Method for producing clean fuel oil from ethylene tar

A technology for ethylene tar and coker gasoline, which is applied to the combined process field of delayed coking and hydrogenation, can solve the problems of poor quality of liquid products - coker gasoline, diesel oil and wax oil, low liquid yield and low yield of light fuel oil products and other problems, to achieve the effect of expanding the source of raw materials, improving the utilization rate and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

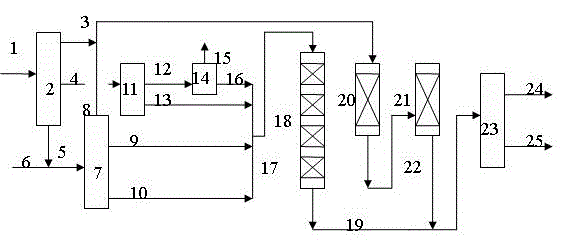

[0046] use figure 1 process. Ethylene tar is divided into light distillate, middle distillate and heavy distillate by distillation. Examples 1 and 2 use 190°C and 420°C as cut points, and their properties are listed in Table 2-1. Example 3 takes 200°C and 480°C as cut points. After distillation, the light distillate, middle distillate and heavy distillate are obtained respectively. The properties are listed in Table 2-2, and the properties of the vacuum residue are listed in Table 3. The obtained ethylene tar heavy fraction was mixed with the vacuum residue, the mixed raw material and its delayed coking process conditions, and the properties of the obtained gasoline and diesel fractions are shown in Table 4. See Table 5 for the pre-hydrofinishing process conditions of ethylene tar light fraction and coker gasoline mixed feedstock and the coker gasoline hydrofinishing process conditions. The middle distillate of ethylene tar is rectified by two towers to obtain a naphthalene-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com