Underpressure distillation tower and underpressure distillation method

A technology for vacuum distillation tower and tower internals, applied in vacuum distillation and other directions, can solve the problems of high tower height, high material consumption, and pressure drop in the whole tower, and achieve the effects of reducing energy consumption, low investment and saving maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

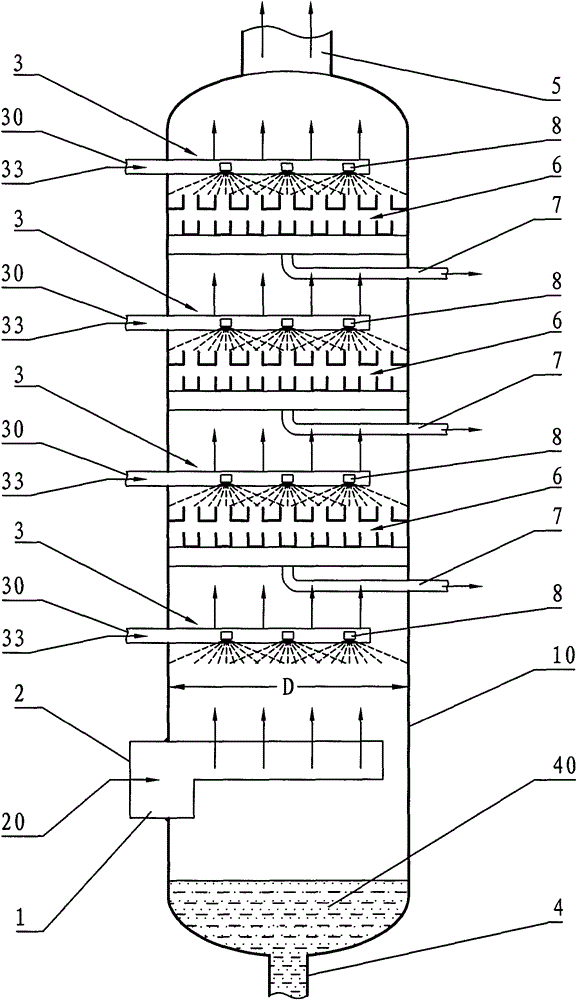

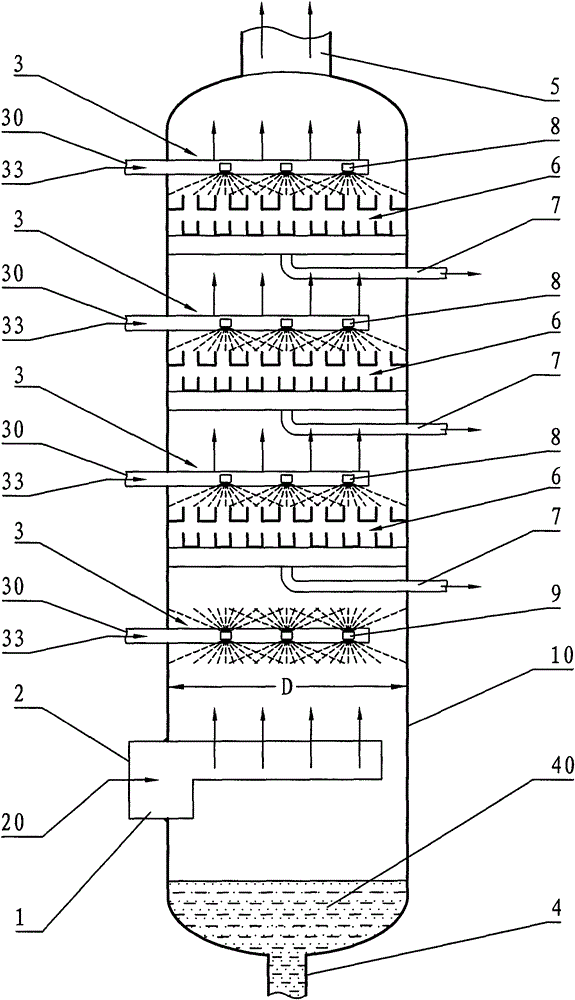

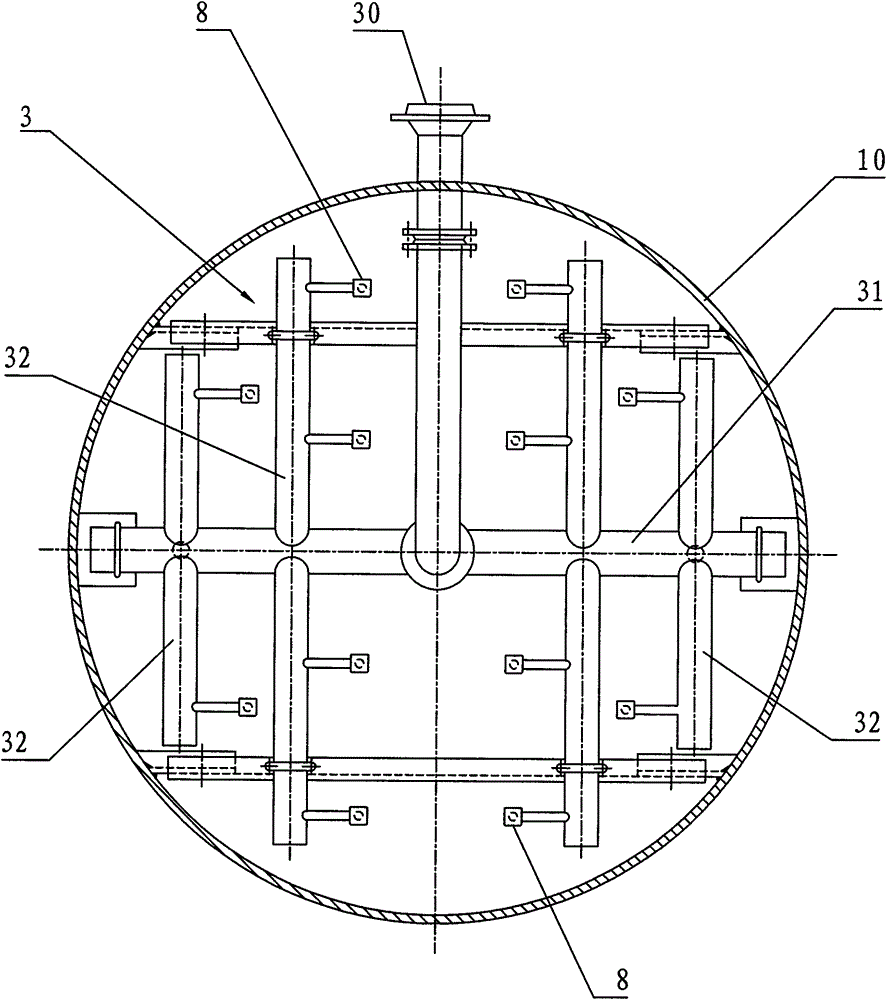

[0034] A company originally had a Φ6400mm vacuum distillation tower to process the atmospheric residue produced by the atmospheric distillation tower, with a designed processing capacity of 2.48 million tons per year. The vacuum distillation tower has a height of 50m (meter), and is provided with a feeding part, a washing part and a fractionating part from bottom to top. The feed section is equipped with a double tangential streamline gas distributor. There is a trough liquid distributor in the washing part, and a section of Mellapak structured packing with a height of 2.2m is arranged under the trough liquid distributor. The fractionation part is equipped with 3 fractionation sections, a total of 3 extraction side lines and 3 middle section refluxes. Each fractionation section is provided with a trough-type liquid distributor, and a 2.4m-high Mellapak structured packing is arranged under the trough-type liquid distributor, and a cylindrical oil collection tank is arranged un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com