Preparation for anhydrous magnesium chloride powder

An anhydrous magnesium chloride, magnesium chloride technology, applied in the direction of magnesium chloride, magnesium halide, etc., can solve the problems of failing to meet user requirements, particle size, particle shape restrictions, etc., and achieve the effects of low cost, convenient operation, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

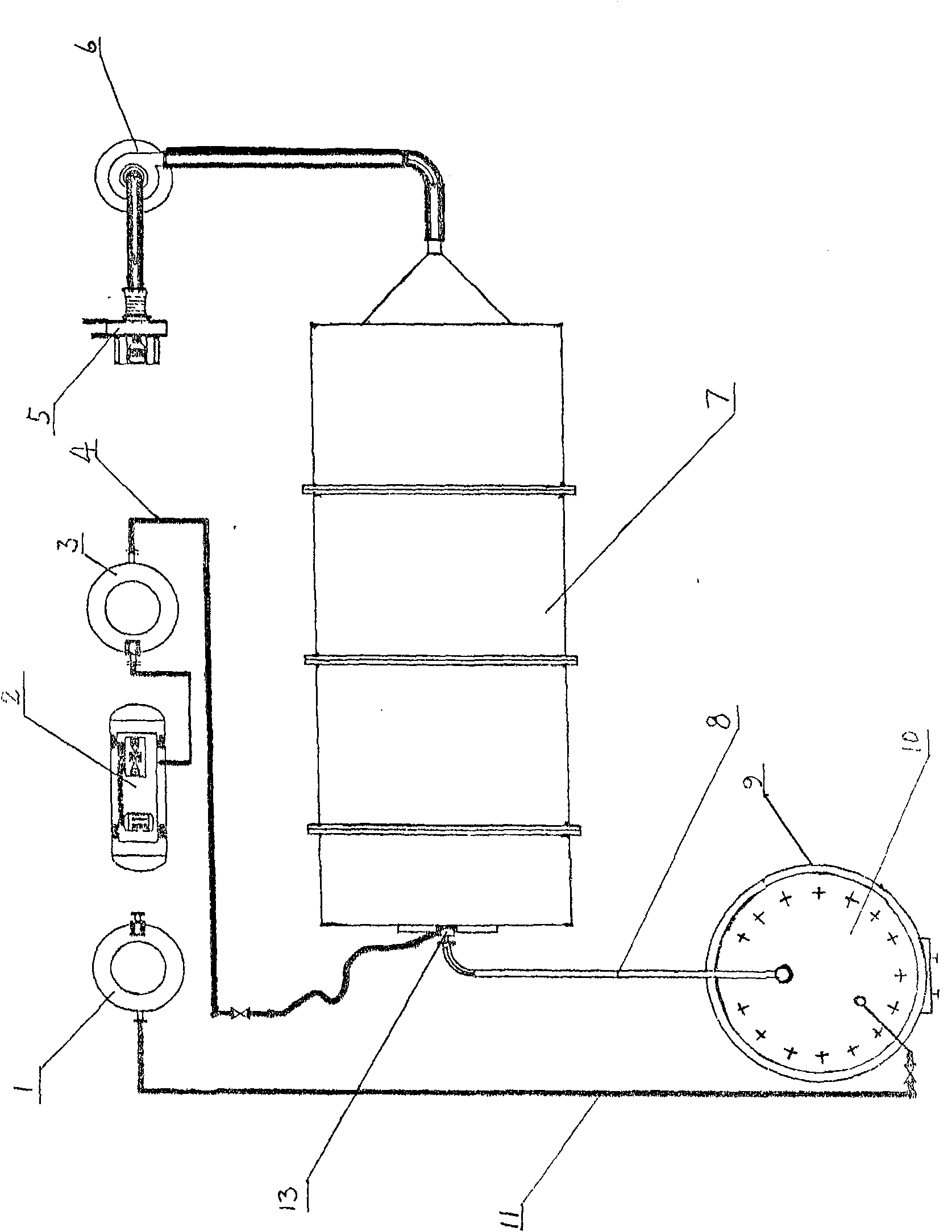

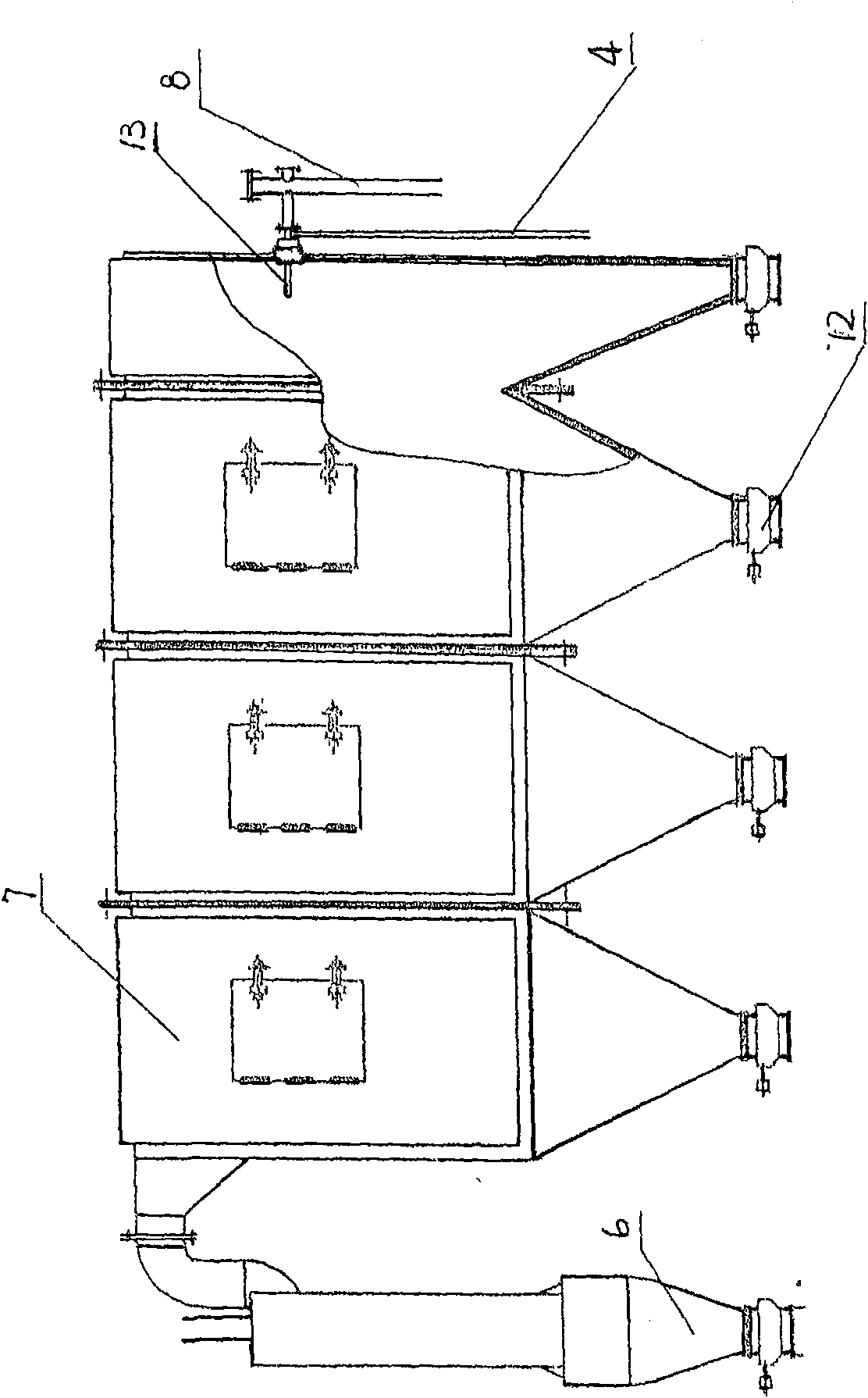

[0035] The top view of the device connection is as follows figure 1 Shown: the equipment of the present invention comprises melting furnace 9, crucible 10, conveying melt pipeline 8, nozzle 13, air compressor 2, collection bin 7, and crucible 10 is placed in melting furnace 9, and crucible 10 is a sealed crucible 10 with a cover , the crucible 10 is connected to the argon gas cylinder 1 with an inert gas delivery pipe 11, the crucible 10 is connected with a melt delivery pipeline 8, the other end of the melt delivery pipeline 8 is connected with a nozzle 13, and the melt delivery pipeline 8 is attached with a pipeline high-frequency Heater (not shown), nozzle 13 is a linear nozzle, nozzle 13 is attached with a nozzle high-frequency heater (not shown), nozzle 13 enters the collection bin 7 heads, and the nozzle 13 side has a compressed air pipe 4, The nozzle 13 and the compressed air intake pipe 4 form a V-shaped spray at an angle to each other, and the angle is 35° to 42°. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com