C2 fraction selective hydrogenation method

A selective hydrogenation and fractionation technology, applied in hydrocarbons, chemical instruments and methods, purification/separation of hydrocarbons, etc., can solve problems such as insufficient loading of active components, impact on catalyst activity, and increase in catalyst cost , to achieve excellent hydrogenation activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

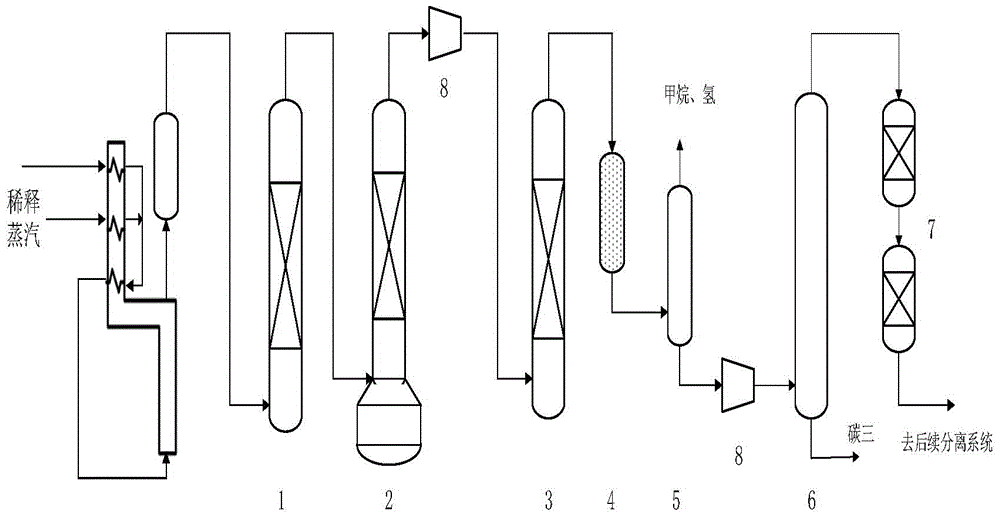

Method used

Image

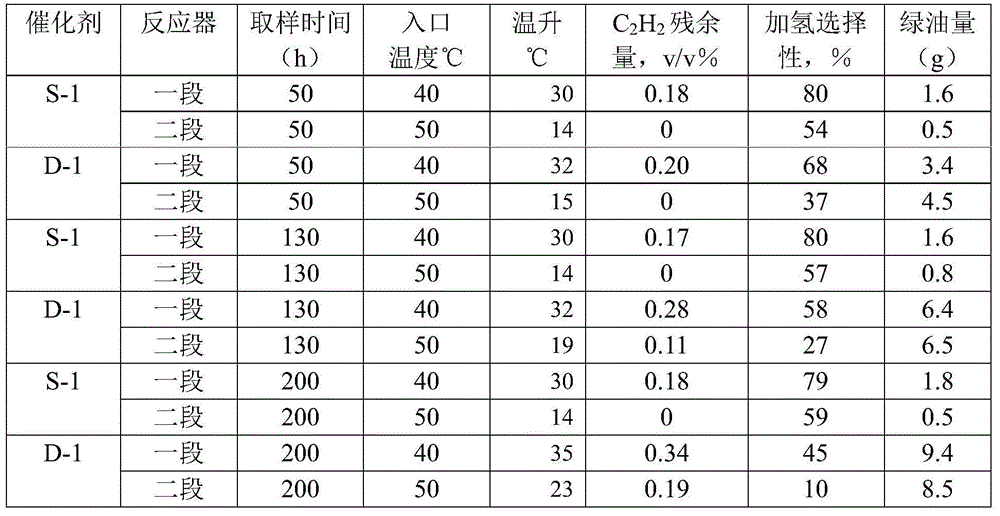

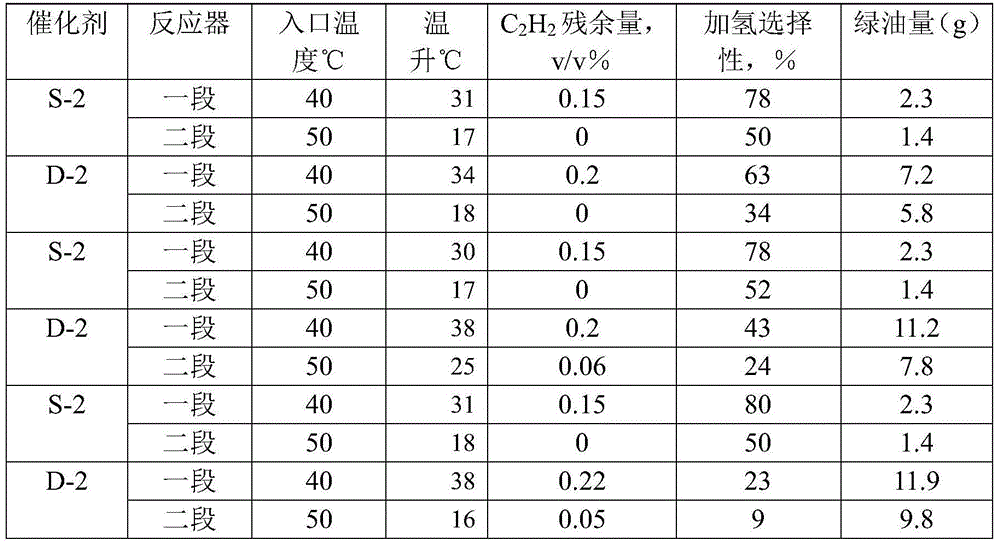

Examples

Embodiment 1

[0049] Weigh Φ3.4, the specific surface area is 21.0m 2 / g, pore volume 0.31mL / g, bulk density 0.81g / ml spherical α-Al 2 o 3 Carrier 500g.

[0050] Dissolve 52.37g of 4,4-dihydroxy-2,2-bipyridine in 500mL ethanol solution, impregnate the above-mentioned carrier in the above-mentioned solution, and let it stand for 2.5h to make 4,4-dihydroxy-2,2-bipyridine completely After being loaded on the alumina support, it was dried at 80°C for 8 hours to obtain the hydroxyl-bipyridine / Al 2 o 3 Prebody.

[0051] Weigh 0.37gPd(NO 3 ) 2 , 1.47gPb(NO 3 ) 2 Dissolve in 500mL deionized water, slowly add 10mL concentrated nitric acid, stir until completely dissolved, adjust pH to 2.2, and prepare a mixed solution. The above-mentioned hydroxyl-bipyridine / Al 2 o 3 The precursor was added to the prepared solution, stirred for 10 minutes, left to stand for 2.5 hours, and the residue was poured out to obtain PdPb-hydroxy-bipyridine / Al 2 o 3 Precursor (number of moles of hydroxyl-bipyrid...

Embodiment 2

[0068] Weigh Φ3.8mm, height 3.8mm, specific surface area is 54.0m 2 / g, cylindrical θ-Al with a pore volume of 0.46ml / g and a bulk density of 0.69g / ml 2 o 3 Carrier 500g.

[0069] Dissolve 2.01g of 4,4-dihydroxy-2,2-bipyridine in 650mL ethanol solution, immerse the above-mentioned carrier in the above-mentioned solution, and let the dihydroxy-2,2-bipyridine be completely loaded on the alumina carrier after standing for 8 hours After drying at 90°C for 8 hours, the hydroxyl-bipyridine / Al 2 o 3 Prebody.

[0070] Weigh 0.73gPd(NO 3 ) 2 , 4.61gPb(NO 3 ) 2 Dissolve in 650mL deionized water, adjust the pH value to 2.8, and make a mixed solution. The above-mentioned hydroxyl-bipyridine / Al 2 o 3 Add the precursor to the prepared solution, stir for 60 minutes, let stand for 8 hours, pour out the residual liquid, and dry the remaining solid at 100°C for 6 hours to obtain PdPb-hydroxy-bipyridine / Al 2 o 3 Precursor (hydroxyl-bipyridine moles: (Pd+Pb)=1).

[0071] The precurs...

Embodiment 3

[0088] Weigh Φ3.0mm, the specific surface area is 34.0m 2 / g, the pore volume is 0.25ml / g, and the heap ratio is 500g of the toothed spherical carrier of 0.76g / ml, in which Al 2 o 3 460g, titanium oxide 40g, Al 2 o 3 It is a mixed crystal form of θ and α.

[0089] Dissolve 98.45g of 6,6'-dihydroxy-3,3'-bipyridine in 700mL ethanol solution, impregnate the above carrier in the above solution, and let 6,6'-dihydroxy-3,3'- After the bipyridine was completely loaded on the alumina carrier, it was dried at 120°C for 4 h to obtain the hydroxyl-bipyridine / Al 2 o 3 Prebody.

[0090] Weigh 0.40gPd(NO 3 ) 2 ,0.74gPb(NO 3 ) 2 Dissolve in 600mL deionized water, adjust the pH value to 3.2, and make a mixed solution. The above-mentioned hydroxyl-bipyridine / Al 2 o 3 Add the precursor to the prepared solution, stir for 60 minutes, let stand for 8 hours, pour out the residue, and dry at 100°C for 8 hours to obtain PdPb-hydroxy-bipyridine / Al 2 o 3 Precursor (number of moles of hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com