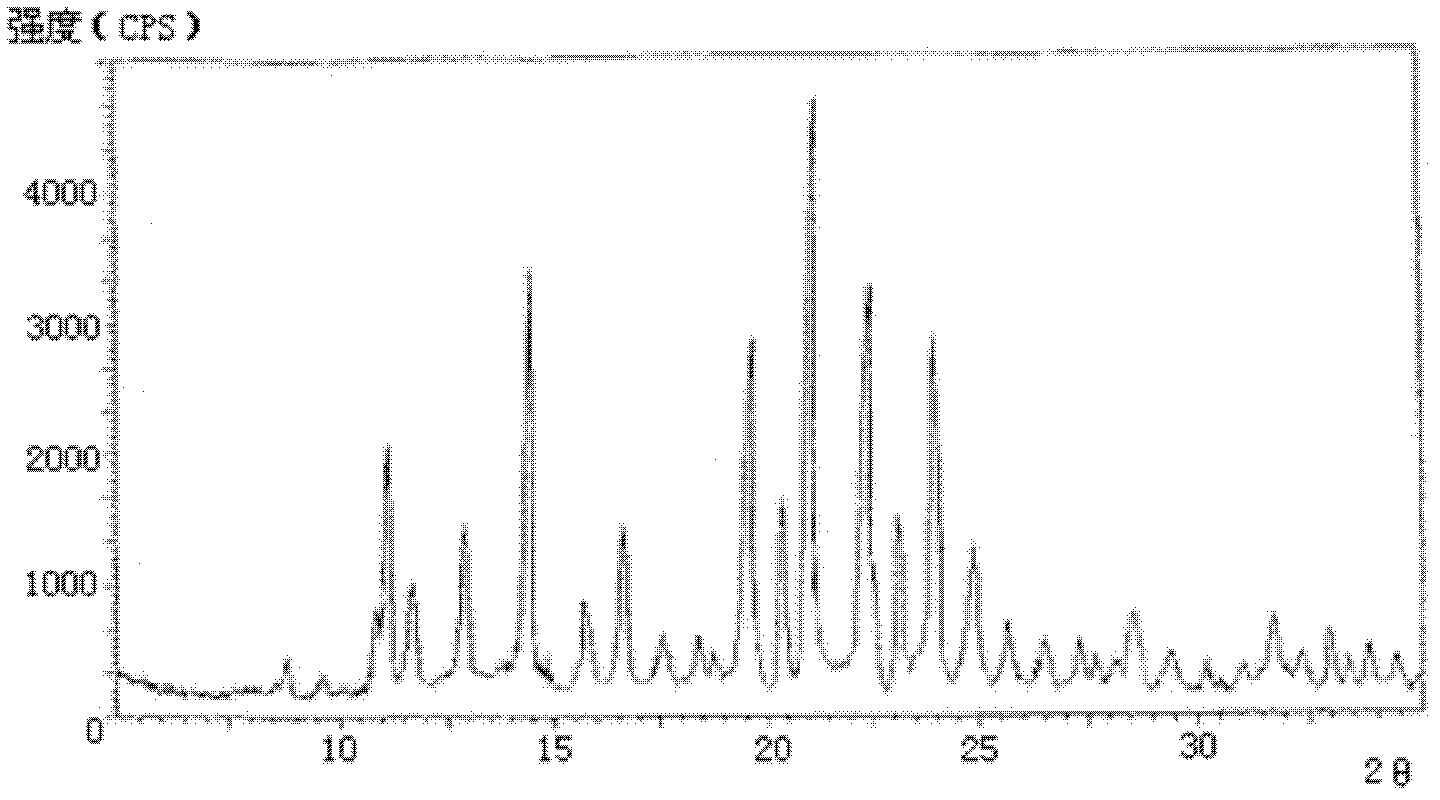

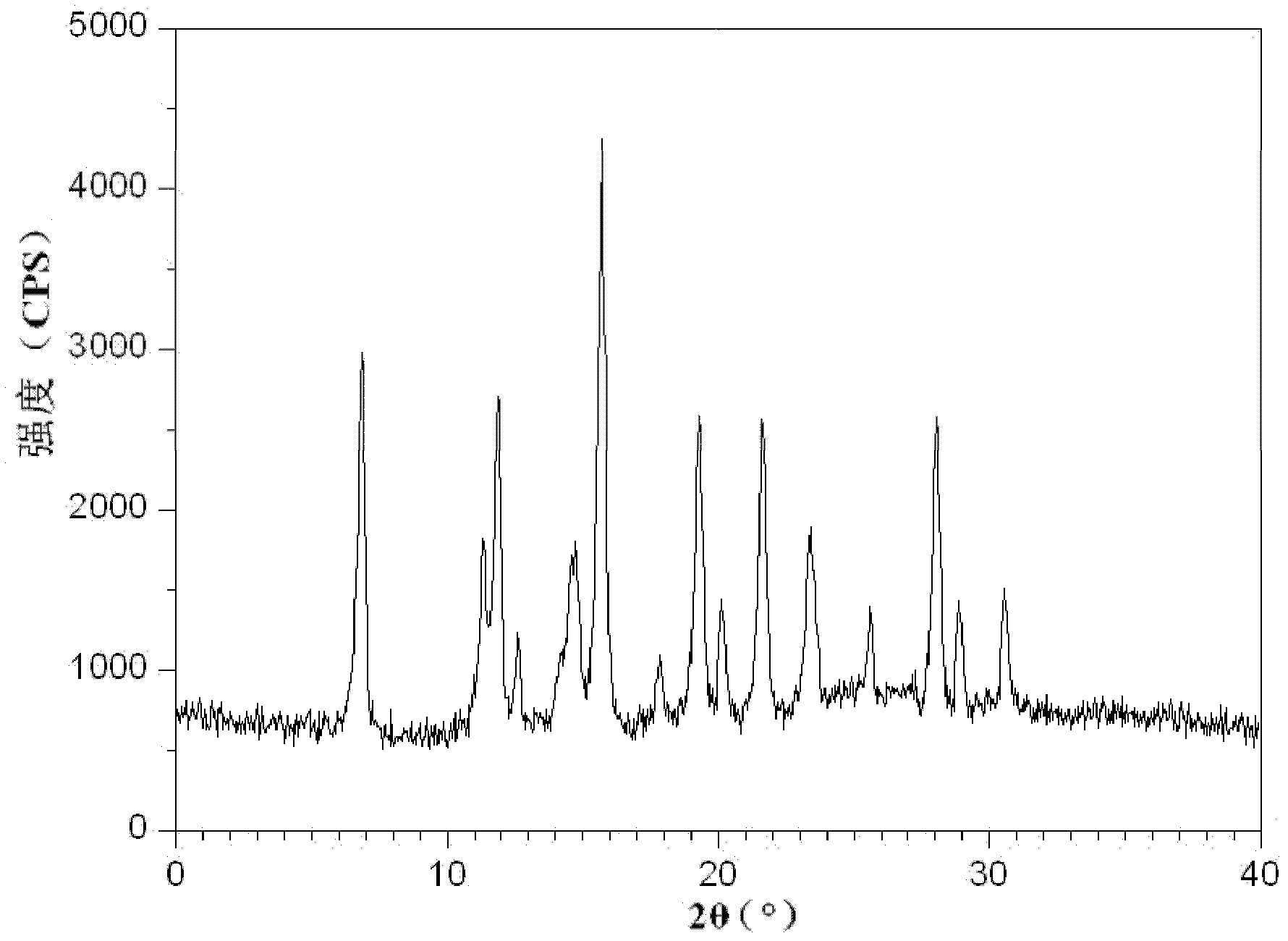

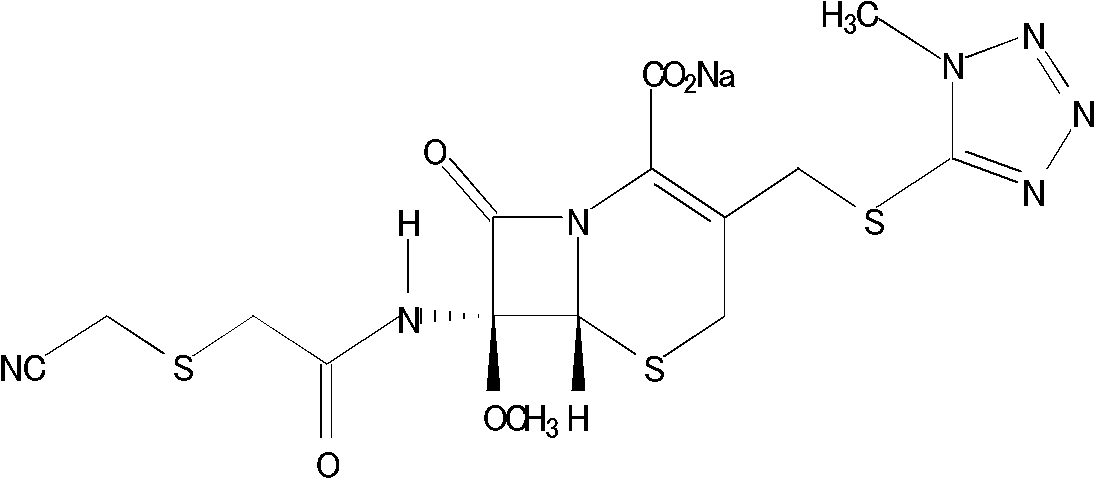

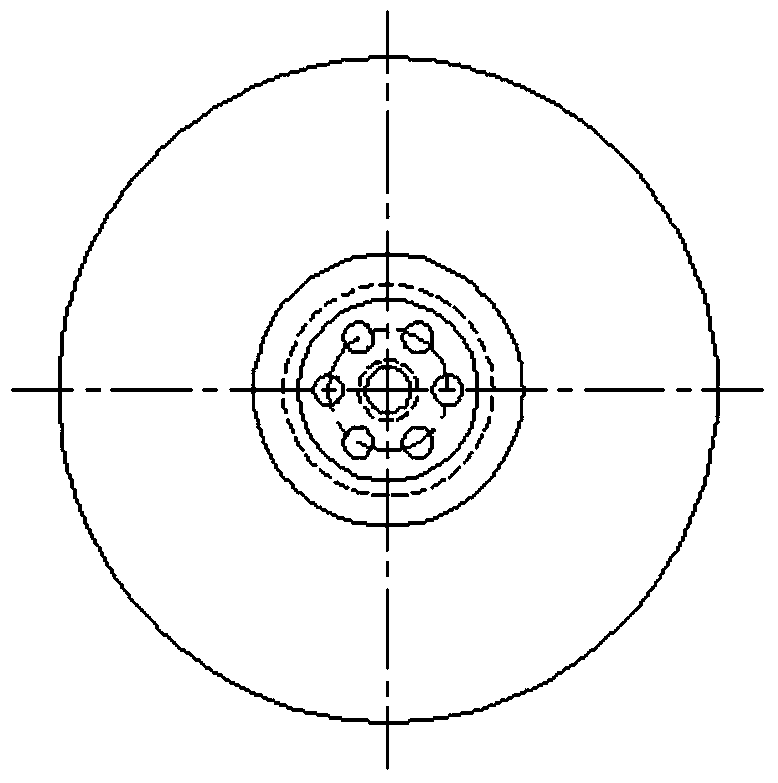

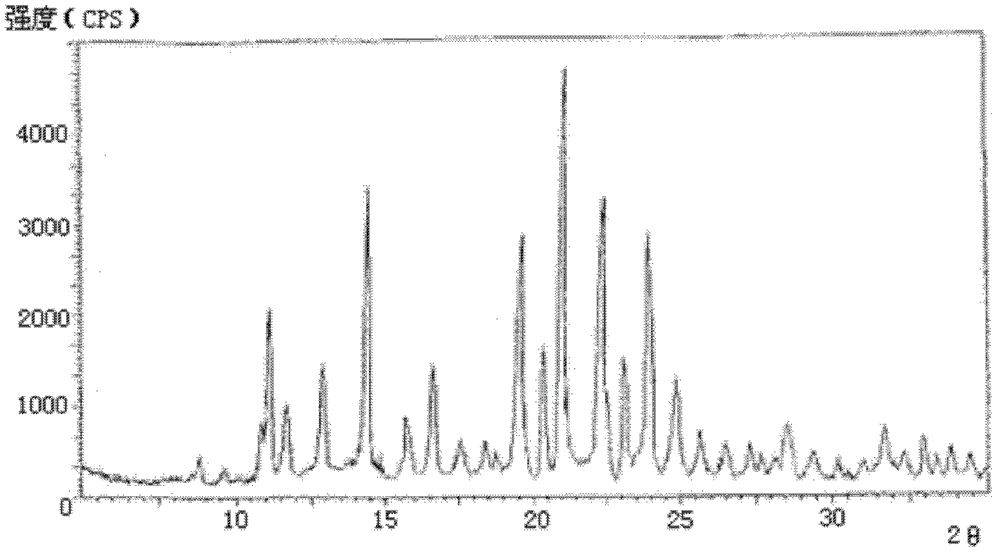

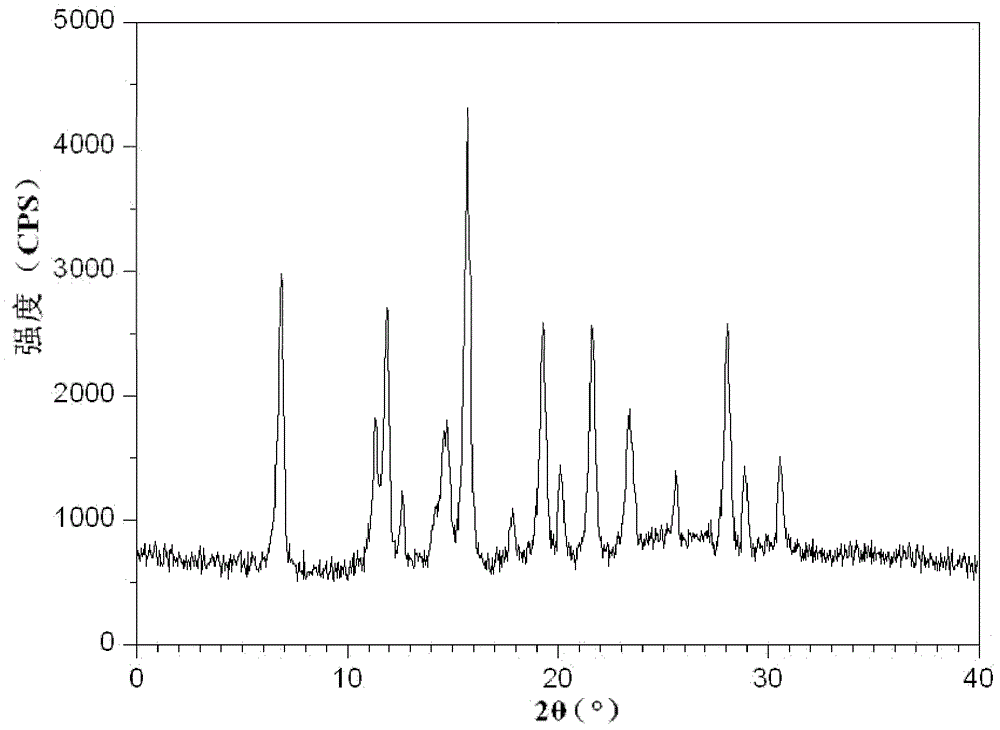

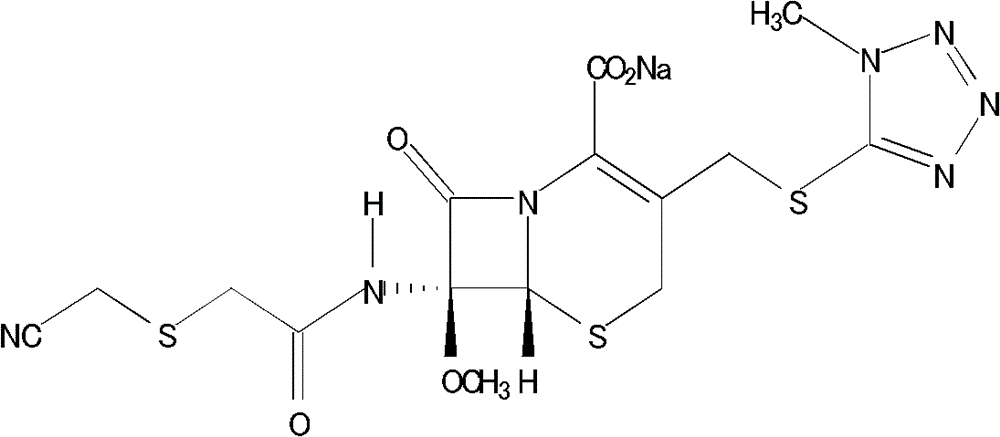

Cefmetazole sodium crystal compound, preparation method thereof and sterile powder for injection containing cefmetazole sodium crystal compound

InactiveCN102659820AGood stabilityChange crystal morphologyAntibacterial agentsOrganic active ingredientsCEFMETAZOLE SODIUMPowder diffraction

The invention relates to a cefmetazole sodium crystal compound, a preparation method thereof and sterile powder for injection containing the crystal compound. The cefmetazole sodium crystal compound is a novel crystal form of cefmetazole sodium. The X-ray powder diffraction of the crystal form measured with a Cu-Kalpha ray shows characteristic peaks when 2theta is 6.8 degrees, 11.4 degrees, 12.0 degrees, 12.6 degrees, 14.8 degrees, 15.8 degrees, 18.0 degrees, 19.4 degrees, 20.1 degrees, 21.7 degrees, 23.4 degrees, 25.6 degrees, 28.0 degrees, 29.0 degrees and 30.6 degrees. The cefmetazole sodium crystal compound provided by the invention has high stability, and is non-hygroscopic basically. The sterile powder for injection has qualified quality and high stability.

Owner:HAINAN HERUI PHARMA

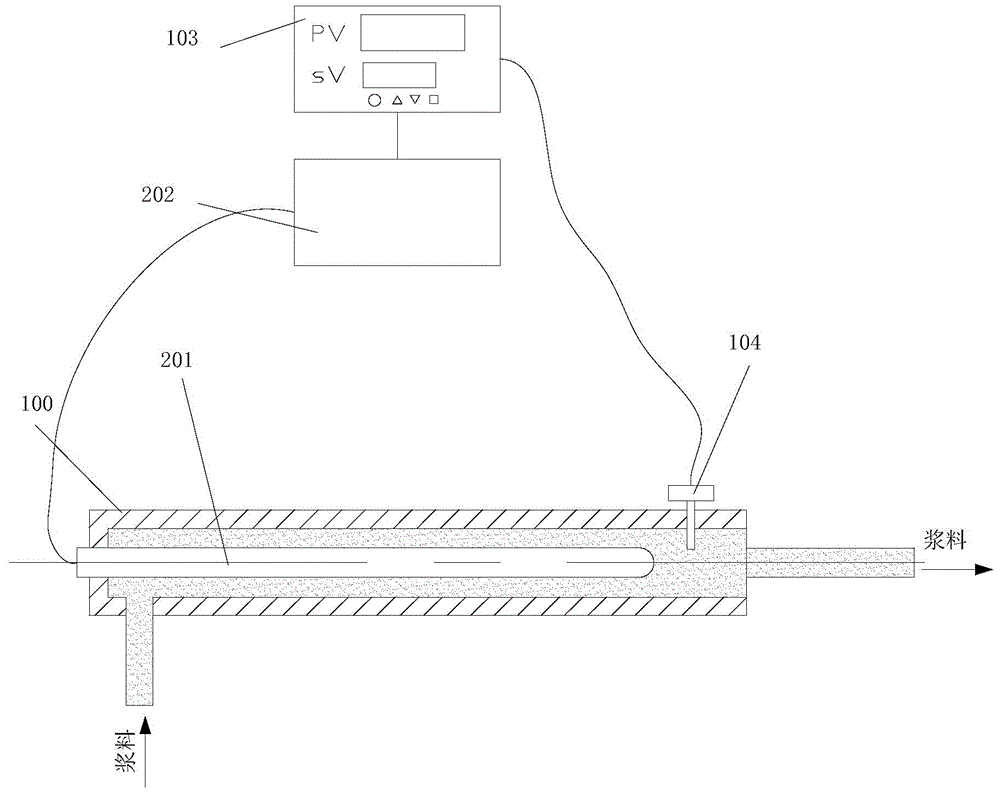

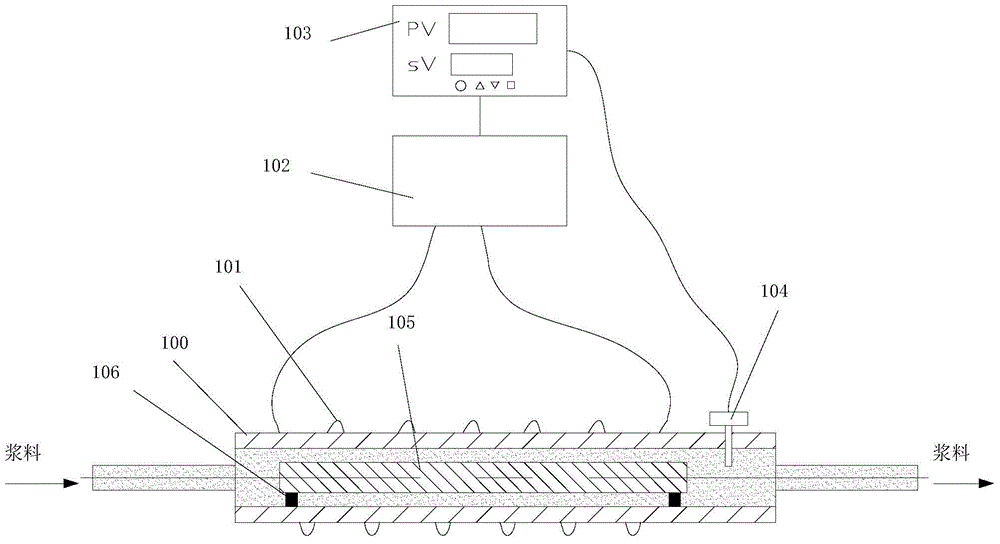

Method and device for auxiliary control of properties of spray-dried powder

InactiveCN104906817AAdjust granularityAdjust shapeEvaporator accessoriesEvaporation by sprayingTemperature controlProcess engineering

The invention relates to a method and device for auxiliary control of properties of a spray-dried powder; the method comprises before slurry goes into an atomizer of a spray dryer, an on-line heating device is arranged, and the properties of the spray-dried powder are auxiliarily controlled through on-line control of the spraying slurry temperature. The method can adjust the particle size, morphology, water content and other properties of the powder, and increases a convenient and effective way for control of the properties of the spray-dried powder. The device comprises a heating container, a heating device, a temperature sensor and a temperature controller.

Owner:姜冬英

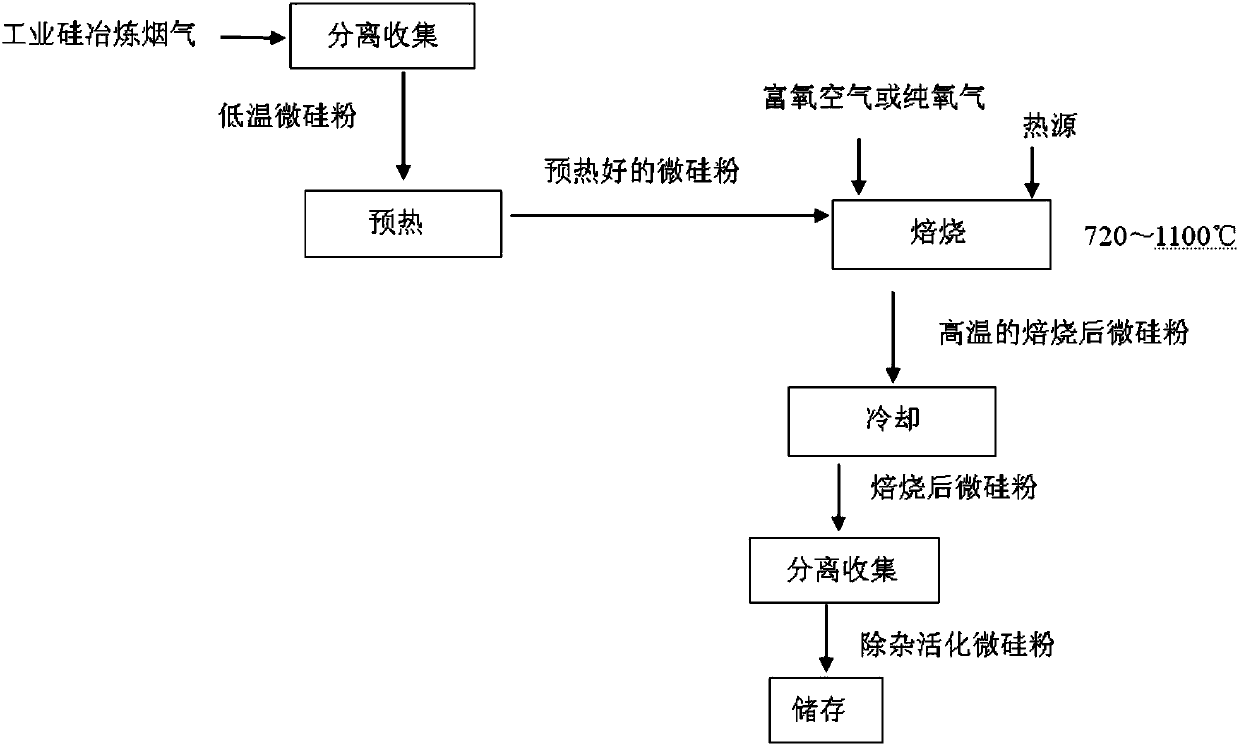

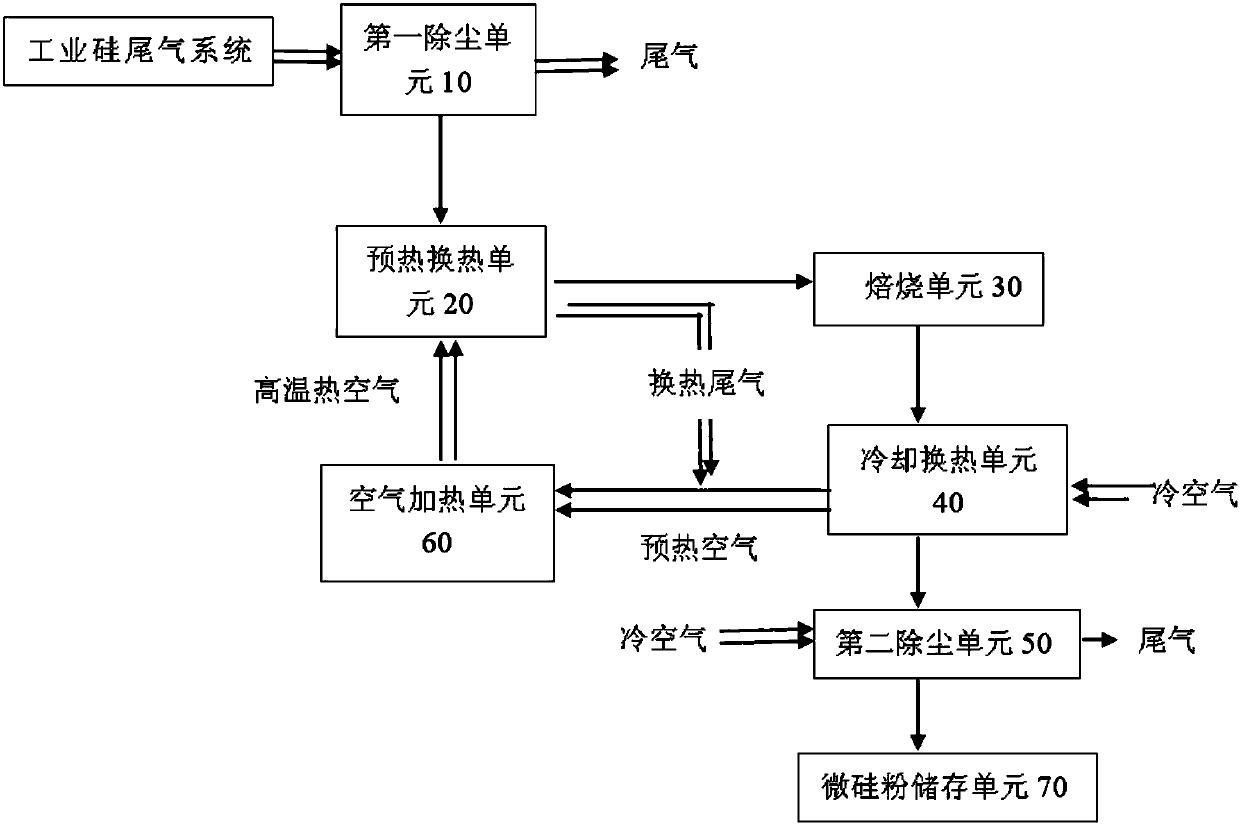

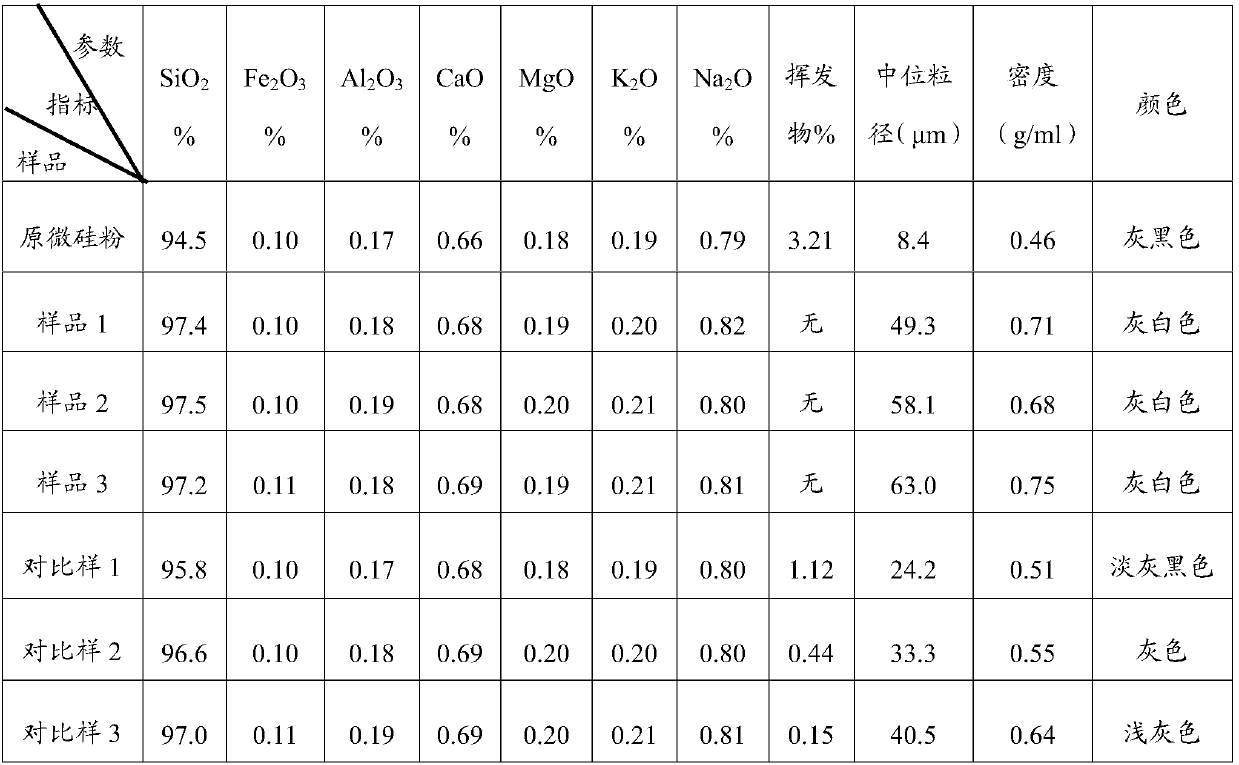

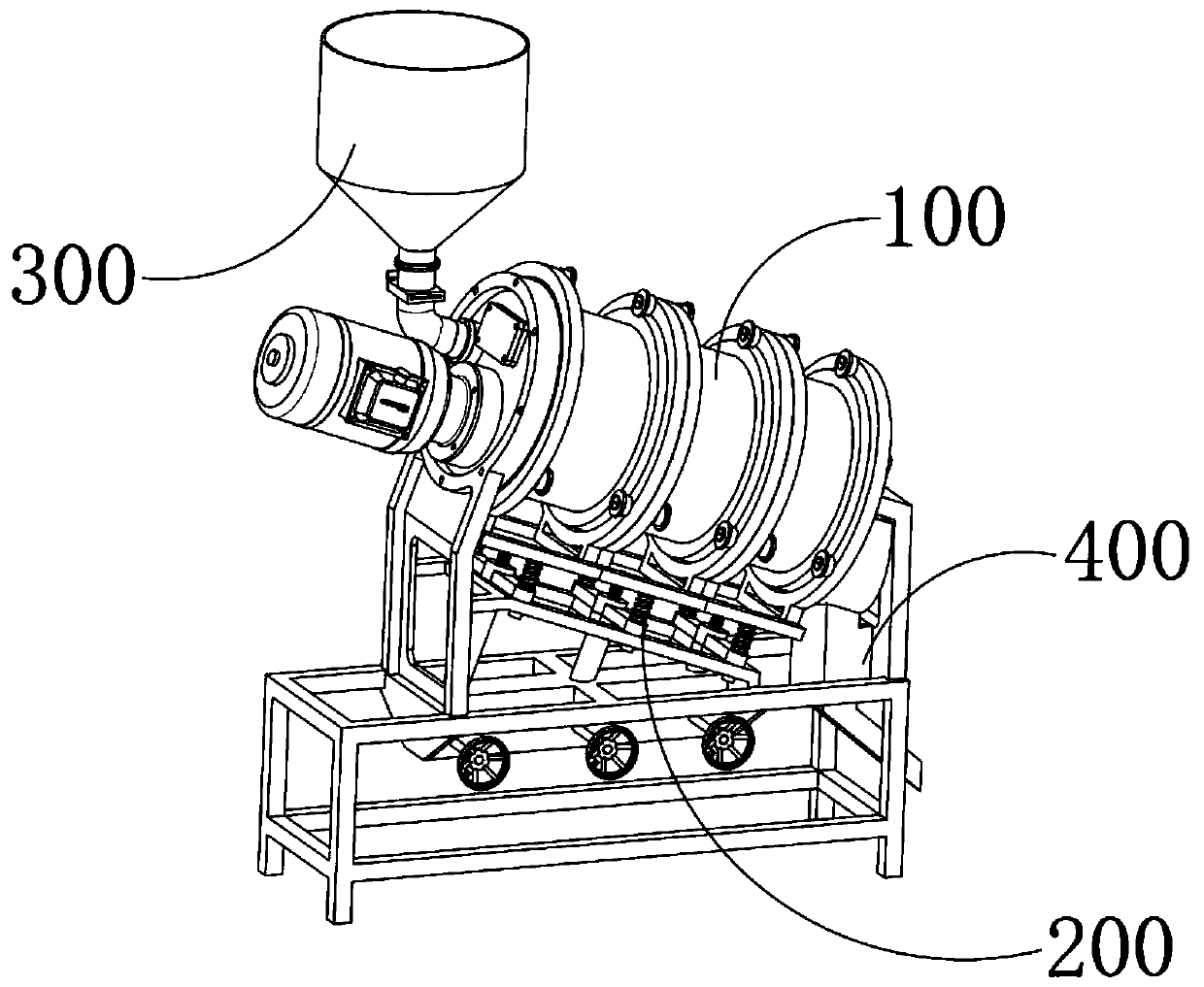

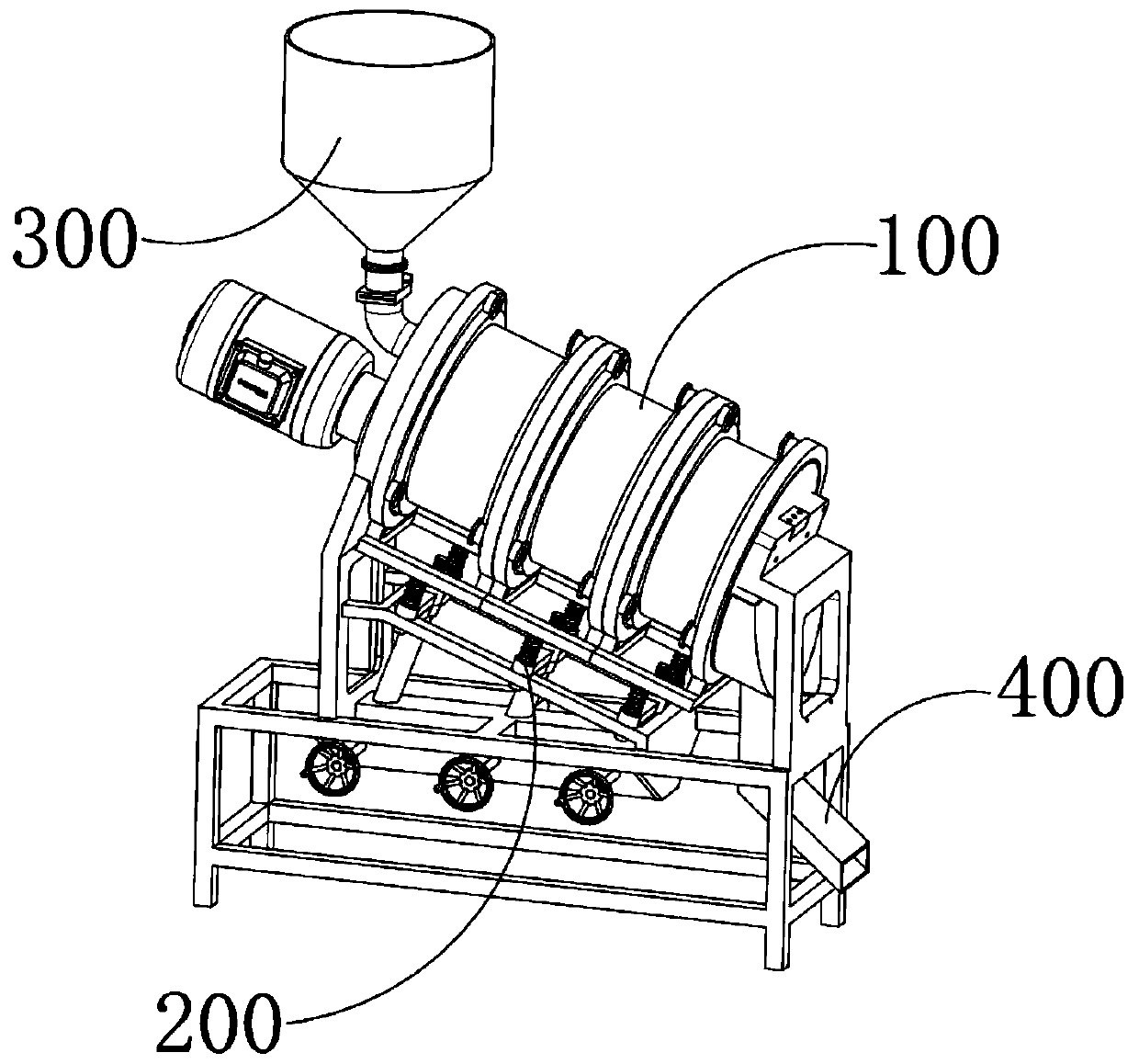

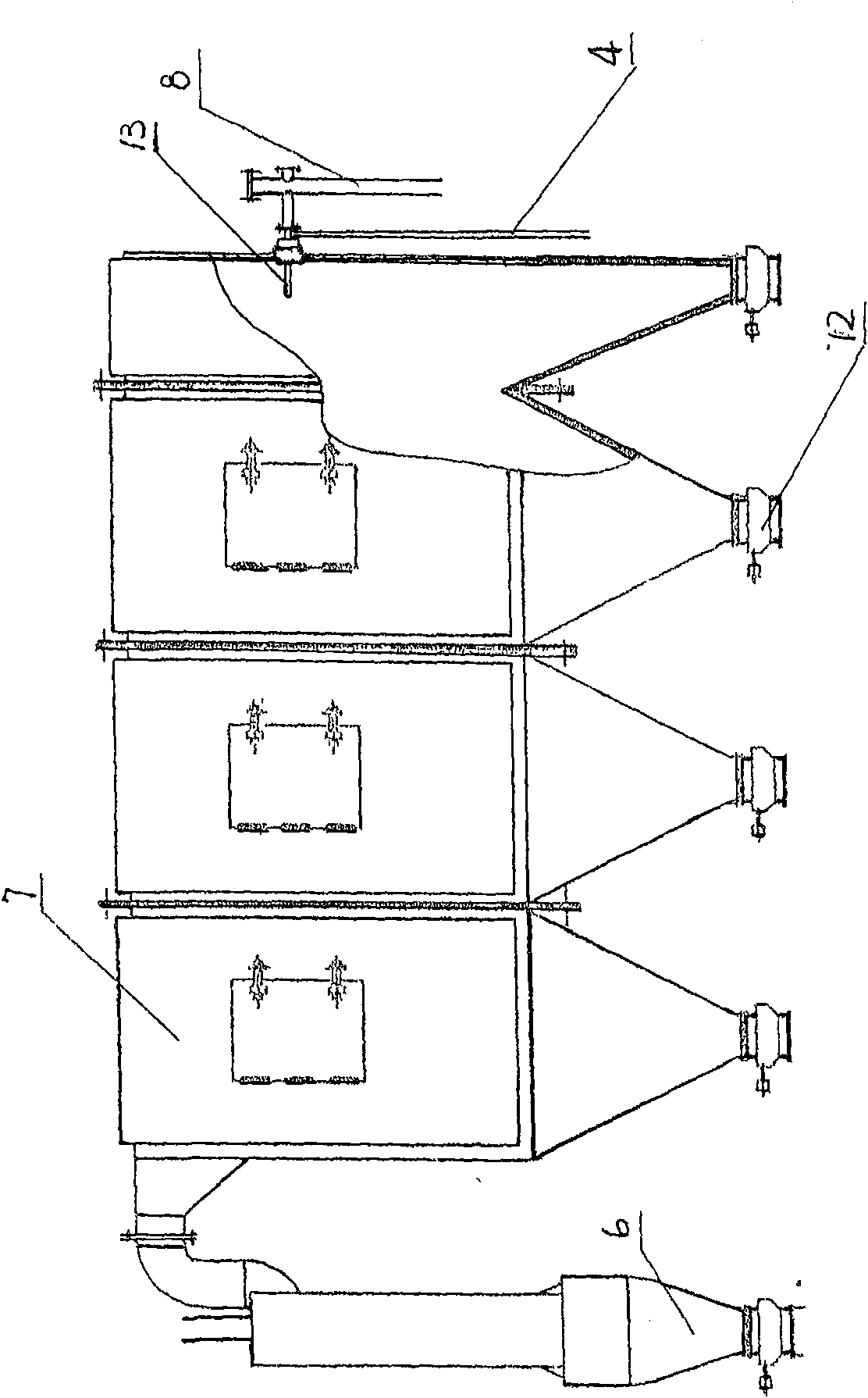

Method and device for purifying and activating industrial silicon microsilica fume

ActiveCN108017064AAdjustable structureAdjust densitySilicaEnergy inputVolatilesBiological activation

The invention discloses a method and a device for purifying and activating industrial silicon microsilica fume. The method comprises the following steps: preheating microsilica fume separated, collected and obtained from industrial silicon smelting fume to 560 to 650 DEG C, carrying out high-temperature roasting on the preheated microsilica fume in an oxygen-enriched atmosphere at 720 to 1100 DEGC in a static or dynamic state, discharging after roasting for 15 to 90 minutes, cooling and separating, thus obtaining purified and activated microsilica fume. The device is used for realizing purification and activation of the industrial silicon microsilica fume, and comprises a first dedusting unit, a preheating heat exchange unit, a roasting unit, a cooling heat exchange unit, a second dedusting unit, a microsilica fume storage unit and an air heating unit. According to the method and the device, disclosed by the invention, influence of organic volatiles such as coal tar and carbon in themicrosilica fume on production and quality of follow-up products can be avoided by removing the organic volatiles such as the coal tar and the carbon in the microsilica fume, and reaction and filter of the follow-up products are facilitated by regulating the density and the granularity of the microsilica fume under the condition that the reaction activity of the microsilica fume is ensured, so that industrial production of follow-up sodium silicate products is realized.

Owner:CHANGJI JISHENG NEW BUILDING MATERIALS CO LTD

Technology for producing building material from vanadium-titanium technology blast furnace dry slag

The invention relates to the technical field of blast furnace dry slag, and discloses a technology for producing a building material from vanadium-titanium technology blast furnace dry slag. The technology comprises the following steps: 1) collecting the blast furnace slag generated in a furnace body by using a professional device, placing the collected blast furnace slag in a processing device bya conveying machine, processing the blast furnace through a hot splashing process by using the processing device, and carrying out air cooling treatment on the processed blast furnace slag; and 2) maximally processing dry slag by using an existing slag bath, controlling the formation of the crystalline phase microstructure of slag blocks to make the dry slag reach the strength of different ores,rapidly solidifying the blast furnace slag by using a water spraying process until the blast furnace slag is cooled in order to make the blast furnace slag meet transshipment conditions, and filling atransporting device with the cooled and solidified blast furnace slag. The technology for producing the building material from vanadium-titanium technology blast furnace dry slag can produce constructional slag broken stone and slag sands, and can massively and comprehensively utilize the blast furnace slag to solve the present situation of waste stockpiling.

Owner:CHENGYU VANADIUM TITANIUM TECH CO LTD

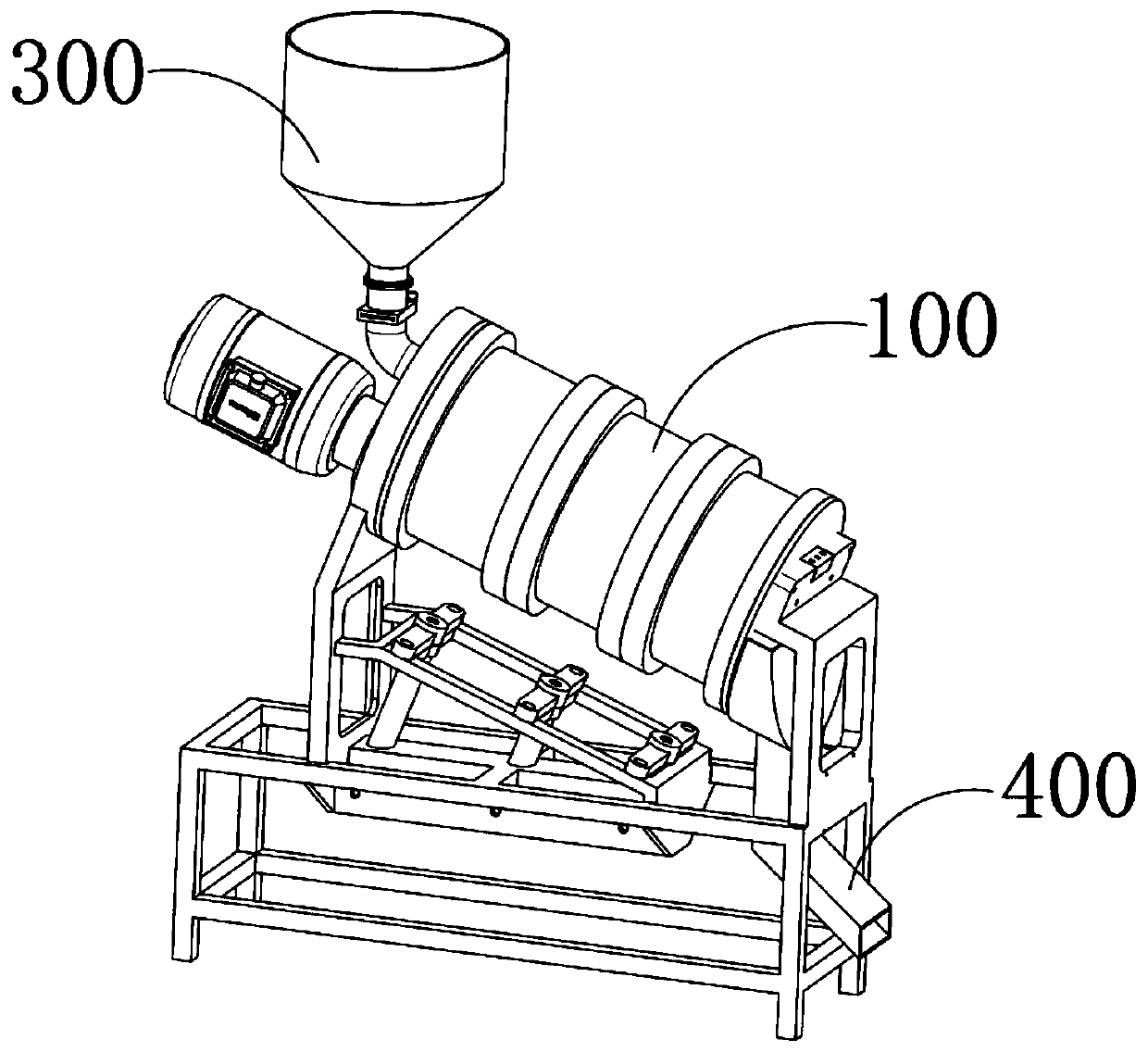

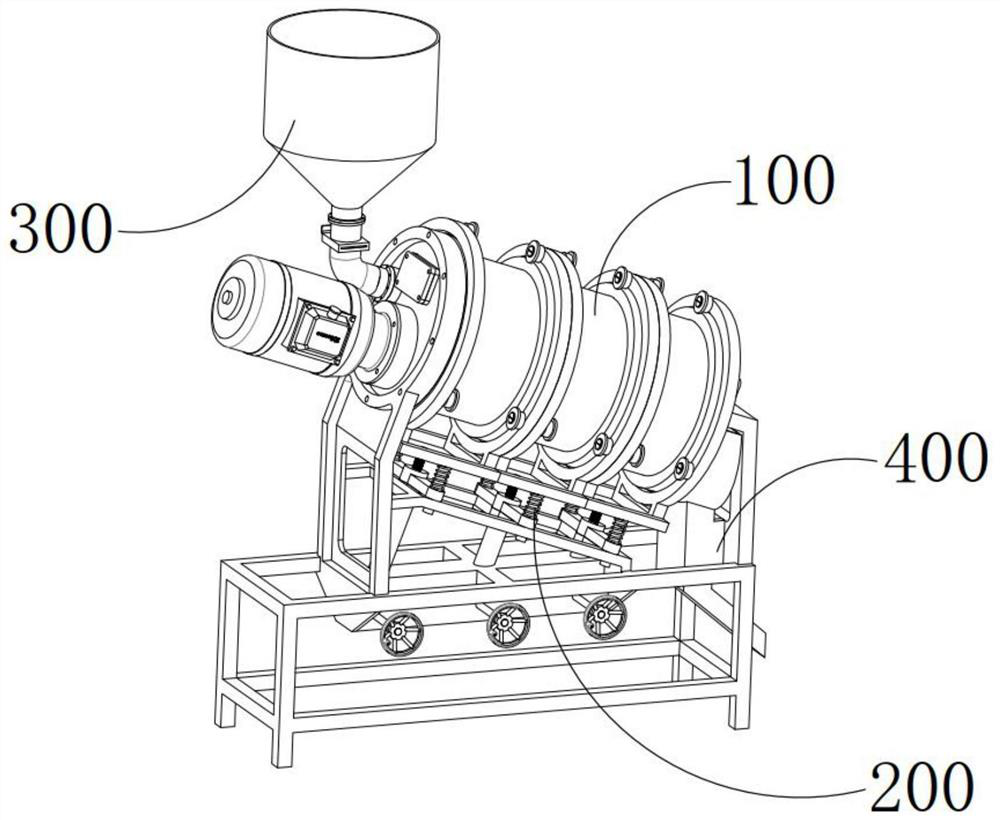

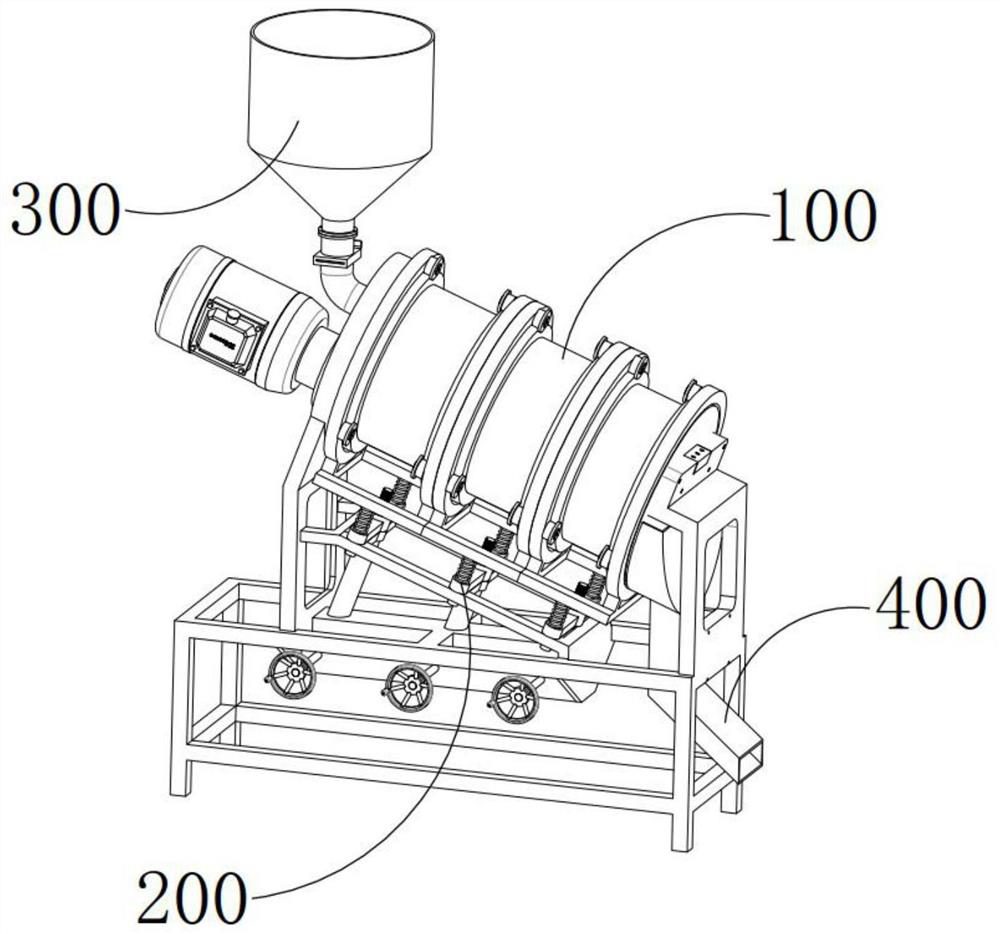

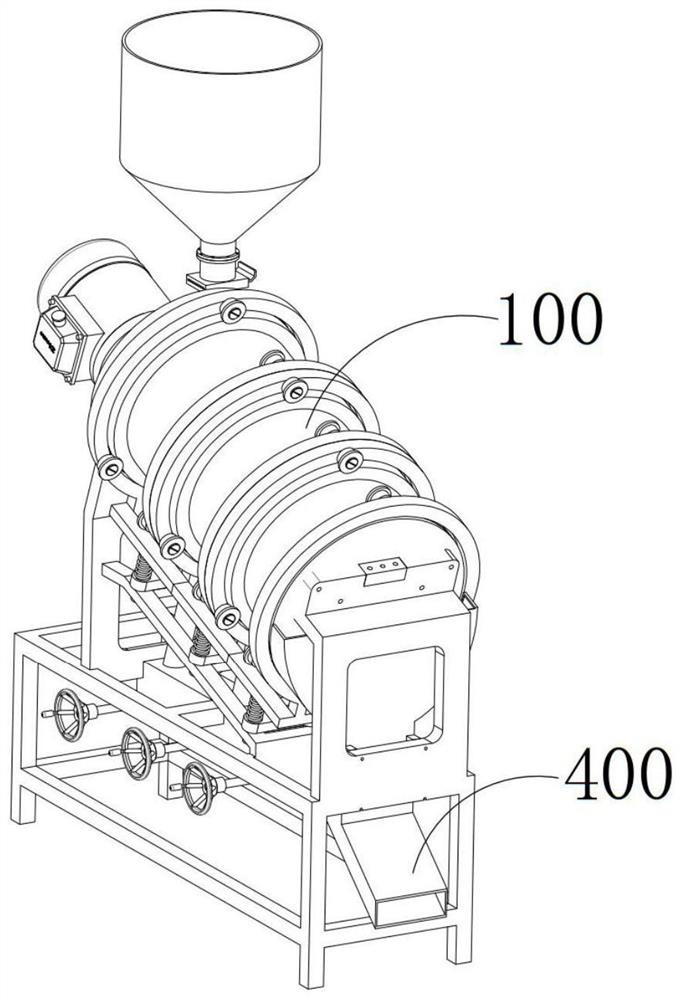

Eccentric flour mill for rice processing

InactiveCN110614147AIngenious structureThe principle is simpleGrain treatmentsGranularityPulp and paper industry

The invention provides an eccentric flour mill for rice processing. The eccentric flour mill comprises a grinding device, a feeding part capable of adding rice to the input end of the grinding device,a discharging part capable of discharging rice powder at the output end of the grinding device, and a floating supporting part. The grinding device comprises outer cylinders axially inclining, and grinding cylinders sleeved with the outer cylinders and located at the eccentric positions of the outer cylinders. The axis of each grinding cylinder is located under the axis of the corresponding outercylinder, and the outer circumferential surface of each grinding cylinder abuts against the inner circumferential surface of the corresponding outer cylinder. The grinding cylinders rotate to drive the outer cylinders to rotate so as to grind and pulverize rice at the abutting portions of the grinding cylinders and the outer cylinders. The floating supporting part adjusts the abutting pressure between the grinding cylinders and the outer cylinders. The eccentric flour mill has the advantages that the grinding cylinders rotate to drive the outer cylinders to synchronously rotate so that rice between the grinding cylinders and the outer cylinders can be ground and pulverized, and meanwhile the pressure between the outer cylinders and the grinding cylinders can be adjusted through the floating supporting part so as to the adjust the rice grinding and pulverizing granularity.

Owner:六安正辉优产机电科技有限公司

Special bacterium-contained organic-inorganic compound fertilizer for tea plants

ActiveCN102372526BHigh activityImprove stress resistanceBio-organic fraction processingOrganic fertiliser preparationPhosphateAlkaloid

The invention discloses a special bacterium-contained organic-inorganic compound fertilizer for tea plants. A fermentation technology comprises the following steps: 1, taking 35% of CMS, 15% of tobacco powder and 30% of a domestic fungal leftover, and uniformly mixing them to obtain a mixture; 2, injecting 0.1% of dry yeast powder and 3% of a mixed Bacillus mucilaginosus and actinomyce solution which is prepared with a compound alkaloid as an bactericide, and composting for 168h; 3, injecting a dissolving solution containing 1% of alum, 0.5% of borax, 0.1% of cooper sulfate and 0.3% of sulfur powder into each 625kg of above fermented material, adding 230kg of urine, 120kg of monoammonium phosphate and 100kg of potassium sulfate, uniformly stirring, and composting for 72h; 4, detecting that whether contents of organic matters, water, nitrogen, phosphor, potassium, effective live bacteria and the like in the fertilizer composted in step 3 satisfy standards shown in the specification; and 5, granulating qualified semi-finished product discs obtained in step 4, and packaging them to prepare finished products after processes of low temperature drying, screening and detection. The fertilizer, which has the effects of soil activation, tea plant root environment improvement, tea strongylid and fusarium inhibition and the like, has important effects on the construction of organic tea gardens and nuisance-free tea gardens.

Owner:漳州美利德生物工程有限公司

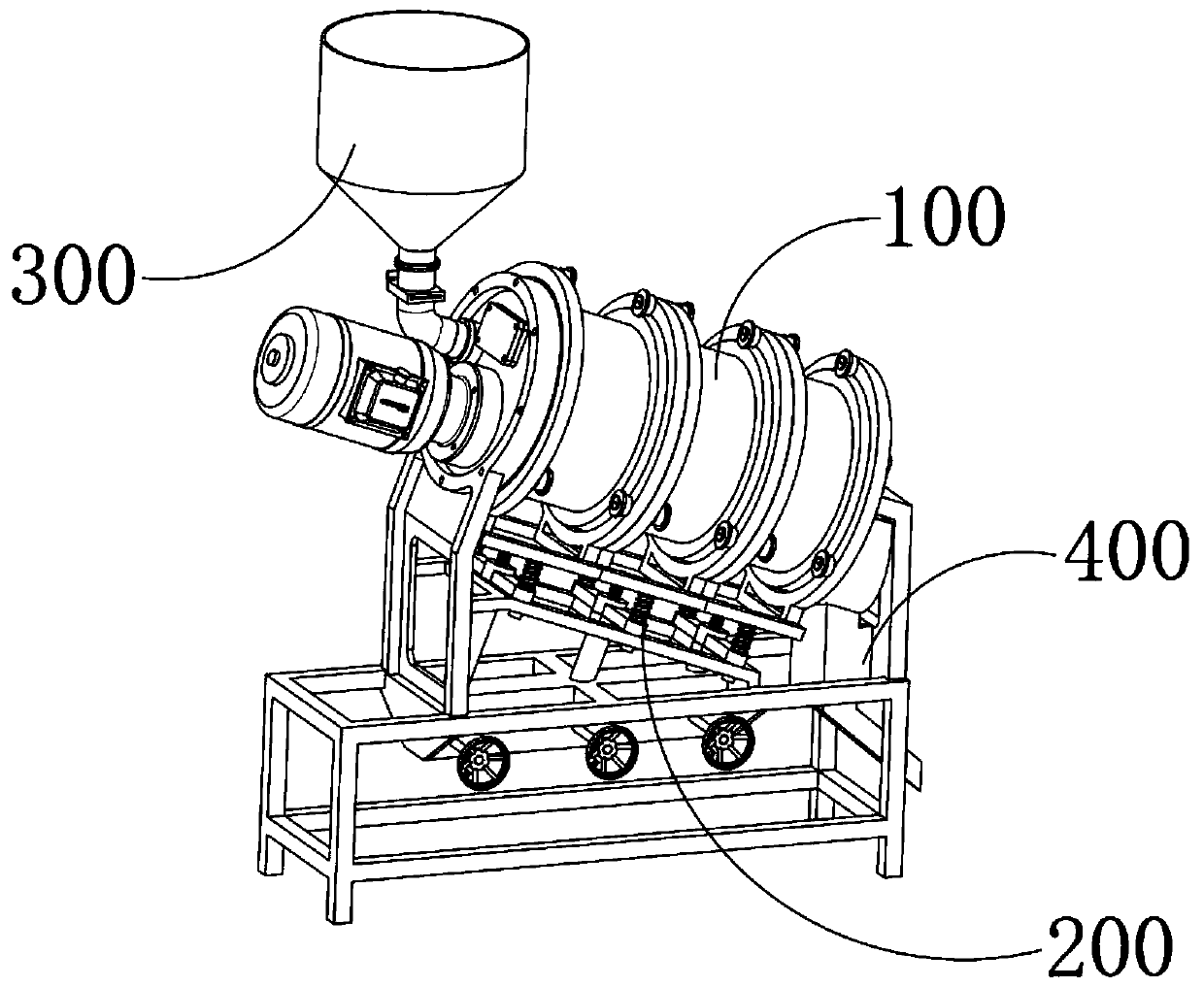

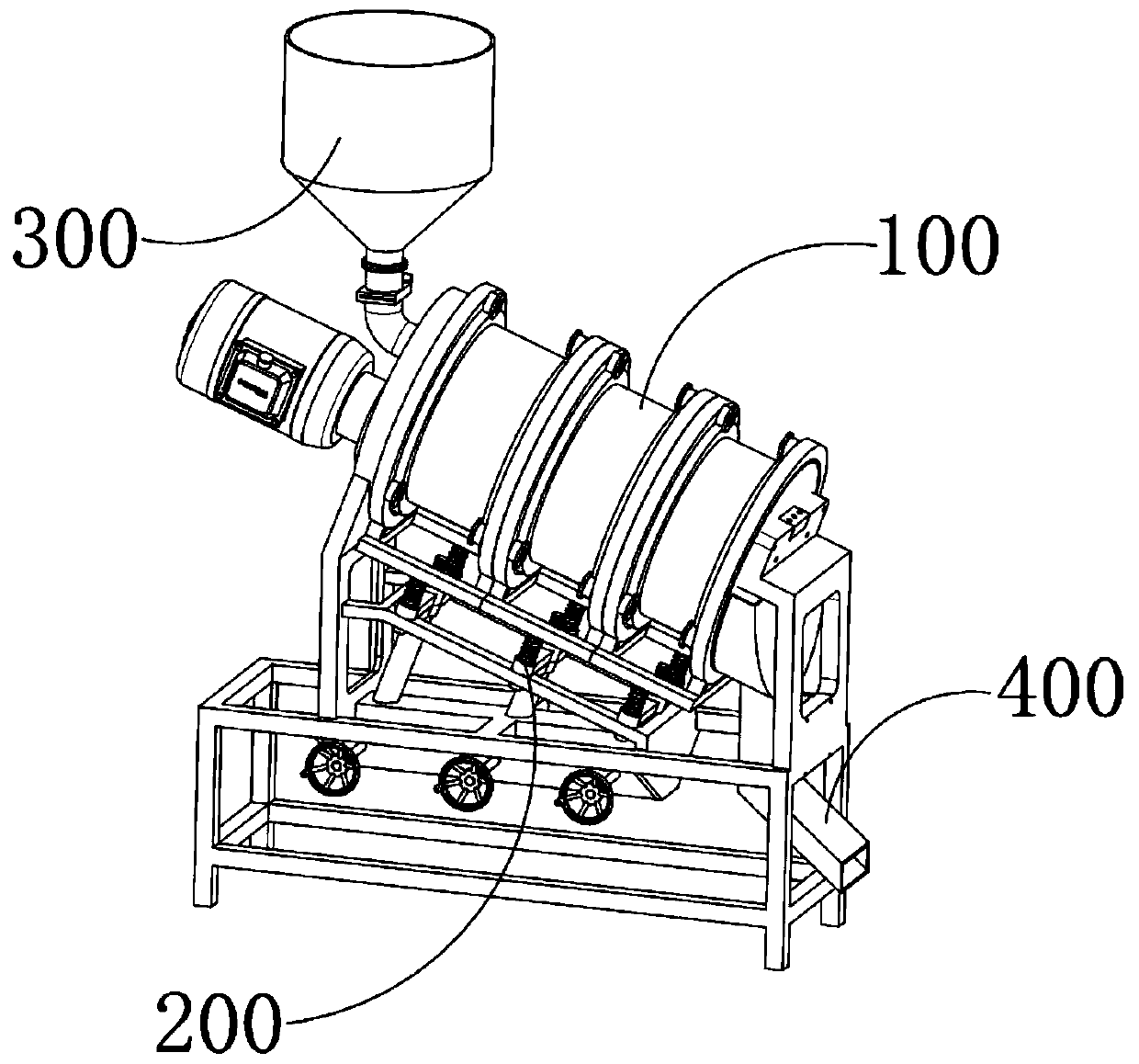

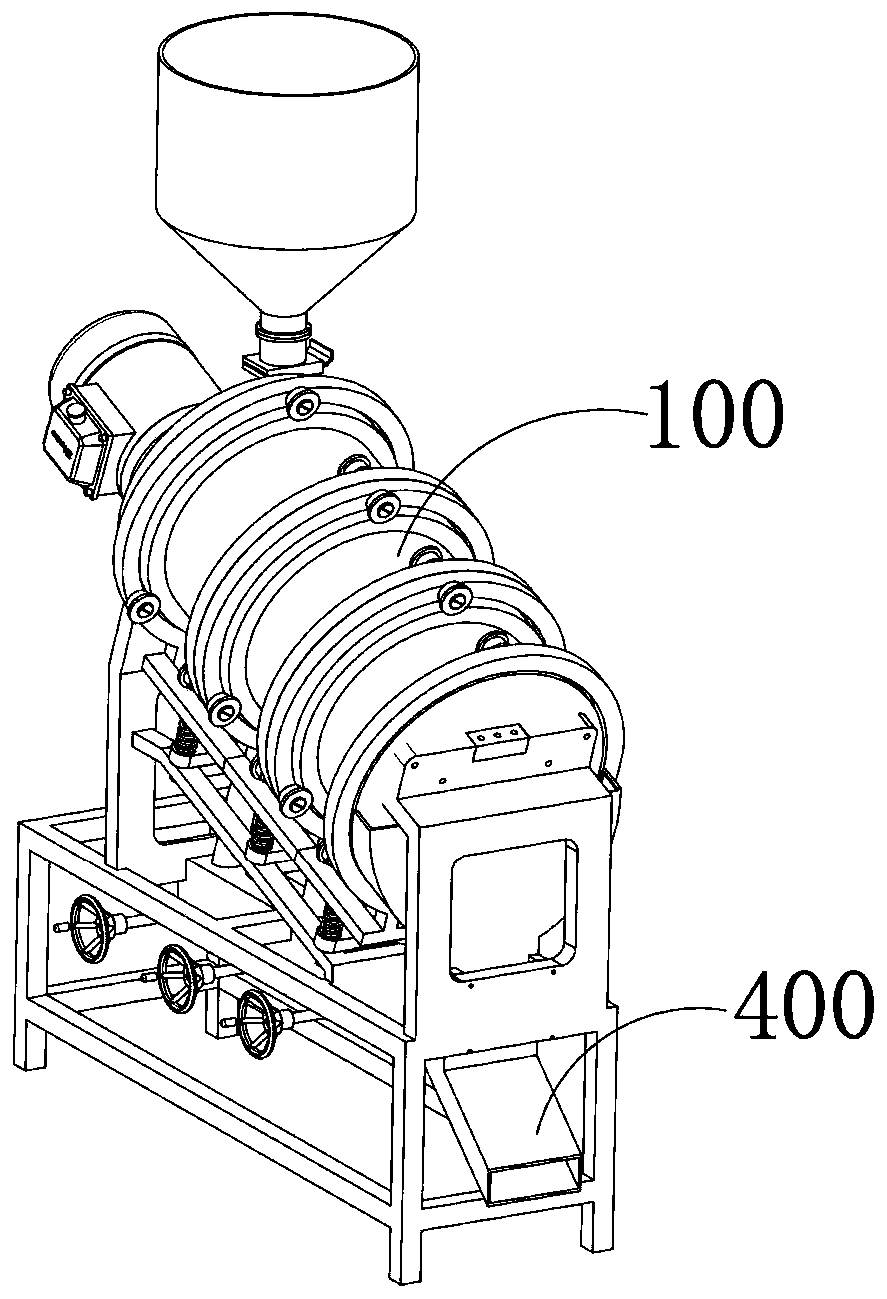

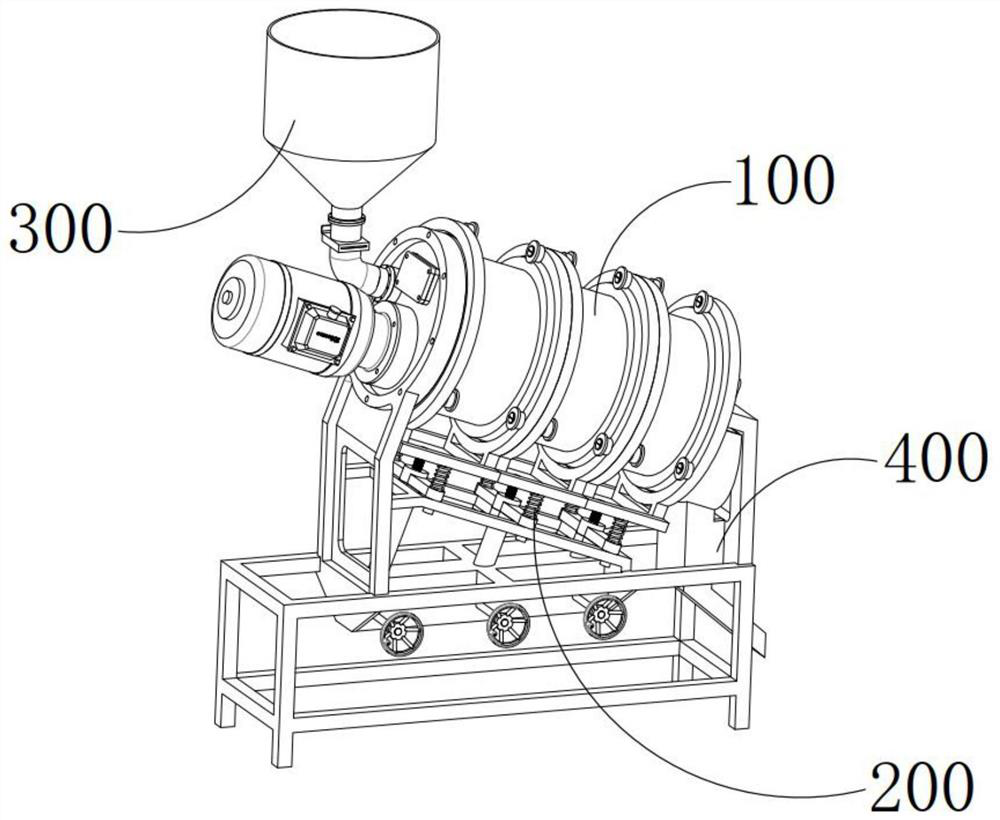

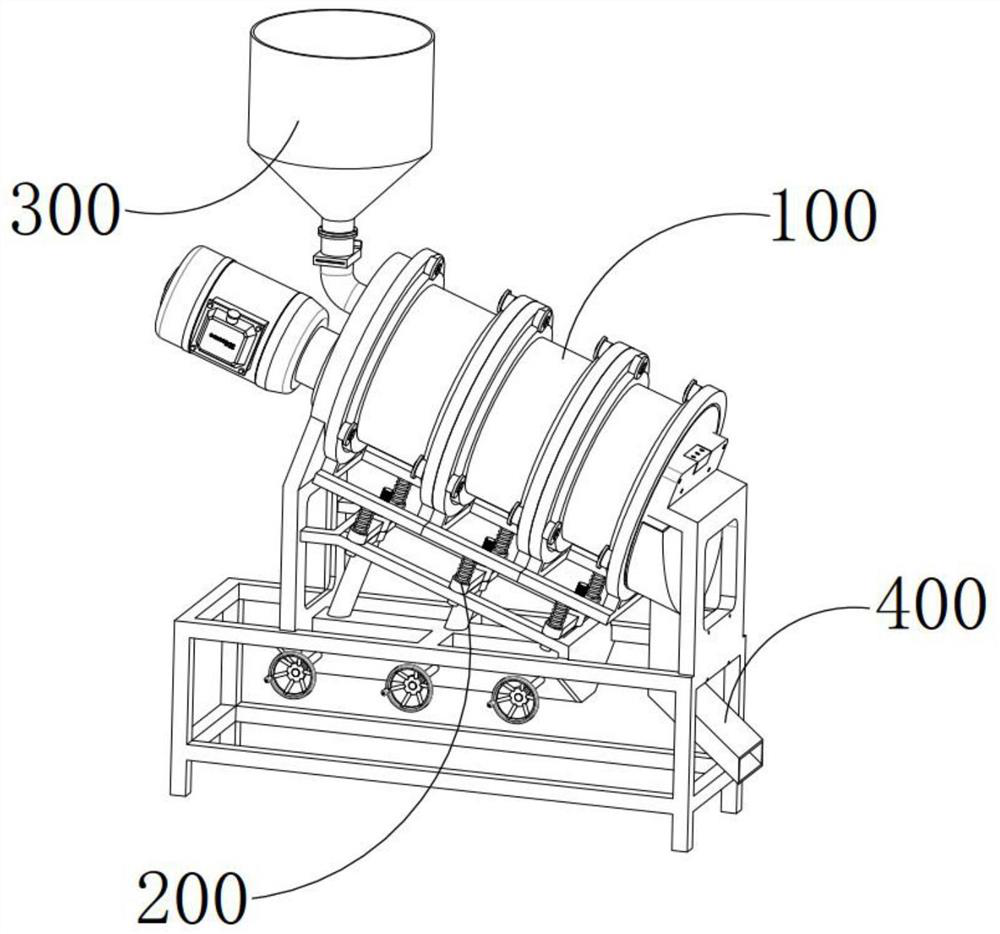

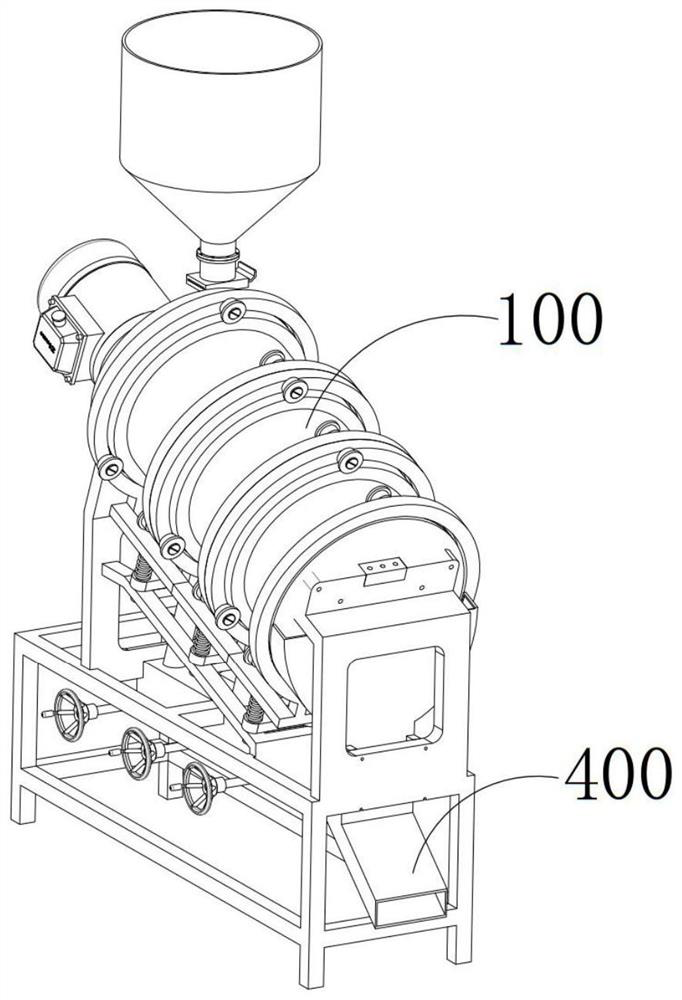

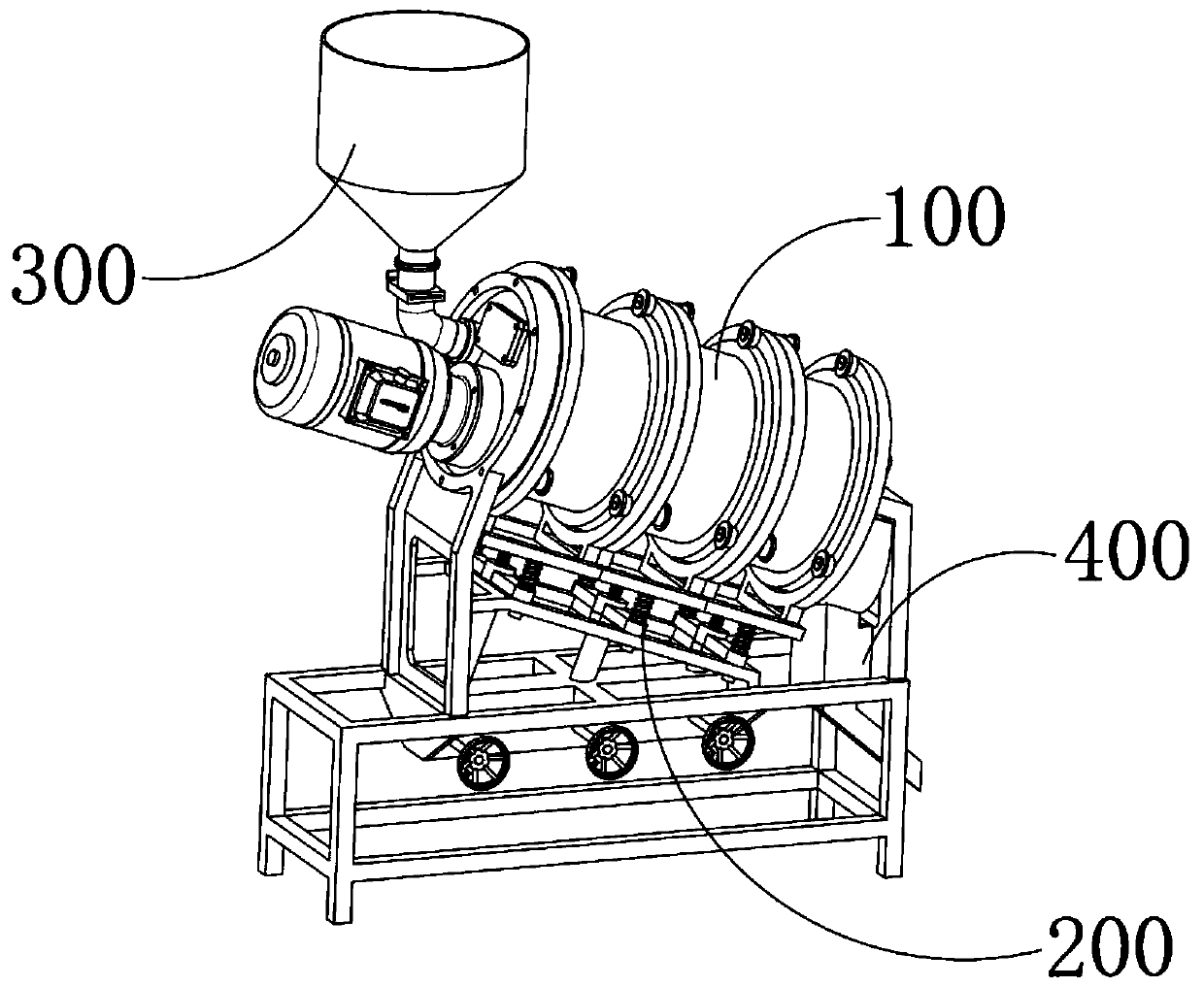

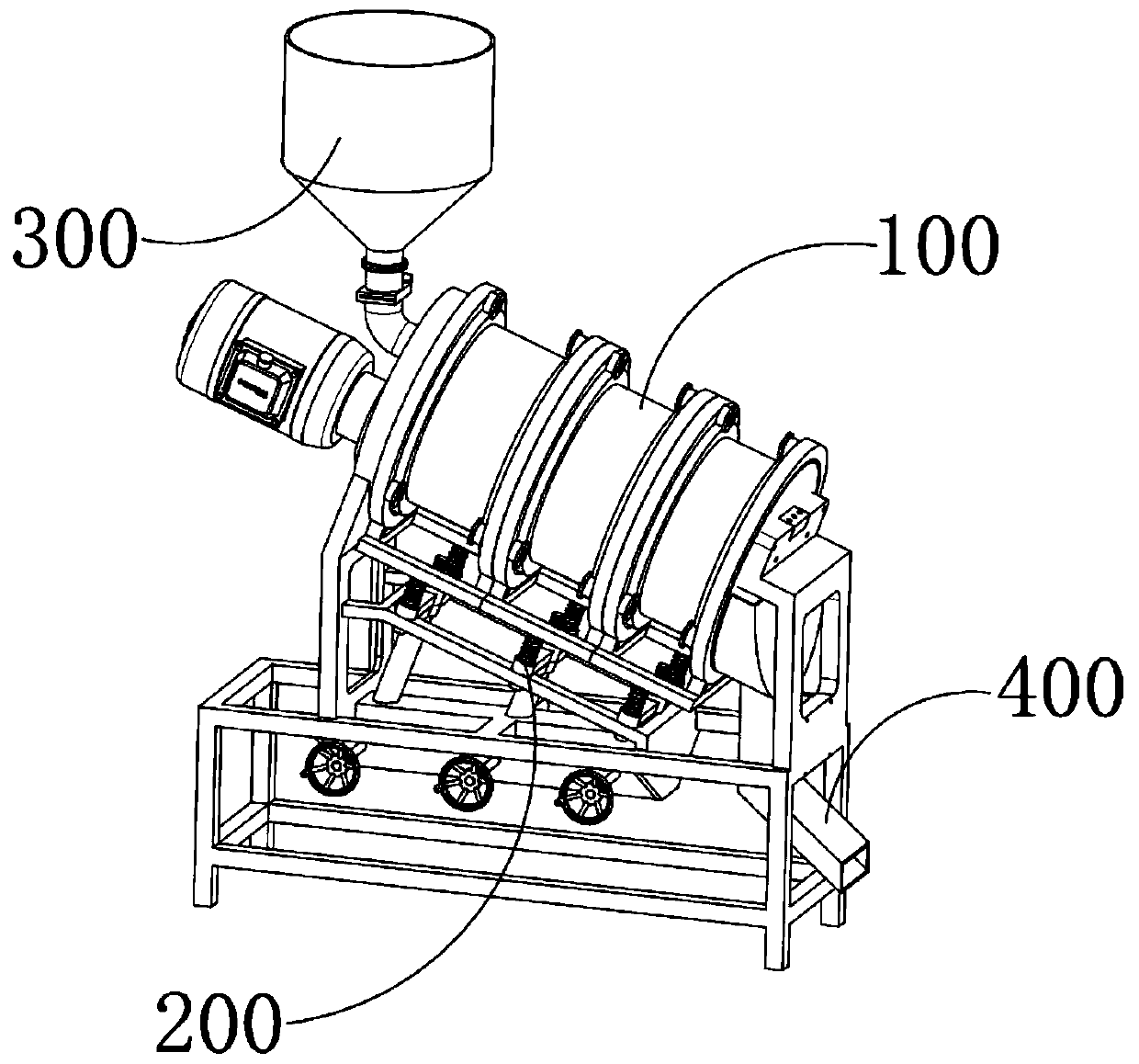

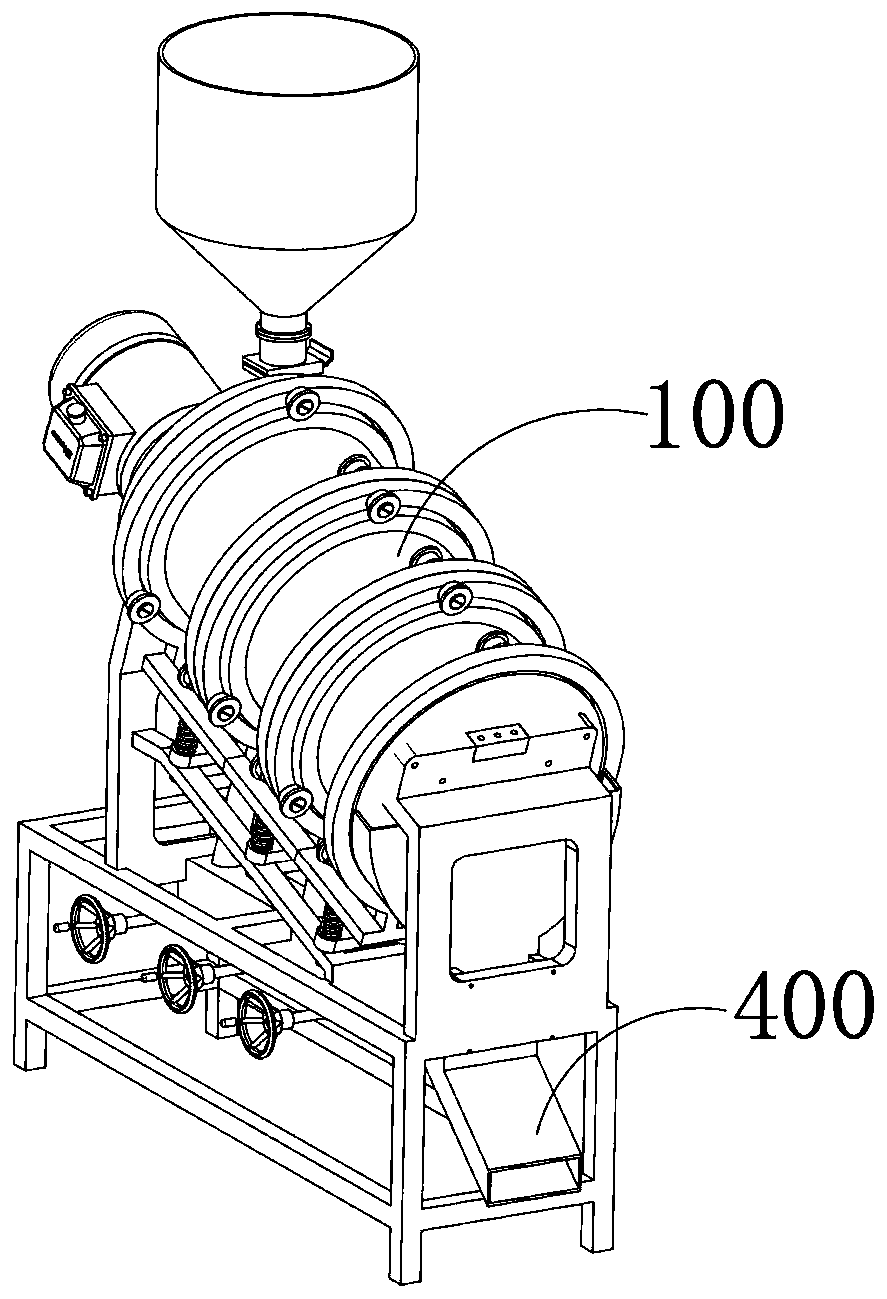

Multi-stage rolling rice milling process

ActiveCN110711627BAdjust granularityImprove grinding efficiencyGrain treatmentsAgricultural engineeringControl theory

The invention provides a multi-stage grinding type rice flour milling process. The multi-stage grinding type rice flour milling process comprises the following steps that firstly, a user adds rice toan outer cylinder I through a funnel; then, a driving member drives a rotating shaft I to rotate, a grinding cylinder I rotates and drives the outer cylinder I to rotate, and the rice located at the combined part of the grinding cylinder I and the outer cylinder I is subjected to grind and coarse grinding processing; a conveying channel conveys the coarse ground rice flour into an outer cylinder II from the outer cylinder I, a rotating shaft I drives a rotating shaft II to rotate, the grinding cylinder II rotates to drive the outer cylinder II to rotate, and the rice flour located at the combined part of the grinding cylinder II and the outer cylinder II is subjected to grind and fine grinding processing; the fine ground rice flour is conveyed into an outer cylinder III from the outer cylinder II through a transmission channel, the rotating shaft II drives a rotating shaft III to rotate, a grinding cylinder III rotates and drives the outer cylinder III to rotate, and the rice flour located at the combined part of the grinding cylinder III and the outer cylinder III is subjected to grind and fine grinding; and finally, the fine ground rice flour is discharged out of the outer cylinder III through a discharging part, and the rice flour enters a discharging channel through a hopper, and guided and output into a collecting vessel through the discharging channel.

Owner:黑龙江省建三江农垦宝丰米业有限责任公司

Multi-stage grinding type rice flour milling process

ActiveCN110711627AAdjust granularityImprove grinding efficiencyGrain treatmentsRice flourMechanical engineering

The invention provides a multi-stage grinding type rice flour milling process. The multi-stage grinding type rice flour milling process comprises the following steps that firstly, a user adds rice toan outer cylinder I through a funnel; then, a driving member drives a rotating shaft I to rotate, a grinding cylinder I rotates and drives the outer cylinder I to rotate, and the rice located at the combined part of the grinding cylinder I and the outer cylinder I is subjected to grind and coarse grinding processing; a conveying channel conveys the coarse ground rice flour into an outer cylinder II from the outer cylinder I, a rotating shaft I drives a rotating shaft II to rotate, the grinding cylinder II rotates to drive the outer cylinder II to rotate, and the rice flour located at the combined part of the grinding cylinder II and the outer cylinder II is subjected to grind and fine grinding processing; the fine ground rice flour is conveyed into an outer cylinder III from the outer cylinder II through a transmission channel, the rotating shaft II drives a rotating shaft III to rotate, a grinding cylinder III rotates and drives the outer cylinder III to rotate, and the rice flour located at the combined part of the grinding cylinder III and the outer cylinder III is subjected to grind and fine grinding; and finally, the fine ground rice flour is discharged out of the outer cylinder III through a discharging part, and the rice flour enters a discharging channel through a hopper, and guided and output into a collecting vessel through the discharging channel.

Owner:黑龙江省建三江农垦宝丰米业有限责任公司

Preparation for anhydrous magnesium chloride powder

The invention provides a method for the production and a device of anhydrous magnesium chloride powder, the magnesium chloride is melted at a temperature above the melting point of the magnesium chloride, the fused mass of the magnesium chloride is sprayed out by an inert gas and the fusing liquid of the magnesium chloride is atomized by the dry compressed air, and the anhydrous magnesium chloridepowder is obtained through condensation. The device comprises a melting furnace, a crucible, a feeding fused mass pipeline, a nozzle, a compressor and a collecting bin; and the method includes following steps of: (1) putting the magnesium chloride into the furnace, (2) melting the magnesium chloride, (3) high-frequency heating to the magnesium chloride feeding pipeline and the nozzle, (4) atomization, and (5) collection and packaging. The atomization of the invention adopts the dried high pressure compressed air to impact the liquid jets of the molten magnesium chloride strongly so as to reach the atomization effect, and the process and operation are simple and convenient, thereby obtaining relative pure anhydrous magnesium chloride powder; the atomized products are spherical and the particle-size distribution is even; and the particle sizes of the products can be adjusted flexibly according to the demands of customers.

Owner:ZUNYI TITANIUM +1

Charcoal supply combustion device capable of refining coal

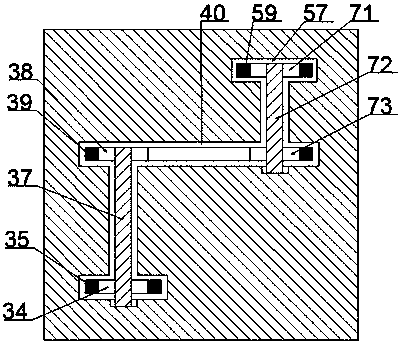

InactiveCN111043588ABurn fullyAdjust granularitySolid fuel combustionLump/pulverulent fuel preparationThermodynamicsCombustion

The invention relates to the field of fuel supply and particularly relates to a charcoal supply combustion device capable of refining coal. The device comprises a machine body, wherein a first workingcavity is formed in the machine body, an eccentric disc is arranged in the first working cavity, a first pin is fixedly arranged on the eccentric disc, a connecting rod is rotatably arranged on the first pin, a moving rod is rotatably arranged on the right side of the connecting rod, and a moving plate is fixedly arranged on the right side of the moving rod. The device is advantaged in that the coal can be automatically supplied to combustion equipment, the coal can be processed to be refined, the refining degree of the coal can be adjusted, the refined coal can be combusted more sufficientlywithin a short time, and thereby heat intensity supplied by the coal within the short time is adjusted.

Owner:宁波械色自动化技术有限公司

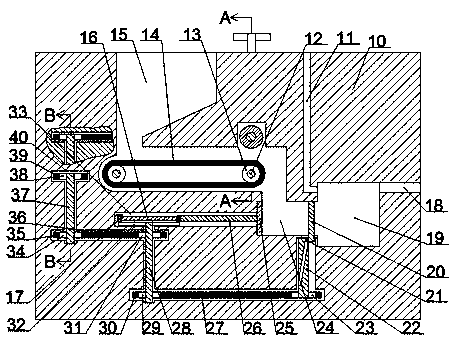

Roller crushing mechanism for rice milling

ActiveCN110614146BAdjust granularityImprove grinding efficiencyGrain treatmentsAgricultural engineeringStructural engineering

The present invention provides a rolling crushing mechanism for rice flour, which includes a primary rolling mechanism ( 110), the two-stage rolling mechanism (120) for finely grinding rice between the first partition (107) and the second partition (108), the second partition (108) and the second fixed board (108) 105) between the three-stage rolling mechanism (130) for finely grinding rice, the primary rolling mechanism (110), the secondary rolling mechanism (120) and the third-stage rolling mechanism (130) are all It includes an outer cylinder arranged obliquely in the axial direction and a rolling cylinder sleeved in the outer cylinder, and the rolling cylinder is located at the eccentric position of the outer cylinder, the axis line of the rolling cylinder is located directly below the axis line of the outer cylinder and the rolling cylinder The outer cylindrical surface of the cylinder is in conflict with the inner cylindrical surface of the outer cylinder, and the rotation of the rolling cylinder drives the rotation of the outer cylinder to crush and crush the rice located in the conflicting part of the two.

Owner:永州上域农业科技发展有限公司

Rolling and crushing mechanism for rice milling

ActiveCN110614146AAdjust granularityImprove grinding efficiencyGrain treatmentsThree stageEngineering

The invention provides a rolling and crushing mechanism for rice milling, and the rolling and crushing mechanism comprises a one-stage rolling mechanism (110) located between a fixed plate I (104) anda partition plate I (107) for performing rough grinding to the rice, a two-stage rolling mechanism (120) located between the partition plate I (107) and a partition plate II (108) for performing finegrinding to the rice, and a three-stage rolling mechanism (130) located between the partition plate II (108) and a fixed plate II (105) for performing accurate grinding to the rice; the one-stage rolling mechanism (110), the two-stage rolling mechanism (120) and the three-stage rolling mechanism (130) comprise outer cylinders arranged axially and obliquely and rolling cylinders sleeved in the outer cylinders, and the rolling cylinders are located at eccentric positions of the outer cylinders; the axial leads of the rolling cylinders are directly below the axial leads of the outer cylinders and the outer circular surfaces of the rolling cylinders are in conflict with the inner circular surfaces of the outer cylinders, and the rotation of the rolling cylinders drive the outer cylinders to rotate so that the rice located at the conflict part of the rolling cylinders and the outer cylinders is rolled and crushed.

Owner:永州上域农业科技发展有限公司

Heavy water reactor fuel canning graphite emulsion paint and preparation method thereof

ActiveCN102558986BAdjust granularityAdjust the particle size ratioEpoxy resin coatingsEmulsionWear resistant

The invention discloses a heavy water reactor fuel canning graphite emulsion paint and a preparation method thereof, and belongs to the technical field of preparation of paints. The paint consists of the following components in percentage by weight: 10-25 percent of graphite powder, 3-20 percent of low-temperature film former, 0.1-3 percent of dispersant, 0.1-2 percent of film forming auxiliary agent and 50-80 percent of mixed solvent. The graphite emulsion paint has the advantages of stable chemical property, uniform dispersion, no bubbling in coating, smooth coating and superior operability; and the coating calcined according to the construction requirements is compact and has high adhesion, superior wear-resistant performance and good lubrication.

Owner:TSINGHUA UNIV

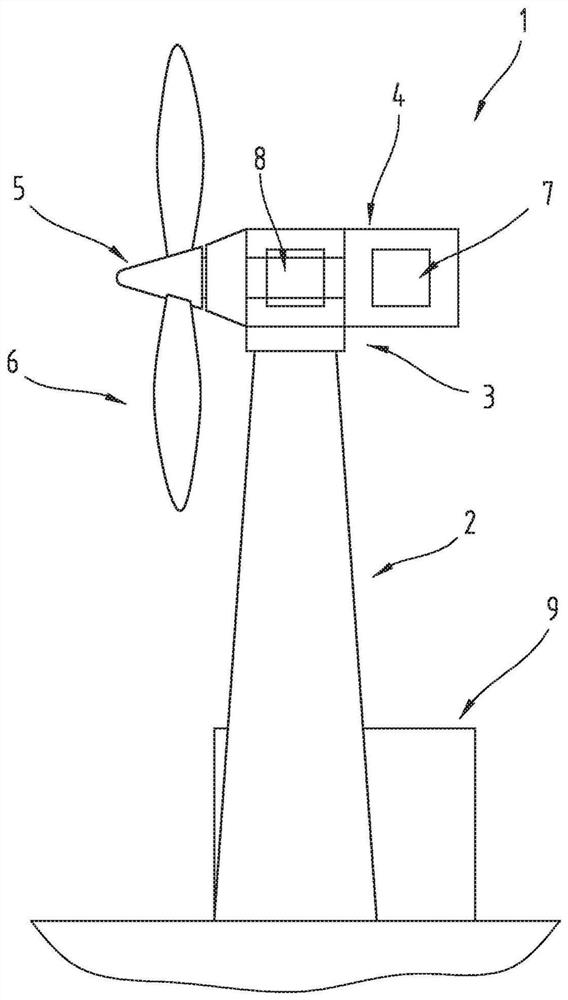

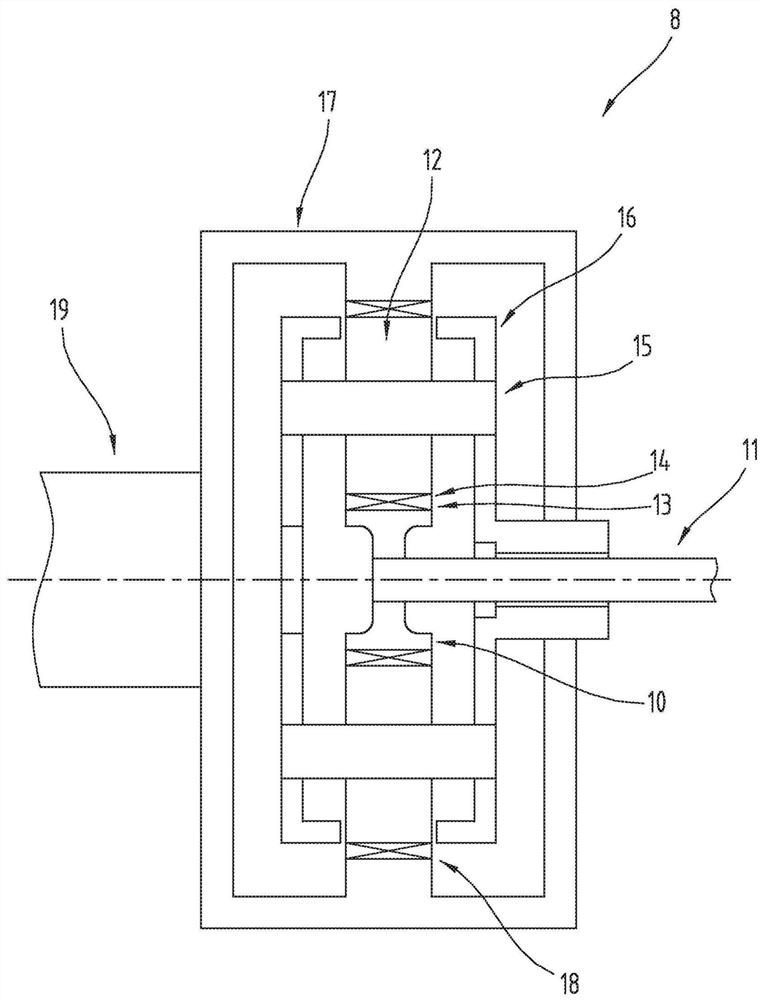

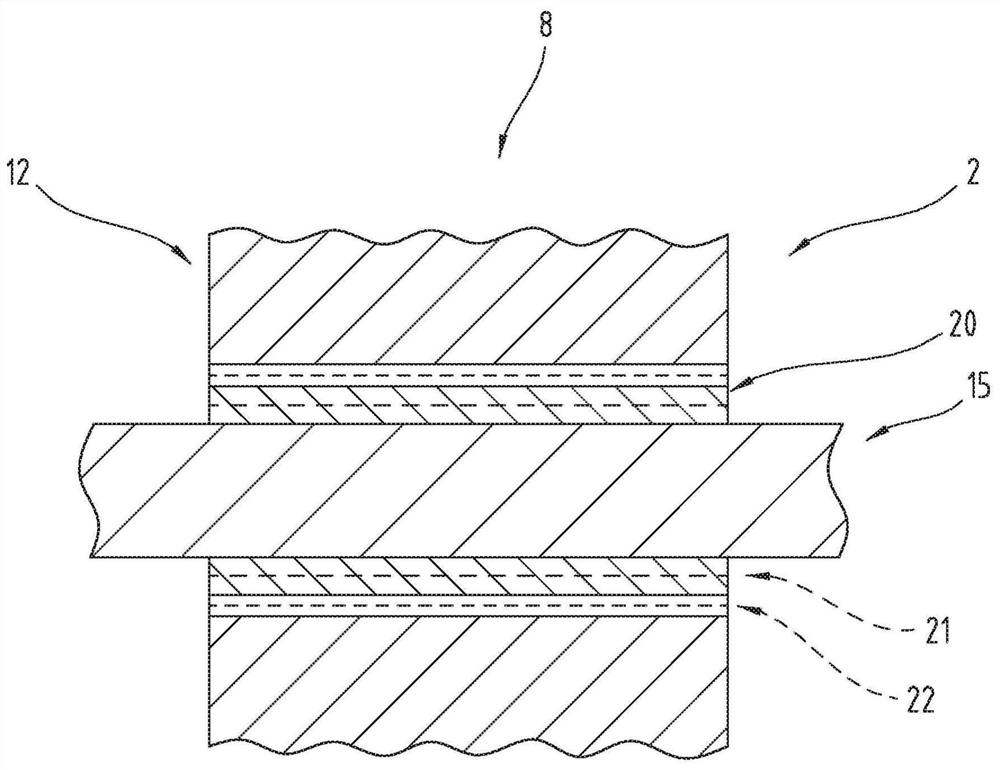

wind power equipment

ActiveCN110678648BAvoid position lossAvoid lostMolten spray coatingEngine fuctionsLine tubingGear wheel

Owner:MIBA SINTER AUSTRIA

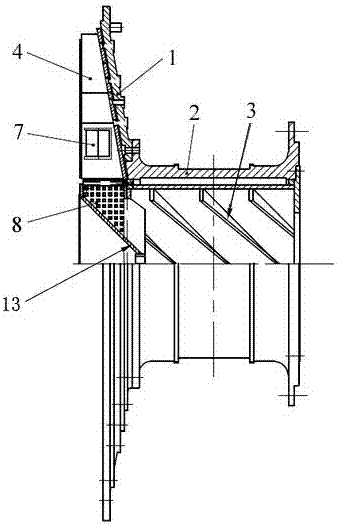

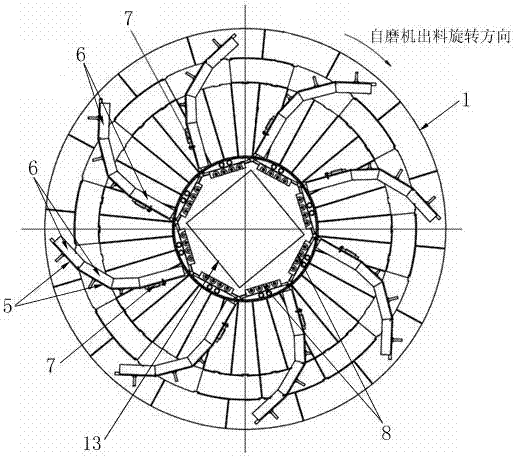

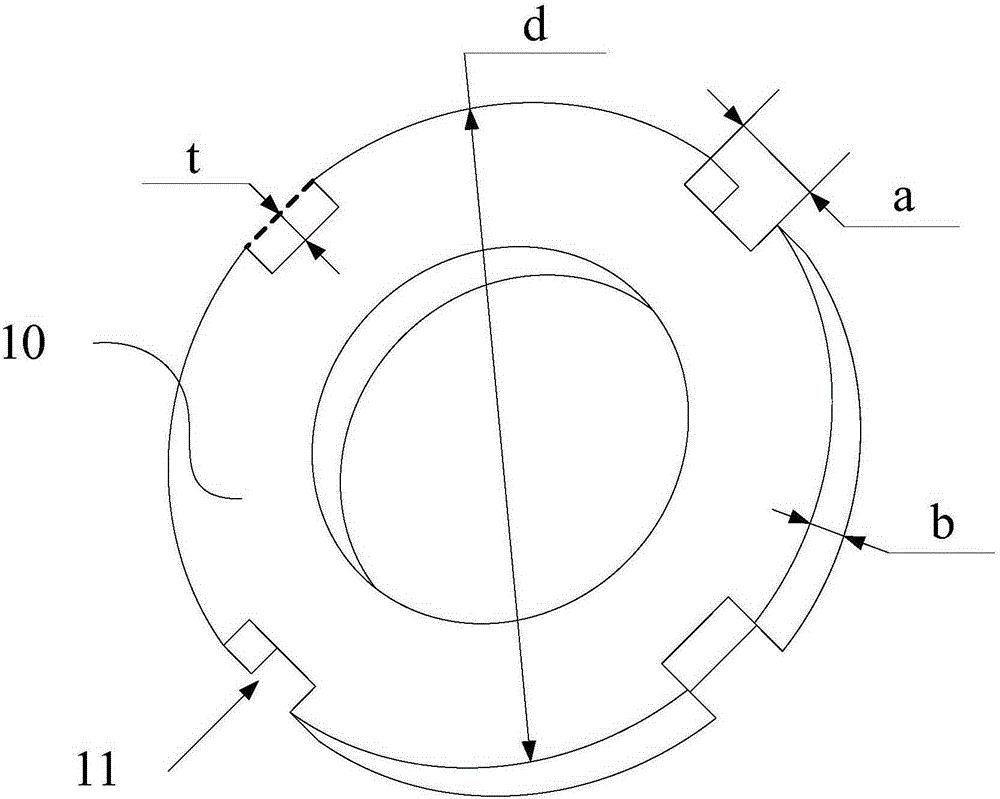

Forced adjustable discharge device used for autogenous mill

The invention discloses a forced adjustable discharge device used for an autogenous mill. The forced adjustable discharge device is arranged on the inner wall of an end cover at the discharge end of a cylinder of the autogenous mill. A discharge hollow shaft is arranged at the center of the end cover, a plurality of forced discharge blades are arranged on the inner wall of the end cover, rotate in the same direction and are distributed in the circumferential direction of the discharge hollow shaft, and the rotating directions of the forced discharge blades are set into a manner that when the cylinder of the autogenous mill rotates to discharge materials, the forced discharge blades discharge the materials to the discharge hollow shaft. The forced discharge blades are provided with adjusting windows, the head ends of the forced discharge blades are close to the outer edge of the end cover, the tail ends of the forced discharge blades are connected with a grid sieve plate, the materials smaller than sieve holes in the grid sieve plate pass through the sieve holes and fall into the discharge hollow shaft through a guide cone which is arranged in the discharge hollow shaft, and spiral blades which are arranged on the inner wall of the discharge hollow shaft discharge the materials out of the autogenous mill. According to the forced adjustable discharge device, by means of the cooperation of the sizes of the adjusting windows in the forced discharge blades and the sizes of the sieve holes in the grid sieve plate, the adjustment of product particle sizes and the optimization of the comminution working condition of the autogenous mill are achieved.

Owner:洛阳宇航重工科技股份有限公司

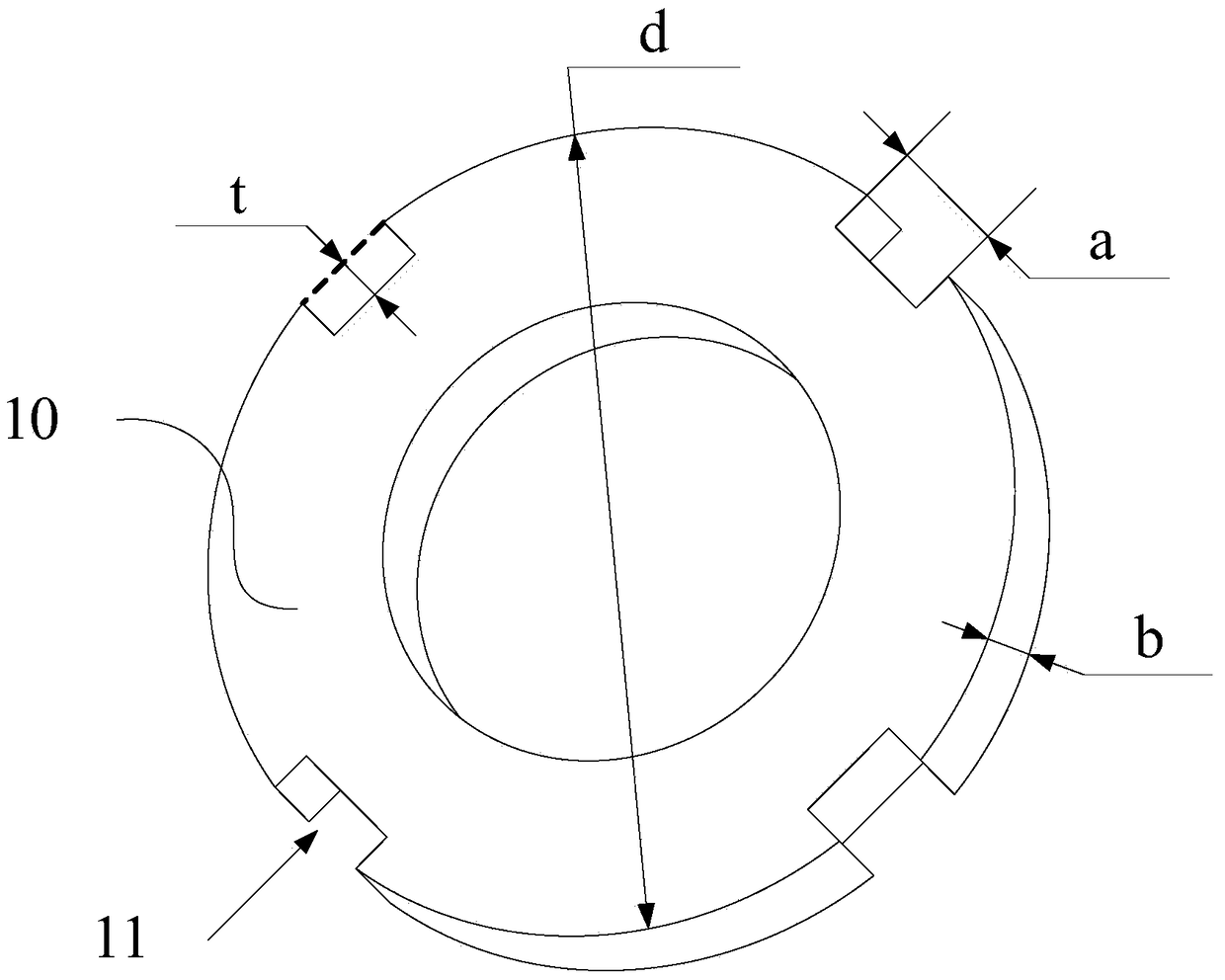

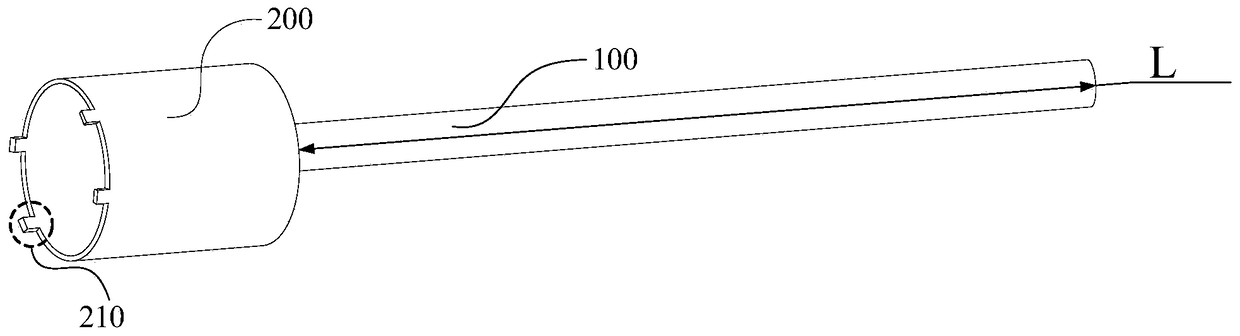

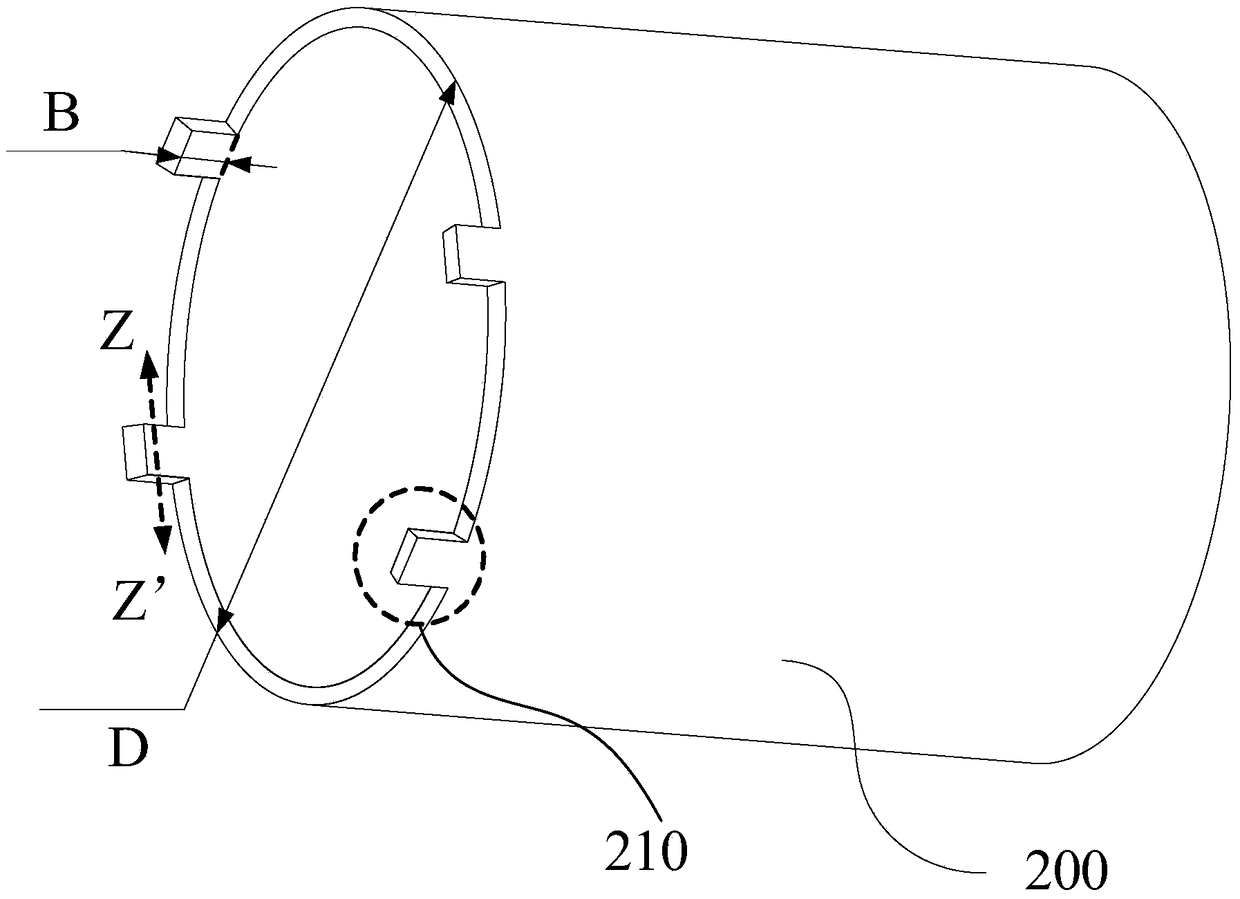

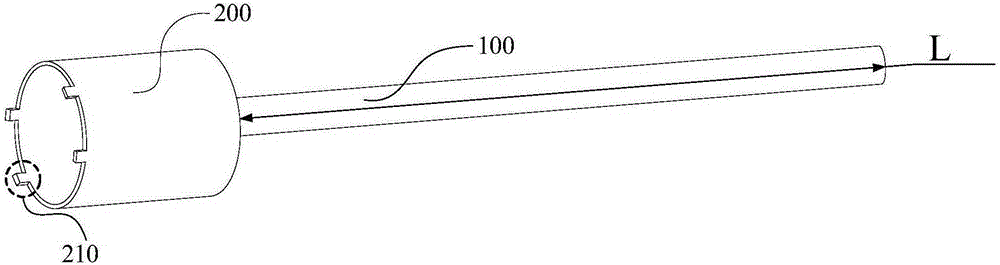

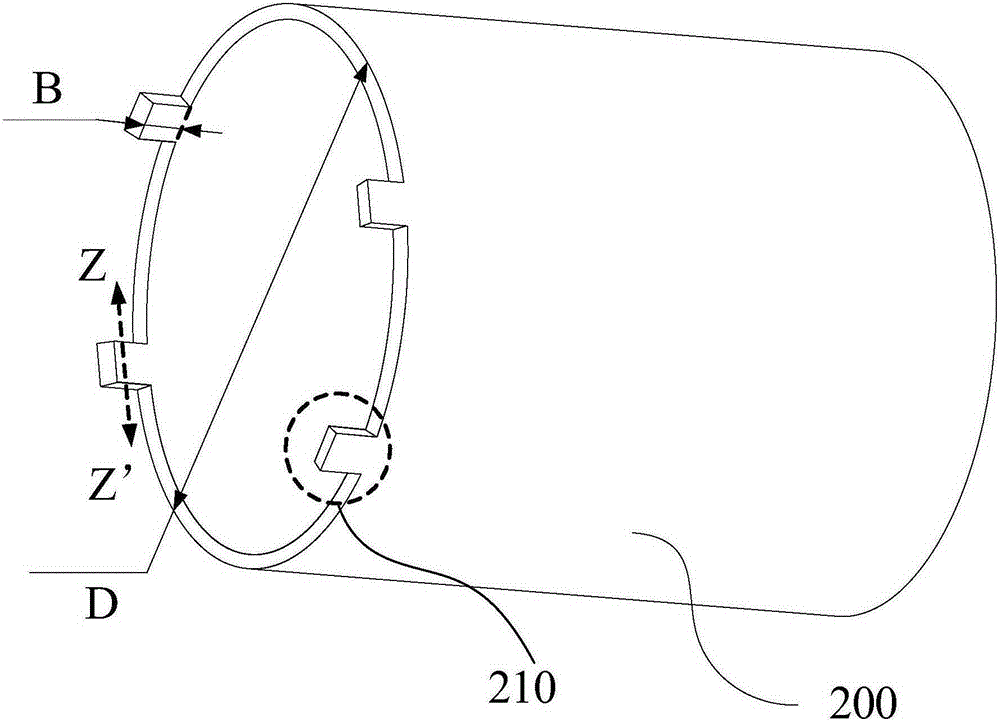

Auxiliary tools for particle size adjustment devices and particle size adjustment systems

The invention provides an auxiliary tool for a granularity adjustment device and a granularity adjustment system, wherein the auxiliary tool comprises a handle used for implementing handheld rotation and a fixing unit connected with one end of the handle, the fixing unit is used for buckled connection with a neck of a control structure, so that the control structure is driven to rotate when the handle rotates. The handle used for implementing handheld rotation drives the fixing unit connected with the handle to rotate, the fixing unit and the control structure are connected in a buckled manner, and the control structure also rotates together when the fixing unit rotates. Therefore, when the granularity needs to be adjusted, a bulk material bin is not dismantled, the handheld handle rotates directly to drive the fixing unit in buckled connection with the control structure to rotate, so that the control structure rotates to adjust the granularity, the operation mode of granularity adjustment is simplified, the labor intensity is reduced, and the labor efficiency is improved.

Owner:宁波创润新材料有限公司

A kind of purification method of ammonium metavanadate deep silicon removal

ActiveCN106044853BIncrease productivitySimple methodVanadium compoundsPurification methodsWastewater

The invention discloses a purification method for deep desiliconization of ammonium metavanadate. 7-9, (5) filtration to obtain ammonium metavanadate. The method of the invention does not use flake caustic soda, does not generate waste water, and the obtained products are high-purity ammonium metavanadate and ammonium sulfate solutions, which can be recycled.

Owner:DALIAN RONGKE ENERGY STORAGE GRP CO LTD

Auxiliary tool for granularity adjustment device and granularity adjustment system

The invention provides an auxiliary tool for a granularity adjustment device and a granularity adjustment system, wherein the auxiliary tool comprises a handle used for implementing handheld rotation and a fixing unit connected with one end of the handle, the fixing unit is used for buckled connection with a neck of a control structure, so that the control structure is driven to rotate when the handle rotates. The handle used for implementing handheld rotation drives the fixing unit connected with the handle to rotate, the fixing unit and the control structure are connected in a buckled manner, and the control structure also rotates together when the fixing unit rotates. Therefore, when the granularity needs to be adjusted, a bulk material bin is not dismantled, the handheld handle rotates directly to drive the fixing unit in buckled connection with the control structure to rotate, so that the control structure rotates to adjust the granularity, the operation mode of granularity adjustment is simplified, the labor intensity is reduced, and the labor efficiency is improved.

Owner:宁波创润新材料有限公司

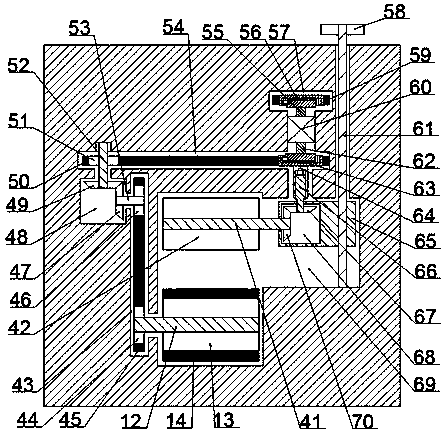

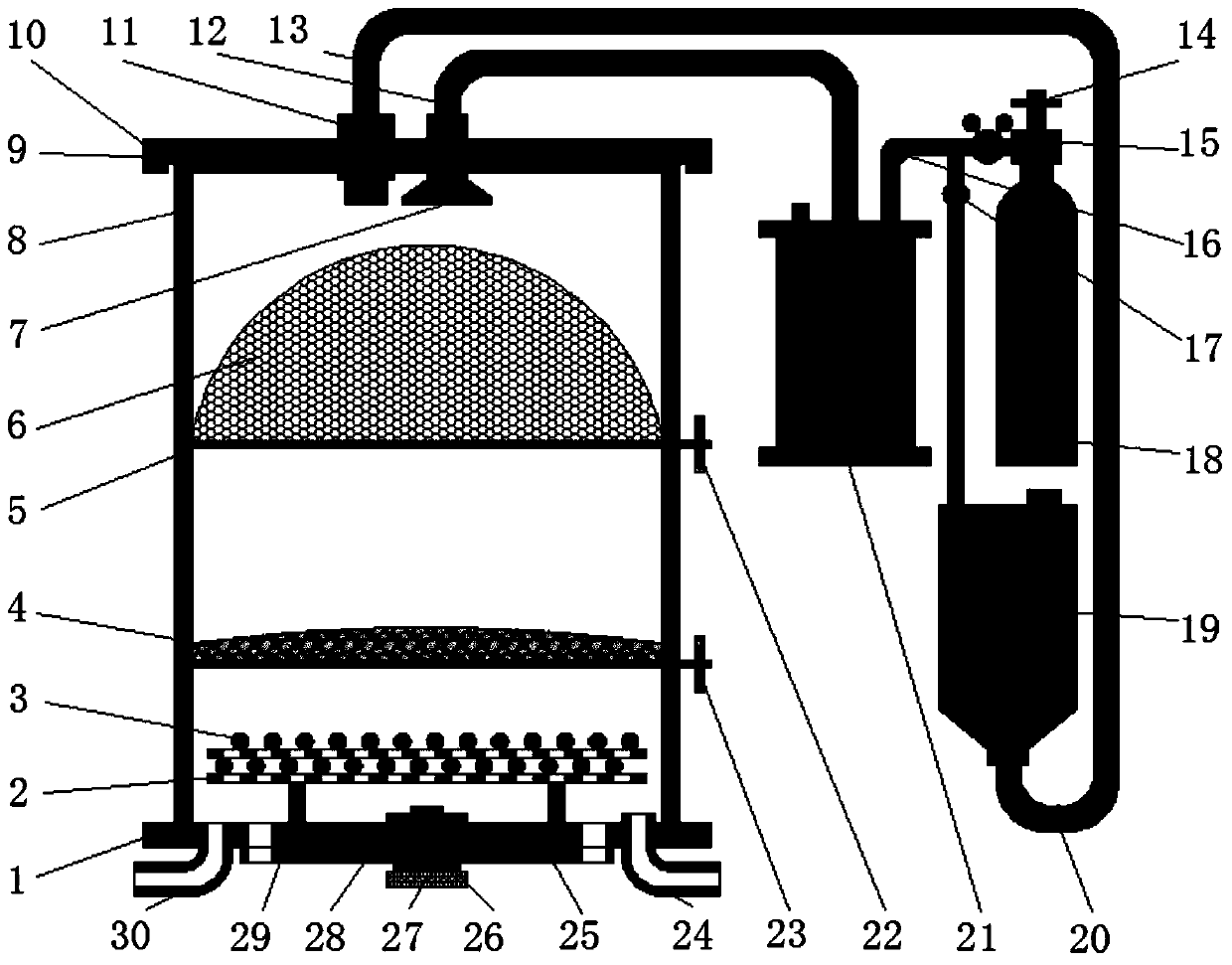

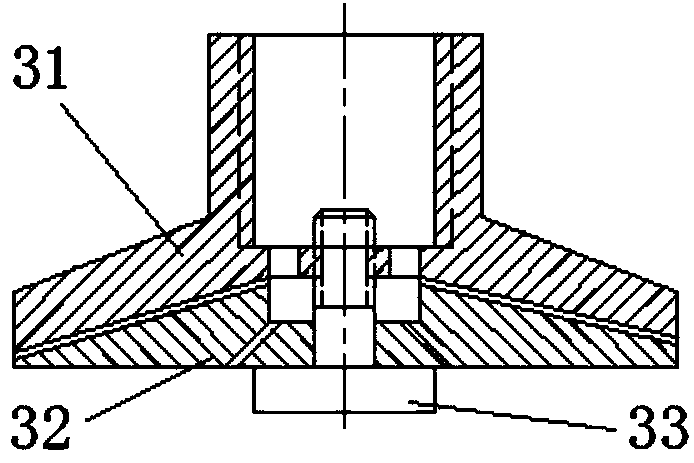

A liquid nitrogen spray freeze granulation vacuum drying device and working method

ActiveCN106268503BIncreased sublimation surface areaEnough to migrateGranulation by liquid drop formationSpray GranulationParticulates

The invention discloses a liquid nitrogen spray frozen granulation vacuum drying device and a working method. The device solves the problem that in the biotechnology field, when liquid materials are frozen and dried directly, due to the fact that the water sublimation surface is small and air current channels among particles are not smooth, the speed is low, and the efficiency is low. The device sprays the liquid materials into continuously sprayed ultralow-temperature liquid nitrogen mist through nitrogen pressure, material liquid drops are rapidly frozen to be amorphous spherical particles, the amorphous particles are in a non-balanced high-energy state, and drying is easy. Particle materials made through co-spray are stacked on screens which can be folded in a spray chamber and have a heating function, and the larger sublimation surface of the particle materials and through moisture migration and overflowing channels formed by particle voids and the porous screens are beneficial for rapid drying of the materials. In addition, when co-spray granulation is conducted, low-temperature nitrogen flow flows through made material particles and condenser pipes from top to bottom, and the material particles can keep low temperature and fully utilize residual cool.

Owner:NANJING UNIV OF POSTS & TELECOMM +1

Cefmetazole sodium crystal compound, preparation method thereof and sterile powder for injection containing cefmetazole sodium crystal compound

InactiveCN102659820BImprove stabilityChange shapeAntibacterial agentsPowder deliveryX-rayCEFMETAZOLE SODIUM

The invention relates to a cefmetazole sodium crystal compound, a preparation method thereof and sterile powder for injection containing the crystal compound. The cefmetazole sodium crystal compound is a novel crystal form of cefmetazole sodium. The X-ray powder diffraction of the crystal form measured with a Cu-Kalpha ray shows characteristic peaks when 2theta is 6.8 degrees, 11.4 degrees, 12.0 degrees, 12.6 degrees, 14.8 degrees, 15.8 degrees, 18.0 degrees, 19.4 degrees, 20.1 degrees, 21.7 degrees, 23.4 degrees, 25.6 degrees, 28.0 degrees, 29.0 degrees and 30.6 degrees. The cefmetazole sodium crystal compound provided by the invention has high stability, and is non-hygroscopic basically. The sterile powder for injection has qualified quality and high stability.

Owner:HAINAN HERUI PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com