Patents

Literature

108results about How to "High hydrogenation selectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

C4 selective hydrogenation catalyst and preparation method thereof

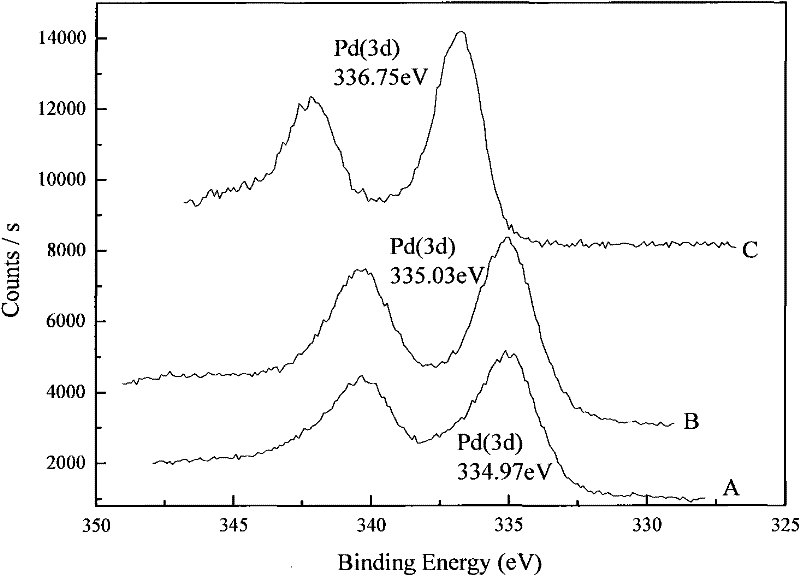

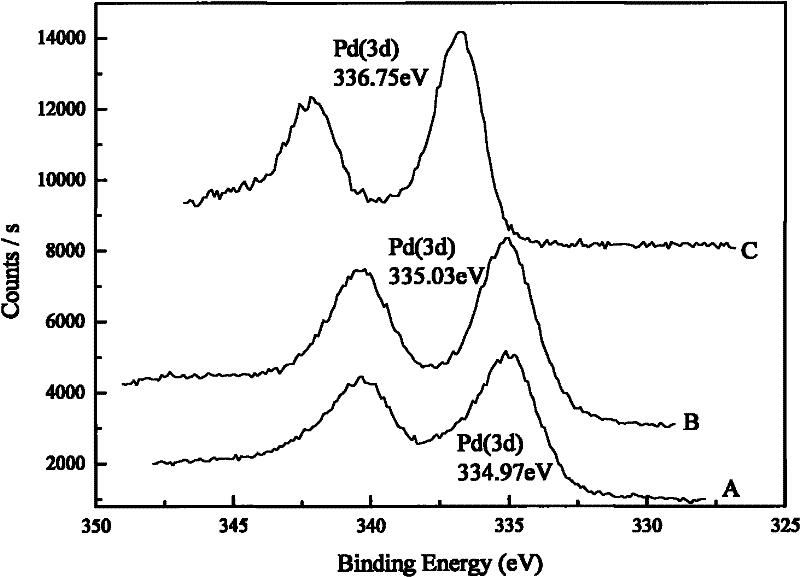

ActiveCN102240547AHigh activityHigh crystallinityHydrocarbon purification/separationCatalyst activation/preparationHydrogenActive component

The invention discloses a C4 selective hydrogenation catalyst and a preparation method and use thereof. The saturated hydrocarbon hydrogenation catalyst is prepared by ionizing radiation reduction of a primary metal active component precursor and a secondary metal active component precursor, which are supported by a carrier, wherein the primary metal active component is Pd monomer; and the average diameters of particles of the primary metal active component and the particles of the secondary metal active component are both smaller than 10 nanometers. The catalyst disclosed by the invention has the advantages of avoiding being reduced by hydrogen in advance, along with high activity and selectivity, direct use and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

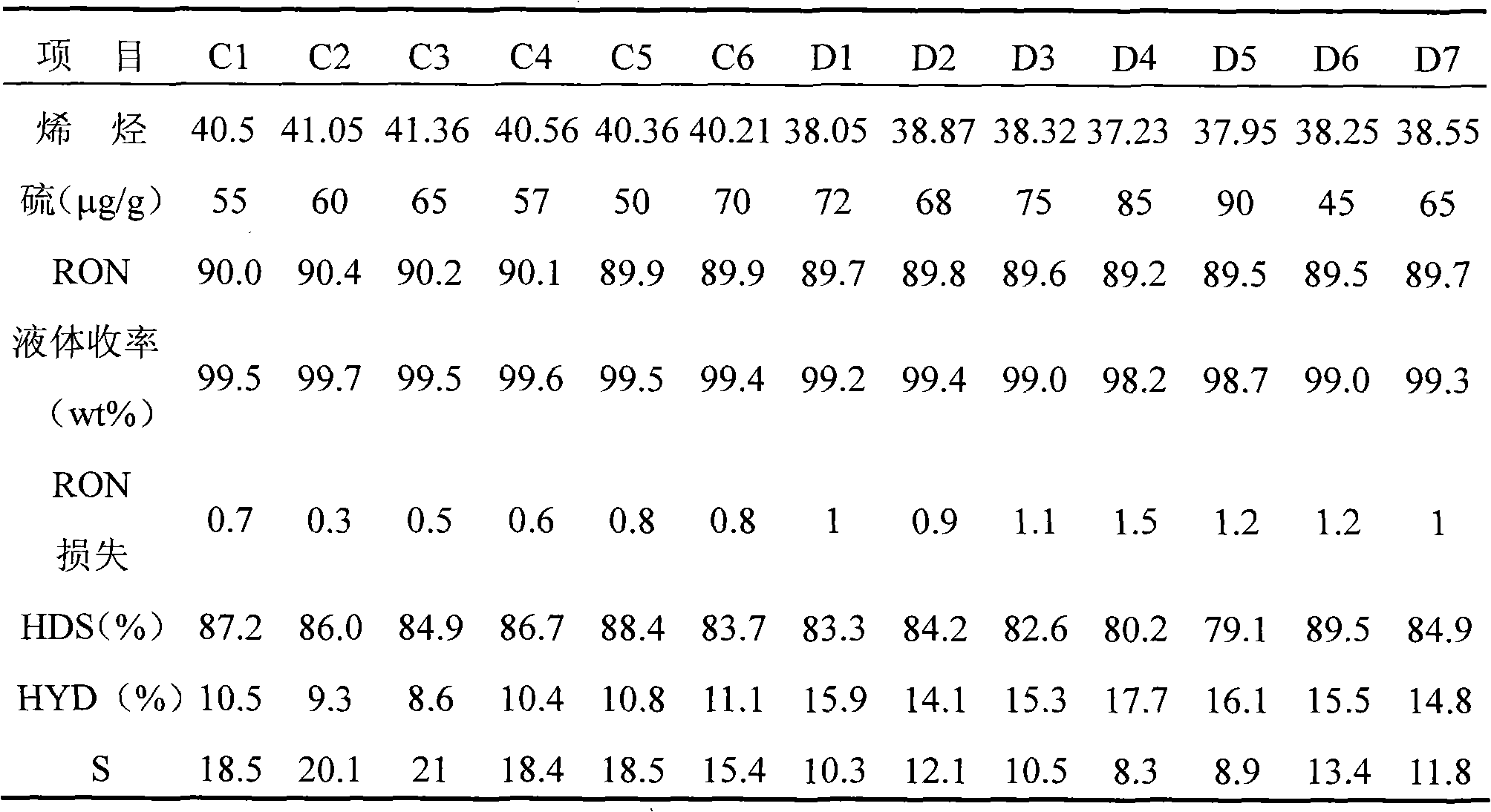

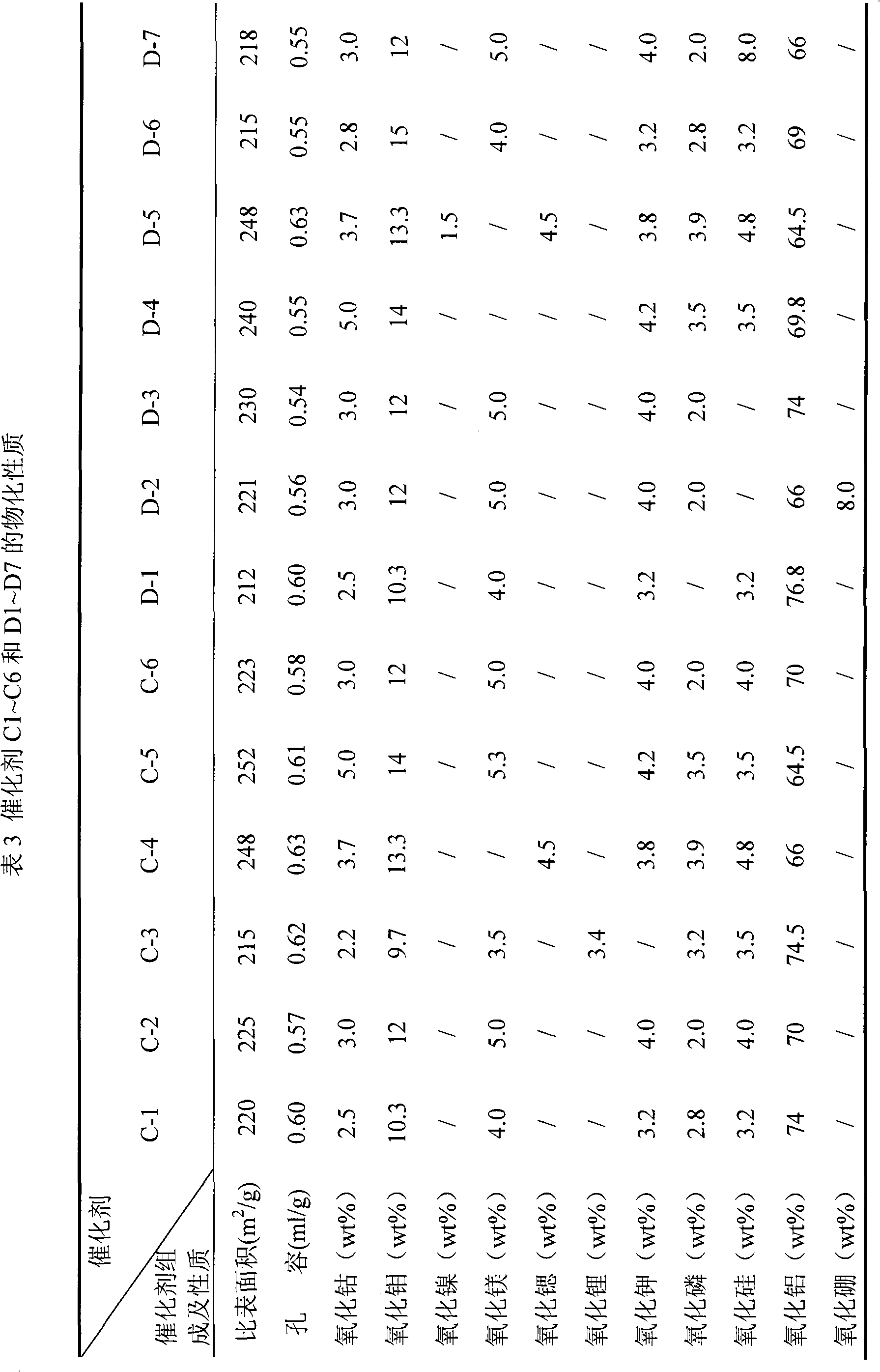

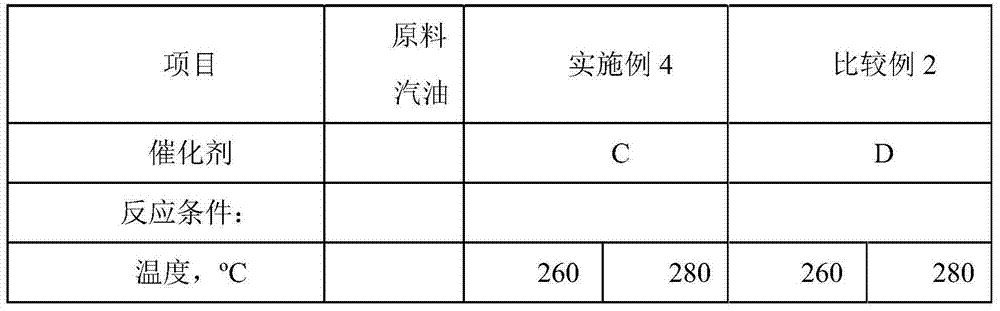

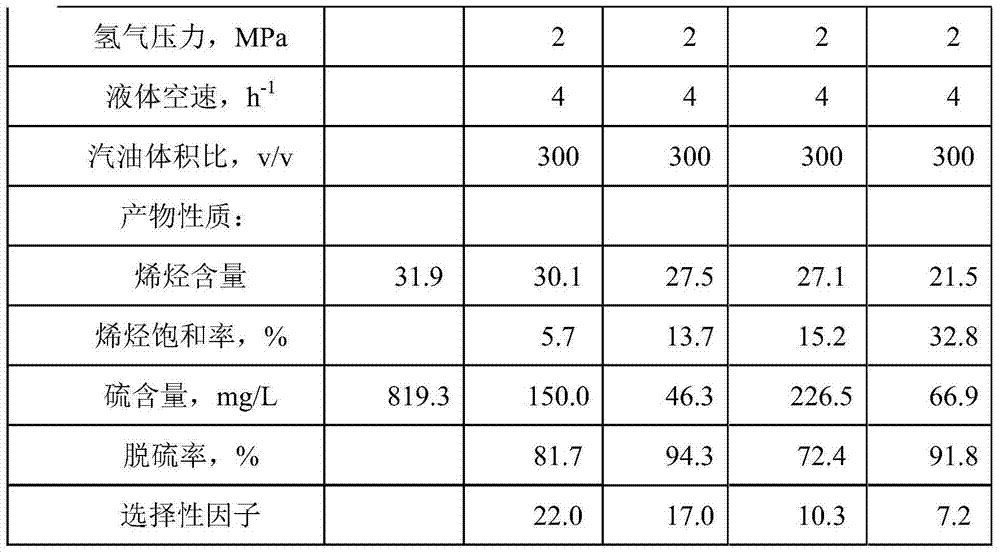

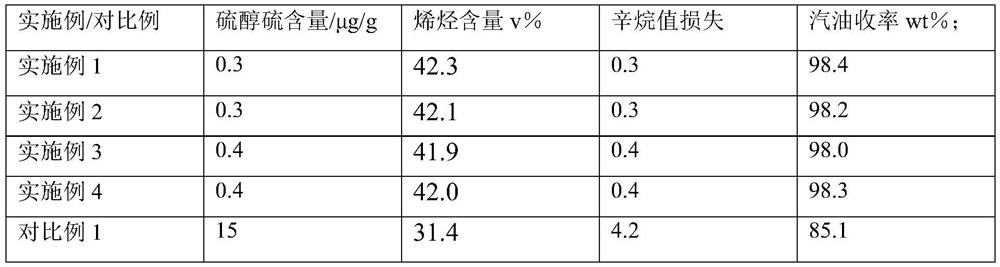

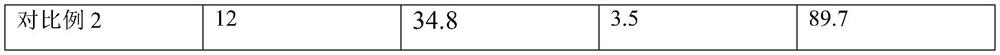

Selective hydrodesulfurization catalyst and preparation method thereof

ActiveCN102335612AReduce acid strengthEnhance the interaction strengthMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAlkaline earth metalHydrodesulfurization

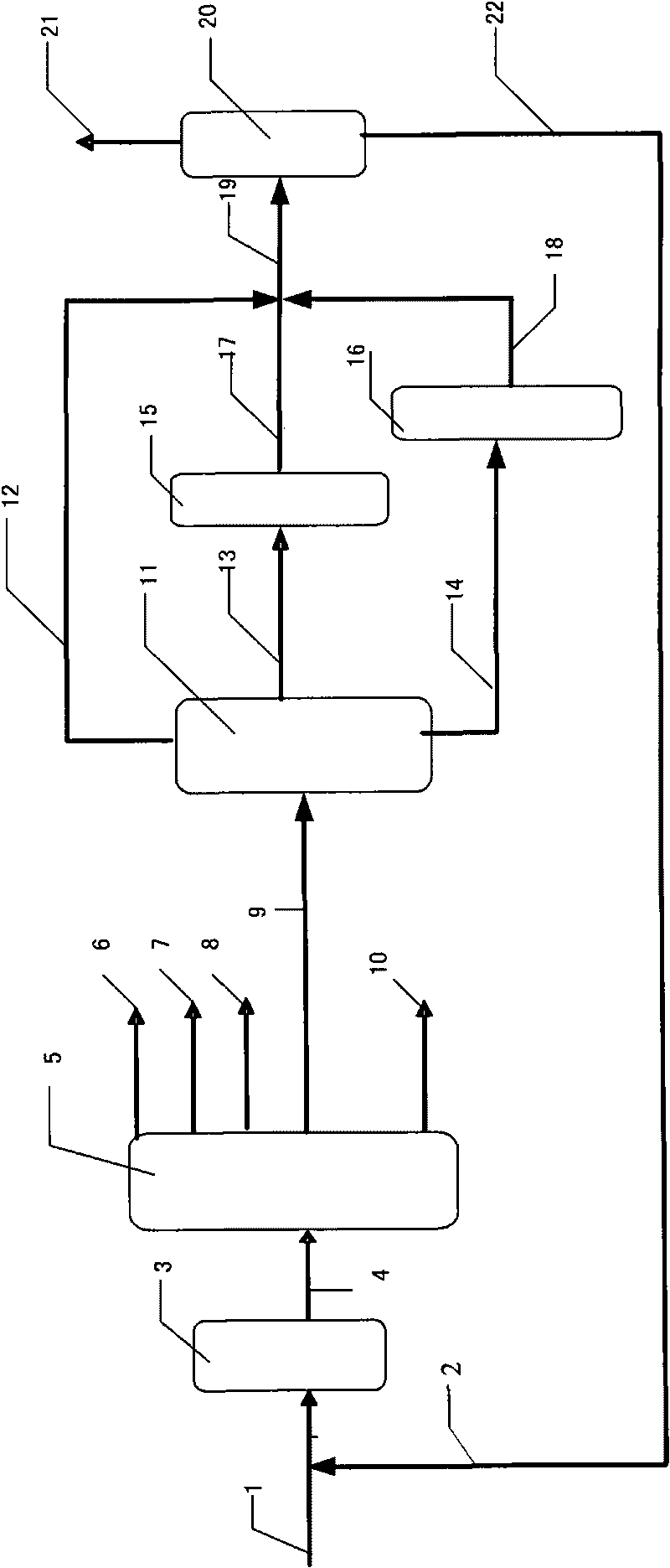

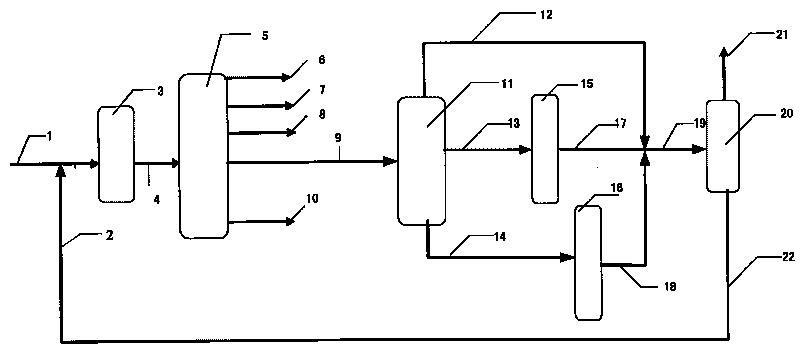

The invention relates to a selective hydrodesulfurization catalyst contains cobalt and molybdenum as active components. The selective hydrodesulfurization catalyst is characterized in that silicon oxide and aluminum oxide are used as carriers of the catalyst; based on the total weight of 100%, the catalyst comprises 2-6wt% of cobalt oxide, 9-15 wt% of molybdenum oxide, 2-8wt% of alkaline earth metal oxide, 2-6wt% of phosphorus oxide, 3-5wt% of alkali metal oxide, 2-6wt% of silicon oxide and 54-80 wt% of aluminum oxide; and the catalyst has the specific surface area of 200-300m<2> / g and the pore volume of 0.5-0.7mL / g. The catalyst has high hydrogenation activity and selectivity, good stability, low research octane number loss and high liquid yield. The catalyst is suitable for selective hydrodesulfrization of low-quality gasoline and is particularly suitable for selective hydrodesulfrization of low-quality FCC (Family Car China) gasoline.

Owner:PETROCHINA CO LTD

Utilization method of catalytic cracking diesel

ActiveCN101760239AHigh aromatic contentBoost octaneTreatment with hydrotreatment processesBoiling pointAromatic hydrocarbon

The invention relates to a utilization method of catalytic cracking diesel, wherein the method comprises the following steps: (1) separating the catalytic cracking diesel into a component with the boiling point being less than 230 DEG C and a component with the boiling point being more than 230 DEG C; (2) hydrogenering for the component with the boiling point being more than 230 DEG C obtained inthe step (1) under the condition that poly-aromatic hydrocarbon is inverted into monocyclic aromatic hydrocarbon; (3) separating the component with the boiling point being less than 230 DEG C obtained in the step (1) and hydrogenation product obtained in the step (2) to obtain diesel rich in the monocyclic aromatic hydrocarbon, and catalytically cracking the diesel rich in the monocyclic aromatichydrocarbon. In the method, firstly, the catalytic cracking diesel is separated into the component with the boiling point being less than 230 DEG C and the component with the boiling point being morethan 230 DEG C, and then the poly-aromatic hydrocarbon in the component with the boiling point being more than 230 DEG C can be hydro-fined into the monocyclic aromatic hydrocarbon, therefore, the hydrogenation selectivity can be improved, and the FCC gasoline with high content of aromatic hydrocarbon and high octane number can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for after-treatment hydrocracking catalyst

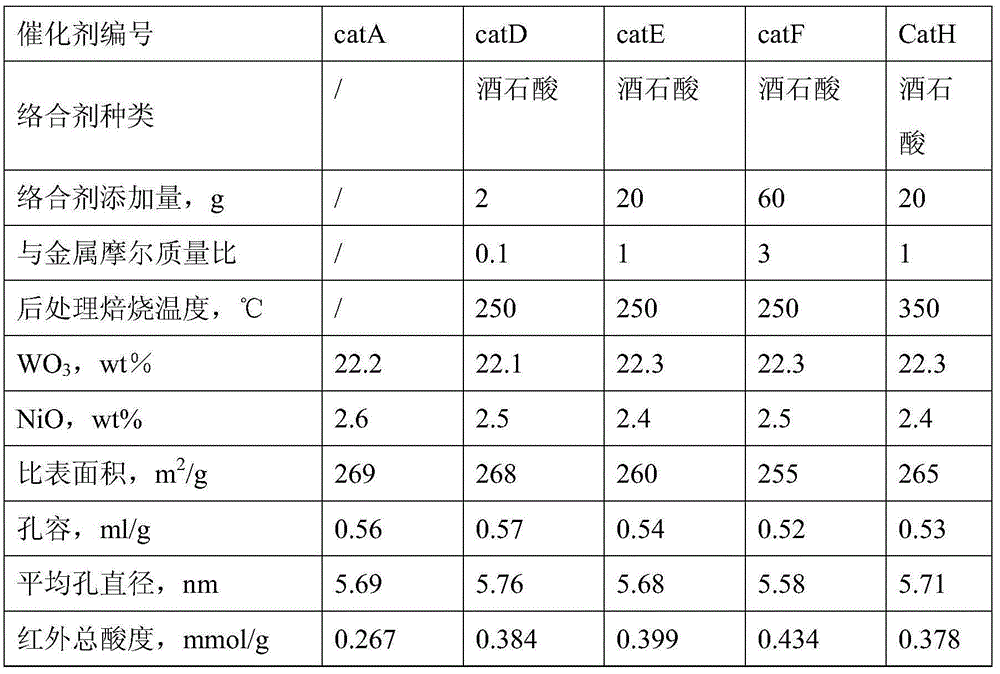

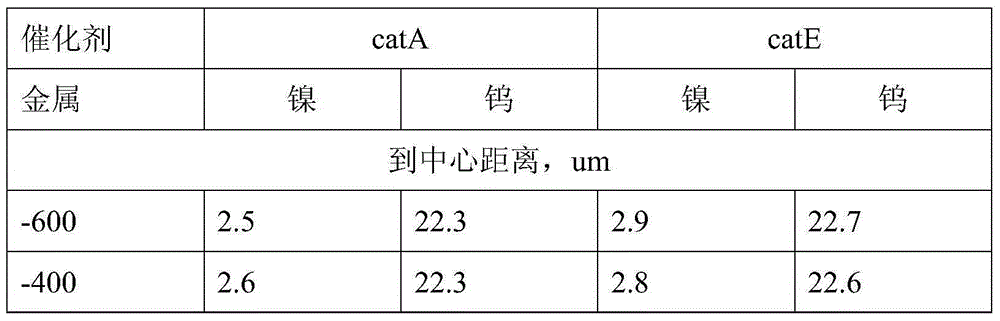

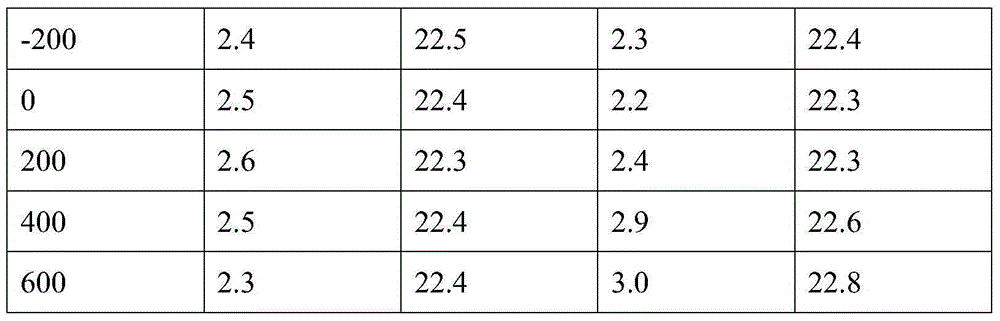

ActiveCN105195231AHigh selectivityVersatilityOrganic-compounds/hydrides/coordination-complexes catalystsAfter treatmentAlcohol

The invention discloses a preparation method for an after-treatment hydrocracking catalyst. The method includes the steps that 1, a hydrocracking catalyst carrier is prepared; 2, the catalyst carrier is steeped in steeping liquid containing active metal components and then dried and calcined at low temperature; 3, after matter capable of changing the arrangement of active metals is dissolved in a solvent according to a certain proportion, the catalyst obtained from the step 2 is steeped in the mixture; 4, materials obtained from the step 3 are dried and calcined for 1-10 hours at the low temperature of 150-400 DEG C, and the final after-treatment hydrocracking catalyst is obtained. The matter capable of changing the arrangement of the active metals is one or more of a phosphoric acid complexing agent, an alcohol amine complexing agent, an aminocarboxylic acid complexing agent, a hydroxy carboxylic acid complexing agent, an organic phosphonic acid complexing agent and a polyacrylic acid complexing agent. The after-treatment hydrocracking catalyst prepared through the method is higher in hydrogenation activity and hydrogenation selectivity, higher in selectivity for middle distillate, and suitable for treating the hydrocracking catalysts composed of various different metals.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Alkyne selective hydrogenation catalyst carrier and preparation method and catalyst thereof

InactiveCN102688783ASimple manufacturing processStrong impact resistanceCatalyst carriersHydrocarbon purification/separationRare-earth elementAlkaline earth metal

The invention discloses an alkyne selective hydrogenation catalyst carrier and a preparation method thereof; the hydrogenation catalyst carrier is obtained by well mixing and compounding alumina with one or two of SiC and talcum, and a catalyst containing an active ingredient of palladium is prepared. The catalyst can also contain co-catalytic ingredients of Ag, Mn, Bi, Mo, W, Cu, Zn, alkali metal, alkaline earth metal, and rare earth elements. The catalyst carrier has low raw material cost, and the obtained catalyst has high selective hydrogenation activity and good selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

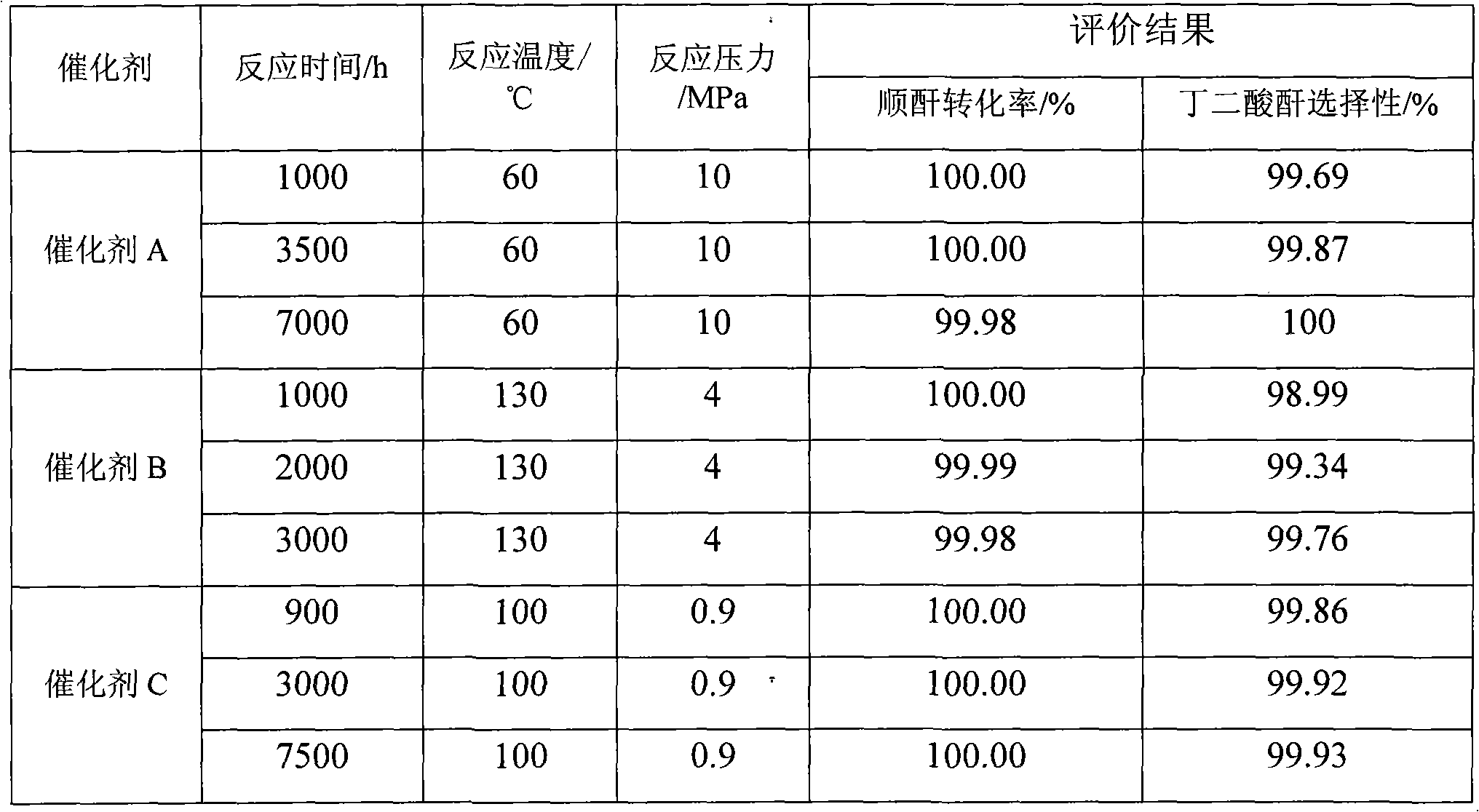

Preparation method of catalyst for continuous production of succinic anhydride from hydrogenation of maleic anhydride

ActiveCN101502802BHigh yieldHigh activityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsFixed bedHigh activity

Owner:SHANXI UNIV

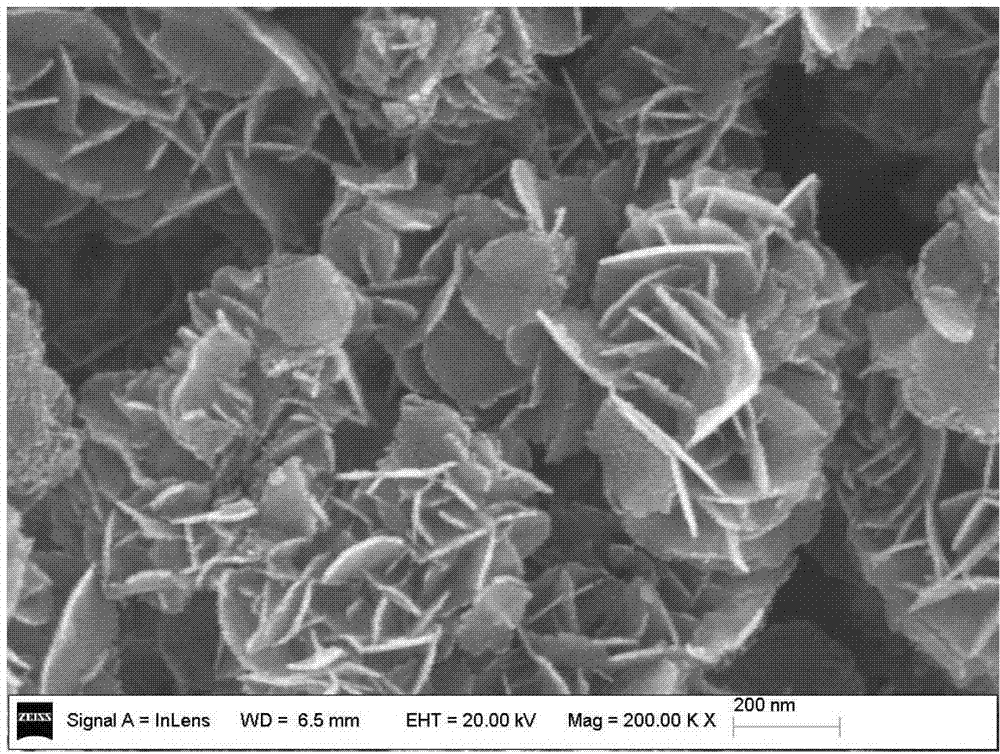

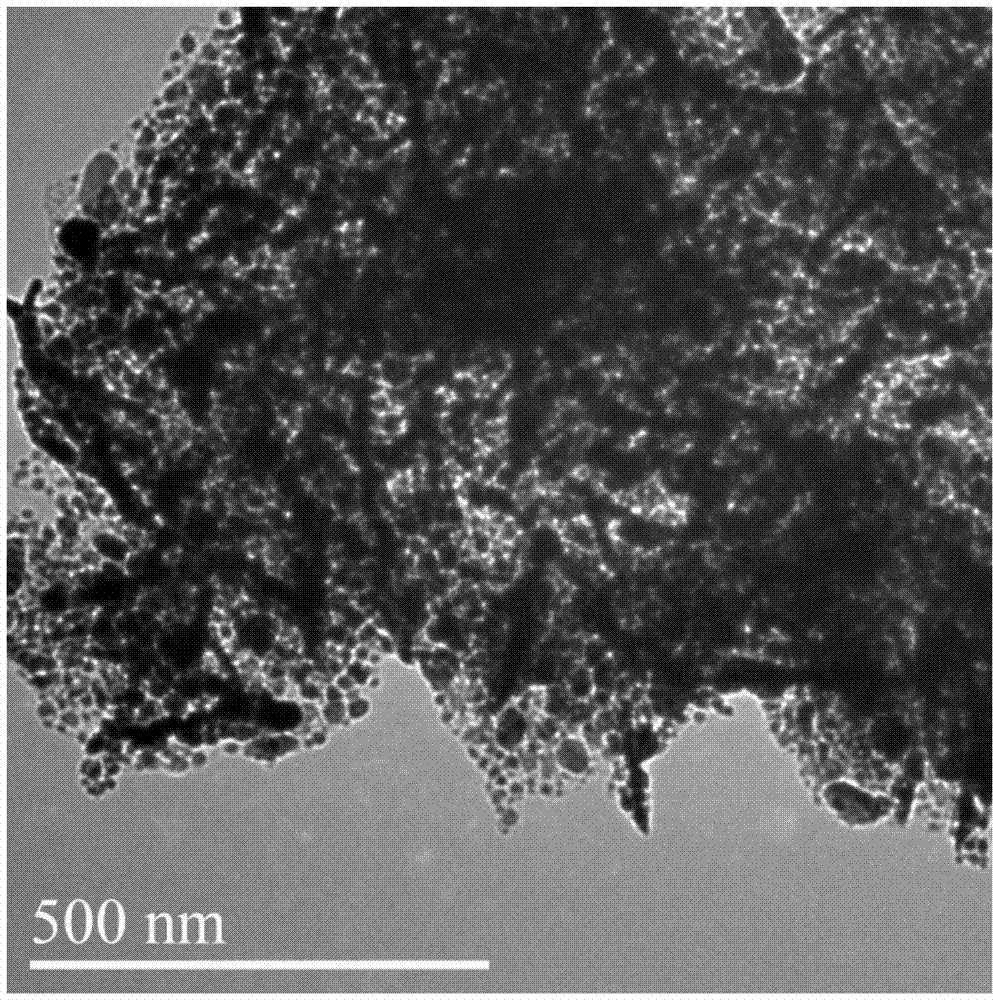

Loaded nickel-indium (Ni-In) intermetallic compound catalyst and preparation method thereof

InactiveCN103223345AType adjustableParticle size controllableOrganic compound preparationHydroxy group formation/introductionLactate dehydrogenaseIndium

The invention belongs to the technical field of the catalyst preparation, and in particular relates to a loaded nickel-indium (Ni-In) intermetallic compound catalyst and a preparation method thereof. Adjustable hydrotalcite consisting of components such as nickel magnesium indium-lactate dehydrogenase (NiMgIn-LDHs) and nickel aluminum indium-lactate dehydrogenase (NiAlIn-LDHs) is selected as a precursor, and the hydrotalcite is slowly heated and reduced at a low temperature to prepare the loaded Ni-In intermetallic compound catalyst. The prepared loaded Ni-In intermetallic compound catalyst is adjustable in variety, controllable in granularity, good in dispersion property, high in hydrogenation selectivity, good in heat stability and adjustable in hydrogenation activity and selectivity for different alpha, beta-unsaturated aldehydes. The preparation method has a simple equipment process and high yield and is convenient for the industrialized production. The catalyst is used for catalyzing selective hydrogenation of different alpha, beta-unsaturated aldehydes to produce unsaturated enol, the conversion rate of reactants is high, the selectivity of products is high, and the yield of the unsaturated enol can reach more than 95 percent.

Owner:BEIJING UNIV OF CHEM TECH

On-site external vulcanization processing method of hydrogenation catalysts

InactiveCN104841493AHigh desulfurization rateReduce saturationCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsVulcanizationPolymer science

The invention discloses an on-site external vulcanization processing method of hydrogenation catalysts. According to the processing method, at least one kind of sulfur compounds are added into the hydrogenation catalysts in atmosphere of inert gas; on-site external vulcanization processing is carried out at the normal pressure; the vulcanization temperature is 200 to 500 DEG C; the vulcanization time is 0.5 to 48 hours. Compared with in-device pre-vulcanized catalysts prepared by a conventional method, the vulcanization hydrogenation catalysts prepared and pre-vulcanized by the method have the advantages that the desulfurization rate of the vulcanization hydrogenation catalysts prepared by the method of the invention is high, and the activity is good. The on-site external vulcanization processing method of the catalysts is suitable for being used in the preparing process of various kinds of distillate oil hydrogenation catalysts.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

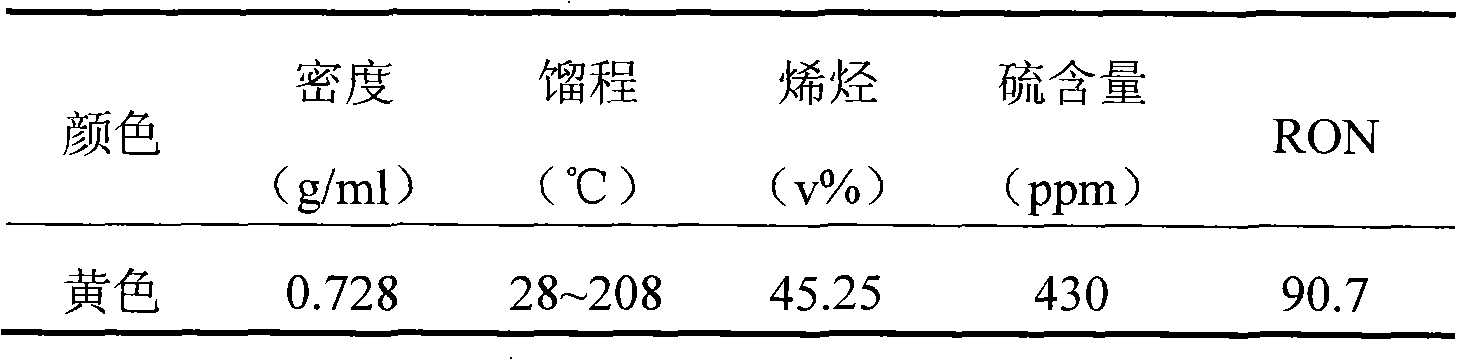

fcc gasoline selective hydrotreating method

ActiveCN109266387BHigh sweetening activityHigh activityHeterogenous catalyst chemical elementsRefining by selective hydrogenationPtru catalystFixed bed

The invention relates to a selective hydrogenation treatment method for FCC gasoline. A fixed bed reactor is adopted, and a catalyst comprises a silicon oxide-aluminum oxide carrier and metallic active ingredients nickel, molybdenum, zinc and lithium which are loaded on the carrier; the reaction process conditions are as follows: the reaction temperature is 100-230 DEG C, the reaction pressure is1.1-5.5 MPa, the volumetric air speed is 1.2-5.0 h<-1>, and the volume ratio of hydrogen to oil is (7-28) to 1. The method is used for selective hydrogenation of the FCC gasoline to remove mercaptan sulfur and alkadiene.

Owner:林雅娟

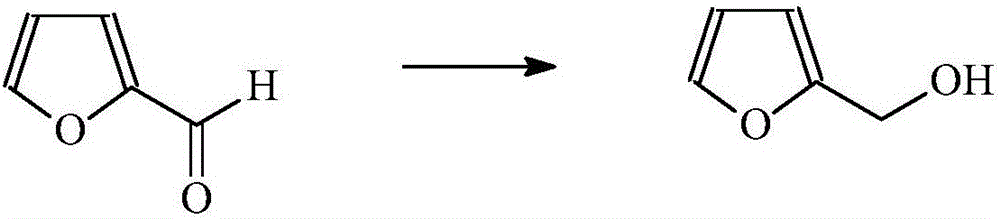

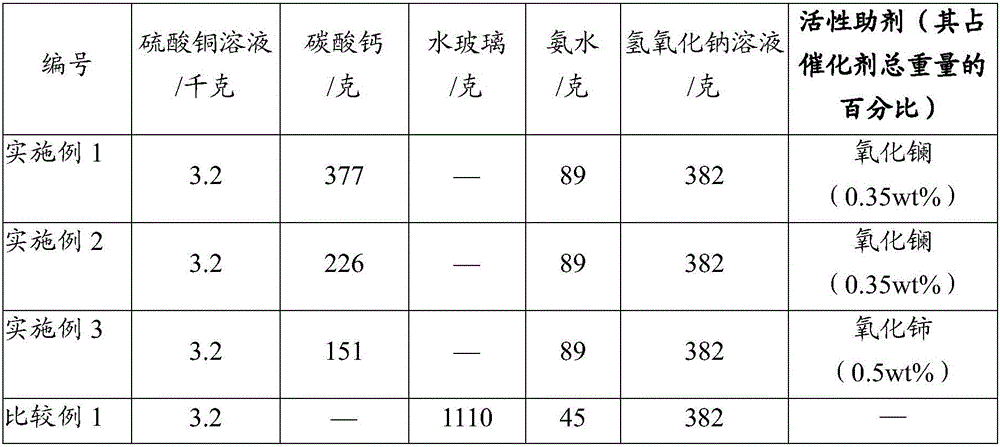

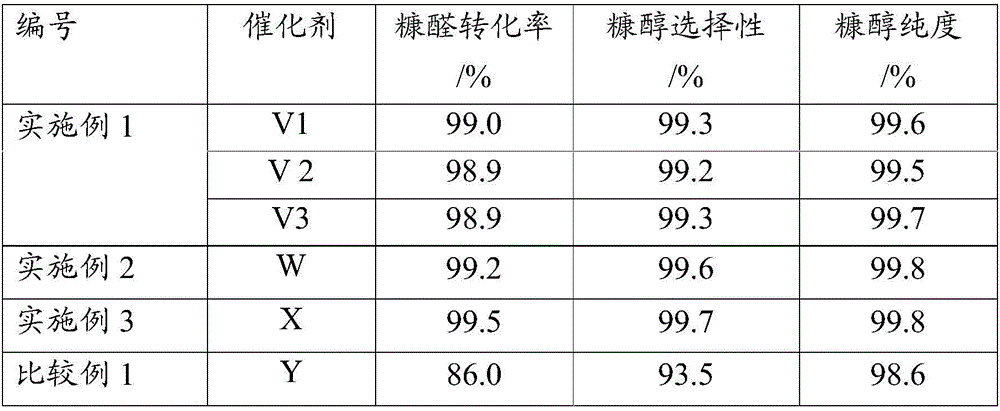

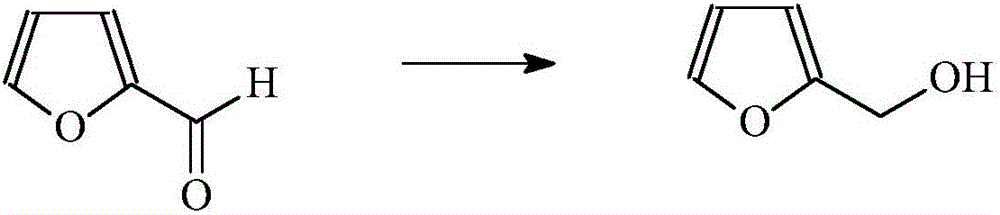

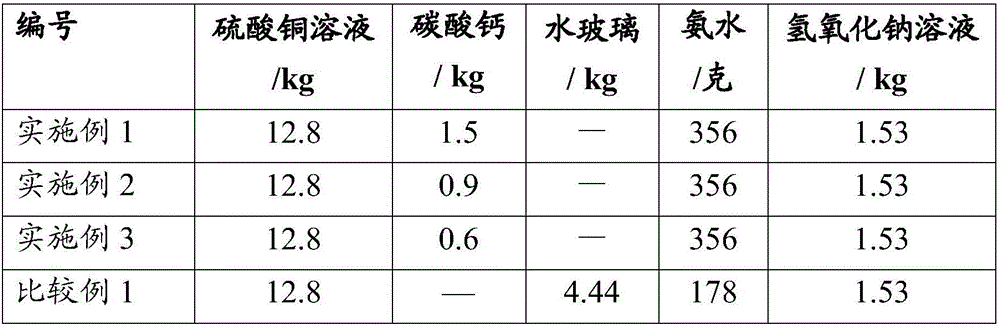

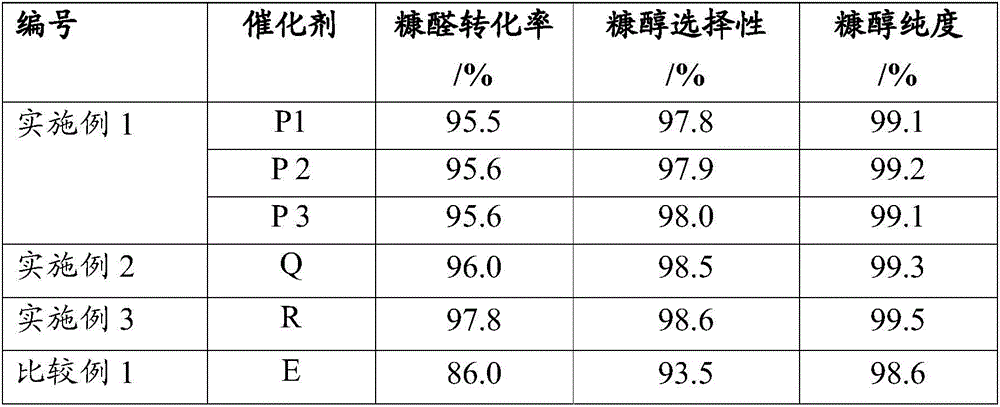

Furfural hydrogenation catalyst containing rare earth elements and preparation method thereof

ActiveCN106732706AAdjust DispersionAdjust granularityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementActive component

The invention discloses a furfural hydrogenation catalyst containing rare earth elements and a preparation method thereof. The catalyst takes calcium carbonate as a carrier, takes copper oxide as an active component and takes a rare earth compound as an active aid; the weight of copper oxide is 28-75wt% of the total weight of the catalyst; the weight of the rear earth compound is 0.1-5wt% of the total weight of the catalyst. According to the furfural hydrogenation catalyst containing rare earth elements and the preparation method thereof, the production cost of the furfural hydrogenation catalyst is effectively controlled; and the furfural hydrogenation catalyst is extremely high in furfural conversion rate and hydrogenation selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +2

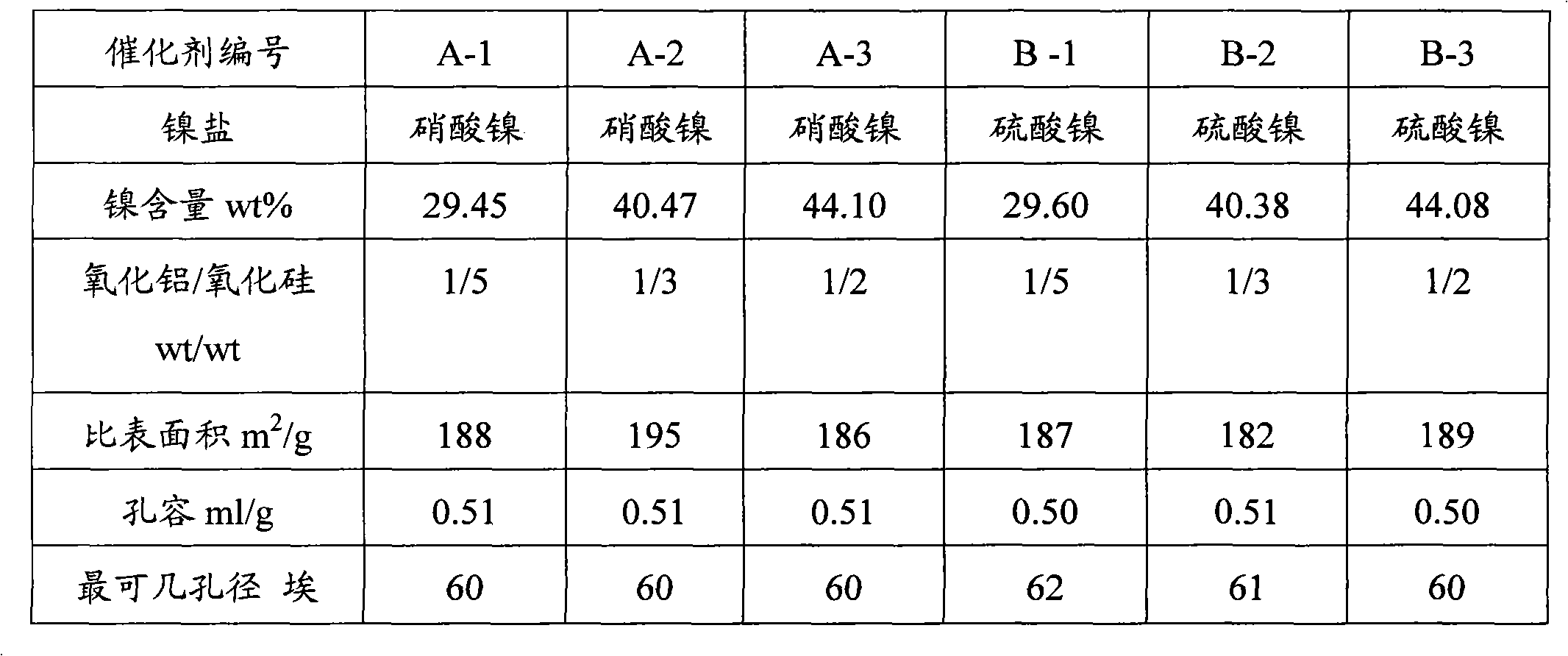

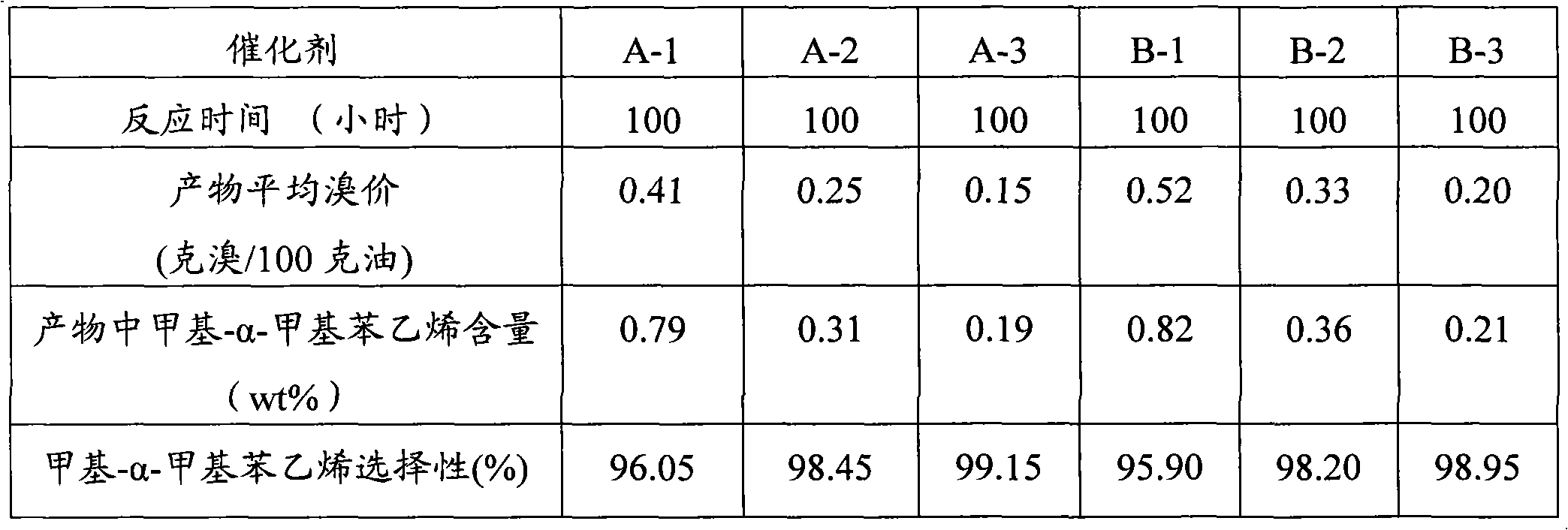

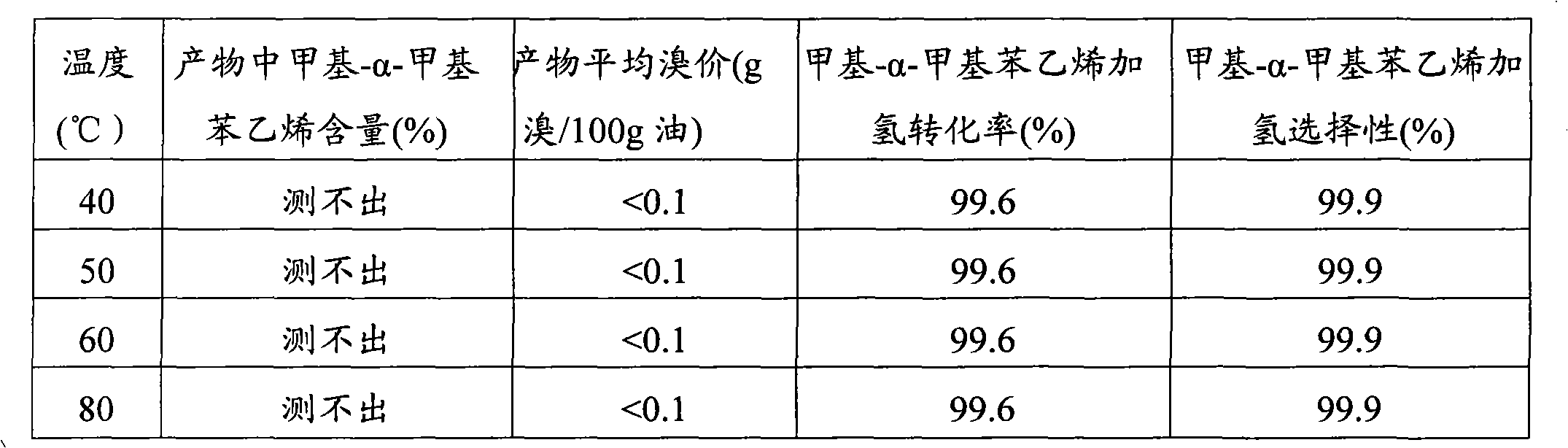

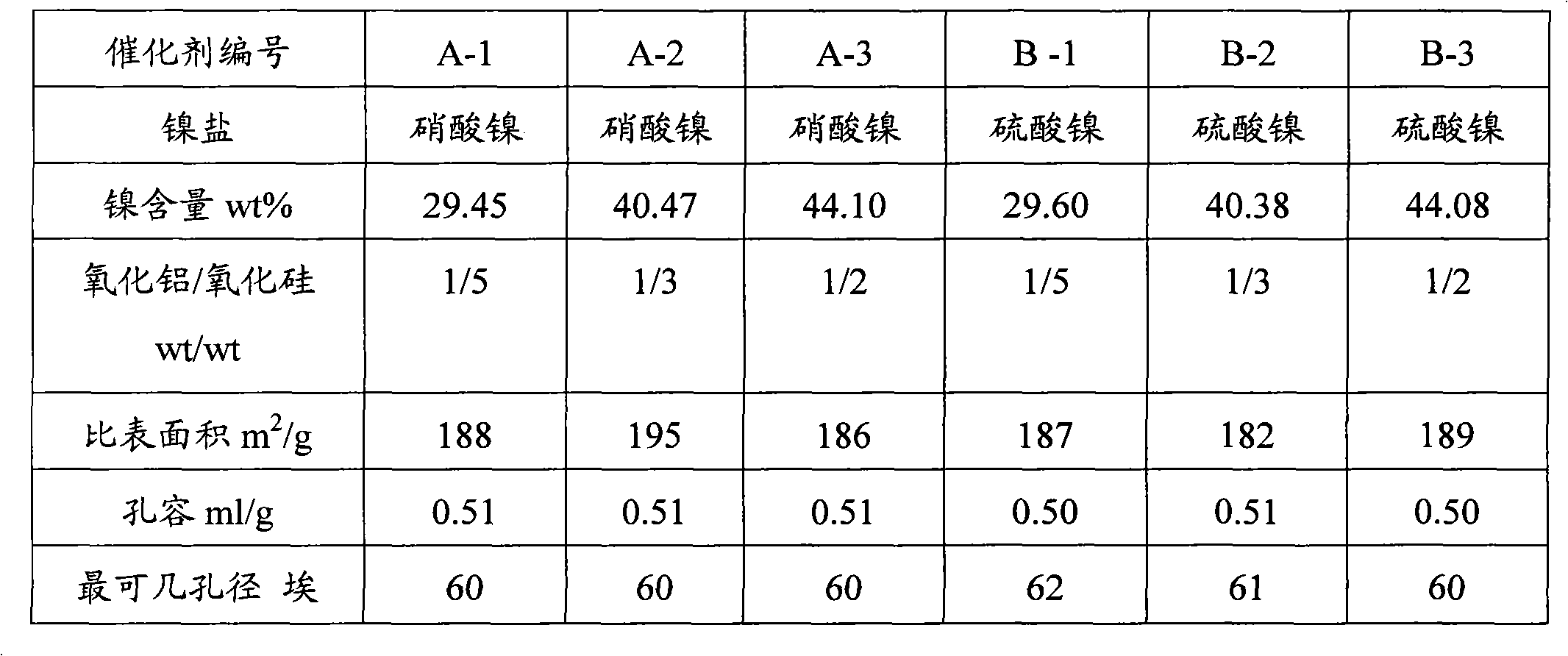

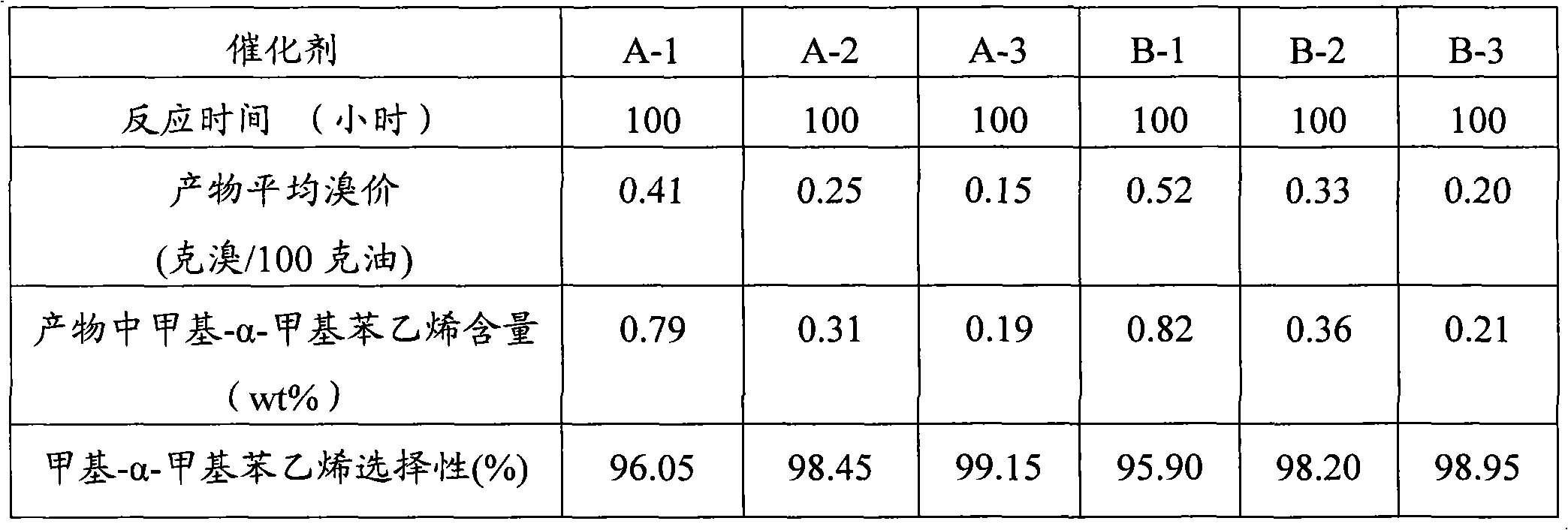

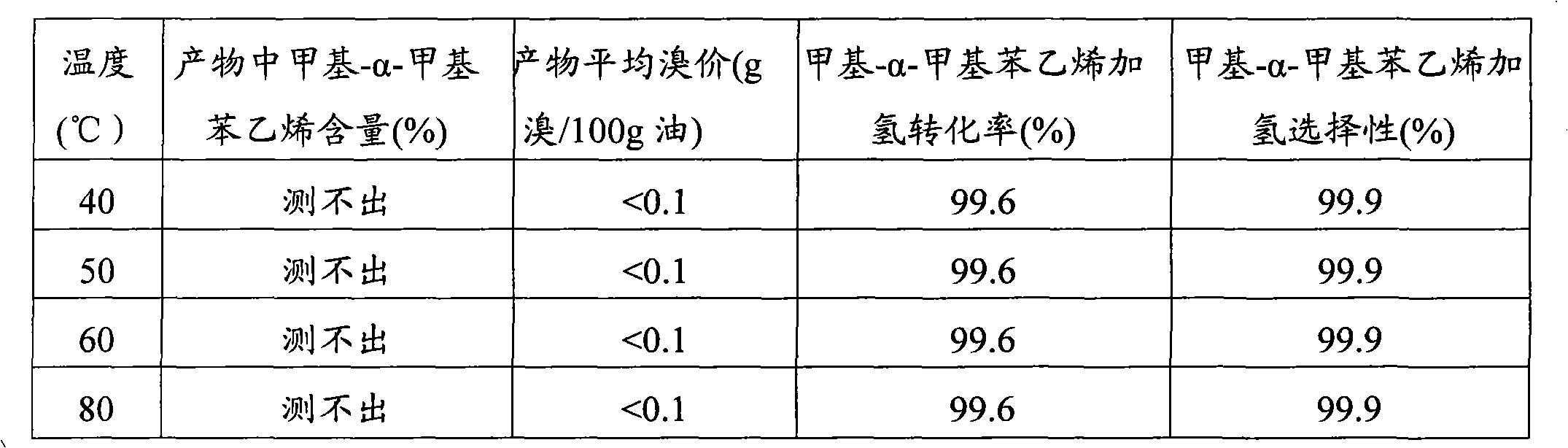

Method for selective hydrogenation of methyl-alpha-methyl styrene

ActiveCN102964199AHigh hydrogenation selectivityLow costHydrocarbon by hydrogenationAlpha-MethylstyreneChemistry

The invention relates to a method for selective hydrogenation of methyl-alpha-methyl styrene, which comprises the following steps: in a fixed bed reactor, allowing a feed flow containing methyl-alpha-methyl styrene to contact with a nickel catalyst in the reactor to perform one-step slow hydrogenation so as to convert the methyl-alpha-methyl styrene in the feed flow into isopropyl toluene, wherein the nickel catalyst adopts an alumina / silica compound as a carrier and adopts metal nickel as an active component. The content of methyl-alpha-methyl styrene in the feed flow is less than or equal to 21 wt%. the hydrogenation conversion rate of the methyl-alpha-methyl styrene is up to 99.9%, and the hydrogenation selectivity is 99.9%.

Owner:CHINA PETROLEUM & CHEM CORP +1

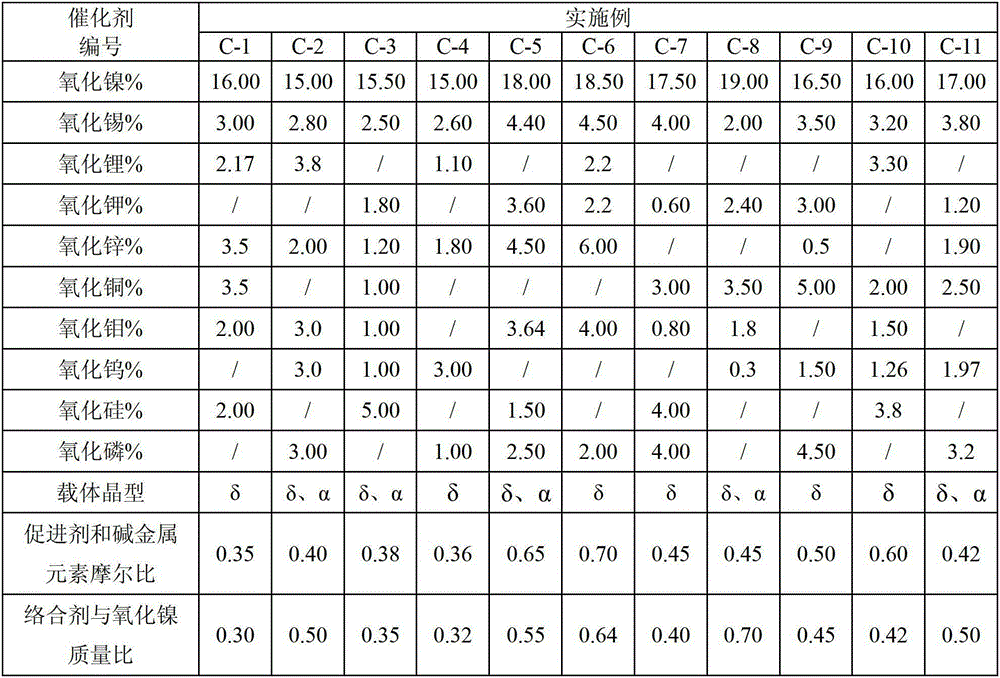

A kind of selective nickel-based hydrogenation catalyst and preparation method thereof

ActiveCN103657668BImprove hydrogenation activityHigh hydrogenation selectivityMetal/metal-oxides/metal-hydroxide catalystsRefining by selective hydrogenationTin dioxideLithium oxide

The invention relates to a selective nickel-based hydrogenation catalyst and a preparation method thereof. With an aluminum oxide as a carrier, the selective nickel-based hydrogenation catalyst comprises the following components in percentage by weight: 14-19 percent of nickel oxide, 2-5 percent of tin oxide, 0.1-8 percent of alkali metal lithium oxide and / or potassium oxide, 0.5-8 percent of copper oxide and / or zinc oxide, 0.3-8 percent of molybdenum oxide and / or tungsten oxide and 0-8 percent of silicon oxide and / or phosphorus oxide. The aluminum oxide carrier is prepared by spraying a complex solution of an alkali metal Li and / or K on an aluminum hydroxide powder body, and thus the hydrogenation stability of the catalyst can be further improved. Due to introduction of auxiliary components such as Sn in the catalyst, the performance such as heat stability, diene hydrogenation selectivity and sulphur and arsenic resistance of the catalyst can be improved.

Owner:PETROCHINA CO LTD

Catalyst for preparing furfuryl alcohol through furfural hydrogenation and preparation method thereof

ActiveCN106824239AAdjust particle size distributionImprove conversion rateOrganic chemistryPhysical/chemical process catalystsCopper oxideActive ingredient

The invention discloses a catalyst for preparing furfuryl alcohol through furfural hydrogenation and a preparation method thereof. The catalyst takes calcium carbonate as a carrier and copper oxide as an active ingredient, wherein the weight of copper oxide is 32-75wt% of the total weight of the catalyst. The catalyst disclosed by the invention has the advantages that the production cost of the catalyst is obviously reduced, and the furfural conversion rate and hydrogenation selectivity are also relatively high.

Owner:CHINA PETROLEUM & CHEM CORP +2

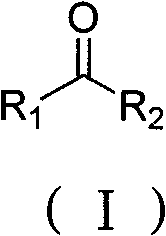

Method for preparing corresponding alcohol through carbonyl compound selective hydrogenation

InactiveCN102603473AHigh hydrogenation selectivityHigh selectivityOrganic compound preparationHydroxy compound preparationBenzeneChemical industry

The invention belongs to the field of organic synthesis in chemical industry and particularly relates to a method for preparing corresponding alcohol through carbonyl compound selective hydrogenation. According to the method, carbonyl compounds, solvents and catalysts are added into a high-pressure kettle, the pH is regulated to be in a range from 8 to 11, hydrogen gas is used as a hydrogen source, and the corresponding alcohol preparation through compound selective hydrogenation is realized at certain temperature and pressure. The method provided by the invention has the advantages that only carbonyl groups in compounds can be hydrogenised, double bonds or benzene rings contained in the compounds are not hydrogenised, the selectivity is higher than 98 percent, and the yield is higher than 95 percent.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for FCC (fluid catalytic cracking) gasoline sweetening

InactiveCN107177370ANot easy to coke and deactivateImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentReaction temperatureFixed bed

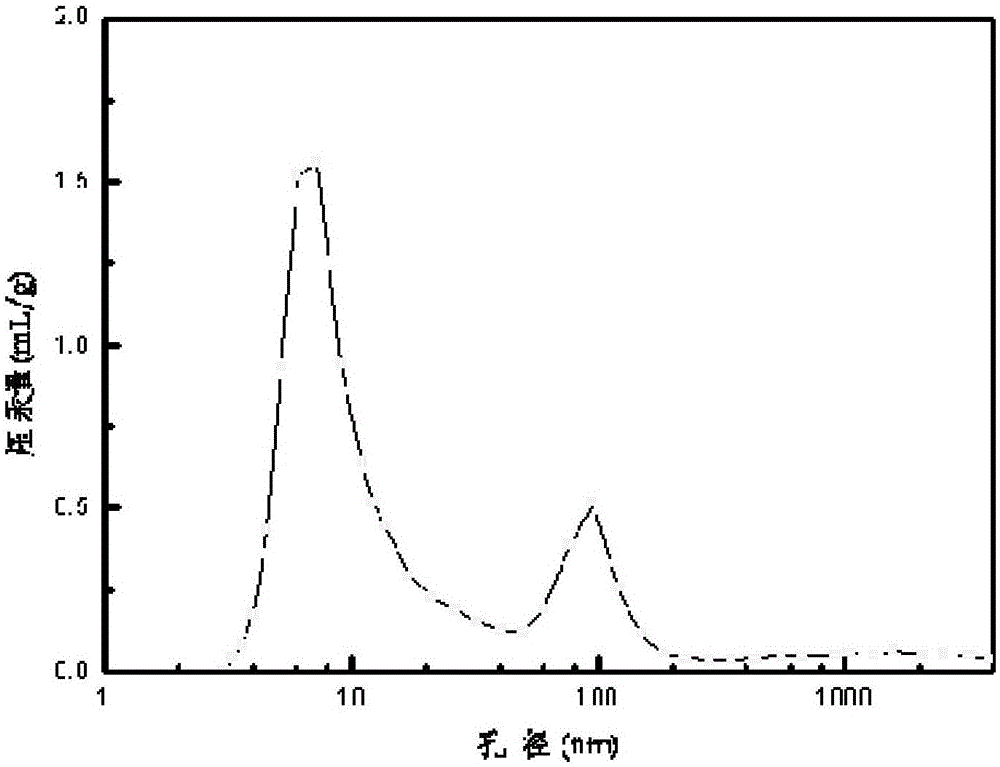

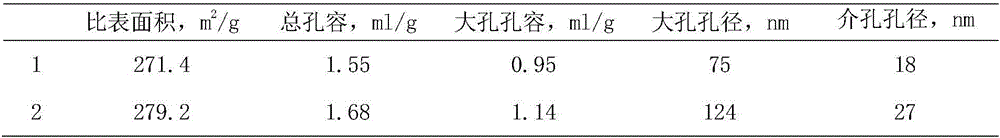

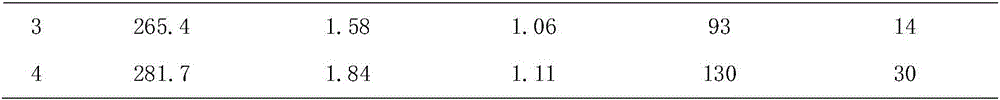

The invention relates to a method for FCC (fluid catalytic cracking) gasoline sweetening. The method adopts a fixed bed reactor, a used catalyst comprises, in weight percentage, 66-91wt% of alumina support with a macro-porous structure, 5-19wt% of metal active component nickel oxide and 2-15wt% of metal active component molybdenum oxide, the metal active component nickel and the metal active component molybdenum are loaded on the support, the alumina support takes chitosan as a pore-expanding agent, the support comprises additive component phosphorus and additive component molybdenum, and the reaction process conditions include that reaction temperature ranges from 110 DEG C to 220 DEG C, reaction pressure ranges from 1.1MPa to 3.5MPa, volume space velocity ranges from 1.2h<-1> to 4.0h<-1>, and hydrogen oil volume ratio is (7-25):1. The sweetening method has strong adaptability to oil products with different sulfur contents, mercaptan sulfur contents and olefin contents.

Owner:QINZHOU UNIV

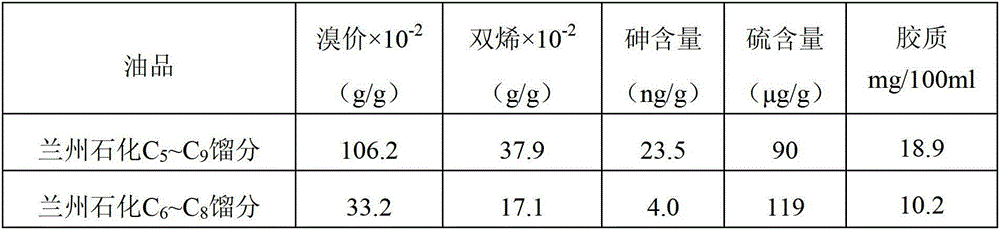

Unsaturated C5 fraction and hydrogenation method

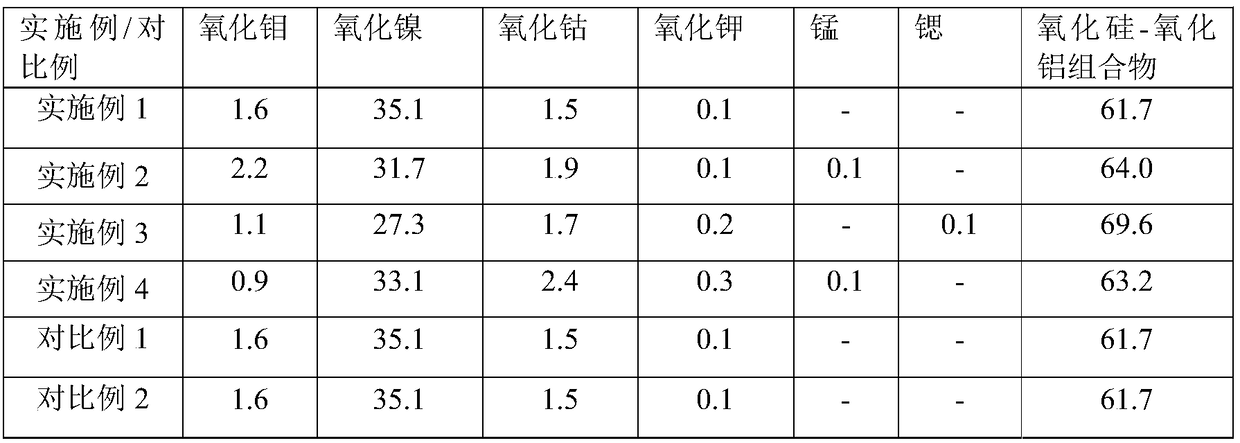

ActiveCN109439364AHigh hydrogenation selectivityReduce reactivityHeterogenous catalyst chemical elementsRefining by selective hydrogenationPotassiumFixed bed

The invention relates to an unsaturated C5 fraction and hydrogenation method. According to the method, by the aid of a fixed bed reactor, a used catalyst is a nickel hydrogenation catalyst, and the catalyst is reduced by the aid of hydrogen or hydrogen-containing gas at the temperature of 350-500 DEG C. The catalyst comprises main active components and a silicon oxide-aluminum oxide composition, and the main active components include molybdenum, nickel, cobalt and potassium. Hydrogenation process conditions include that a reactor inlet temperature is 30-660 DEG C, reaction pressure is 1.5-6.0MPa, liquid volume per hour is 1.0-6.0h<-1>, and the volume ratio of hydrogen to oil is 100:400. According to the unsaturated C5 fraction and hydrogenation method, the used nickel-based saturated hydrogenation catalyst has high hydrogenation activity and the advantages that the catalyst is resistant to sulfur, water and colloid, and hydrogenation reaction can be performed at low temperature.

Owner:兰州金润宏成新材料科技有限公司

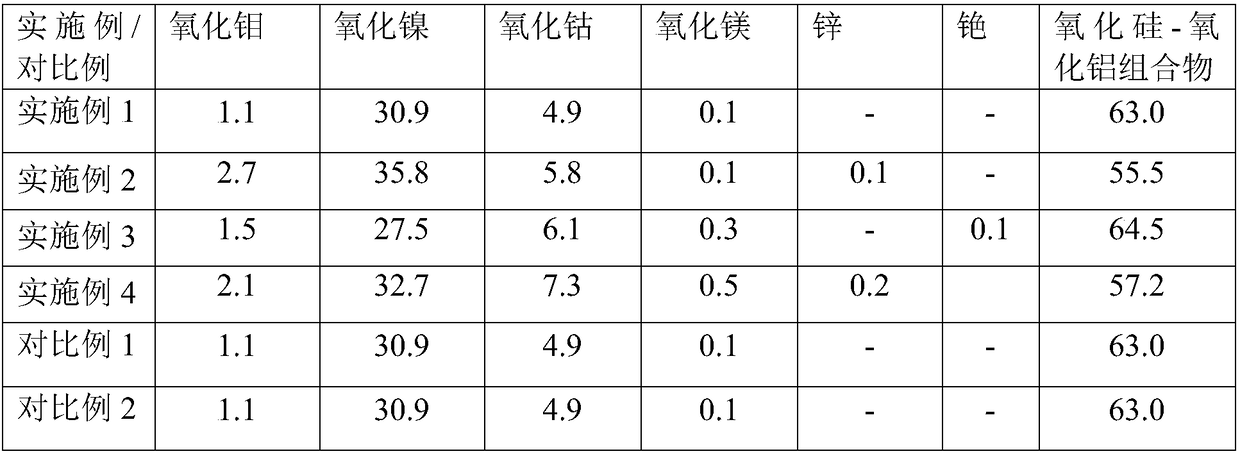

Hydrogenation method of C4 unsaturated hydrocarbon

ActiveCN109439365AHigh hydrogenation selectivityReduce reactivityHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsFixed bedSilicon oxide

The invention relates to a hydrogenation method of C4 unsaturated hydrocarbon. According to the method, by the aid of a fixed bed reactor, a nickel saturated hydrogenation catalyst is reduced outsidea hydrogenation reactor at the temperature of 350-500 DEG C, air is led in to passivate the catalyst, the passivated catalyst is reduced in the reactor by hydrogen at the temperature of 120-200 DEG C,the C4 unsaturated hydrocarbon is added, alkyne and diolefin in the C4 unsaturated hydrocarbon are hydrogenated into corresponding alkane, the nickel saturated hydrogenation catalyst comprises activecomponents and silicon oxide-aluminum oxide composition, and the active components include molybdenum, nickel , cobalt and magnesium. Reaction process conditions include that inlet temperature of thereactor is 30-55 DEG C, reaction pressure is 1.0-4.5MPa, liquid volume per hour is 1.5-4.5h<-1>, and the volume ratio of hydrogen to oil is (120-450):1. According to the hydrogenation method of theC4 unsaturated hydrocarbon, the catalyst is good in hydrogenation activity, good in gelatine and water resistance and high in sulfur resistance.

Owner:兰州金润宏成新材料科技有限公司

Method for selective hydrogenation of methyl-alpha-methyl styrene

ActiveCN102964199BHigh hydrogenation selectivityLow costHydrocarbon by hydrogenationNickel catalystActive component

The invention relates to a method for selective hydrogenation of methyl-alpha-methyl styrene, which comprises the following steps: in a fixed bed reactor, allowing a feed flow containing methyl-alpha-methyl styrene to contact with a nickel catalyst in the reactor to perform one-step slow hydrogenation so as to convert the methyl-alpha-methyl styrene in the feed flow into isopropyl toluene, wherein the nickel catalyst adopts an alumina / silica compound as a carrier and adopts metal nickel as an active component. The content of methyl-alpha-methyl styrene in the feed flow is less than or equal to 21 wt%. the hydrogenation conversion rate of the methyl-alpha-methyl styrene is up to 99.9%, and the hydrogenation selectivity is 99.9%.

Owner:CHINA PETROLEUM & CHEM CORP +1

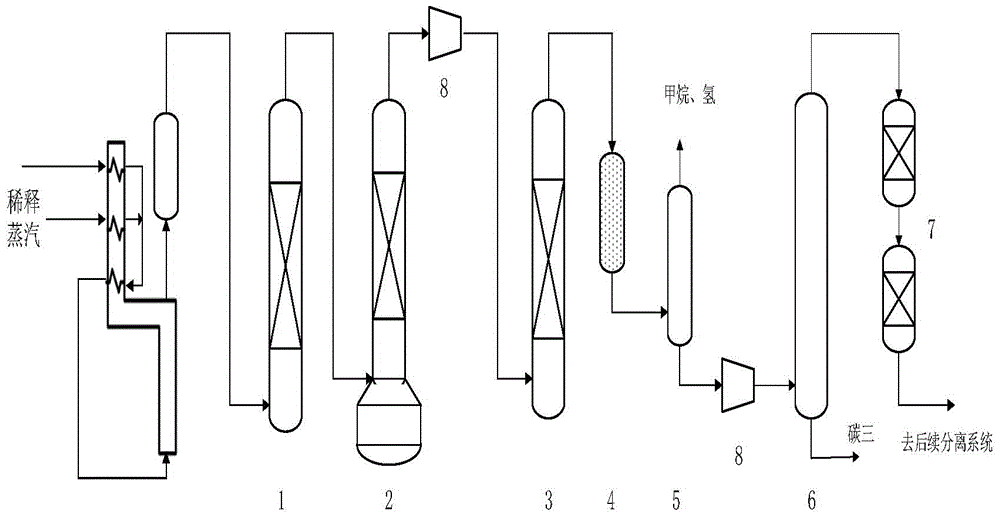

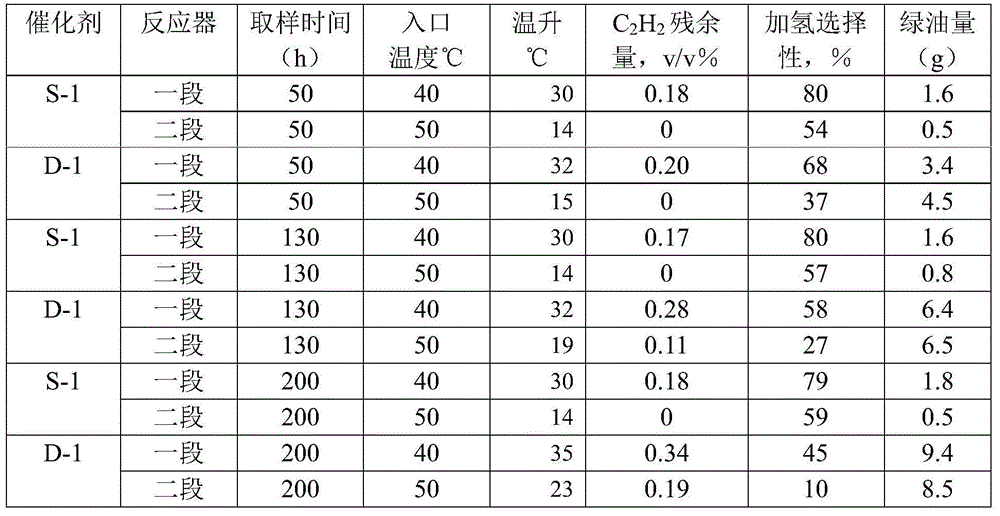

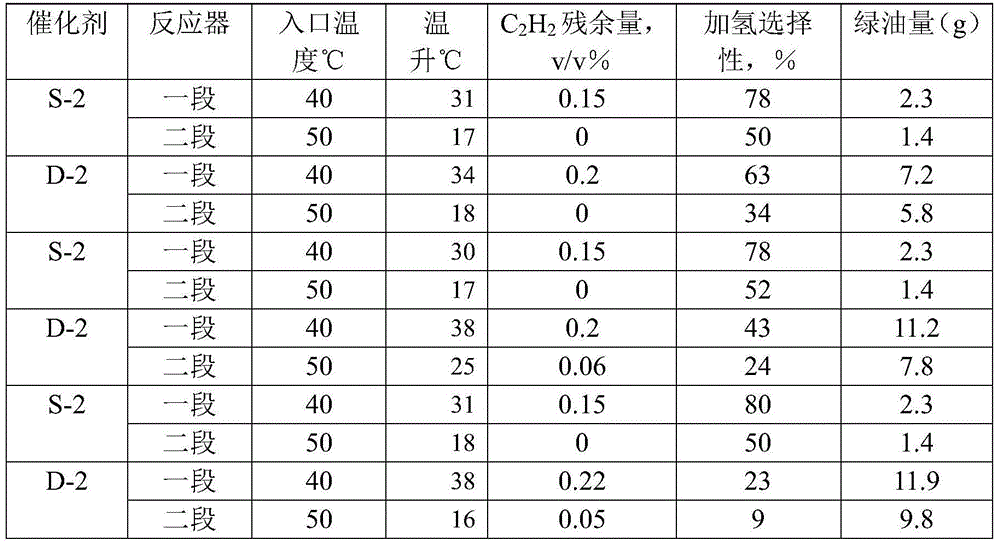

C2 fraction selective hydrogenation method

The invention relates to a C2 fraction selective hydrogenation method. A fixed bed reactor used for hydrogenation is positioned behind a demethanation tower, allows a C2 material from a front deethanization tower in an ethylene device to undergo pressurization hydrogen matching, enter a heat insulation bed reactor and undergo selective hydrogenation; the fixed bed reactor is filled with a Pd-Pb series catalyst, and hydroxydipyridine combined to a carrier and an active component form a metal complex through the combination of an alumina series carrier and a hydroxy group-containing dipyridine derivative in the preparation method of the catalyst. The hydrogenation reaction activity of the method provided by the invention is greatly better than that of traditional hydrogenation methods, and the generation amount of green in the hydrogenation process is greatly reduced. Reduction of the green oil makes the active site of the catalyst not be covered with byproducts and the activity and the selectivity of the catalyst be well kept; and when a hydrogenation raw materials contains 1000ppm or below of a C4 fraction, the catalyst also has an excellent hydrogenation performance.

Owner:PETROCHINA CO LTD

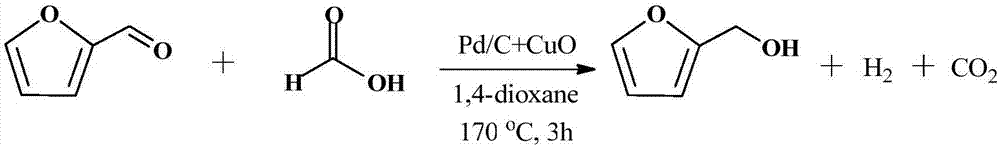

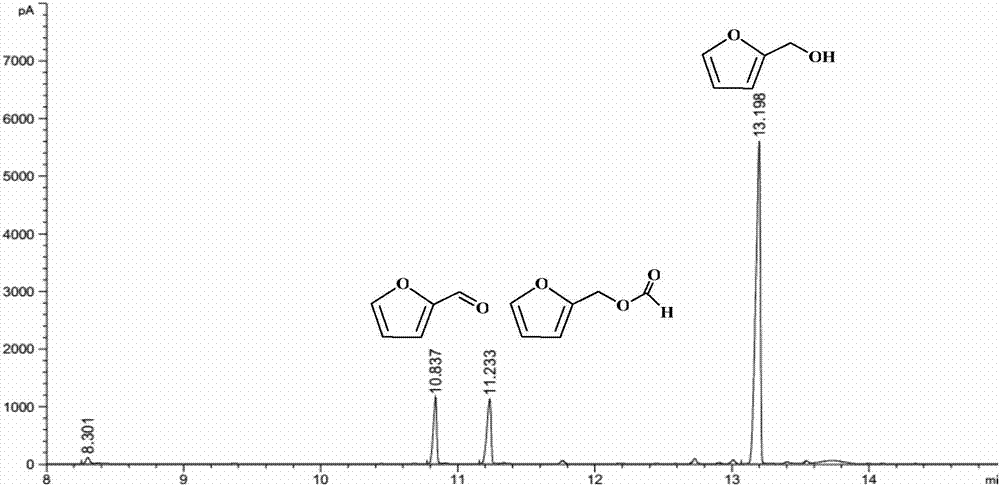

Method for preparing furfuryl alcohol by formic acid transfer and hydrogenation of furfural

The invention discloses a method for preparing furfuryl alcohol by formic acid transfer and hydrogenation of furfural, and relates to a preparation method for the furfuryl alcohol. The method comprises the following steps: adding a reaction substance to an organic solvent, and preparing reactant solution; mixing the reactant solution, an anhydrous formic acid and a catalyst in a reaction kettle, exhausting the air, to obtain the furfuryl alcohol after a hydrogenation reaction. Pd / C and CuO are used as a composite catalyst, and the formic acid is used as a hydrogen donor. In an organic solventsystem, the furfuryl alcohol is prepared through decomposing the formic acid to generate hydrogen and catalyzing the furfural for the reduction. The whole process is simple, the operation is easy, theconsumed time is short, the cost is low, the reaction system is green, the catalyst activity is high, and the furfuryl alcohol yield is high. In addition, the reaction system is capable of effectively solving a problem that the furfural and furfuryl alcohol in an acid system are easily polymerized, and has the extensive industrial application prospect.

Owner:XIAMEN UNIV

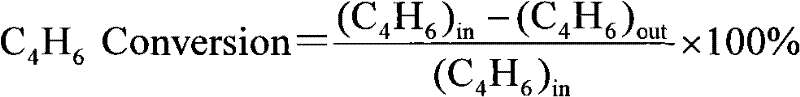

Total fraction cracking gasoline selective hydrogenation method

ActiveCN109022025AHigh hydrogenation selectivityImprove anti-glue abilityHydrocarbon oils refiningHydrocarbon oils treatment productsFixed bedReaction temperature

The invention relates to a total fraction cracking gasoline selective hydrogenation method. A fixed bed reactor is used; a catalyst is reduced in hydrogen gas atmosphere; after the reduction process is completed, the process condition is regulated to the reaction process conditions; gasoline raw material total fraction cracking is performed; selective hydrogenation reaction is performed; the catalyst is prepared from silicon oxide-aluminum oxide carriers and metal active ingredients of palladium loaded on the carriers; the content of the palladium is based on 0.15 to 0.45 weight percent of thetotal weight of the catalysts. The hydrogenation process conditions are shown as follows: the reaction inlet temperature is higher than or equal to 50 DEG C; the reaction temperature is 2.0 to 4.5MPa; the hydrogen oil volume ratio is (60 to 400):1; the liquid volume air speed is 2.5 to 5.0 h<-1>. The catalyst gum resistant capability is high; the arsenic resistant, sulfur resistant and water-resistant capability is high; the stability is high.

Owner:东营华浩化工有限公司

Method for removing thiol in FCC gasoline through hydrogenation

ActiveCN109370637AHigh sweetening activityGood choiceMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentFixed bedReaction temperature

The invention relates to a method for removing thiol in FCC gasoline through hydrogenation. A fixed bed reactor is adopted; a catalyst contains a silica-alumina supporter and metal active components including nickel, molybdenum, zinc and strontium supported on the supporter and particularly contains the following components in percentage by weight: 2wt%-15wt% of nickel oxide, 2wt%-18wt% of molybdenum oxide, 0.1wt%-5wt% of zinc oxide, 0.1wt%-2.0wt% of strontium oxide and 65wt%-85wt% of the silica-alumina supporter; and the reaction process conditions are as follows: the reaction temperature is110-240 DEG C, the reaction pressure is 1.1MPa-5.5MPa, the volume velocity is 1.2h<-1>-5.5h<-1>, and the hydrogen-oil volume rate is (7-25) to 1. The catalyst has high thiol removal activity and diolefin hydrogenation selectivity and strong adaptability to different raw materials.

Owner:博兴兴业精细化工产业发展有限公司

Selective hydrogenation method for full-range pyrolysis gasoline

ActiveCN109364945AHigh hydrogenation selectivityImprove anti-glue abilityHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsLanthanumChemistry

The invention relates to a selective hydrogenation method for full-range pyrolysis gasoline, which adopts a reactor of an adiabat bed reactor. The catalyst comprises silica-alumina carrier and metal active component palladium loaded on the carrier, wherein the palladium is 0.15-0.45 percent of total weight of the catalyst; and the silica-alumina carrier is prepared from the following components inpercentage by weight: 0.1-12 percent of silica, 0.1-10 percent of nickel-doped lanthanum ferrite and 0.05-7.8 percent of magnesium. According to the hydrogenation process conditions, the reaction inlet temperature is more than or equal to 50 DEG C, the reaction pressure is 2.0-4.5MPa, the hydrogen-oil volume ratio is 60-450, and the liquid hourly space velocity is 3.0-5.0h<-1>. The catalyst has good gum resistance and strong performance of arsenic resistance, sulfur resistance and water resistance.

Owner:毛琴飞

Selective hydrogenation catalyst and preparation method thereof

ActiveCN102451714ALarge hole volumeIncrease the areaMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentAdditive ingredientSodium aluminate

The invention discloses a selective hydrogenation catalyst and a preparation method thereof. In the catalyst, aluminum oxide containing titanium and silicon is taken as a carrier, an active metal ingredient is palladium, an aid ingredient is Mo and / or Co, and the active metal ingredient and the aid ingredient are distributed on the surface of the carrier in an eggshell shape; the aluminum oxide containing the titanium and the silicon is prepared from sodium aluminate, sodium silicate, titanium sulfate and CO2 by a precipitation method; the sodium aluminate and the sodium silicate are subjected to cocurrent flow, the CO2 is introduced to make the pH value constant for precipitation, the titanium sulfate and a NaHCO3 and / or Na2CO3 solution are subjected to cocurrent flow precipitation, and the obtained aluminum oxide containing the titanium and the silicon has large pore volume and specific surface area and high high-temperature stability; in addition, the aid ingredient can interact with the active ingredient palladium, palladium particles are uniformly distributed, and interaction between the palladium and the carrier can be enhanced, so that the loss of the palladium is reduced, the utilization rate of the palladium is improved, and the service life of the catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

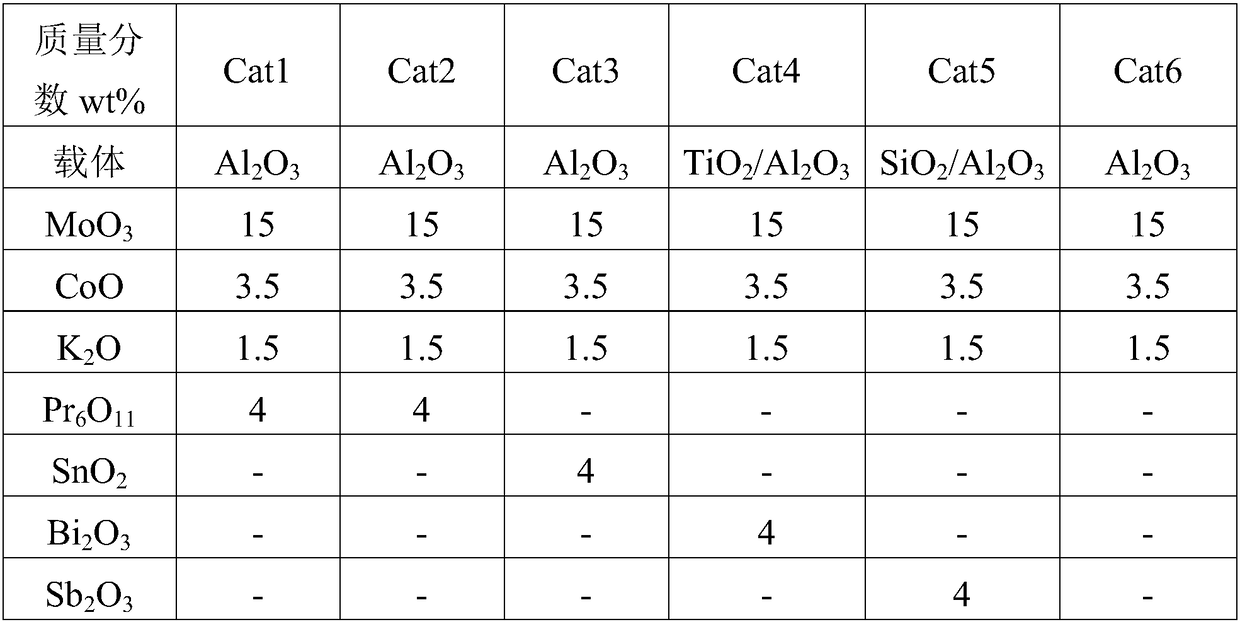

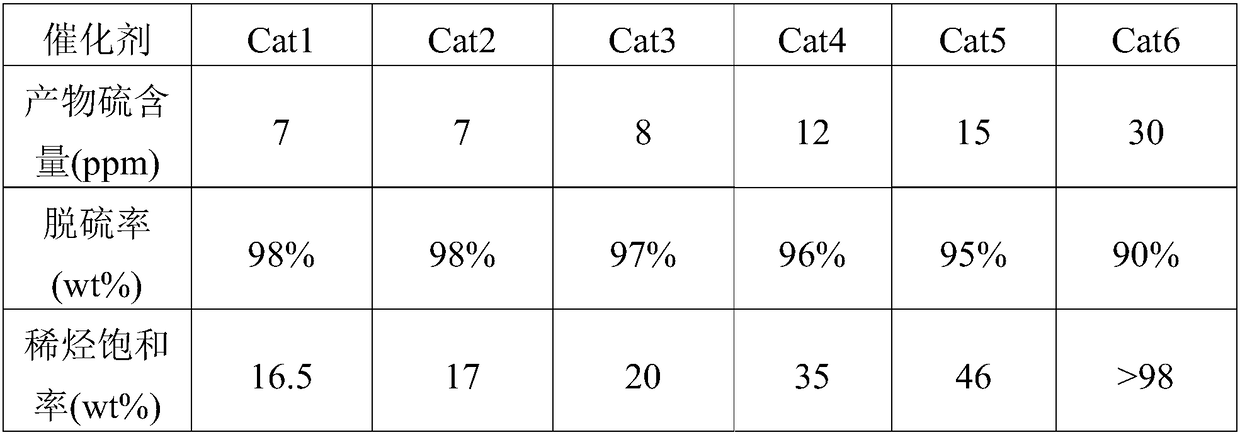

Modified hydrodesulfurization catalyst and preparation method and application of modified hydrodesulfurization catalyst

InactiveCN108212168AImprove oxygen storage capacityHigh hydrogenation selectivityHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalHydrodesulfurization

The invention discloses a modified hydrodesulfurization catalyst and a preparation method and the application of the modified hydrodesulfurization catalyst. The active component of the catalyst is oneor more of groups of metals cobalt, molybdenum, nickel and tungsten, a carrier is one or more of groups of modified Al2O3, SiO2, TiO2 and MgO, an auxiliary is an alkali metal or alkaline earth metal,wherein the modified element is one or more of groups of Pr, Sn, Bi and Sb. The catalyst fully inhibits olefine hydrogenation produced by the side reaction, maintains the octane number, and fully reduces the sulfur content in the catalytic gasoline subjected to hydrodesulfurization.

Owner:PETROCHINA CO LTD

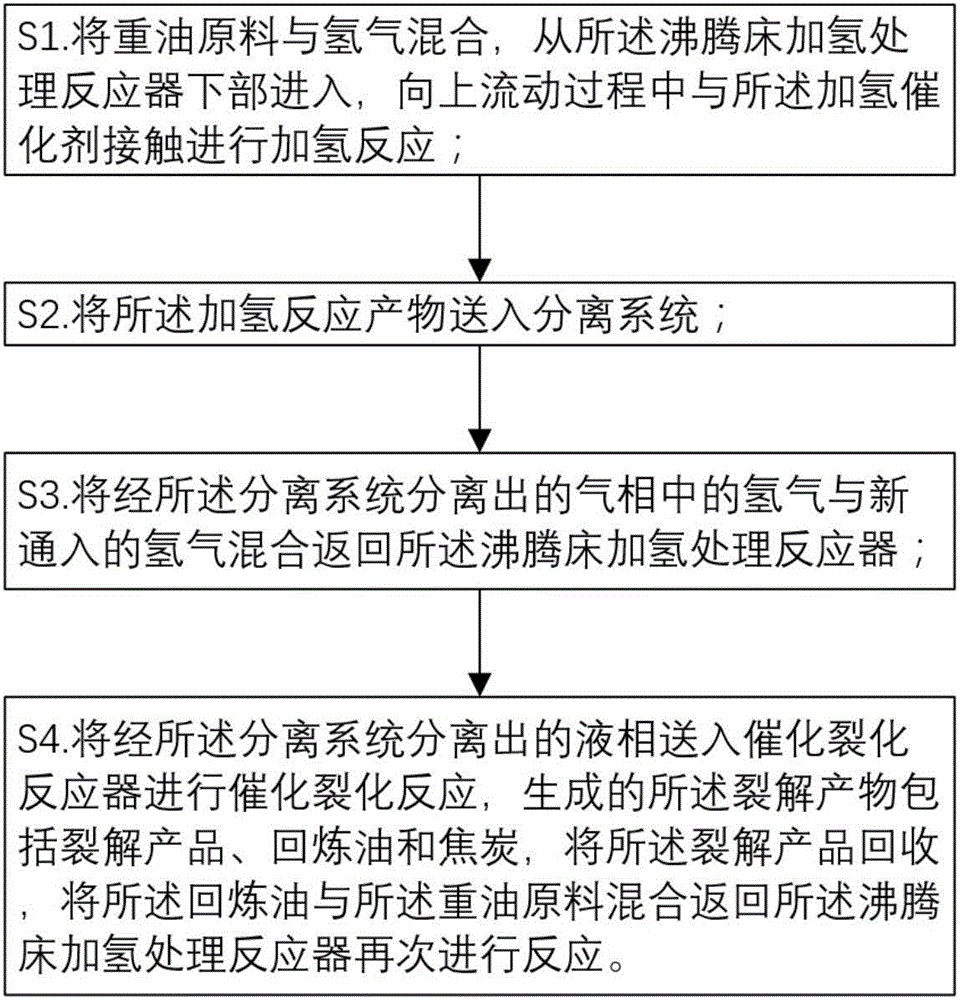

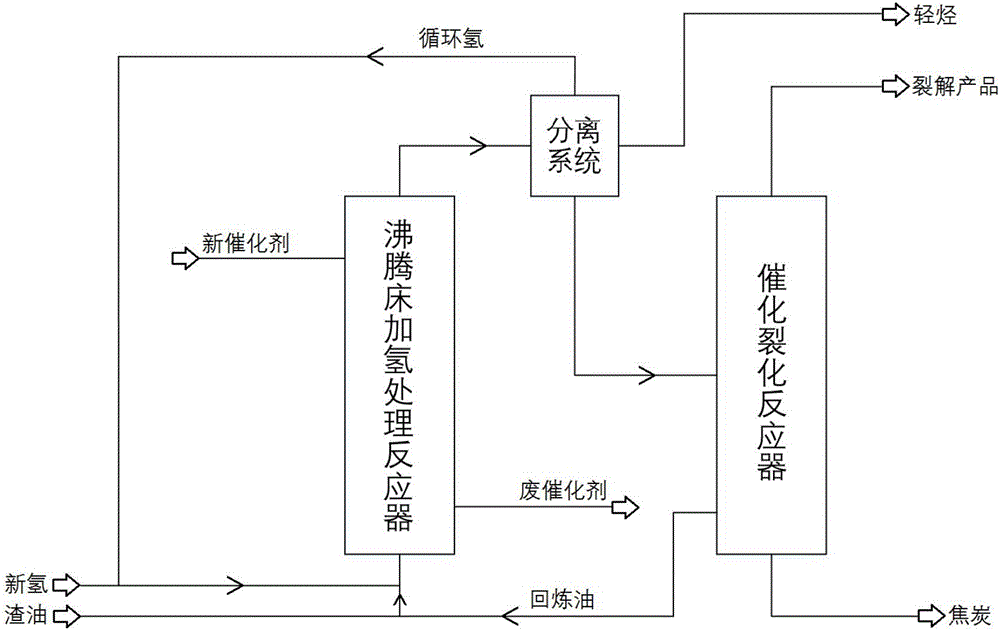

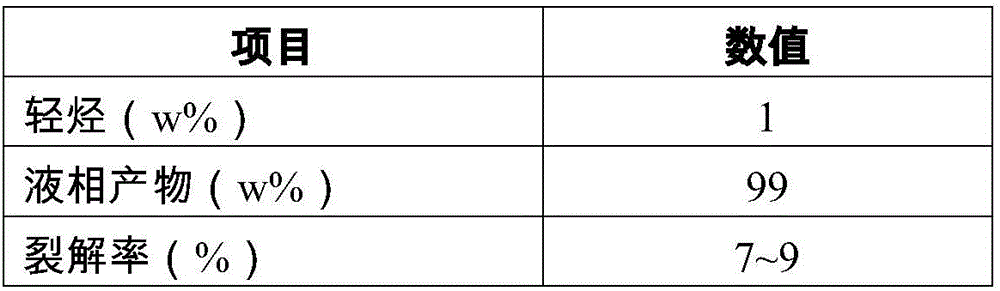

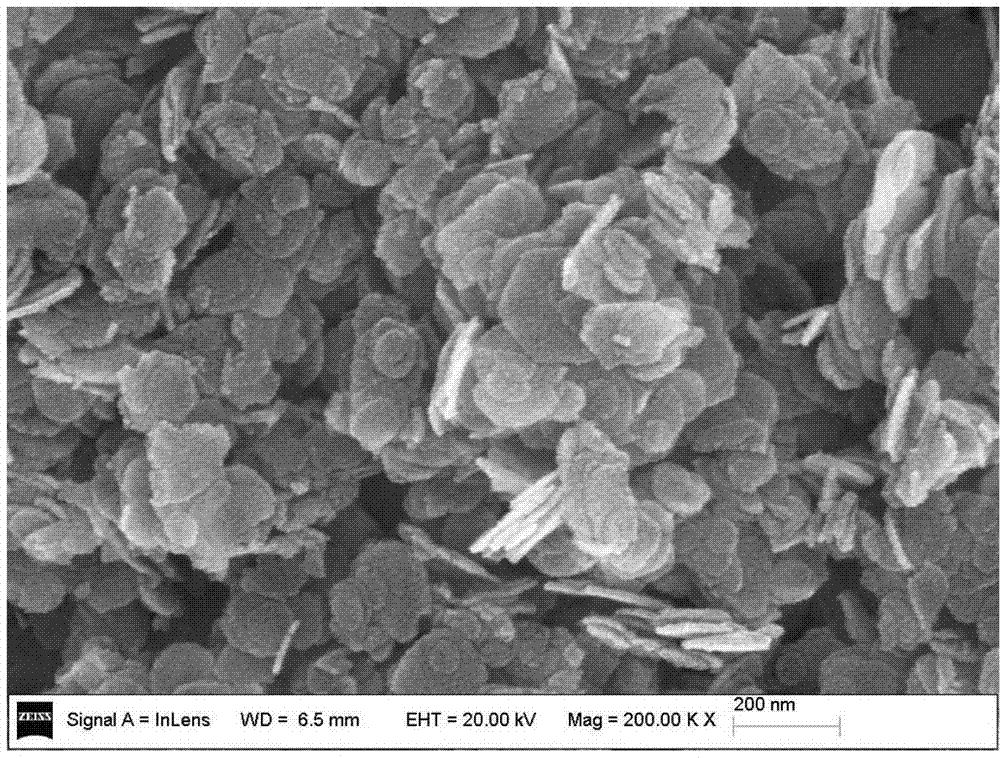

Fluidized bed hydrogenation and heavy oil catalytic cracking combining method and hydrogenation catalyst

InactiveCN106833741AReduce yieldHigh yieldTreatment with hydrotreatment processesMetal/metal-oxides/metal-hydroxide catalystsGas phaseSlurry

The embodiments of the present invention provide a combined method of ebullating bed hydrogenation and heavy oil catalytic cracking and a hydrogenation catalyst. The heavy oil raw material and hydrogen are subjected to hydrogenation reaction under the catalysis of hydrogenation catalyst, the hydrogenation reaction product is subjected to gas-liquid separation, the hydrogen in the separated gas phase is recycled for hydrogenation reaction, and the separated liquid phase is further catalyzed Cracking reaction, recovering the cracking products in the cracking products, mixing and recycling the recycled oil and heavy oil raw materials in the cracking products for hydrogenation reaction; the hydrogenation catalyst is a particle supported by silicon-aluminum oxide, with a particle size range of 0-300 μm, Directed hydrogenation of aromatic rings in heavy oil molecules, including gums, can be performed. The technical scheme of the invention improves the quality of catalytic cracking raw materials, improves the distribution of products, greatly reduces the oil slurry yield of catalytic cracking, or does not produce oil slurry, and can greatly improve the economic benefits of the combined process.

Owner:SHANGHAI HOTO PETROCHEM ENG

Gasoline sweetening method

InactiveCN109331830AHigh sweetening activityGood choiceHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsFixed bedReaction temperature

The invention relates to a gasoline sweetening method. A fixed bed reactor is adopted, and a catalyst comprises a silica-alumina support, metal active components nickel, molybdenum and copper supported on the support and aid phosphorus. Based on the weight of the catalyst, the catalyst comprises 2wt.%-15wt.% of nickel oxide, 2wt.%-18wt.% of molybdenum oxide, 0.1wt.%-2.0wt.% of copper oxide and 0.01wt.%-2.2wt.% of the aid phosphorus. The reaction is conducted under conditions that reaction temperature is 110-220 DEG C, reaction pressure is 1.1-3.5 MPa, gaseous hourly space velocity is 1.2-4.0 h<-1>, and volume ratio of hydrogen to oil is (7-25):1. The catalyst has the characteristics of high sweetening activity, high diolefin hydrogenation selectivity, low octane number loss and strong adaptability to different oil products.

Owner:张丽娥

Loaded nickel-indium (Ni-In) intermetallic compound catalyst and preparation method thereof

InactiveCN103223345BType adjustableParticle size controllableOrganic compound preparationHydroxy group formation/introductionLactate dehydrogenaseIndium

The invention belongs to the technical field of the catalyst preparation, and in particular relates to a loaded nickel-indium (Ni-In) intermetallic compound catalyst and a preparation method thereof. Adjustable hydrotalcite consisting of components such as nickel magnesium indium-lactate dehydrogenase (NiMgIn-LDHs) and nickel aluminum indium-lactate dehydrogenase (NiAlIn-LDHs) is selected as a precursor, and the hydrotalcite is slowly heated and reduced at a low temperature to prepare the loaded Ni-In intermetallic compound catalyst. The prepared loaded Ni-In intermetallic compound catalyst is adjustable in variety, controllable in granularity, good in dispersion property, high in hydrogenation selectivity, good in heat stability and adjustable in hydrogenation activity and selectivity for different alpha, beta-unsaturated aldehydes. The preparation method has a simple equipment process and high yield and is convenient for the industrialized production. The catalyst is used for catalyzing selective hydrogenation of different alpha, beta-unsaturated aldehydes to produce unsaturated enol, the conversion rate of reactants is high, the selectivity of products is high, and the yield of the unsaturated enol can reach more than 95 percent.

Owner:BEIJING UNIV OF CHEM TECH

A kind of unsaturated hydrocarbon selective hydrogenation catalyst and preparation method

ActiveCN109433218BHigh hydrogenation selectivityImprove anti-glue abilityHeterogenous catalyst chemical elementsHydrocarbon oils refiningPtru catalystUnsaturated hydrocarbon

Owner:YANTAI BAICHUAN HUITONG TECH CO LTD

Selective hydrogenation method for pyrolysis gasoline

ActiveCN109364929AHigh hydrogenation selectivityImprove anti-glue abilityHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsLanthanumMagnesium

The invention relates to a selective hydrogenation method for pyrolysis gasoline. A catalyst comprises a silicon oxide-aluminum oxide carrier and a metal active component palladium loaded to the carrier. Palladium accounts for 0.15-0.45wt% of the total weight of the catalyst. The silicon oxide-aluminum oxide carrier comprises 0.1-12wt% of silicon oxide, 0.1-10wt% of nickel doped lanthanum ferriteand 0.05-7.8wt% of magnesium. The hydrogenation process conditions are as follows: the reaction inlet temperature is lower than or equal to 45 DEG C, the reaction pressure is 2.5-4.5 MPa, the hydrogenoil volume ratio is 60-450, and the liquid volume airspeed is 3.0-5.5h<-1>. The catalyst is good in colloid resistance and high in arsenic, sulfur and water resistance.

Owner:陈雅菁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com