Hydroconversion method of deep cut anthracene oil

A technology for hydroconversion and deep extraction of anthracene oil, which is applied in the directions of hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problem that it is difficult for the nitrogen content of heavy fractions to meet the feed requirements, the activity and stability of the hydrogenation catalyst are unfavorable, and the Affect the operation cycle of the device and other problems, and achieve the effects of safe and stable operation, improved yield, and improved utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

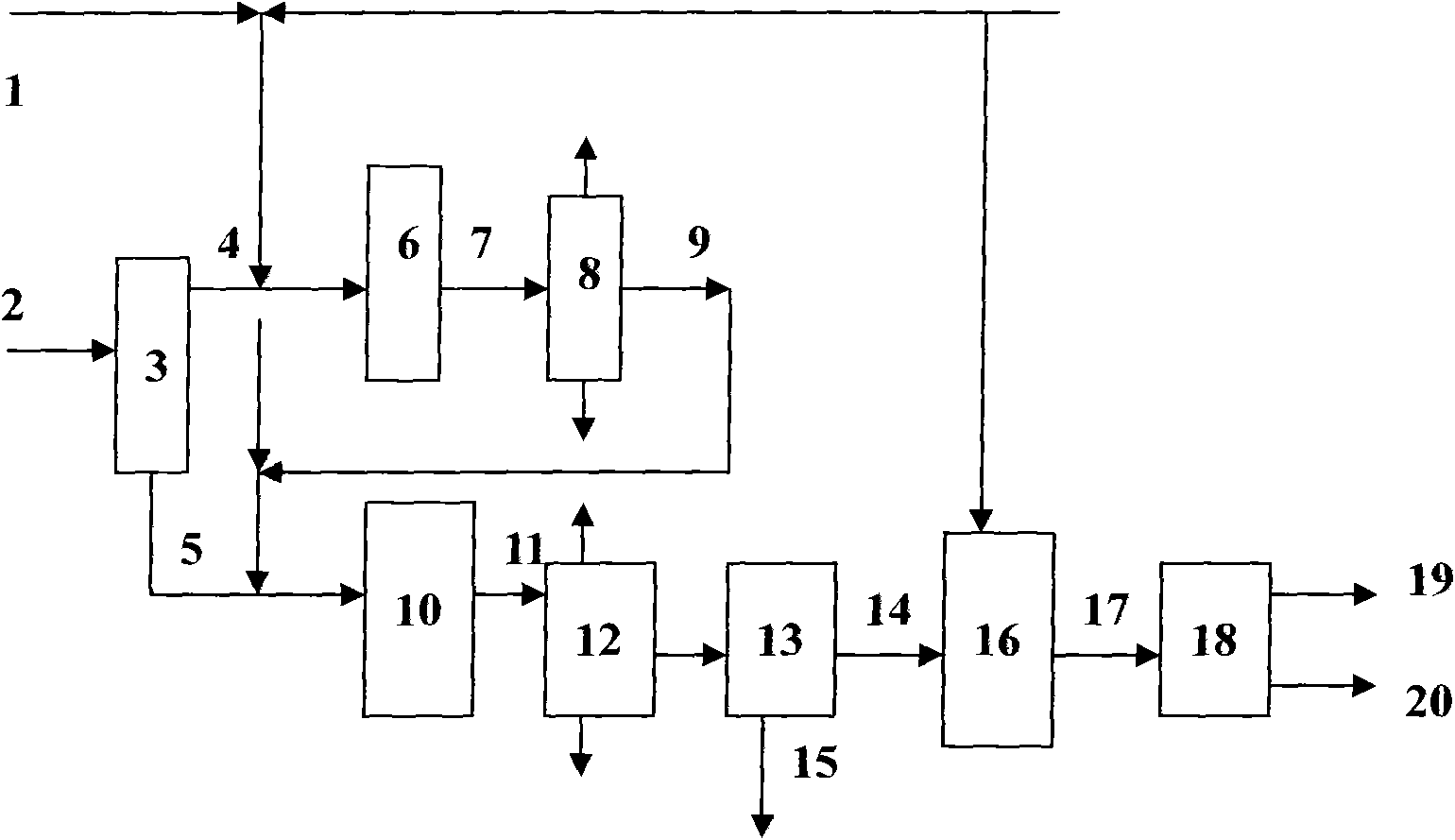

[0048] See Table 2 and Table 4 for the properties of the light and heavy fractions of the deep carbinthrene oil used. Embodiment flow chart is shown in Fig. 1. The hydrofinishing reaction zone adopts two reactors, the first reactor is equipped with hydrogenation protection agent FZC-103, and the second reactor is equipped with hydrofinishing catalyst 3936. In the embodiment, the volume ratio of FZC-103 and 3936 is as follows: 15: 85. The results of the reaction are shown in Table 3.

[0049] Table 2 Properties of the light distillate of deep dianthrene oil

[0050] crude oil name

Light distillates of deep carbinthrene oil (<430°C)

Distillation range / ℃

IBP / 10%

200 / 224

30% / 50%

260 / 320

70% / 90%

367 / 392

95% / EBP

410 / 441

Density(20℃) / g·cm -3

1.01

[0051] S / μg·g -1

5300

N / μg·g -1

12000

Four components*, % (mass fraction)

Saturation

0.57

...

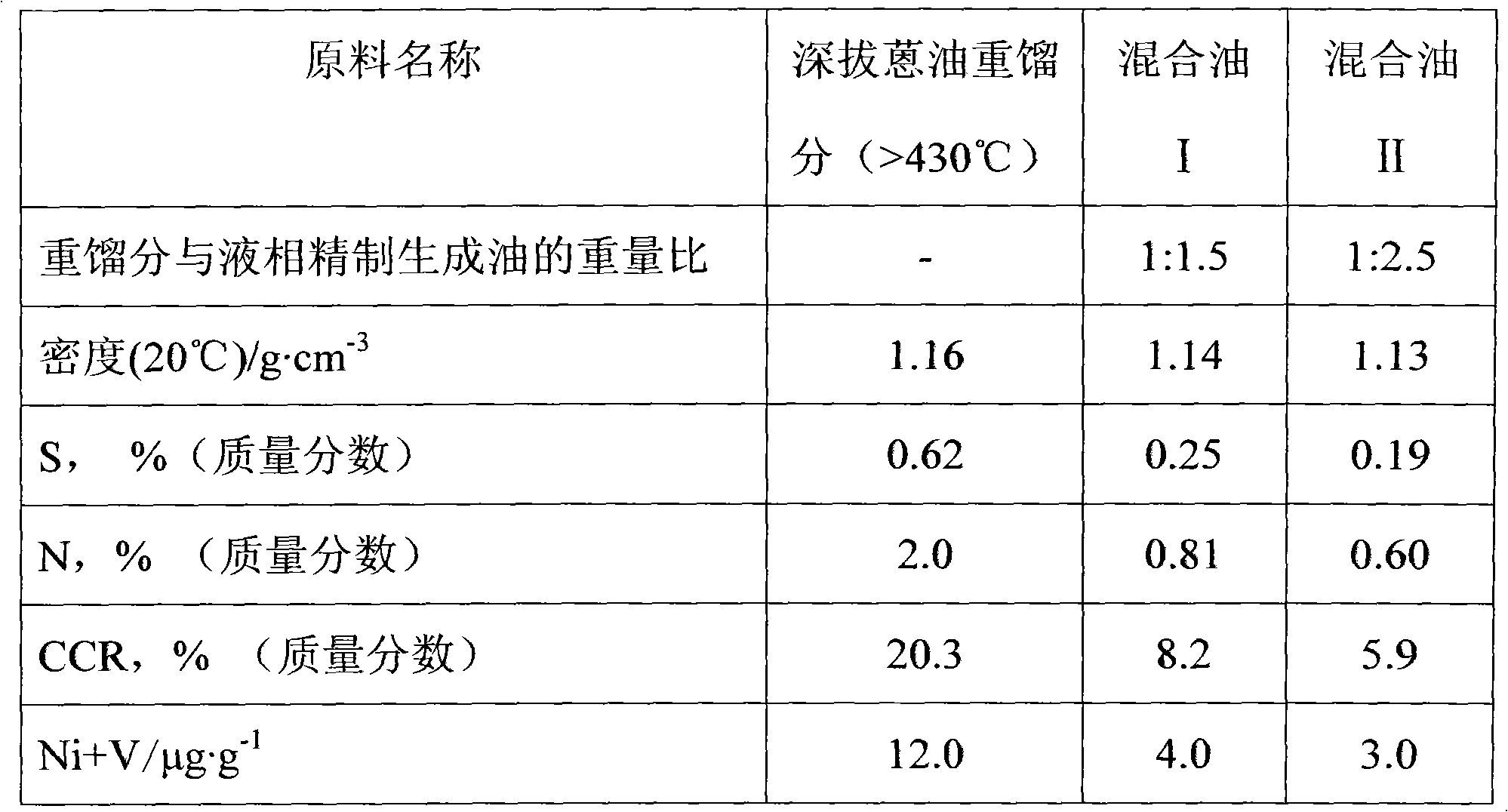

Embodiment 4

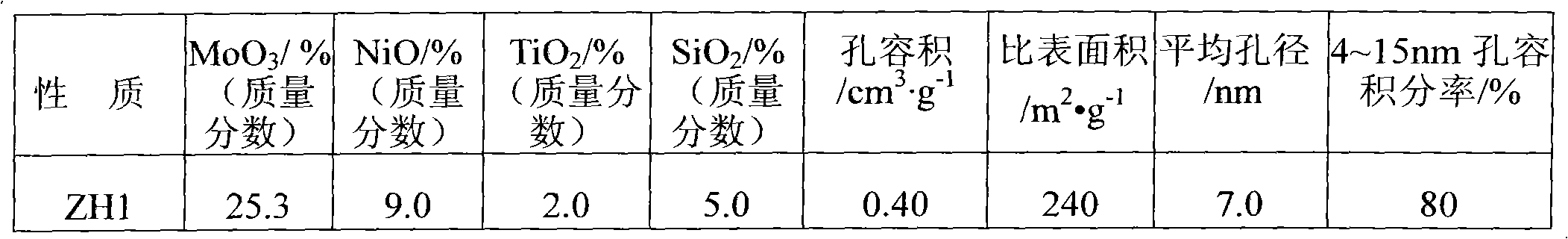

[0058] The mixed oil I enters the hydroconversion reaction zone, wherein the volume ratio of the hydroprotection catalyst, the hydrofinishing catalyst, the hydrodecarbonization catalyst and the hydroconversion catalyst is 8:30:35:27, wherein the hydroprotection catalyst used The catalysts are FZC-100 and FZC-102B, the volume ratio is 1:2, the hydrofining catalyst is 3936, and the loading volume ratio of the hydrogenation carbon removal catalyst HDC-1 and HDC-2 is 4:6, and the hydrogenation Conversion catalyst such as the catalyst obtained in Example 1 of CN02109422.5 is denoted as ZH1. The loading sequence of the above catalysts is as follows: FZC-100, FZC-102B, 3936, HDC-1, HDC-2, ZH1. Its properties are shown in Table 5.

[0059]Table 5 Composition and properties of hydroconversion catalyst

[0060]

[0061] In this example, the process conditions of the hydroconversion reaction zone are as follows: the reaction pressure is 16MPa, the reaction temperature is 390-400°C, ...

Embodiment 5

[0063] Compared with Example 4, the raw material was changed to mixed oil II, and the loading volume ratio of the used hydrodecarbonization catalyst HDC-1 and HDC-2 was changed to 5:5, and the rest were the same as in Example 4. The reaction results are shown in Table 6. The hydroconverted product is fractionated into the first fraction (called hydrocracking feedstock II) and the second fraction, with a cut point of 500°C.

[0064] Table 6 Heavy fraction hydrotreating results

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com