Unsaturated C5 fraction and hydrogenation method

An unsaturated, fractional technology, applied in chemical instruments and methods, through selective hydrorefining, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem that diolefins do not have hydrogenation selectivity, etc. Achieve the effect of improving anti-colloid ability, low coking rate and high hydrogenation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of silica-alumina composition 1

[0032] 1. Preparation of nickel-containing magnesium aluminate LaMgAl 11 o 19 The process is as follows:

[0033] Take 7.8 grams of basic magnesium carbonate, 25 grams of lanthanum carbonate and 70.5 grams of aluminum hydroxide, mix well, add deionized water to form a highly dispersed suspension, then add 8 grams of nickel nitrate, spray dry, and dry at 140 ° C for 5 hours. and placed in an air atmosphere at 1300° C. for 4 hours and then ball milled for 18 hours to obtain nickel-containing magnesium lanthanum aluminate powder. The nickel-containing magnesium-lanthanum aluminate powder is added with water, and the highly dispersed nickel-containing magnesium-lanthanum aluminate slurry is obtained after ultrasonic vibration.

[0034] 2. Preparation of silica-alumina composition

[0035] Take 150g of pseudo-boehmite and 24g of scallop powder, mix evenly, add dilute nitric acid, then add 26g of sodium polyacrylate nitric...

Embodiment 2

[0039] (1) Preparation of silica-alumina composition 2

[0040] The preparation of nickel-containing magnesium lanthanum aluminate is the same as in Example 1, the preparation of the silica-alumina composition is the same as in Example 1, and 68% of pseudo-boehmite is mixed evenly with squat powder, and the pore-enlarging agent 1 is sodium polyacid. The added amount accounts for 19% of the mass of the added alumina, and the added amount of the pore expander 2 chitosan accounts for 4% of the added mass of the alumina and silicon oxide. The silica-alumina composition contained 6.1 wt% of silica and 5.8 wt% of nickel-containing magnesium lanthanum aluminate.

[0041] (2) Preparation of catalyst

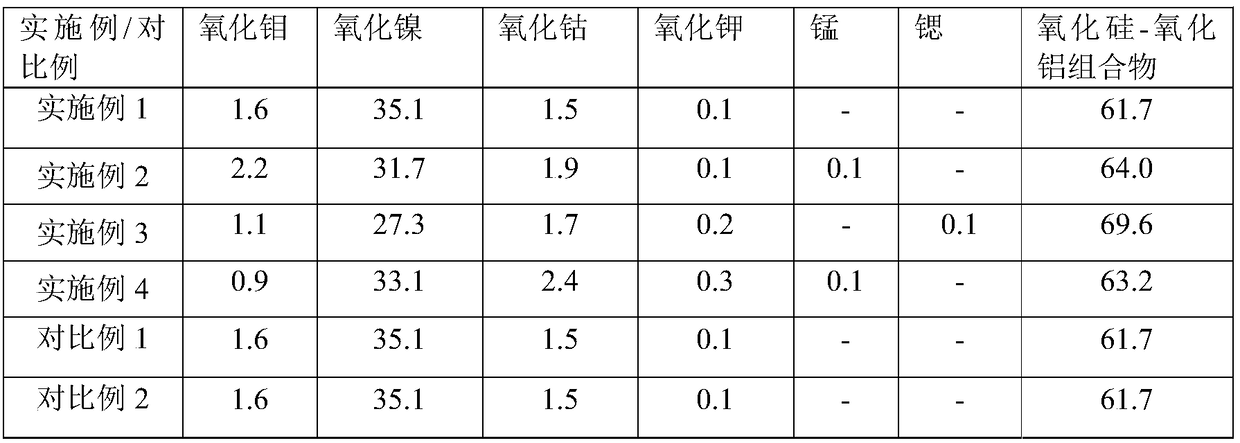

[0042] The preparation method of the catalyst is the same as in Example 1. The polyacrylic acid solution and the silica-alumina composition powder are mixed evenly in a volume ratio of 1.8:1. The composition of the catalyst is shown in Table 1.

Embodiment 3

[0044] (1) Preparation of silica-alumina composition 3

[0045] The preparation of nickel-containing magnesium lanthanum aluminate is the same as in Example 1, the preparation of the silica-alumina composition is the same as in Example 1, and 72% of pseudo-boehmite is mixed evenly with squat powder, and the pore-enlarging agent 1 is polyacrylate The added amount accounts for 21% of the mass of the added alumina, and the added amount of the pore-enlarging agent 2 methylcellulose accounts for 2.6% of the added mass of the alumina and silicon oxide. The silica-alumina composition contained 4.3 wt% silica and 5.9 wt% nickel-containing magnesium lanthanum aluminate.

[0046] (2) Preparation of catalyst

[0047] The preparation method of catalyst 3 was the same as that in Example 1. Sodium polyacrylate was added to dilute nitric acid and mixed evenly with the silica-alumina composition powder at a volume ratio of 1.5:1. The composition of the catalyst was shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com