Modified hydrodesulfurization catalyst and preparation method and application of modified hydrodesulfurization catalyst

A hydrodesulfurization and catalyst technology, which is applied in the production of clean gasoline hydrofining catalyst and its preparation, can solve the problems of low desulfurization rate, difficult process and large-scale preparation, etc., to maintain octane number, reduce sulfur content, and improve dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention relates to a preparation method of a modified hydrodesulfurization catalyst, and the specific steps may be:

[0035] Preparation of catalyst support: Al 2 o 3 , SiO 2 、TiO 2 One or more of the group consisting of MgO and MgO is prepared by sol-gel method, co-precipitation method or mechanical mixing method to prepare catalyst carrier powder, and extruding the catalyst carrier powder;

[0036] For example, the step of preparing catalyst carrier powder by sol-gel method is (wherein the carrier is made of Al 2 o 3 example):

[0037] Take 0.5mol / L of Al(NO 3 ) 3 9H 2 O solution and citric acid were mixed and dissolved at a molar ratio of 2:1, ammonia solution was added dropwise to adjust the pH value of the solution to 1, and a light yellow transparent solution was obtained, which was aged in a water bath at 70°C for 2 hours, then placed in a vacuum drying oven at 120°C Dry at constant temperature for 12 hours to obtain dry gel, then place the d...

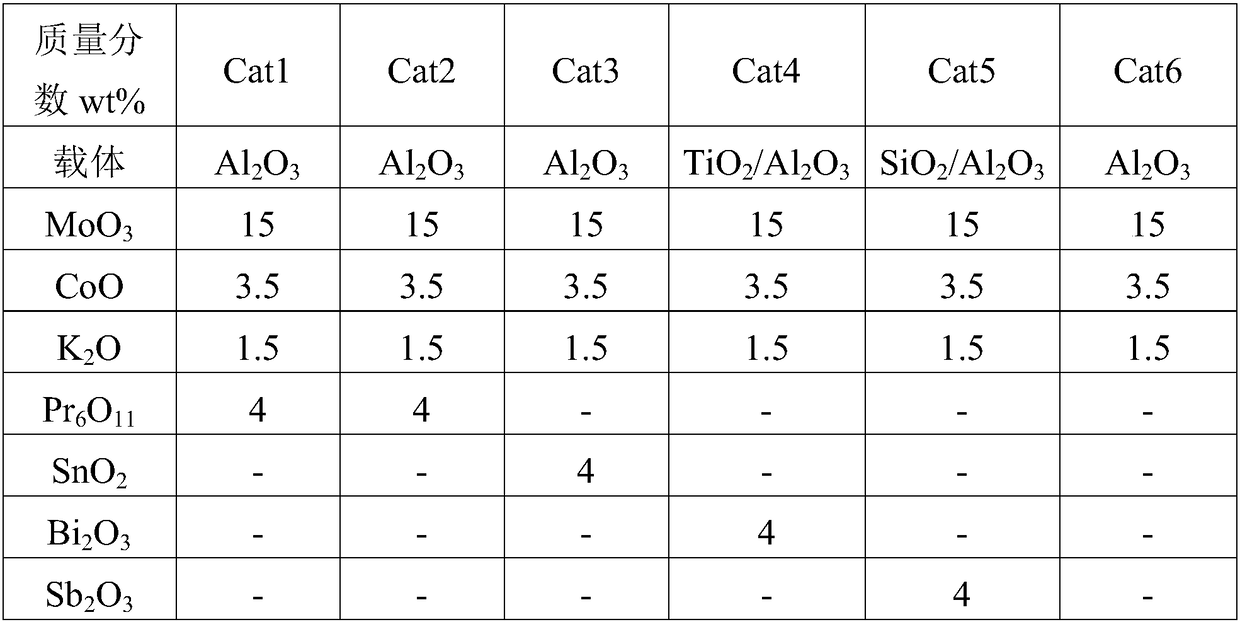

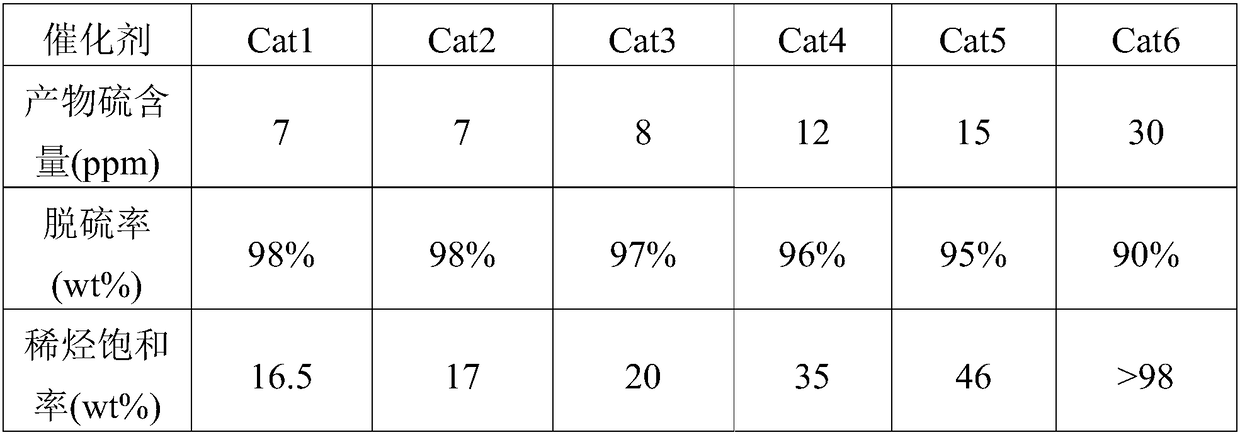

Embodiment 1

[0050] Preparation of Al by Sol-Gel Method 2 o 3 Carrier, the modified element is selected as Pr, which is mixed in the process of preparing carrier powder, Pr 6 o 11 The mass fraction of the catalyst is 4wt%.

[0051] Take 500mL of analytically pure 0.5mol / L Al(NO 3 ) 3 9H 2 O and citric acid were mixed and dissolved at a molar ratio of 2:1, and 3 mol / L ammonia solution was added dropwise to adjust the pH value of the solution to 1, and a light yellow transparent solution was obtained, which was designated as solution A. 0.4mol / L Pr(NO 3 ) 3 The solution (praseodymium oxide is heated and dissolved in nitric acid) is recorded as solution B. After mixing 392mL A and 8mL B solution for 1h, put it in a water bath at 70°C for 2h aging, then put it in a vacuum drying oven, and dry it at a constant temperature of 120°C for 12h to obtain dry Gel, and then put the dried gel in a muffle furnace and bake it at 800°C for 4 hours, and grind it into powder to obtain Pr with a Pr el...

Embodiment 2

[0054] Preparation of Al by Sol-Gel Method 2 o 3 Carrier, select the modifying element as Pr, Pr 6 o 11 The mass fraction of the catalyst is 4wt%, and the difference is that the carrier powder is impregnated and modified after the carrier powder is prepared.

[0055] Take 500mL of analytically pure 0.5mol / L Al(NO 3 ) 3 9H 2 O solution and citric acid were mixed and dissolved at a molar ratio of 2:1, and 3mol / L ammonia solution was added dropwise to adjust the pH of the solution to 1 to obtain a light yellow transparent solution, which was aged in a water bath at 70°C for 2 hours, and then placed in a vacuum drying oven. Inside, dry at 120°C for 12 hours to obtain dry gel, then place the dry gel in a muffle furnace to roast at 800°C for 4 hours, and grind it into powder to obtain Al 2 o 3 carrier. 40mL0.4mol / L Pr(NO 3 ) 3 Solution (praseodymium oxide heated and dissolved in nitric acid) impregnated with 50g Al 2 o 3 The carrier was then placed in an oven at 120°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com