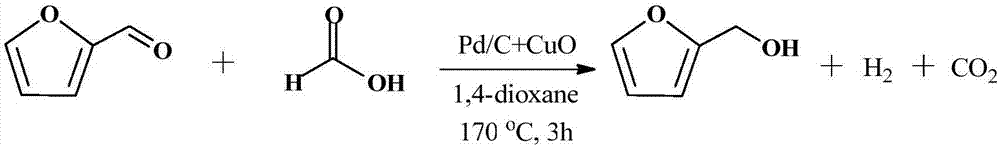

Method for preparing furfuryl alcohol by formic acid transfer and hydrogenation of furfural

A transfer hydrogenation and aldehyde-formic acid technology, applied in the direction of organic chemistry, to achieve the effect of mild conditions, simple process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 0.3g furfural to 20g 1,4-dioxane, then add 0.15g anhydrous formic acid and 0.04g metal catalyst (the mass ratio of Pd / C (5wt%) and CuO is 3:1) and mix In a closed high-pressure reactor, replace the air with nitrogen for 3 to 5 times to discharge the air, and react at 170°C for 3 hours to obtain furfuryl alcohol with a conversion rate of 47.8% and a yield of 45.7%.

Embodiment 2

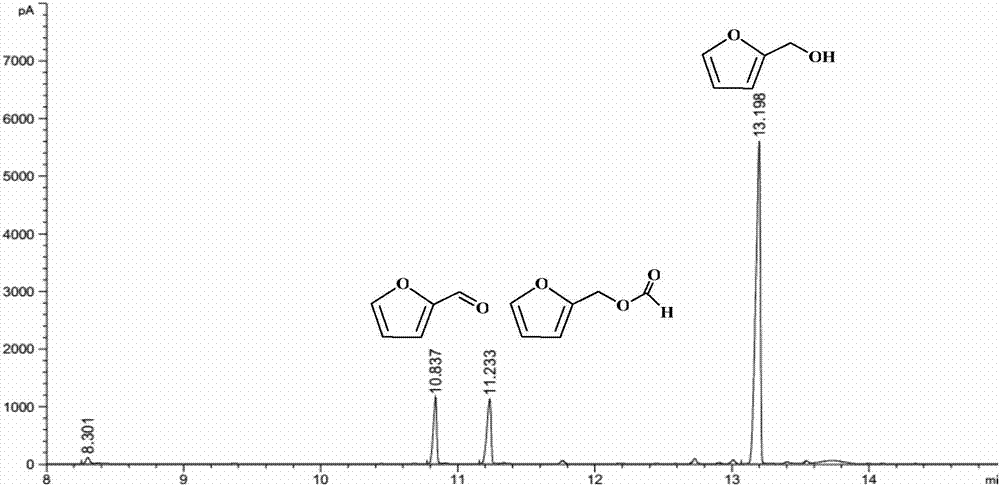

[0023] Add 0.3g furfural to 20g 1,4-dioxane, then add 0.3g anhydrous formic acid and 0.04g metal catalyst (the mass ratio of Pd / C (5wt%) and CuO is 3:1) and mix In a closed high-pressure reactor, replace the air with nitrogen for 3 to 5 times, and react at 170°C for 3 hours to obtain furfuryl alcohol with a conversion rate of 73.9% and a yield of 70.2%. figure 2 .

Embodiment 3

[0025] Add 0.3g furfural to 20g 1,4-dioxane, then add 0.6g anhydrous formic acid and 0.04g metal catalyst (the mass ratio of Pd / C (5wt%) and CuO is 3:1) and mix In a closed high-pressure reactor, replace the air with nitrogen 3 to 5 times to discharge the air, and react at 170°C for 3 hours to obtain furfuryl alcohol with a conversion rate of 100.0% and a yield of 98.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com