Interlayer structure for reducing interlayer strain of double-pulse solid engine

A solid engine, double-pulse technology, applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc., can solve the problems of large hoop strain, easy damage, weak internal ballistic adjustment ability, etc., to reduce hoop strain, Effect of reducing probability and improving regulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

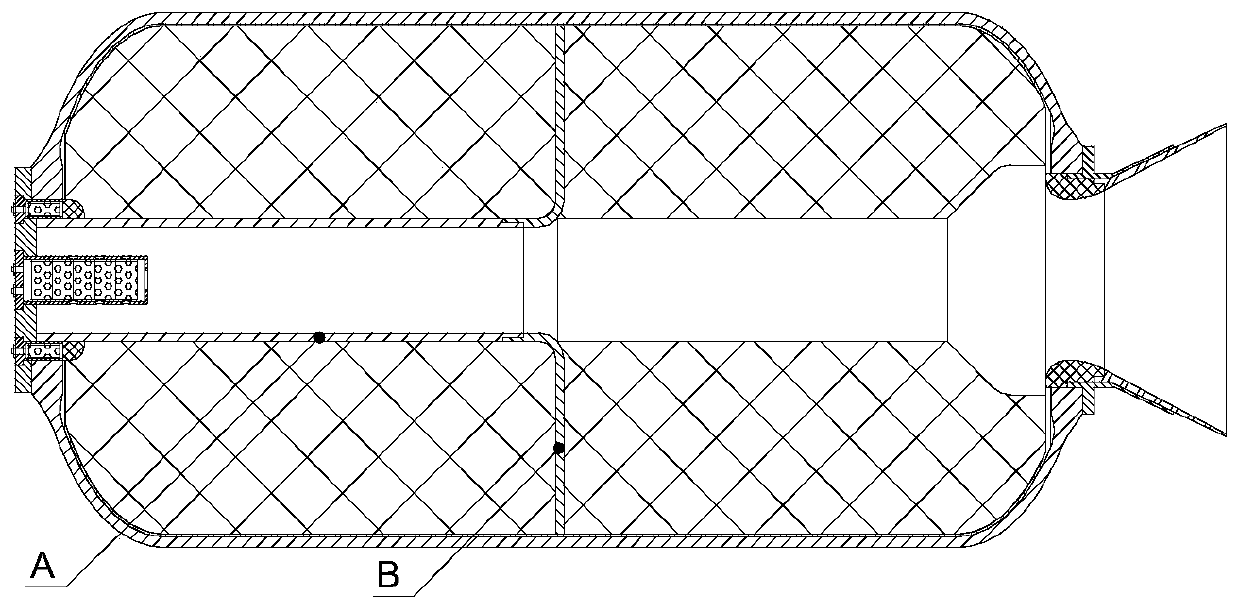

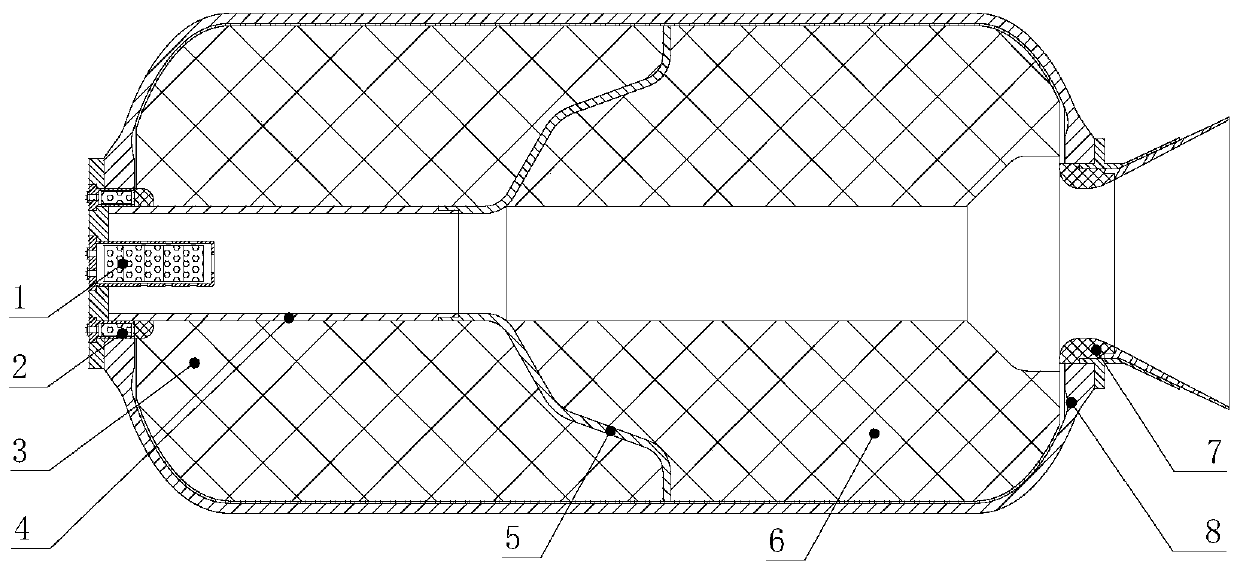

[0018] Such as figure 2 As shown, the interlayer double-pulse solid motor structure includes I pulse igniter 1, II pulse igniter 2, I pulse grain 6, interlayer structure, II pulse grain 3, nozzle 7 and adiabatic shell 8, and the insulation The grain structure separates the grains I pulse grain 6 and grain II pulse grain 3 .

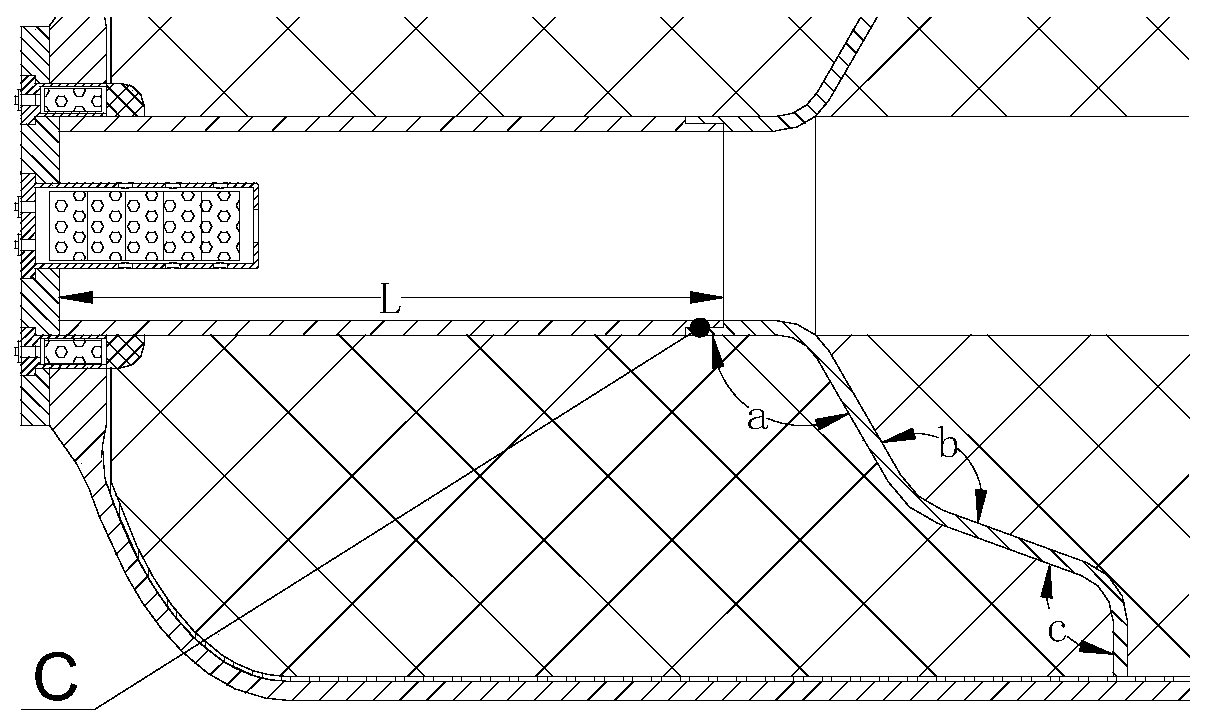

[0019] A kind of interlayer structure that reduces the interlayer strain of double-pulse solid motor provided by this embodiment, such as image 3 As shown, it includes a radial partition 4 and an axial partition 5. The radial partition 4 is wrapped on the inner circumference of the II pulse grain 3, and the radial partition 4 is bonded to the shaft at the axis of the solid motor. To the inner side of the head of the partition layer 5, the overall sealing structure of the partition layer is formed, and the radius length of the bond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com