Method and device for auxiliary control of properties of spray-dried powder

An auxiliary control and drying powder technology, which is applied in the direction of spray evaporation, evaporator accessories, etc., can solve the problem of large size and it takes a certain time to achieve it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

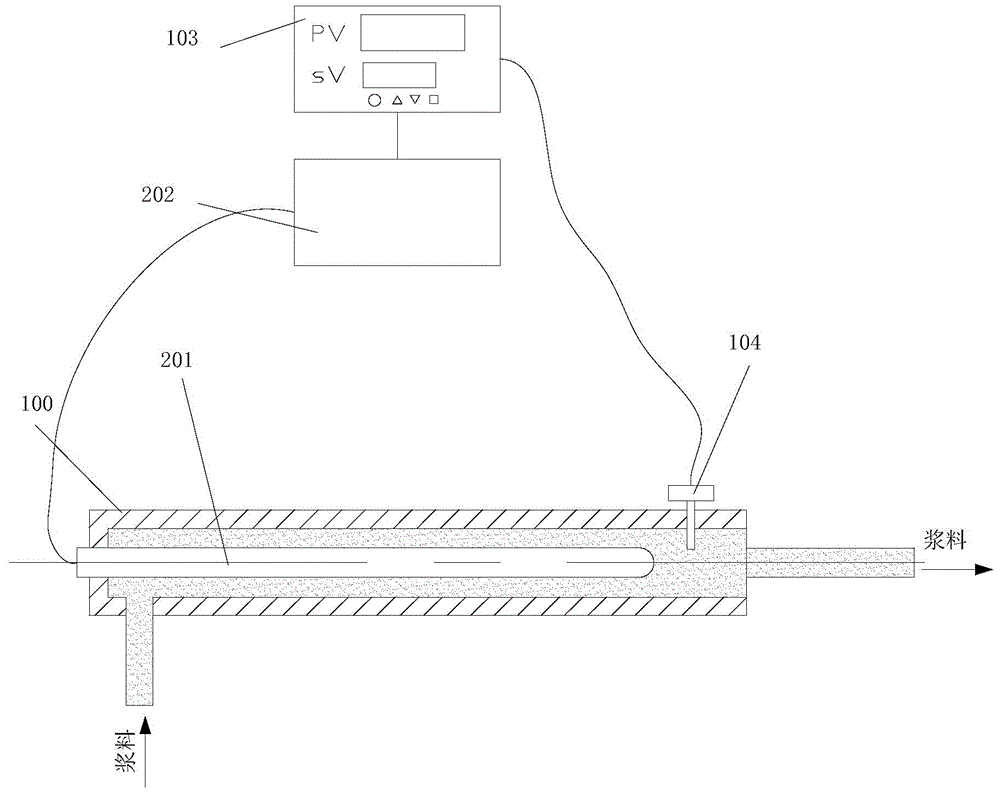

[0023] like figure 1 Shown is an auxiliary device for controlling the performance of the spray-dried powder in the resistance heating mode. The slurry enters the heating vessel 100 from the side of the heating vessel 100, and the resistance heater 201 is an electric heating rod installed in the center of the heating vessel 100 along the axial direction. The heater 201 is used to heat the slurry, the resistance heater 201 is connected with the power device 202, and a temperature sensor 104 is arranged at the discharge end of the heating container 100, and the temperature sensor 104 is connected with the temperature controller 103, and the temperature controller 103 is connected with the power device 202 connect. During operation, the temperature controller 103 controls the heating power of the power device 202 according to the set slurry temperature and the actual slurry temperature measured by the temperature sensor 104 to obtain the required slurry temperature.

[0024] The ...

Embodiment 2

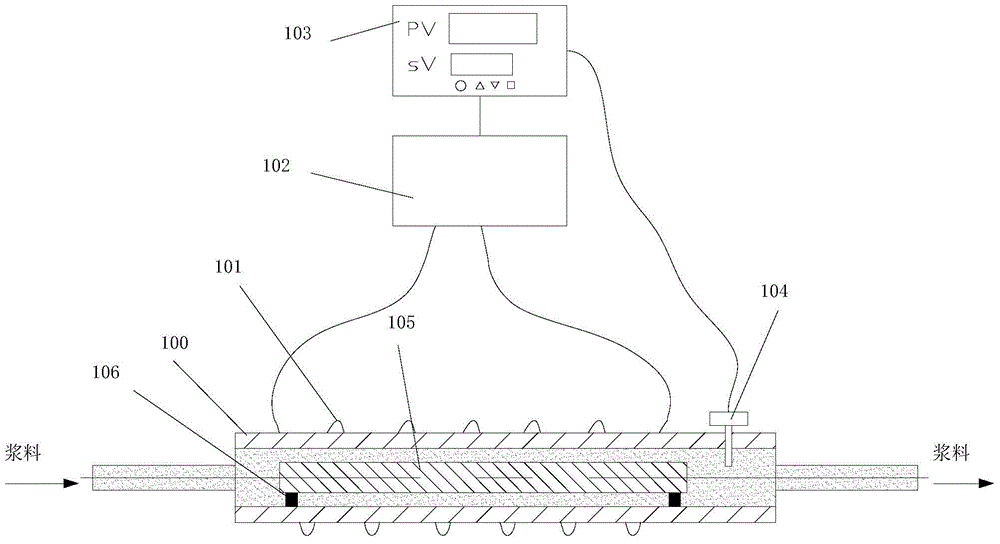

[0029] like figure 2 Shown is an auxiliary device for controlling the performance of the spray-dried powder in the electromagnetic heating mode. The slurry enters the heating container 100 from the lower end of the heating container 100. The electromagnetic heating coil 101 is arranged outside the heating container 100. The electromagnetic heating coil 101 and the electromagnetic heating control The temperature sensor 104 is set at the discharge end of the heating vessel 100, the temperature sensor 104 is connected with the temperature controller 103, and the temperature controller 103 is connected with the electromagnetic heating controller 102. The heating power of the electromagnetic heating controller 102 is controlled according to the slurry temperature and the actual slurry temperature measured by the temperature sensor 104 so as to obtain the required slurry temperature.

[0030] The electromagnetic heating technology is an existing public technology and will not be de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com