Patents

Literature

58results about How to "Conducive to long cycle operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for treating waste liquid from catalytic cracking flue gas desulfurization

InactiveCN104418447AReduce dust concentrationReduce wearWater/sewage treatment by centrifugal separationSludge treatmentLiquid wasteSlurry

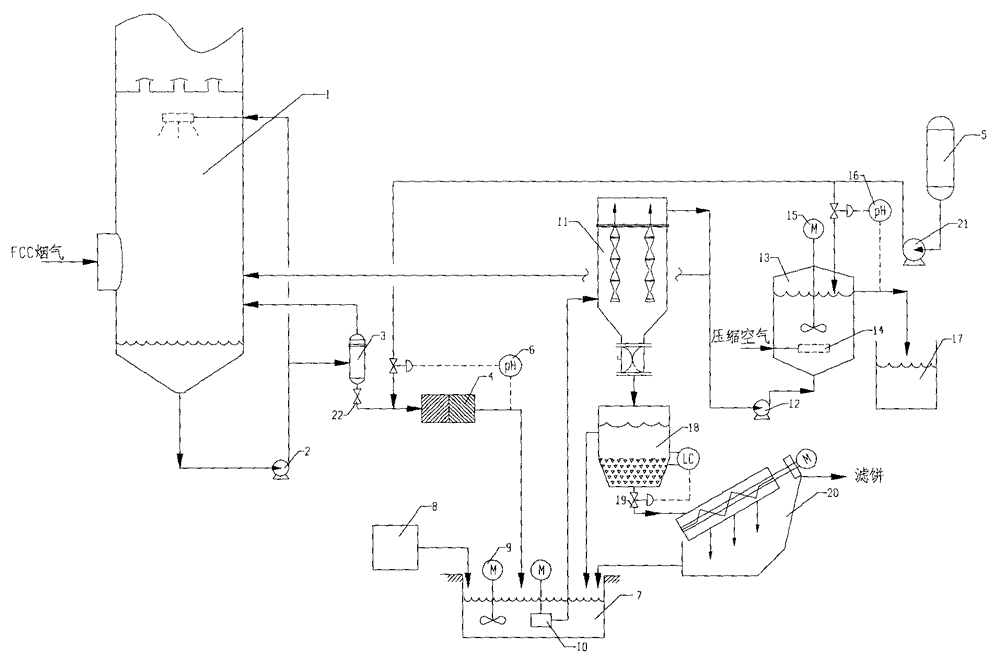

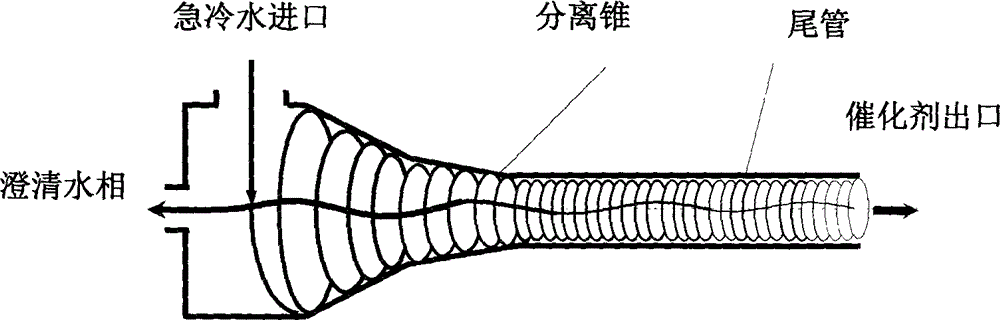

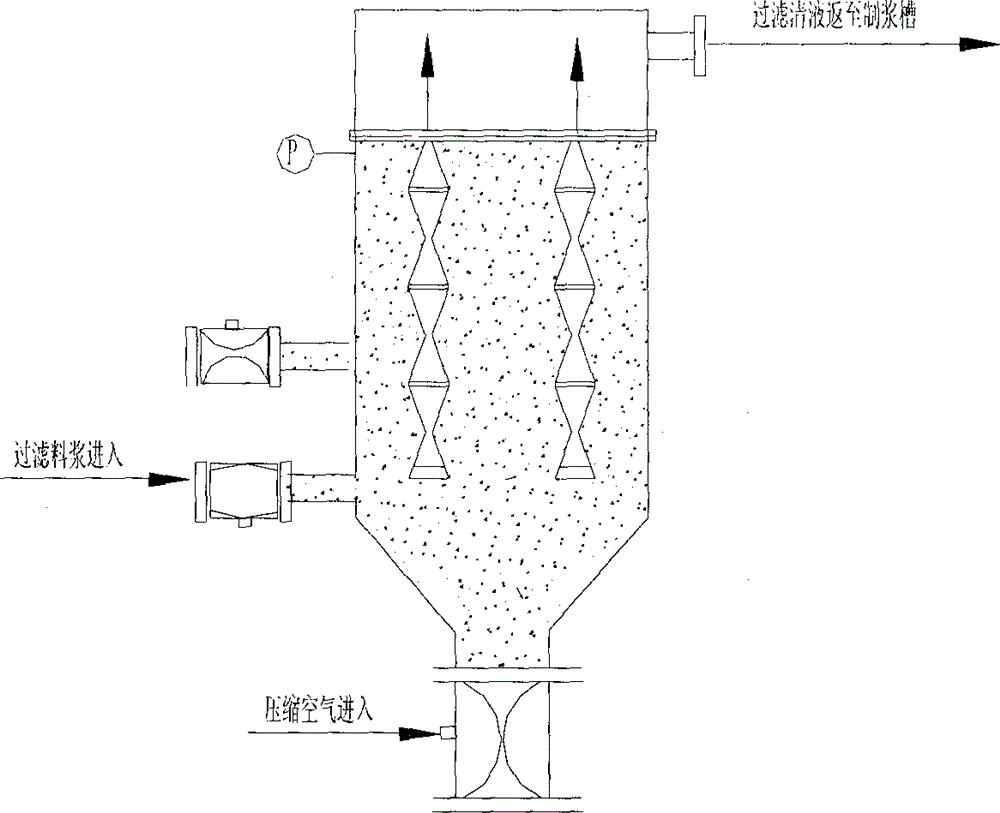

The invention provides a process for treating waste liquids from catalytic cracking flue gas desulfurization. The process comprises the following steps: enabling a part of waste liquids from a quenching washing tower to enter a hydraulic cyclone separator so as to be subjected to solid-liquid separation, returning the thin liquids to the quenching washing tower so as to be recycled, enabling the thick liquids to enter a neutralization reactor so as to be subjected to neutralization reaction, enabling the neutralized waste liquids to enter a slurry pond so as to be mixed with a flocculating agent uniformly, and enabling the mixture to enter an expansion-drum type filter so as to be subjected to solid-liquid separation with a thick slurry and a supernatant being obtained; returning part of the supernatant to the quenching washing tower so as to be recycled, discharging the remaining supernatant into an oxidation tank, removing the pseudo-COD containing sulfite roots and bisulfite roots by oxidizing, and directly discharging the qualified sewage; enabling the thick slurry to enter a settling pond from the bottom of the expansion-drum type filter so as to be further settled, feeding the thick slurry subjected to settlement into a dewatering machine so as to be concentrated and dewatered, directly transporting the filter cakes obtained by dewatering the thick slurry, returning the filtrate from the dewatering of the thick slurry to the slurry pond, and mixing the filtrate with the waste liquids so as to be retreated. The process provided by the invention has the advantages of a stable and efficient treatment effect, strong shock resistance, low investment and small floor area occupation and convenience of operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

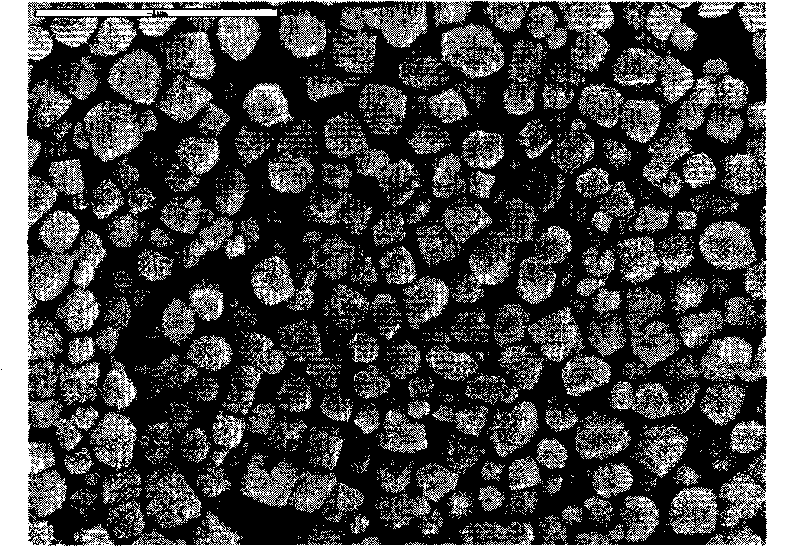

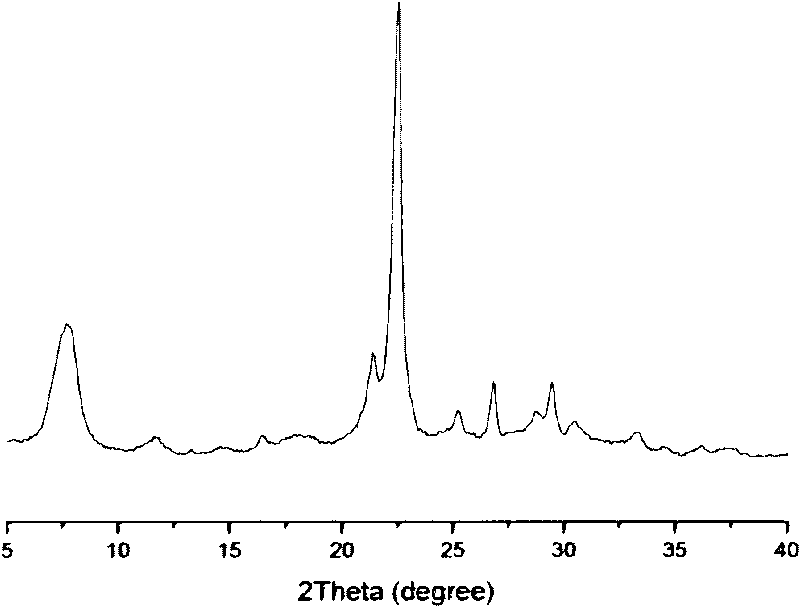

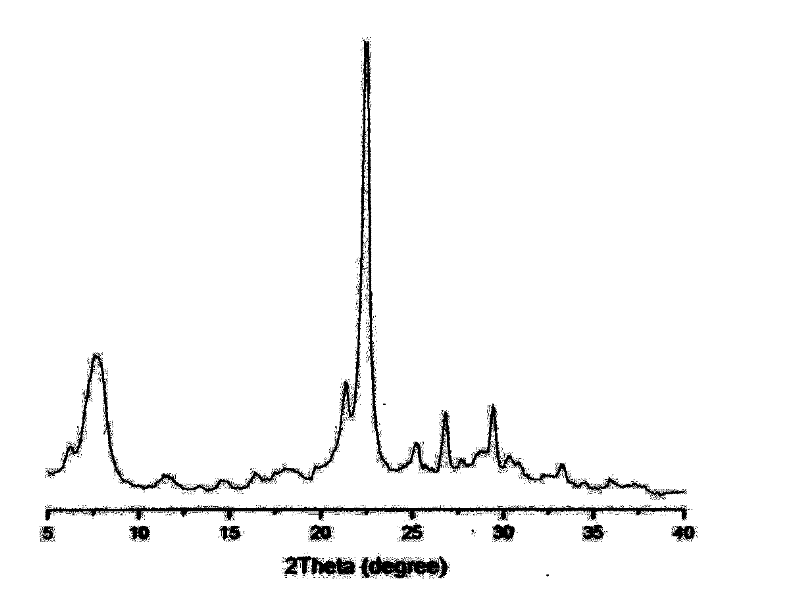

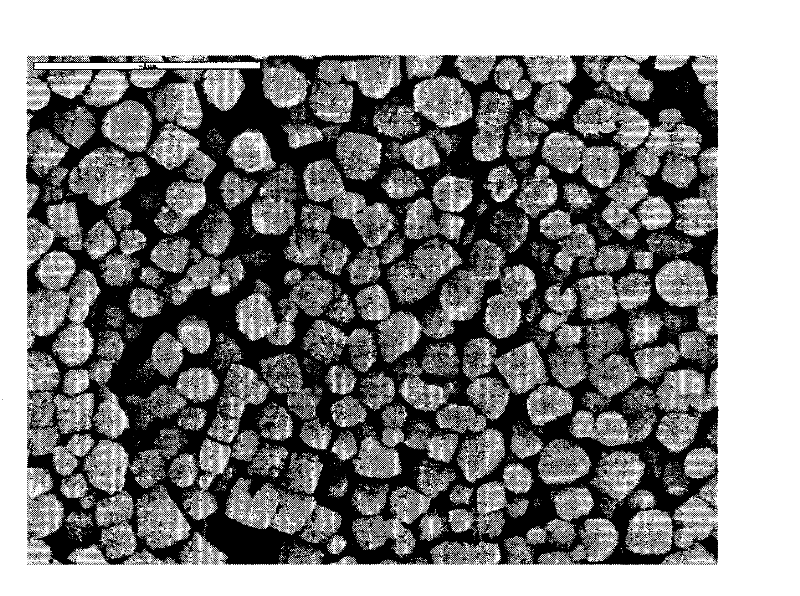

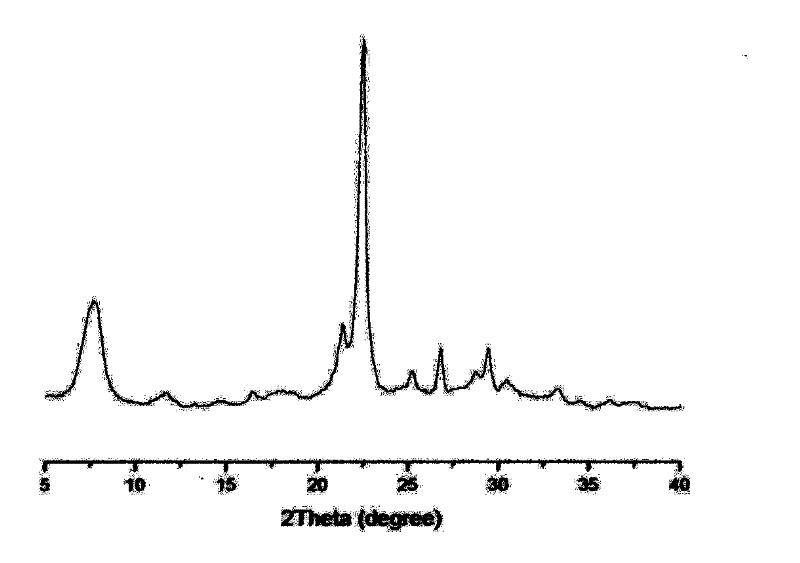

Nano-beta molecular sieve with low Si/Al ratio and preparation method thereof

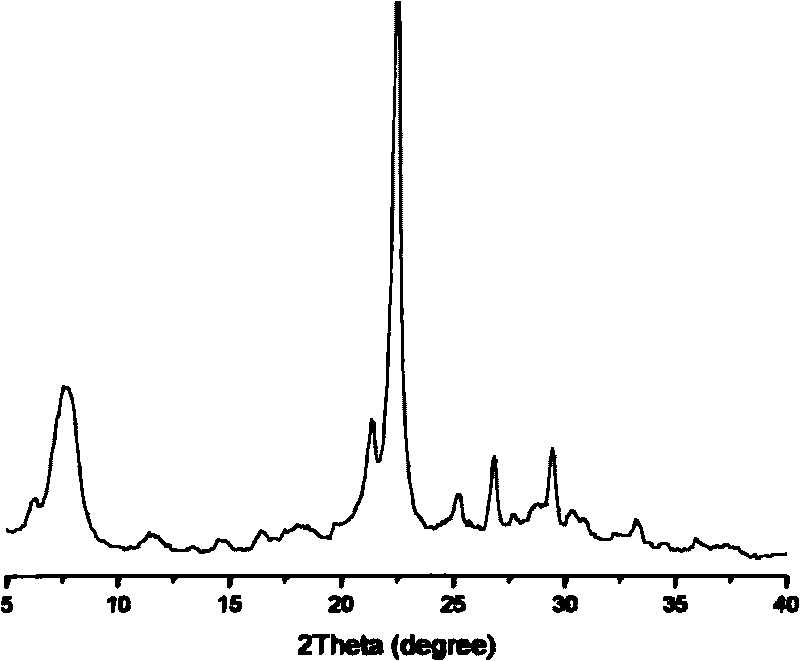

ActiveCN101723394AIncrease acidityHigh catalytic activityMolecular-sieve and base-exchange compoundsMolecular sieveSynthesis methods

The invention relates to a nano-beta molecular sieve with low Si / Al ratio and a synthesis method thereof. The method uses a low-cost microporous molecular sieve of FAU configuration as an aluminum source to synthesize the nano-beta molecular sieve under the condition of adding a conventional silicon source and a non-toxic cheap template agent. The Si / Al molar ratio of a framework of the nano-beta molecular sieve is between 4 and 9, grains are spherical or cuboidal, and the grain size is between 30 and 200nm. Due to the two characteristics of low Si / Al ratio and nanoscale grain size, the nano-beta molecular sieve can remarkably improve catalytic activity and inhibit the generation of coking at the same time. A raw material, namely the FAU molecular sieve adopted by the method has lower cost, so the method is particularly suitable for industrial mass production and industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

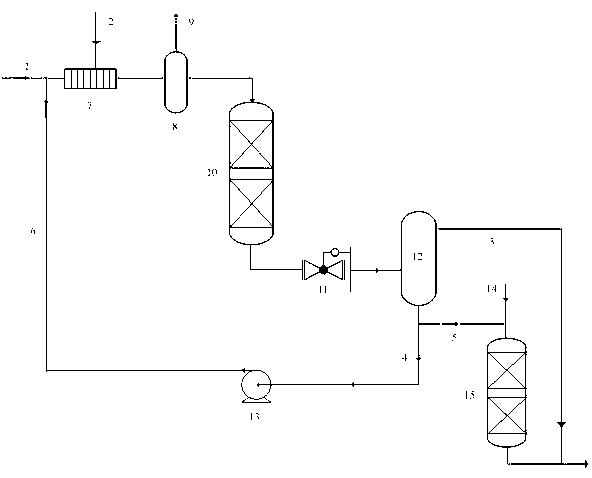

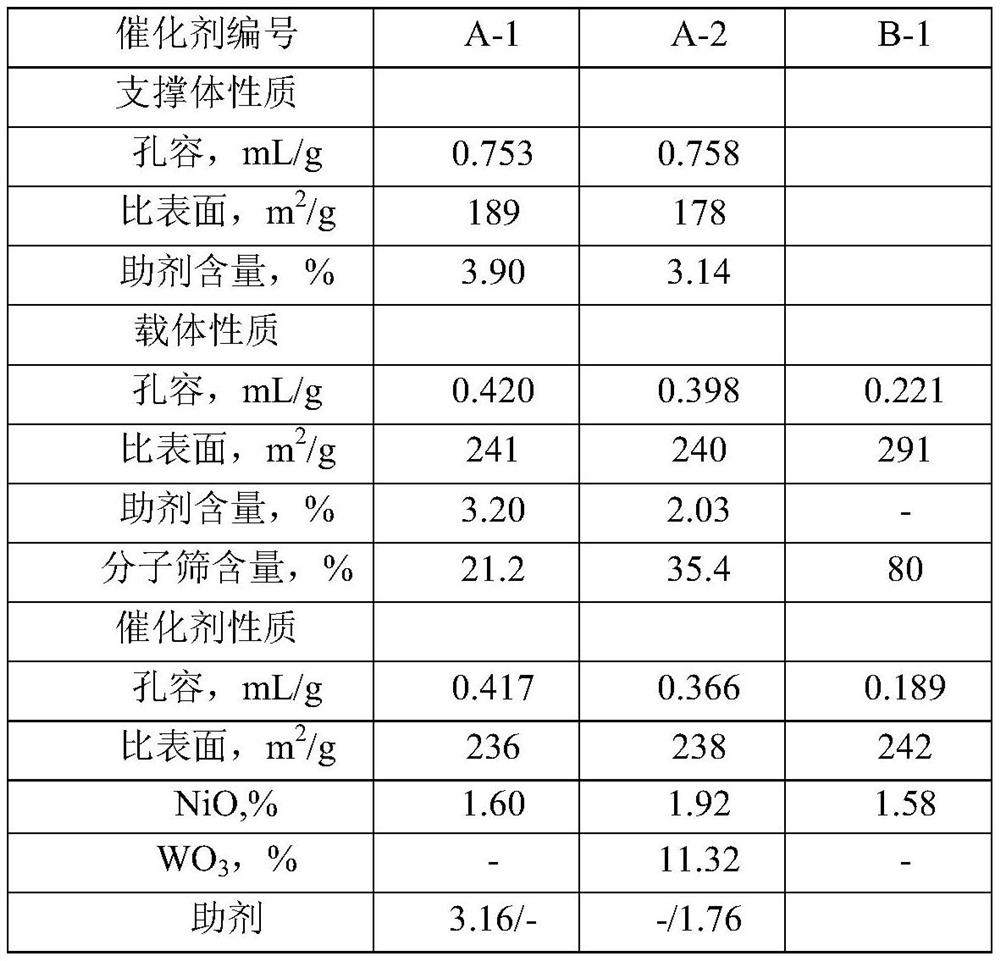

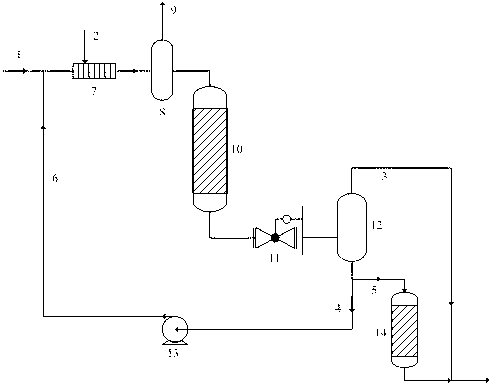

Deep desulphurization dearomatization combination method of diesel oil

ActiveCN102876367AImprove efficiencyModerate operating conditionsTreatment with hydrotreatment processesHydrodesulfurizationSulfide

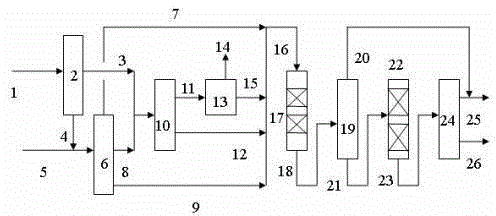

The invention discloses a deep desulphurization dearomatization combination method of diesel oil, comprising the following steps of: allowing fresh diesel oil feedstock to enter a hydrogen mixing pot, fully dissolving hydrogen, and entering a liquid phase hydrogenation reactor for refining reaction; allowing the obtained refined effluent to enter a high-temperature low-pressure flash evaporation pot for flash evaporation so as to obtain a liquid phase heavy fraction; allowing part of the heavy fraction to recycle and return to the hydrogen mixing pot and the other part of the heavy fraction to undergo hydrogenation modification, mixing the modified heavy fraction and the light fraction obtained by flash evaporation, and separating to obtain the diesel oil product. According to the method, liquid-phase hydrogenation is performed under mild conditions to remove simple sulfide in the diesel oil feedstock; after flash evaporation, the recycled heavy fraction continues to undergo hydrodesulfurization; and through hydrogenation modification, hardly-removed dibenzothiophene compounds and aromatic hydrocarbons in the heavy fraction are selectively removed. In comparison with a traditional technology, the method provided by the invention has advantages of deeper desulphurization and dearomatization and high yield of diesel oil. Under the same reaction depth, the operation condition is milder, which is beneficial to long-period running of equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

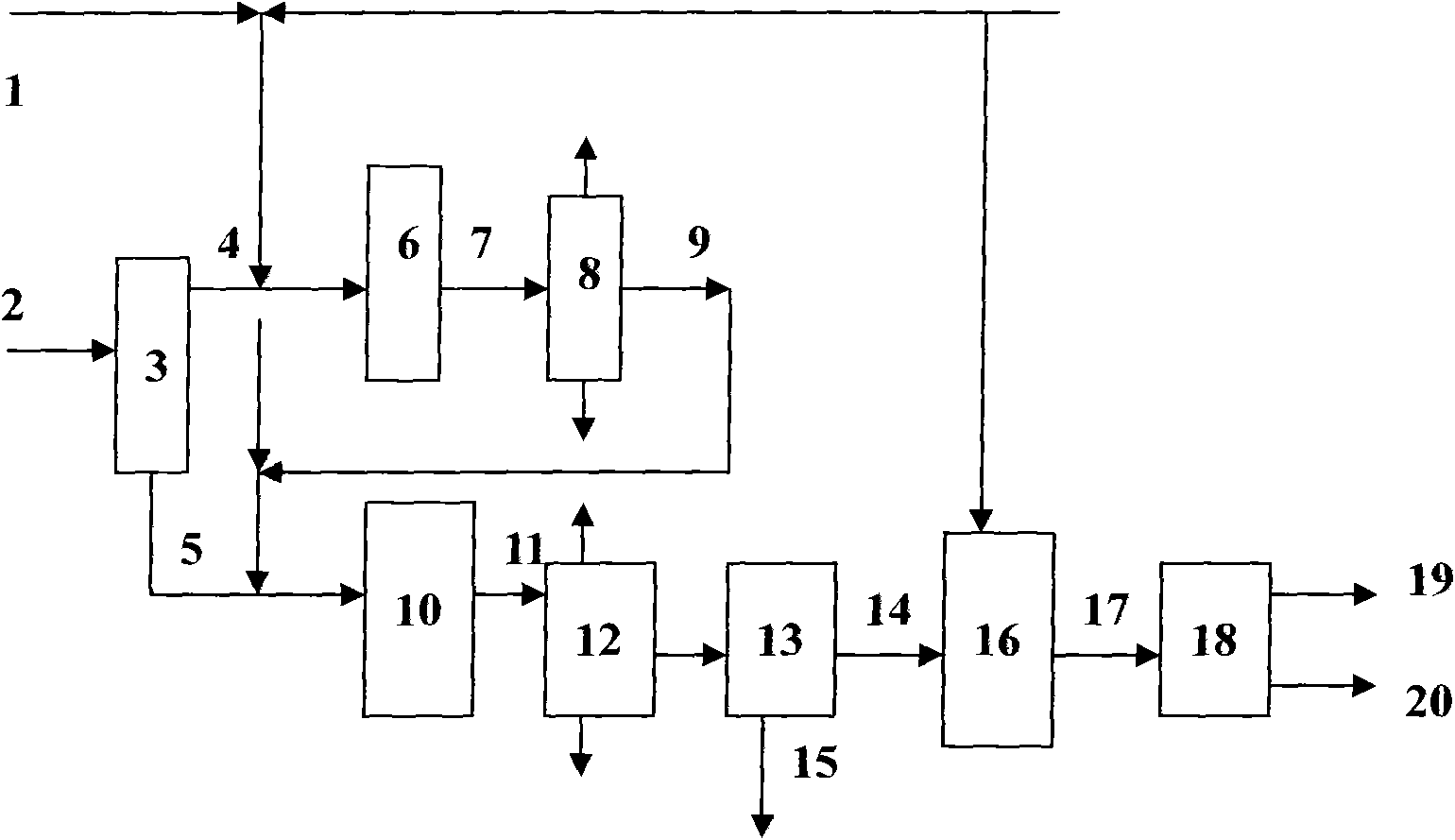

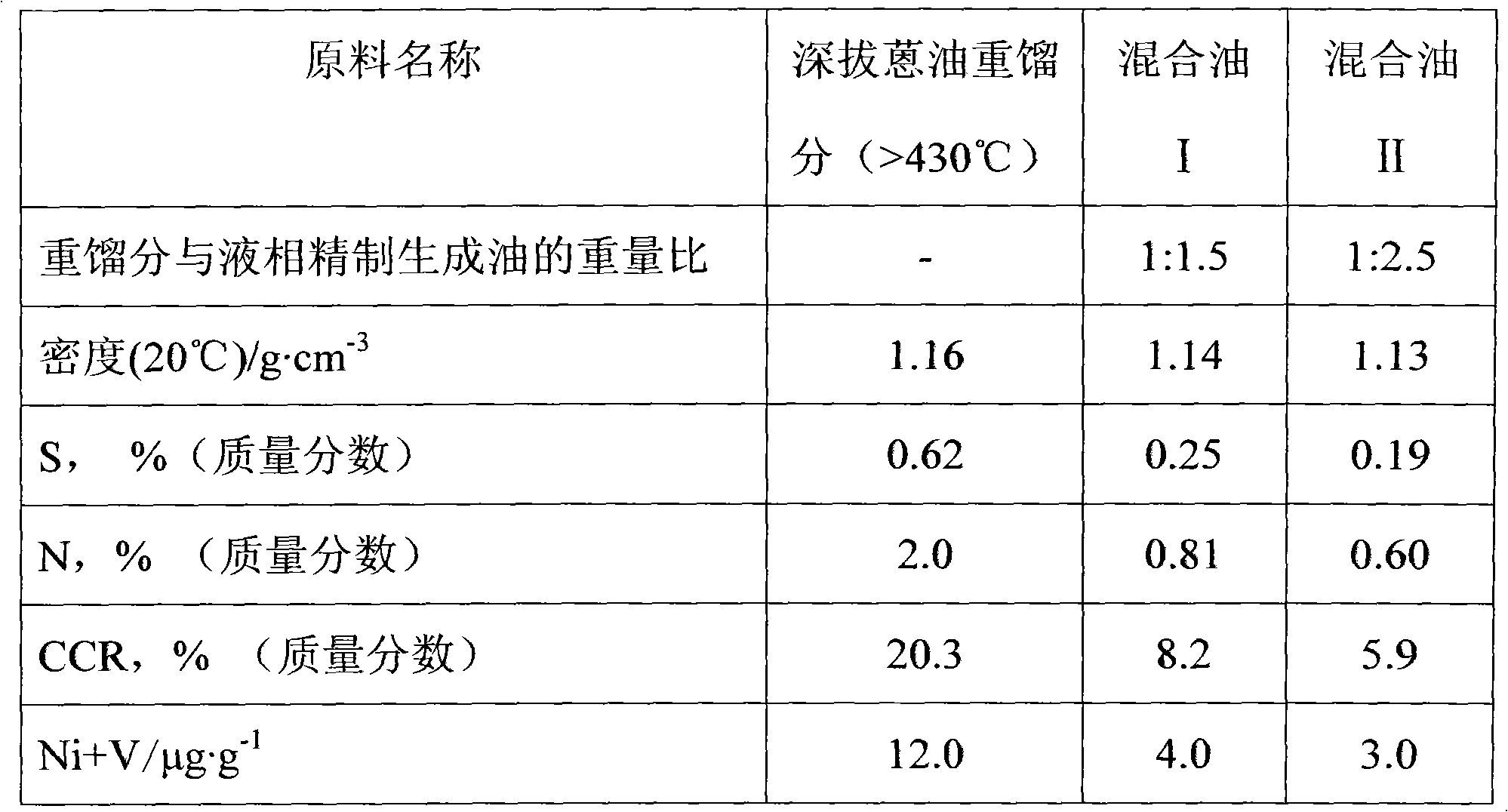

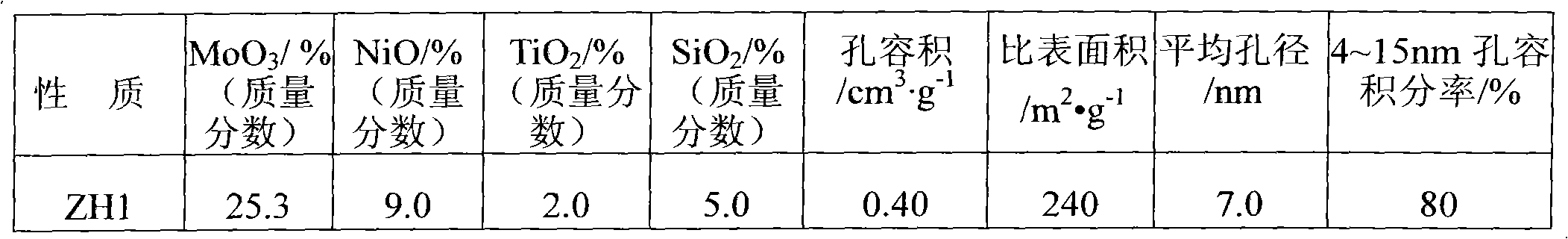

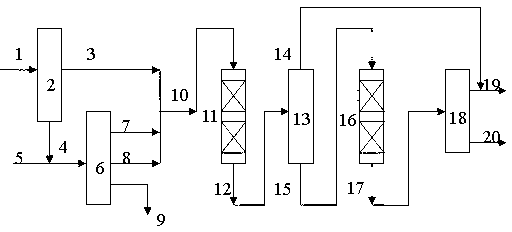

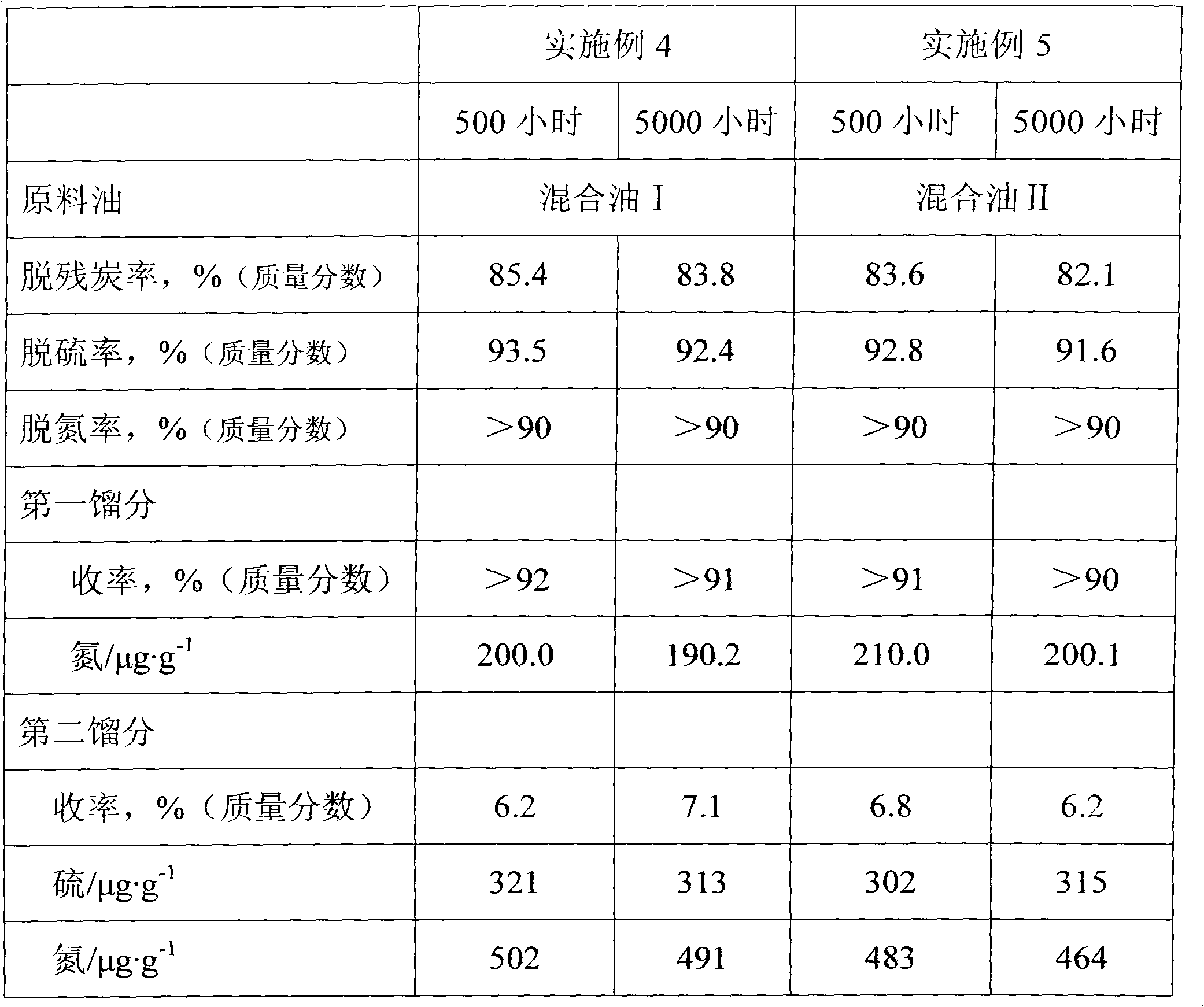

Hydroconversion method of deep cut anthracene oil

ActiveCN102041079AHigh yieldIncrease added valueTreatment with hydrotreatment processesAnthraceneLighter fuel

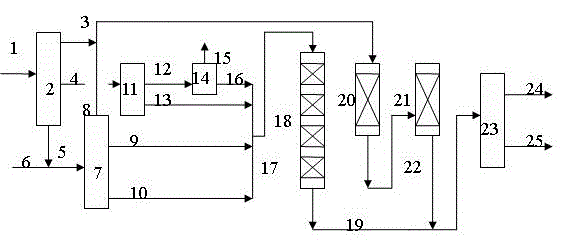

The invention provides a hydroconversion method of deep cut anthracene oil. The method comprises the following steps of: fractionating deep cut anthracene oil into a light fraction and a heavy fraction, then separating the light fraction after hydrofining, refining the liquid phase which is obtained during the separating process to generate an oil, infusing the oil and the heavy fraction into the hydroconversion region and then separating the heavy fraction from the oil which is generated during the hydroconversion process, wherein the first fraction which is light is entered into the hydrocracking region, and the cracked product which is obtained during the hydrocracking process is infused into the fractionation system to obtain gasoline and diesel fractions. The hydroconversion method of deep cut anthracene oil provided by the invention has the advantages that the deep cut anthracene oil is inversed into light fuel oil by means of hydroconversion, an application way with high additional value is provided to coal tar, the operation of the device is stable by optimizing the process, and the running period of the device is long.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing light fuel oil from ethylene tar

ActiveCN103102979AImprove product qualityBroaden sources of raw materialsTreatment with hydrotreatment processesLighter fuelGasoline

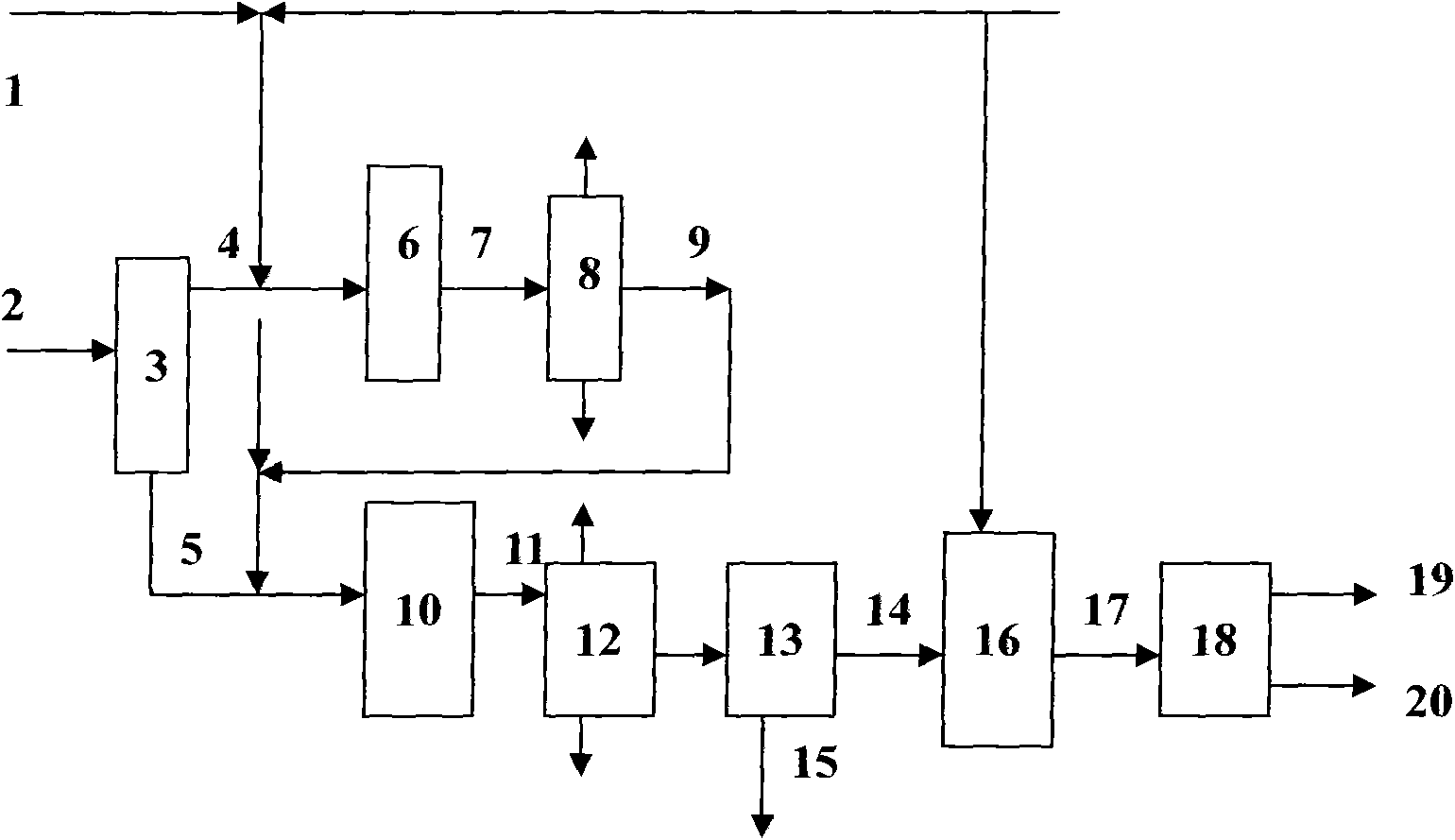

The invention discloses a method for producing light fuel oil from ethylene tar. The method is as below: fractionating ethylene tar into a light fraction and a heavy fraction; mixing the heavy fraction with a conventional coking raw material, and subjecting the mixture to delayed coking to obtain coker gasoline, coker diesel and coker gas oil; mixing the coker gasoline and the coker diesel with the light fraction of the ethylene tar, and subjecting the mixture to a hydrofining reaction; distilling the product to obtain a gasoline fraction I and a fraction heavier than the gasoline; subjecting the fraction heavier than the gasoline to a hydrogenation treatment to obtain light fuel oil, and distilling to obtain a gasoline fraction II and a diesel product; and mixing the gasoline fraction I and the gasoline fraction II to obtain a final gasoline product. The method provided by the invention utilizes the characteristics of high contents of ethylene tar aromatic hydrocarbons, colloid, carbon residue and glial and asphaltene of ethylene tar to fractionate the ethylene tar into the light fraction and the heavy fraction; different processing methods are employed to improve the added value of ethylene tar, increase yield of gasoline and diesel, improve product quality of light fuel oil and realize long-period stable operation of devices.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of transformer oil base oil

ActiveCN112625773AReduce manufacturing costIncrease profitCatalyst carriersMolecular sieve catalystsPtru catalystProcess engineering

The invention discloses a preparation method of transformer oil base oil, and the method comprises the following steps of: sequentially carrying out hydrodewaxing reaction and hydrofinishing reaction on raw oil to obtain the transformer oil base oil. According to the method, a hydrodewaxing catalyst with a specific structure is adopted in the hydrodewaxing reaction process, and the hydrofinishing process is combined, so that the prepared transformer oil base oil is low in pour point and aromatic hydrocarbon content.

Owner:CHINA NAT OFFSHORE OIL CORP +3

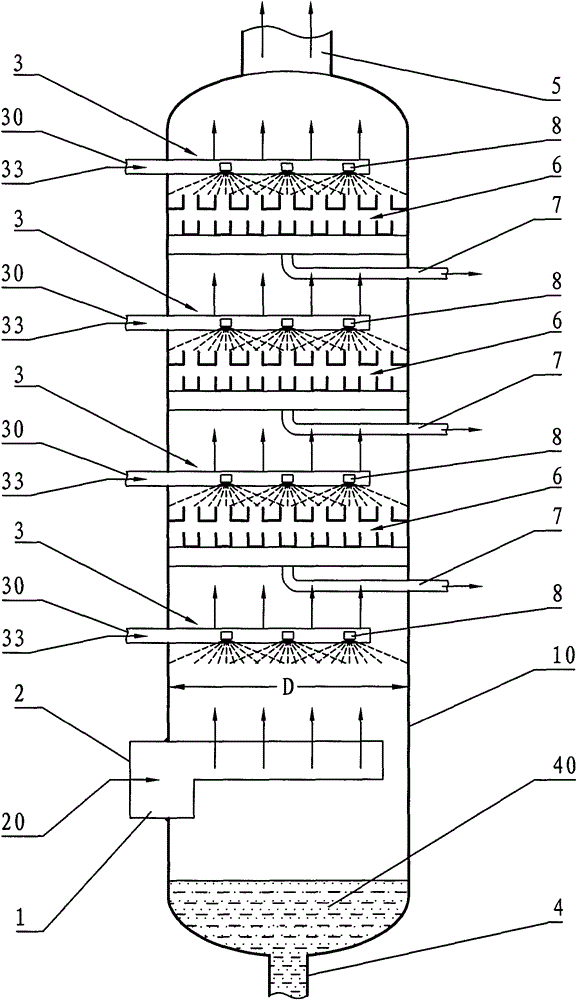

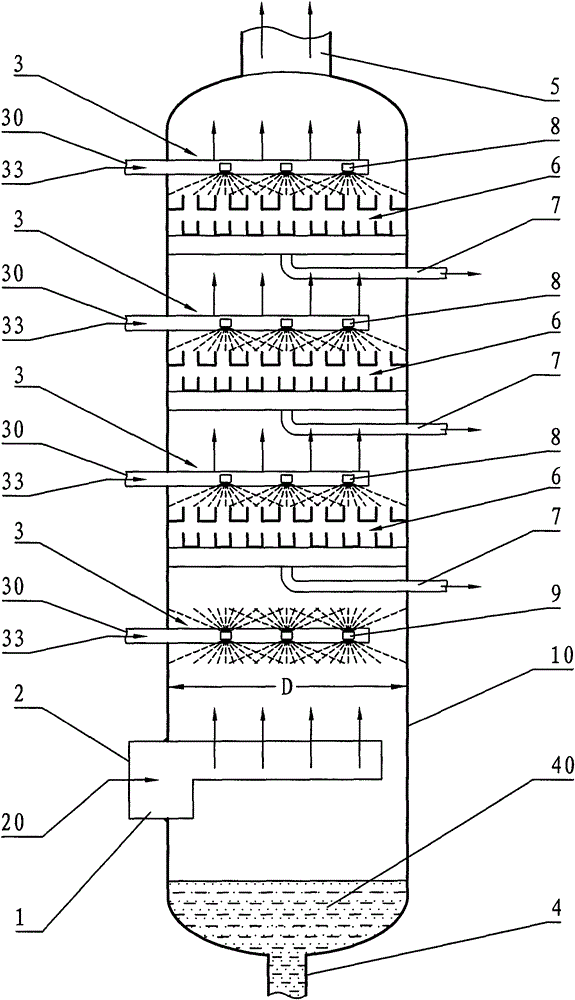

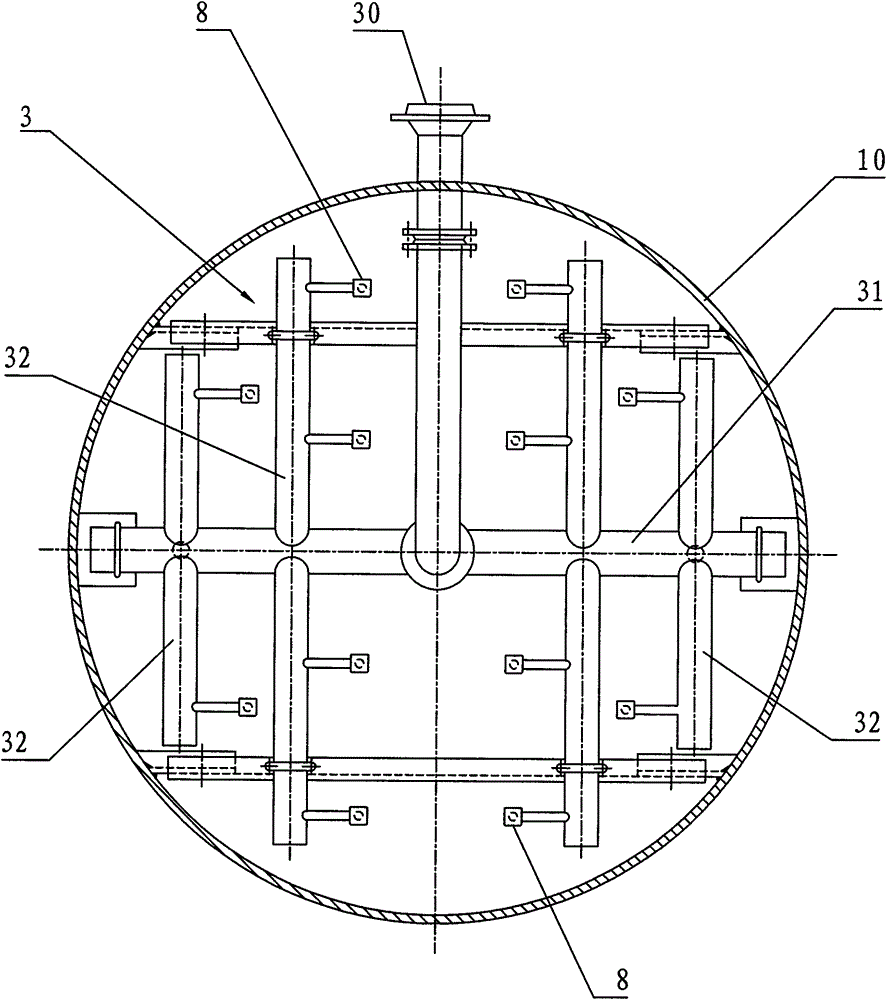

Underpressure distillation tower and underpressure distillation method

The invention discloses an underpressure distillation tower and an underpressure distillation method, which belong to the petroleum refining industry, so that problems of high height of the tower due to much filling material, large material consumption and high pressure drop of whole tower of the current underpressure distillation towers can be solved. The underpressure distillation tower comprises a cylindrical shell (10) and a tower inner member, a charging part, a washing part and a fractionation part from up to down. A gas distributor (1) is arranged in the charging part. Several fractionation segments are arranged at the fractionation part, each fractionation segment is composed of a spray-type liquid distributor (3) and an oil collection tank (6); a unidirectional nozzle (8) is arranged on the spray-type liquid distributor, and the oil collection tank is positioned below the spray-type liquid distributor. The underpressure distillation method is carried out by employing the underpressure distillation tower. The underpressure distillation method is mainly used for petroleum refining industry, height, material consumption and pressure drop of the whole drop of the underpressure distillation tower can be reduced, pull-out rate is increased, and product quality is improved.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP +1

Unsaturated C5 fraction and hydrogenation method

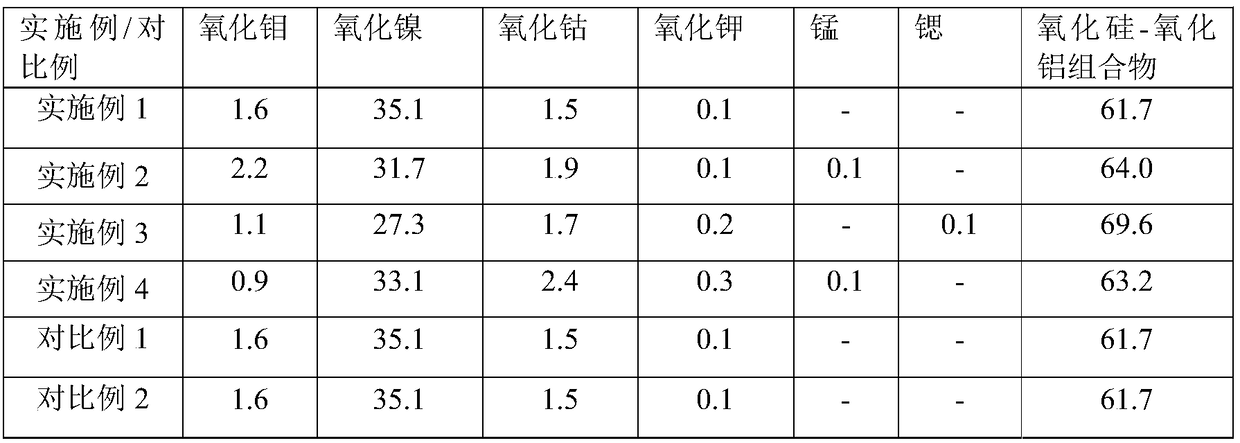

ActiveCN109439364AHigh hydrogenation selectivityReduce reactivityHeterogenous catalyst chemical elementsRefining by selective hydrogenationPotassiumFixed bed

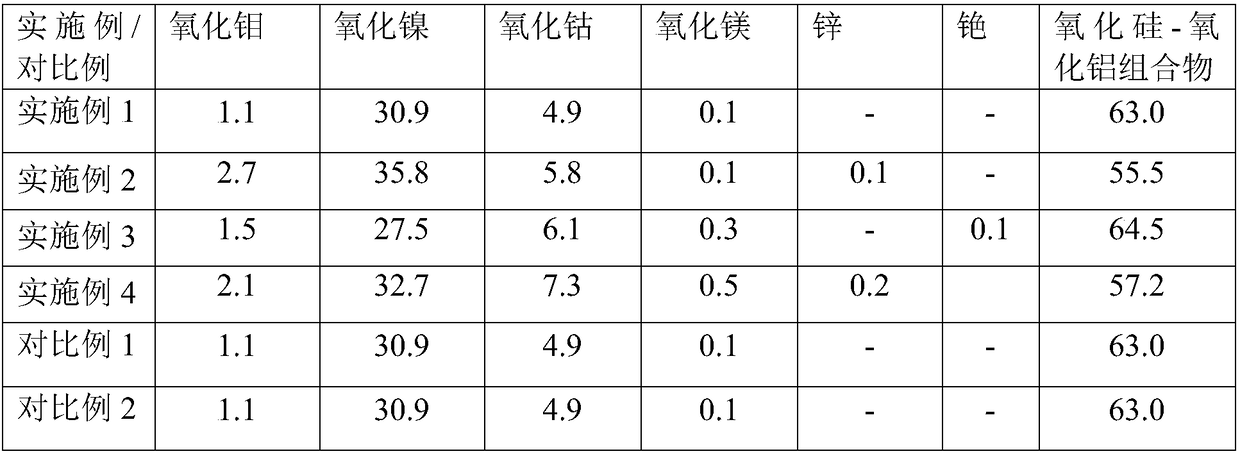

The invention relates to an unsaturated C5 fraction and hydrogenation method. According to the method, by the aid of a fixed bed reactor, a used catalyst is a nickel hydrogenation catalyst, and the catalyst is reduced by the aid of hydrogen or hydrogen-containing gas at the temperature of 350-500 DEG C. The catalyst comprises main active components and a silicon oxide-aluminum oxide composition, and the main active components include molybdenum, nickel, cobalt and potassium. Hydrogenation process conditions include that a reactor inlet temperature is 30-660 DEG C, reaction pressure is 1.5-6.0MPa, liquid volume per hour is 1.0-6.0h<-1>, and the volume ratio of hydrogen to oil is 100:400. According to the unsaturated C5 fraction and hydrogenation method, the used nickel-based saturated hydrogenation catalyst has high hydrogenation activity and the advantages that the catalyst is resistant to sulfur, water and colloid, and hydrogenation reaction can be performed at low temperature.

Owner:兰州金润宏成新材料科技有限公司

Nano-beta molecular sieve with low Si/Al ratio and preparation method thereof

ActiveCN101723394BIncrease acidityHigh catalytic activityMolecular-sieve and base-exchange compoundsMolecular sieveSynthesis methods

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation method of C4 unsaturated hydrocarbon

ActiveCN109439365AHigh hydrogenation selectivityReduce reactivityHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsFixed bedSilicon oxide

The invention relates to a hydrogenation method of C4 unsaturated hydrocarbon. According to the method, by the aid of a fixed bed reactor, a nickel saturated hydrogenation catalyst is reduced outsidea hydrogenation reactor at the temperature of 350-500 DEG C, air is led in to passivate the catalyst, the passivated catalyst is reduced in the reactor by hydrogen at the temperature of 120-200 DEG C,the C4 unsaturated hydrocarbon is added, alkyne and diolefin in the C4 unsaturated hydrocarbon are hydrogenated into corresponding alkane, the nickel saturated hydrogenation catalyst comprises activecomponents and silicon oxide-aluminum oxide composition, and the active components include molybdenum, nickel , cobalt and magnesium. Reaction process conditions include that inlet temperature of thereactor is 30-55 DEG C, reaction pressure is 1.0-4.5MPa, liquid volume per hour is 1.5-4.5h<-1>, and the volume ratio of hydrogen to oil is (120-450):1. According to the hydrogenation method of theC4 unsaturated hydrocarbon, the catalyst is good in hydrogenation activity, good in gelatine and water resistance and high in sulfur resistance.

Owner:兰州金润宏成新材料科技有限公司

Total fraction cracking gasoline selective hydrogenation method

ActiveCN109022025AHigh hydrogenation selectivityImprove anti-glue abilityHydrocarbon oils refiningHydrocarbon oils treatment productsFixed bedReaction temperature

The invention relates to a total fraction cracking gasoline selective hydrogenation method. A fixed bed reactor is used; a catalyst is reduced in hydrogen gas atmosphere; after the reduction process is completed, the process condition is regulated to the reaction process conditions; gasoline raw material total fraction cracking is performed; selective hydrogenation reaction is performed; the catalyst is prepared from silicon oxide-aluminum oxide carriers and metal active ingredients of palladium loaded on the carriers; the content of the palladium is based on 0.15 to 0.45 weight percent of thetotal weight of the catalysts. The hydrogenation process conditions are shown as follows: the reaction inlet temperature is higher than or equal to 50 DEG C; the reaction temperature is 2.0 to 4.5MPa; the hydrogen oil volume ratio is (60 to 400):1; the liquid volume air speed is 2.5 to 5.0 h<-1>. The catalyst gum resistant capability is high; the arsenic resistant, sulfur resistant and water-resistant capability is high; the stability is high.

Owner:东营华浩化工有限公司

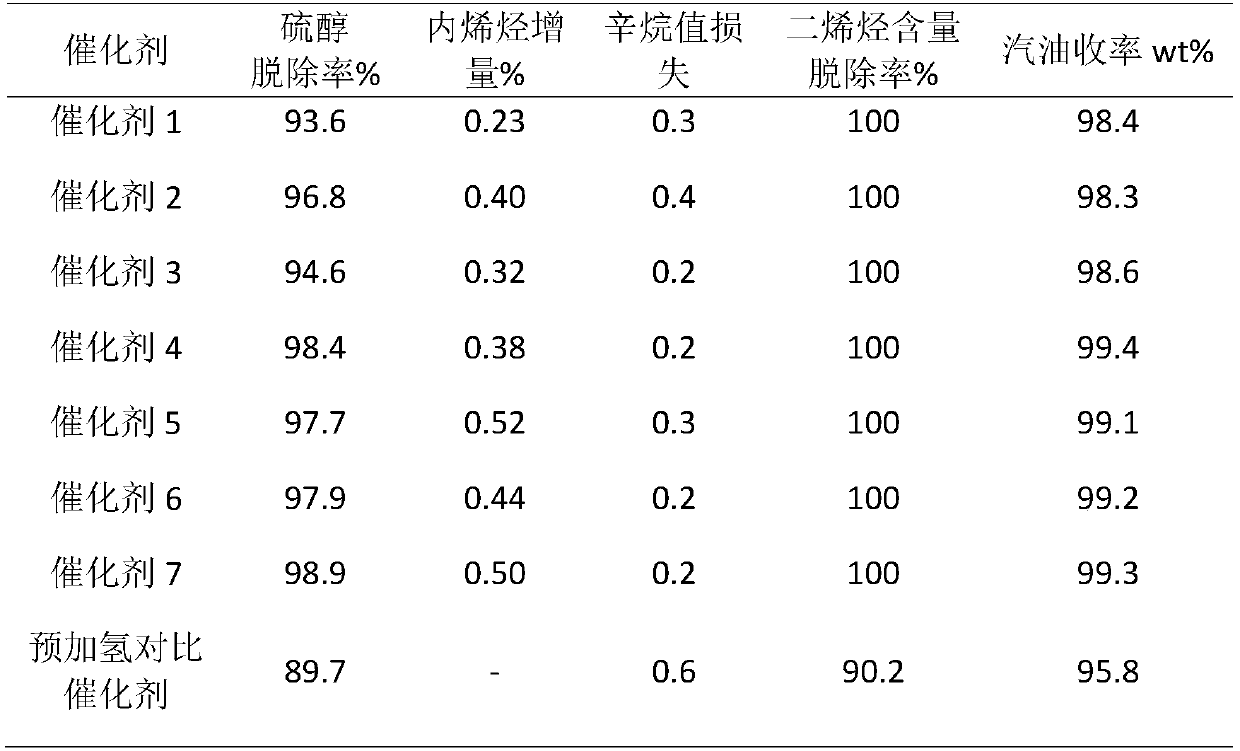

Method of removing mercaptan of catalytically cracked gasoline

ActiveCN109207191AHigh sweetening activityGood choicePhysical/chemical process catalystsRefining by selective hydrogenationReaction temperatureFixed bed

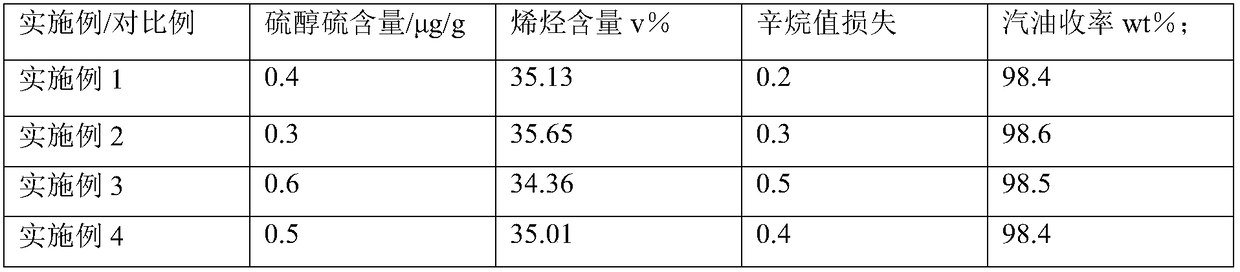

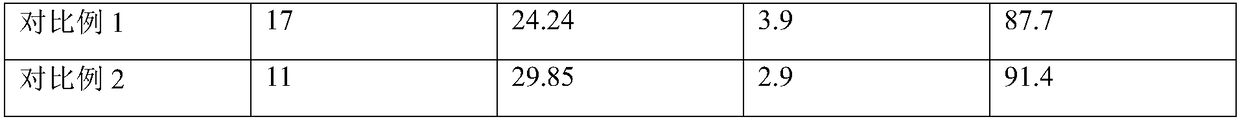

The invention relates to a method of removing mercaptan of catalytically cracked gasoline. According to the method, a fixed bed reactor is adopted; a catalyst comprises a silicon oxide-aluminum oxidecarrier, metal active components (nickel, molybdenum, and iron) loaded on the carrier, and an auxiliary agent (phosphorus); nickel oxide accounts for 2 to 15 wt% of the catalyst, molybdenum oxide accounts for 2 to 18 wt% of the catalyst, iron oxide accounts for 0.1 to 5.5 wt% of the catalyst, the auxiliary agent (phosphorus oxide) accounts for 0.01 to 2.2 wt% of the catalyst, the silicon oxide-aluminum oxide carrier accounts for 65 to 85 wt% of the catalyst, the micro pores, mesopores, macro pores are unevenly distributed in the carrier; the reaction temperature is 110 to 220 DEG C, the reaction pressure is 1.1 to 4.5 MPa, the volume air speed is 1.2 to 5.0 h<-1>, and the volume ratio of hydrogen to oil is 7-25:1. The catalyst has the characteristics of high mercaptan removing activity, high selectivity of diolefin hydrogenation, few side reactions, and low octane value loss.

Owner:宁夏瑞科新源环保科技研发有限公司

Selective hydrogenation method for full-range pyrolysis gasoline

ActiveCN109364945AHigh hydrogenation selectivityImprove anti-glue abilityHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsLanthanumChemistry

The invention relates to a selective hydrogenation method for full-range pyrolysis gasoline, which adopts a reactor of an adiabat bed reactor. The catalyst comprises silica-alumina carrier and metal active component palladium loaded on the carrier, wherein the palladium is 0.15-0.45 percent of total weight of the catalyst; and the silica-alumina carrier is prepared from the following components inpercentage by weight: 0.1-12 percent of silica, 0.1-10 percent of nickel-doped lanthanum ferrite and 0.05-7.8 percent of magnesium. According to the hydrogenation process conditions, the reaction inlet temperature is more than or equal to 50 DEG C, the reaction pressure is 2.0-4.5MPa, the hydrogen-oil volume ratio is 60-450, and the liquid hourly space velocity is 3.0-5.0h<-1>. The catalyst has good gum resistance and strong performance of arsenic resistance, sulfur resistance and water resistance.

Owner:毛琴飞

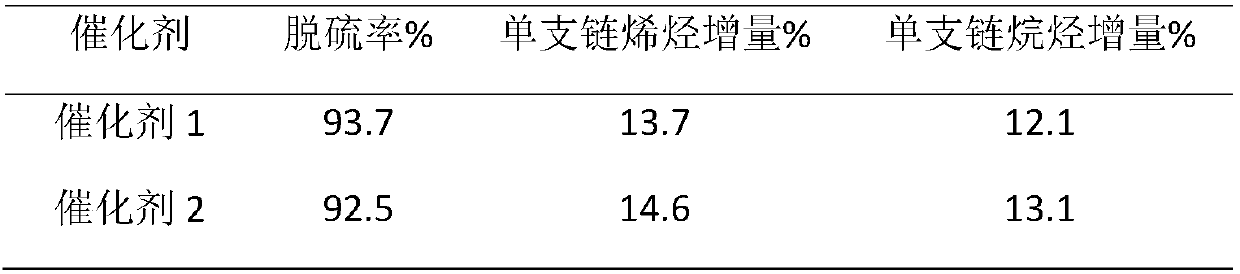

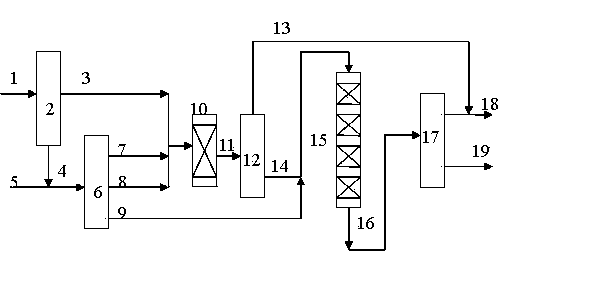

FCC gasoline upgrading method

ActiveCN109097104AHigh yieldHigh activityTreatment with hydrotreatment processesChemical recyclingAlkaneIsomerization

The invention relates to a FCC gasoline upgrading method. FCC gasoline is subjected to a mercaptan etherification and double-bond isomerism reaction under the action of a prehydrogenation catalyst bya prehydrogenation reactor, a prehydrogenation reaction effluent is cut into light and heavy gasoline fractions, the light gasoline fraction is subjected to isomerization reaction under the action ofan isomerization catalyst, the heavy gasoline fraction is subjected to selective hydrodesulfurization under the action of a hydrodesulfurization-isomerization catalyst, and simultaneously, linear olefin is isomerized into single branched olefin or single branched paraffin; then, the heavy gasoline fraction after the reaction enters an octane number recovery unit and is in contact with an octane number recovery catalyst to be subjected to a double branched isomerization reaction; finally, the light and heavy gasoline fractions are blended to obtain a clean gasoline product with low olefin content, ultra low sulfur content and a high octane number.

Owner:FUZHOU UNIV

A kind of unsaturated hydrocarbon selective hydrogenation catalyst and preparation method

ActiveCN109433218BHigh hydrogenation selectivityImprove anti-glue abilityHeterogenous catalyst chemical elementsHydrocarbon oils refiningPtru catalystUnsaturated hydrocarbon

Owner:YANTAI BAICHUAN HUITONG TECH CO LTD

Selective hydrogenation method for pyrolysis gasoline

ActiveCN109364929AHigh hydrogenation selectivityImprove anti-glue abilityHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsLanthanumMagnesium

The invention relates to a selective hydrogenation method for pyrolysis gasoline. A catalyst comprises a silicon oxide-aluminum oxide carrier and a metal active component palladium loaded to the carrier. Palladium accounts for 0.15-0.45wt% of the total weight of the catalyst. The silicon oxide-aluminum oxide carrier comprises 0.1-12wt% of silicon oxide, 0.1-10wt% of nickel doped lanthanum ferriteand 0.05-7.8wt% of magnesium. The hydrogenation process conditions are as follows: the reaction inlet temperature is lower than or equal to 45 DEG C, the reaction pressure is 2.5-4.5 MPa, the hydrogenoil volume ratio is 60-450, and the liquid volume airspeed is 3.0-5.5h<-1>. The catalyst is good in colloid resistance and high in arsenic, sulfur and water resistance.

Owner:陈雅菁

Nickel selective hydrogenation catalyst and preparation method thereof

ActiveCN109364934AHigh hydrogenation selectivityImprove anti-glue abilityHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsSulfurPotassium

The invention relates to a nickel selective hydrogenation catalyst. The catalyst is prepared from a silica-alumina carrier and metal active ingredients, including nickel, molybdenum and potassium, loaded on the carrier, and comprises the following components based on total weight of the catalyst: 9-25 weight percent of nickel oxide, 2.5-8 weight percent of molybdenum oxide, 0.02-2.5 weight percentof potassium oxide and 75-91 weight percent of silica-alumina carrier. The catalyst has strong colloid resistance, arsenic resistance, sulfur resistance and water resistance.

Owner:江苏华海三联净化材料有限公司

Selective hydrogenation catalyst for pyrolysis gasoline and preparation method thereof

ActiveCN109289868AHigh hydrogenation selectivityImprove anti-glue abilityHeterogenous catalyst chemical elementsHydrocarbon oils refiningPotassiumLanthanum

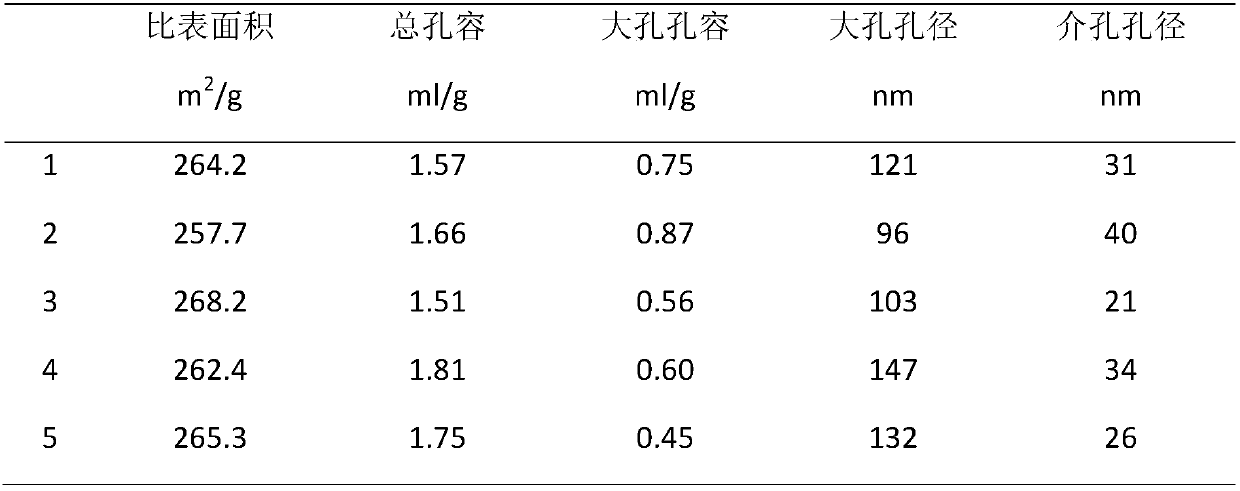

The invention relates to a selective hydrogenation catalyst for pyrolysis gasoline. The catalyst includes a silica-alumina carrier and a metal active component palladium loaded on the carrier, the content of palladium is 0.15-0.45 wt% based on the total weight of the catalyst, and the silica-alumina carrier contains 0.1-12 wt% of silica, 0.1-10 wt% of nickel-doped lanthanum ferrite and 0.05-6.8 wt% of potassium; carrier mesopores account for 3-75% of total pores, and macropores account for 1.5-60% of the total pores. The catalyst has the advantages of good colloid resistant ability, and strongarsenic resistant, sulfur resistant and water resistant abilities, and is especially suitable for selective hydrogenation of first-section C6-C8 and C8 fractions of pyrolysis gasoline.

Owner:YANTAI BAICHUAN HUITONG TECH CO LTD

First-stage selective hydrogenation method for pyrolysis gasoline

ActiveCN109355094AHigh hydrogenation selectivityImprove anti-glue abilityRefining by selective hydrogenationHydrocarbon oils treatmentPotassiumReaction temperature

The invention relates to a first-stage selective hydrogenation method for pyrolysis gasoline. The first-stage selective hydrogenation method is implemented by the aid of heat-insulation bed reactors.The first-stage selective hydrogenation method includes carrying out reduction on nickel catalysts in the presence of hydrogen under the condition of the temperature of 400-480 DEG C; carrying out cooling and passivation and then carrying out adjustment until reaction technological conditions are met. The reaction technological conditions include the reaction inlet temperatures of 45-120 DEG C, the reaction pressures of 2.5-5.5 MPa and the hydrogen-oil volume ratios of 60-220:1. The liquid volume space velocities are 2.0-6.5 h<-1>; the catalysts comprise silicon oxide-aluminum oxide carriers and metal active components including nickel, molybdenum and potassium, and the metal active components are loaded on the carriers. The first-stage selective hydrogenation method has the advantage thatthe catalysts are applicable to first-stage selective hydrogenation for the pyrolysis gasoline.

Owner:陈明海

Unsaturated hydrocarbon selective hydrogenation catalyst and preparation method thereof

ActiveCN109433218AHigh hydrogenation selectivityImprove anti-glue abilityHeterogenous catalyst chemical elementsHydrocarbon oils refiningSulfurUnsaturated hydrocarbon

The invention relates to a unsaturated hydrocarbon selective hydrogenation catalyst, which comprises a silicon-alumina carrier and metal active components such as nickel, molybdenum and magnesium loaded on the carrier. The catalyst comprises the following components based on the total weight of the catalyst: 7-18wt% of nickel oxide, 3.5-12wt% of molybdenum oxide, 0.05-2.0% of magnesium oxide, 75-91wt% of the silica-alumina carrier, 3-70% of mesopores of the carrier accounting for the total pores, and 1.5-55% of the macropores accounting for the total pores. The catalyst is prepared by an impregnation method. The catalyst has good colloid resistance, strong arsenic resistance, sulfur resistance and water resistance.

Owner:YANTAI BAICHUAN HUITONG TECH CO LTD

Deep desulphurization combination method of diesel oil

ActiveCN102876369ALow device investment and operating costsReduce energy consumptionTreatment with hydrotreatment processesProcess engineeringEnvironmental geology

The invention discloses a deep desulphurization combination method of diesel oil, comprising the following steps of: allowing fresh diesel oil feedstock to enter a hydrogen mixing pot for hydrogen mixing, allowing diesel oil dissolved in hydrogen to enter a liquid phase hydrogenation reactor for refining reaction; allowing the obtained refined effluent to enter a high-temperature low-pressure flash tank for flash evaporation so as to obtain a liquid phase heavy fraction; allowing part of the heavy fraction to recycle and return to the hydrogen mixing pot and part of the heavy fraction to undergo oxidative desulfurization, mixing the heavy fraction which has undergone oxidative desulfurization and the light fraction obtained by flash evaporation, and separating to obtain the diesel oil product. According to the method, liquid phase hydrogenation is performed under mild conditions to remove simple sulfide in the diesel oil feedstock; after flash evaporation, the recycled heavy fraction continues to undergo hydrodesulfurization, and residual heavy fraction is selectively subjected to oxidative desulfurization so as to realize deep desulphurization of diesel oil. According to the method, by full utilization of advantages of hydrodesulfurization and oxidative desulfurization, equipment investment and operation cost are reduced, and energy consumption is minimized. Therefore, the method can satisfy the demand of producing clean diesel oil by deep desulphurization of diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

All-fraction selective hydrogenation method for pyrolysis gasoline

ActiveCN109355093AHigh hydrogenation selectivityImprove anti-glue abilityRefining by selective hydrogenationHydrocarbon oils treatmentSilicon oxideHydrogen

The invention relates to an all-fraction selective hydrogenation method for pyrolysis gasoline. The all-fraction selective hydrogenation method includes procedures of carrying out reduction on nickelcatalysts in the presence of hydrogen under the condition of the temperature of 400-500 DEG C; carrying out cooling and passivation and then carrying out adjustment until reaction technological conditions are met. The reaction technological conditions include the reaction inlet temperatures of 45-110 DEG C, the reaction pressures of 2.0-4.5 MPa and the hydrogen-oil volume ratios of 60-200:1. The liquid volume space velocities are 2.0-5.5 h<-1>; the catalysts comprise silicon oxide-aluminum oxide carriers and metal active components including nickel, molybdenum and magnesium, and the metal active components are loaded on the carriers. The all-fraction selective hydrogenation method has the advantage that the catalysts are good in colloid resistance, high in arsenic resistance, sulfur resistance and water resistance and applicable to long-period stable operation of devices.

Owner:陈明海

pyrolysis gasoline c 6 -c 8 Distillate oil selective hydrogenation method

ActiveCN109355095BHigh hydrogenation selectivityImprove anti-glue abilityRefining by selective hydrogenationNickel catalystPtru catalyst

The invention relates to a cracked gasoline C6-C8 distillate selective hydrogenation method, comprising: performing reducing at 400-500 DEG C via a nickel catalyst in the presence of hydrogen, coolingfor passivation, and adjusting to reaction process conditions; subjecting raw oil, hydrogen and the catalyst to contact and selective hydrogenation under the reaction temperature of 40-160 DEG C, reaction pressure of 2.0-5.0 MPa, fresh oil space velocity of 1-10 h<-1> and hydrogen-oil volume ratio of (50-260):1, wherein the catalyst includes a silica-alumina carrier as well as metallic active components of nickel, molybdenum and potassium carried on the carrier; the catalyst has high resistance to gel, arsenic, sulfur and resistance. The method herein is highly adaptable to different materials.

Owner:陈明海

Catalyst for selective hydrogenation of pyrolysis gasoline and its preparation method

ActiveCN109289868BHigh hydrogenation selectivityImprove anti-glue abilityHeterogenous catalyst chemical elementsHydrocarbon oils refiningPtru catalystSilicon oxide

Owner:YANTAI BAICHUAN HUITONG TECH CO LTD

pyrolysis gasoline c 6 -c 8 Distillate hydrotreating catalyst and preparation method

ActiveCN109317158BImprove anti-glue abilityImprove stabilityHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystSilicon oxide

The present invention relates to a kind of pyrolysis gasoline C 6 -C 8 Distillate hydrotreating catalyst, the catalyst uses molybdenum, cobalt, nickel, and potassium as active components, and uses silica-alumina as a carrier. Based on the total weight of the catalyst, the catalyst contains 6-22% of molybdenum oxide and 0.1-2.2% of cobalt oxide , nickel oxide 4.0-7.2%, potassium oxide content 0.1-3.0%, silica-alumina carrier content 75-88wt%, carrier mesopores account for 3-70% of total pores, macropores account for 1.5- 55%. The catalyst has good anti-colloid ability, strong anti-arsenic, anti-sulfur, and strong anti-water ability.

Owner:泉州市利泰石化科技有限公司

Processing method of ethylene tar

ActiveCN103102978BBroaden sources of raw materialsImprove product qualityTreatment with hydrotreatment processesLighter fuelGasoline

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method of ethylene tar

ActiveCN103102976BBroaden sources of raw materialsImprove product qualityDistillation purification/separationTreatment with hydrotreatment processesGasolineHydrogen treatment

Owner:CHINA PETROLEUM & CHEM CORP +1

One-stage selective hydrogenation method for pyrolysis gasoline

ActiveCN109022026BHigh hydrogenation selectivityImprove anti-glue abilityHydrocarbon oils refiningHydrocarbon oils treatment productsPtru catalystHydrogenation process

The invention relates to a pyrolysis gasoline one-section selective hydrogenation method. A catalyst is prepared from a silicon oxide-aluminum oxide carrier and a metal active ingredient palladium loaded on the carrier; the palladium content is 0.15 to 0.45 weight percent of the total weight of the catalyst; the pectin resistant capability of the catalyst is good; the anti-arsenic, anti-sulfur andwater-resistant capability is high. Under the hydrogenation process condition, the reaction inlet temperature is smaller than or equal to 45 DEG C; the reaction pressure is 2.5 to 4.5MPa; the hydrogen oil volume ratio is 60 to 450; the liquid volume space velocity is 3.0 to 5.5h<-1>. The catalyst has high adaptability on pyrolysis gasoline raw materials with different arsenic content, different sulphur content, water content and pectin content; the low-temperature activity of the catalyst is high.

Owner:宁夏宁鲁石化有限公司

Method for producing clean fuel oil from ethylene tar

ActiveCN103805248BIncrease profitImprove product qualityTreatment with hydrotreatment processesWaxLighter fuel

The invention discloses a method for producing clean fuel oil from ethylene tar. The method is as follows: fractionating the ethylene tar into a light fraction, a middle fraction and a heavy fraction, mixing the heavy fraction with a conventional coking raw material, conducting delayed coking to obtain coker gasoline, coker diesel oil and coker wax oil, mixing the obtained coker gasoline with the ethylene tar light fraction, leaving the mixed material to undergo hydrofining, performing rectification / crystallization purification on the middle fraction to obtain naphthaline, mixing naphthaline removal oil after naphthaline extraction and naphthaline post-fraction oil with the coker diesel oil and the coker wax oil for hydrotreating, and separating an obtained product and the hydrofining product of the coker gasoline and the ethylene tar light fraction to obtain gasoline diesel oil products. Directed at the characteristics of high content of aromatic hydrocarbons, colloid, carbon residue and asphaltene in the ethylene tar, the method provided in the invention fractionates the ethylene tar into the light fraction, the middle fraction and the heavy fraction, and adopts different processing processes, thus not only enhancing the additional value of the ethylene tar, improving the product quality of light fuel oil in the same time of obtaining of the chemical raw material naphthaline, but also enabling the equipment to run smoothly for a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydroconversion method of deep cut anthracene oil

ActiveCN102041079BReduce concentrationReduce temperature riseTreatment with hydrotreatment processesAnthraceneLighter fuel

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com