Module type hydraulic classification device with variable cone angle

A hydraulic classification and modular technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve problems such as inability to change, blockage of inclined plates, blockage of side discharge ports, etc., to reduce maintenance and replacement costs , improve grading efficiency, and ensure normal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the embodiments (see accompanying drawings).

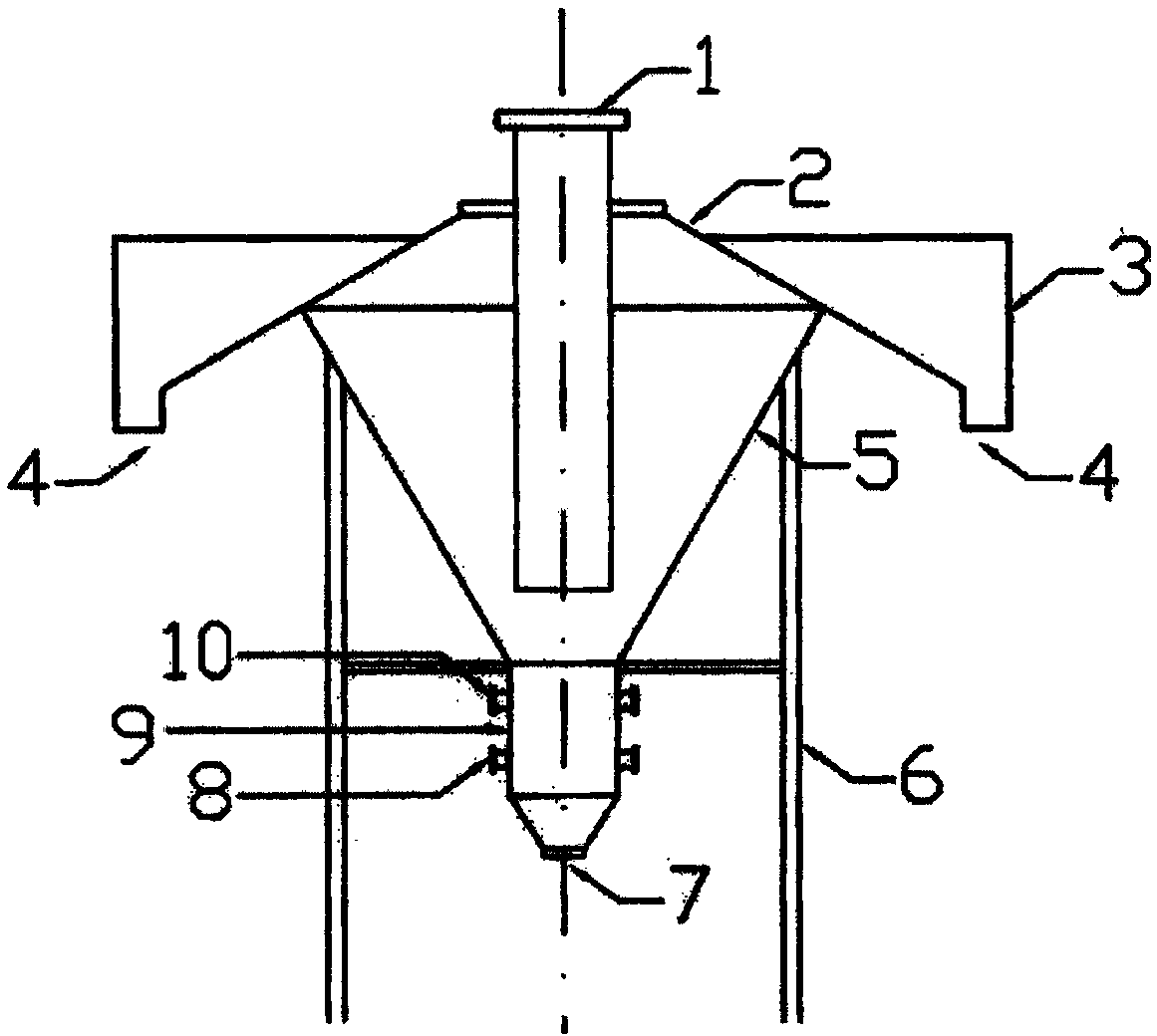

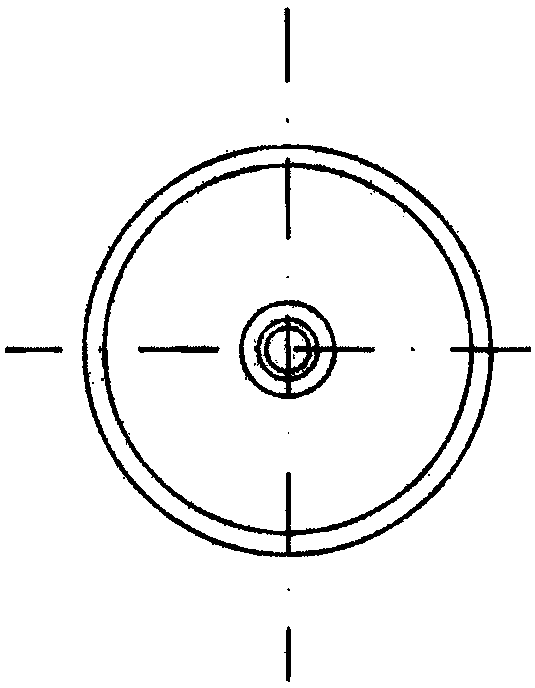

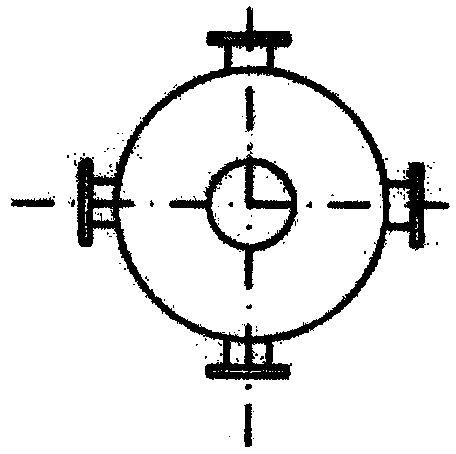

[0030] Such as figure 1 , 2 As shown, the modular hydraulic grading device with variable cone angle of the present invention comprises three modules installed on the support frame 6 successively from top to bottom; 2. The overflow collecting tank is set around the outer conical surface below the feed port of the upper shell. 3. The feed well 1 is installed in the feed port of the upper shell through fixing parts in a coaxial manner with the main body of the hydraulic classifier. ; The second module is made up of the lower casing 5 of the inverted cone structure with variable taper angle which is fastened together with the upper casing in the middle; It consists of a hollow column section 9 with a top water inlet pipe and a conical discharge section arranged at the bottom of the hollow column section. The discharge port 7 is arranged at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com