Patents

Literature

34 results about "Hoop strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hoop stress/strain: empirical relationship of hoop stress to the change in diameter of the tube and fitting. Hoop stress resistance generated by the cell walls increases the shear strength of the confined infill, thus creating a stiff mattress and distributing the load over a wider area.

System and method for uniform and localized wall thickness measurement using fiber optic sensors

ActiveUS20120099097A1Accurately determineClean and high signal to noise ratioFluid pressure measurement by electric/magnetic elementsUsing optical meansRelative strainFiber Bragg grating

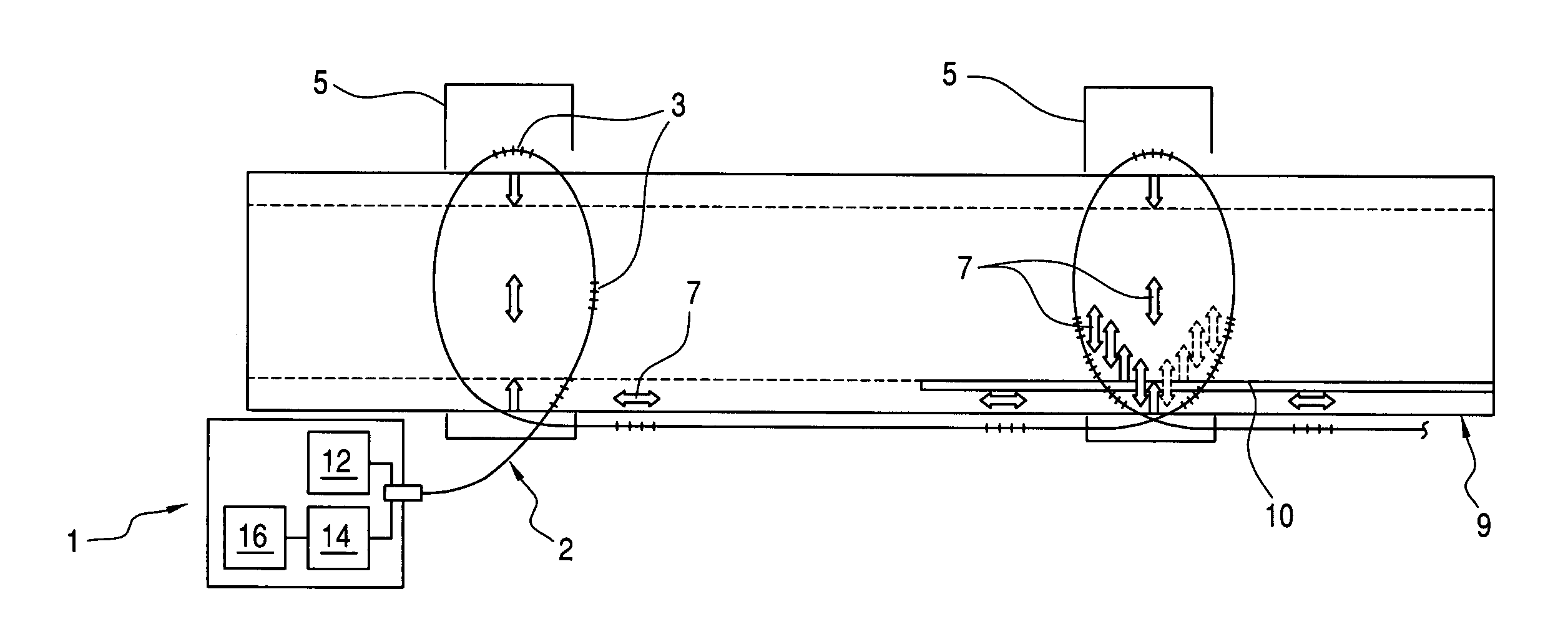

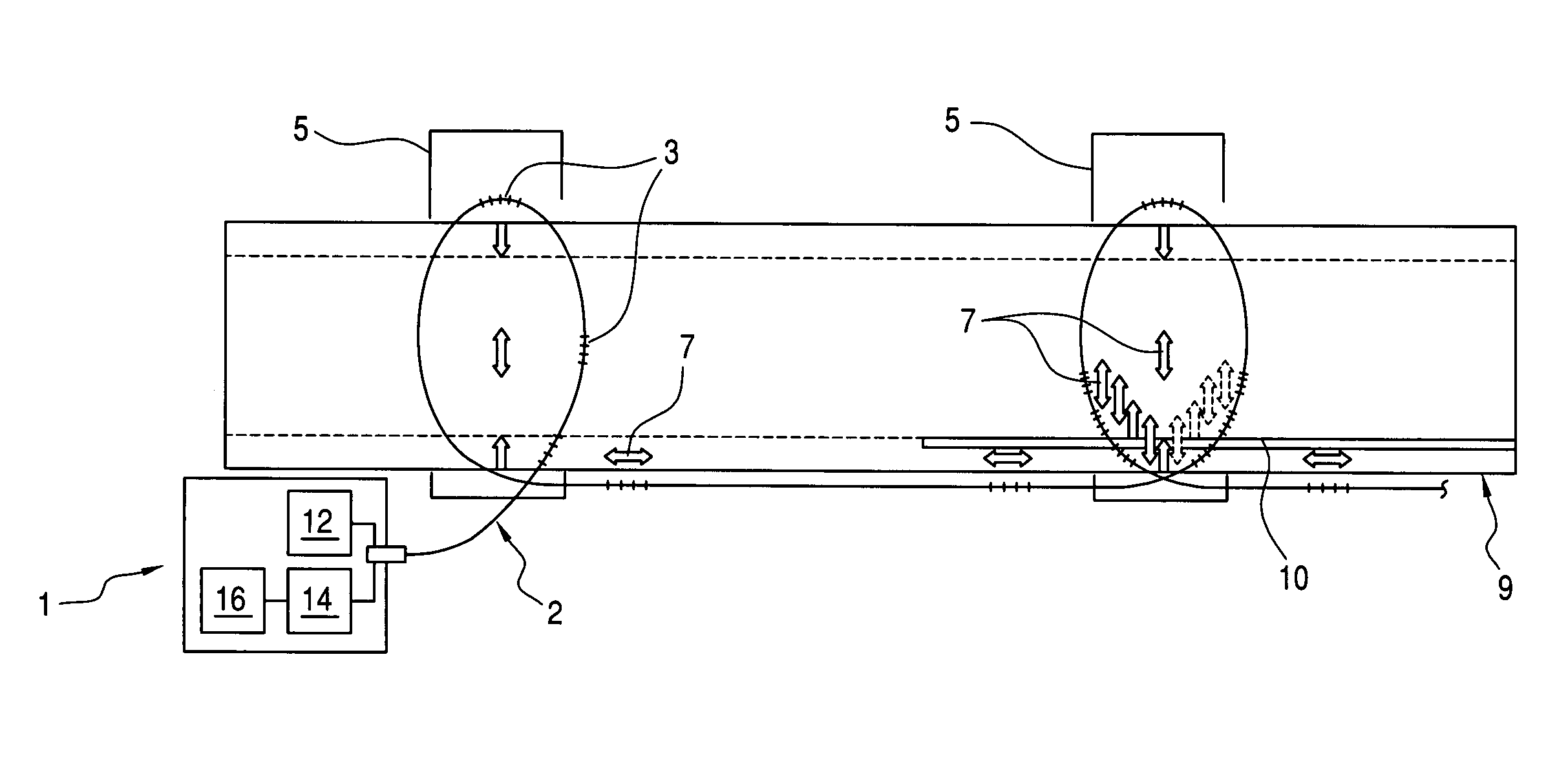

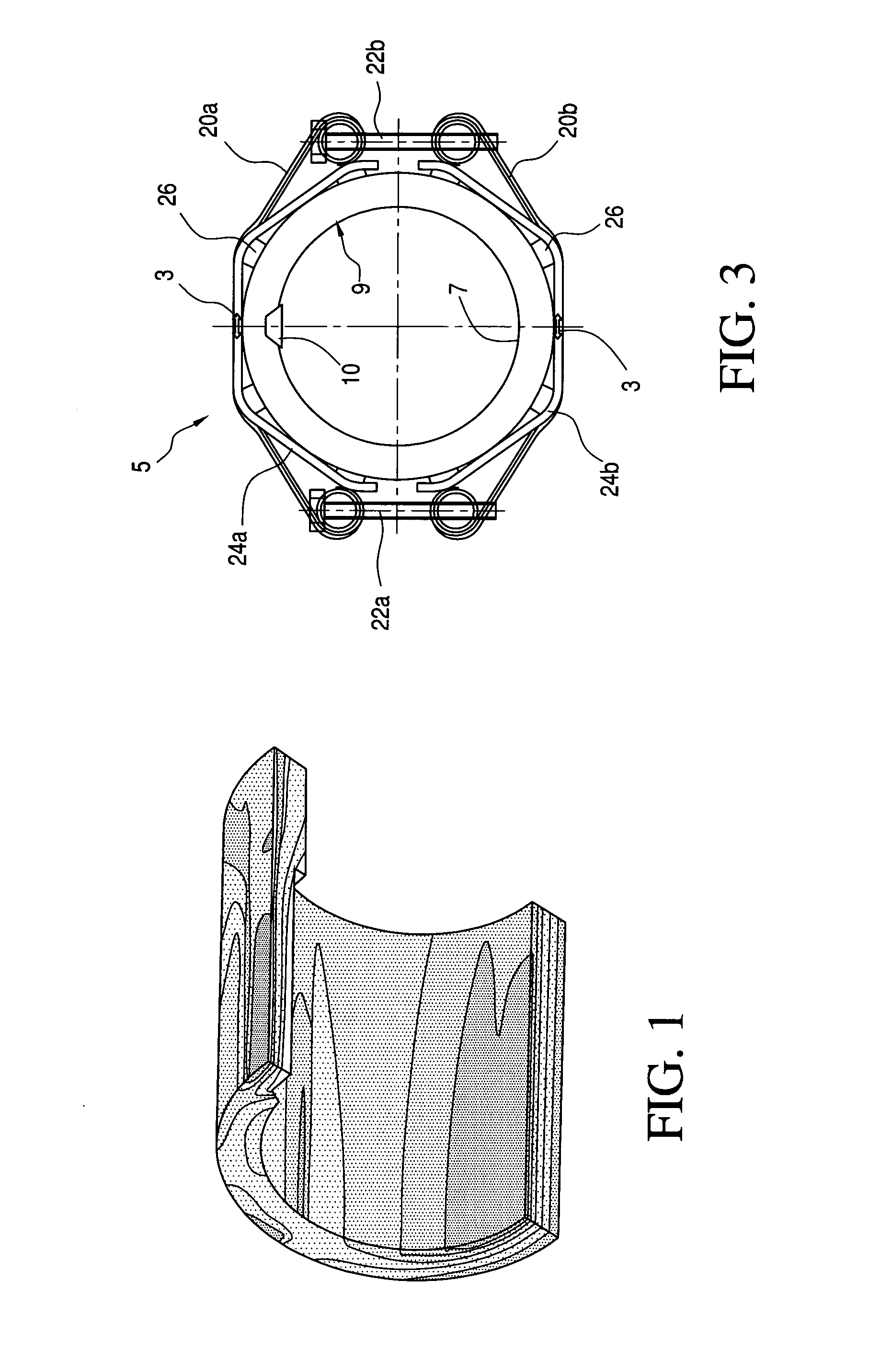

A system and method are provided for determining wall thickness of a structure such as a metallic pressurized pipe. The system includes an optical fiber having a plurality of Fiber Bragg Gratings (FBGs), and a mounting for securing the FBGs over discrete portions of the exterior surface of the pipe such that strain in the pressurized pipe wall is transmitted to the FBGs. The system further includes a light source and a light sensor coupled to an end of the optical fiber. The light sensor converts light reflected back from the FBGs into electrical signals that a digital processor converts into strain measurements. The FBGs are mounted around portions of the pipe expected to have significant metal loss as well as portions of the pipe expected to have negligible metal loss. The method includes at least one of comparing relative strains at locations with negligible metal loss to those with significant metal loss to accurately determine the thickness of the wall with metal loss; compensating for temperature effects by considering relative strains at areas of the pipe with and without metal loss; and measuring axial strain on the pipe with one or more of the FBGs to correct for at least one of bending and torsion effects on hoop strain.

Owner:SCHLUMBERGER TECH CORP

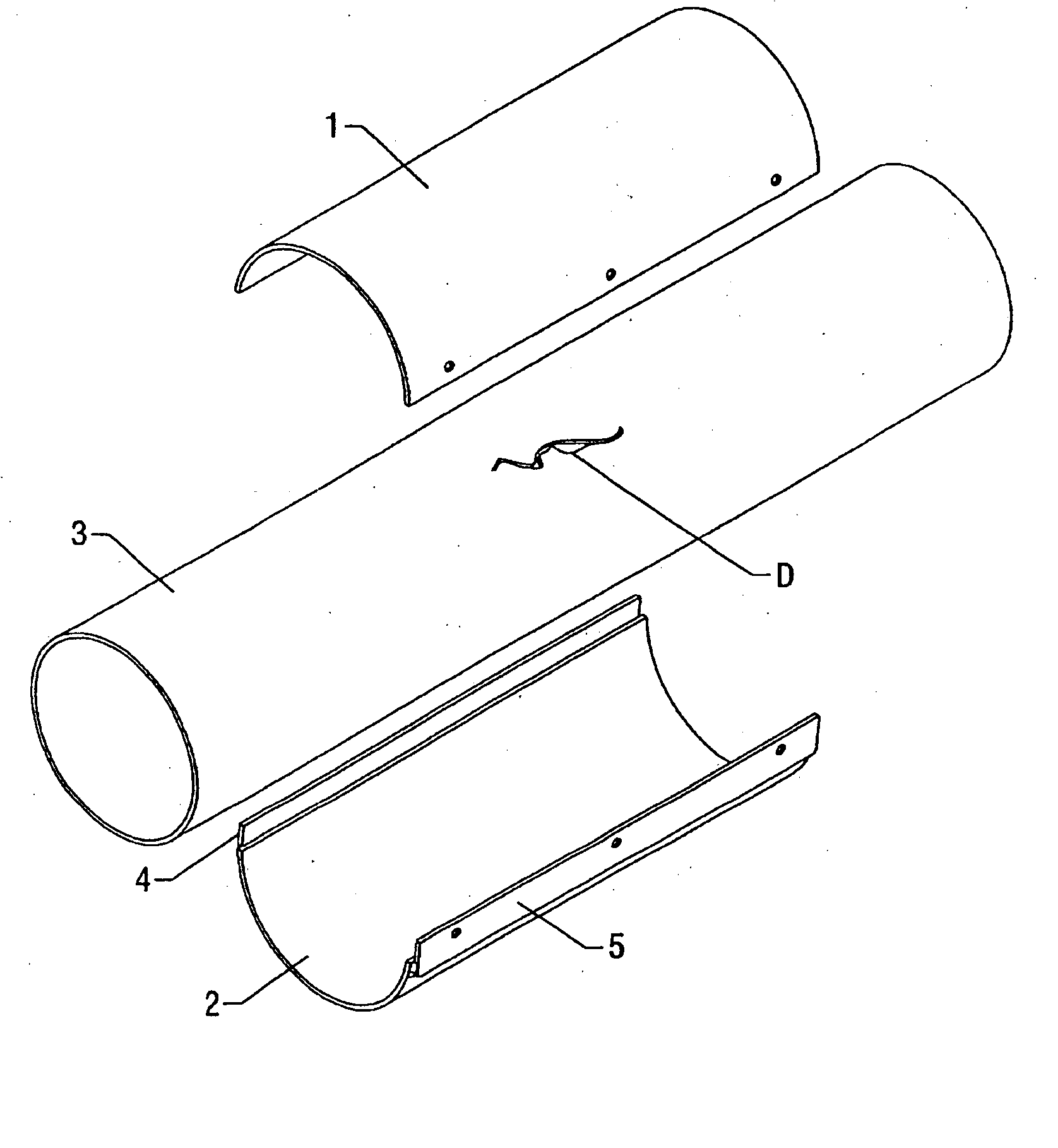

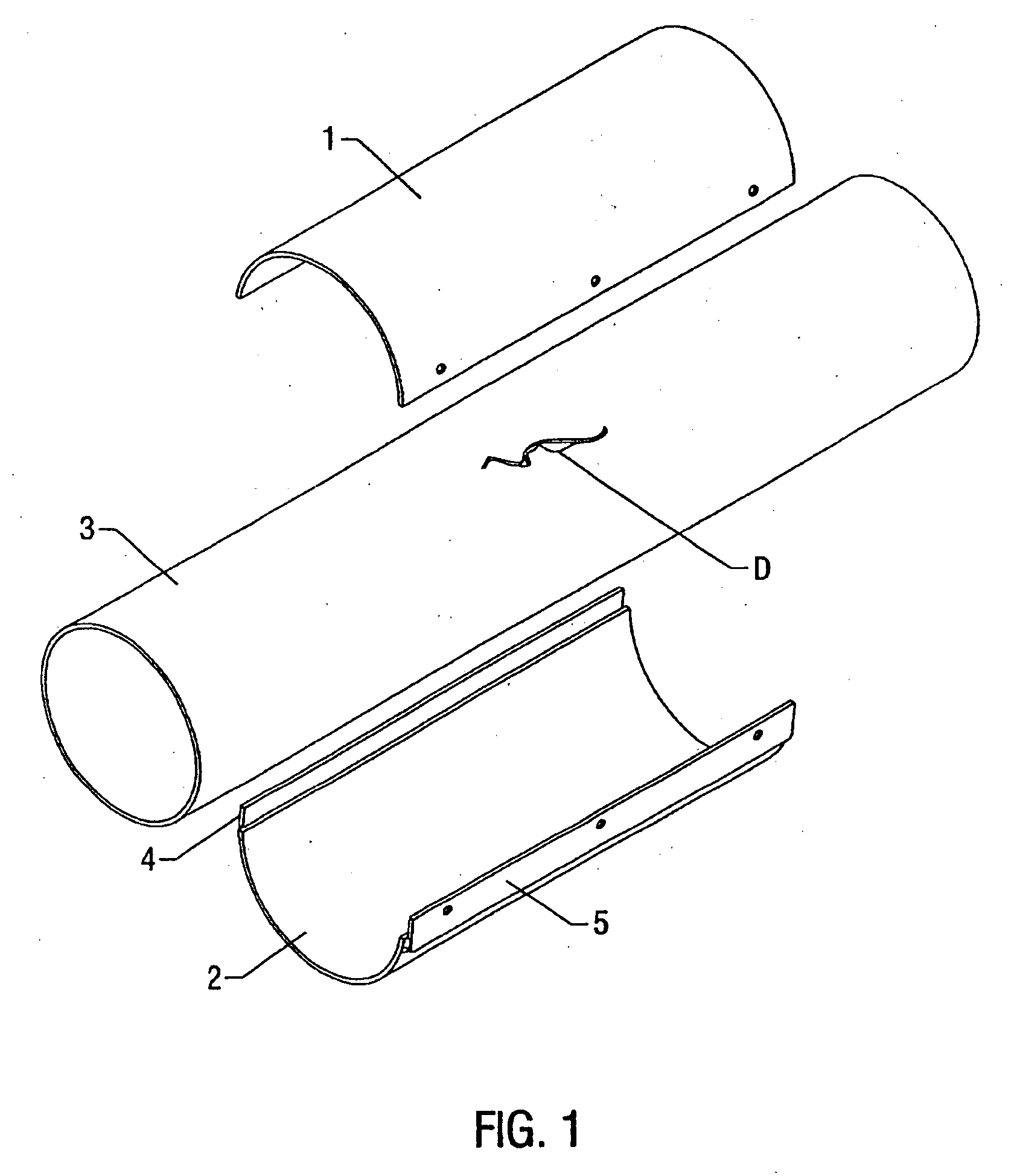

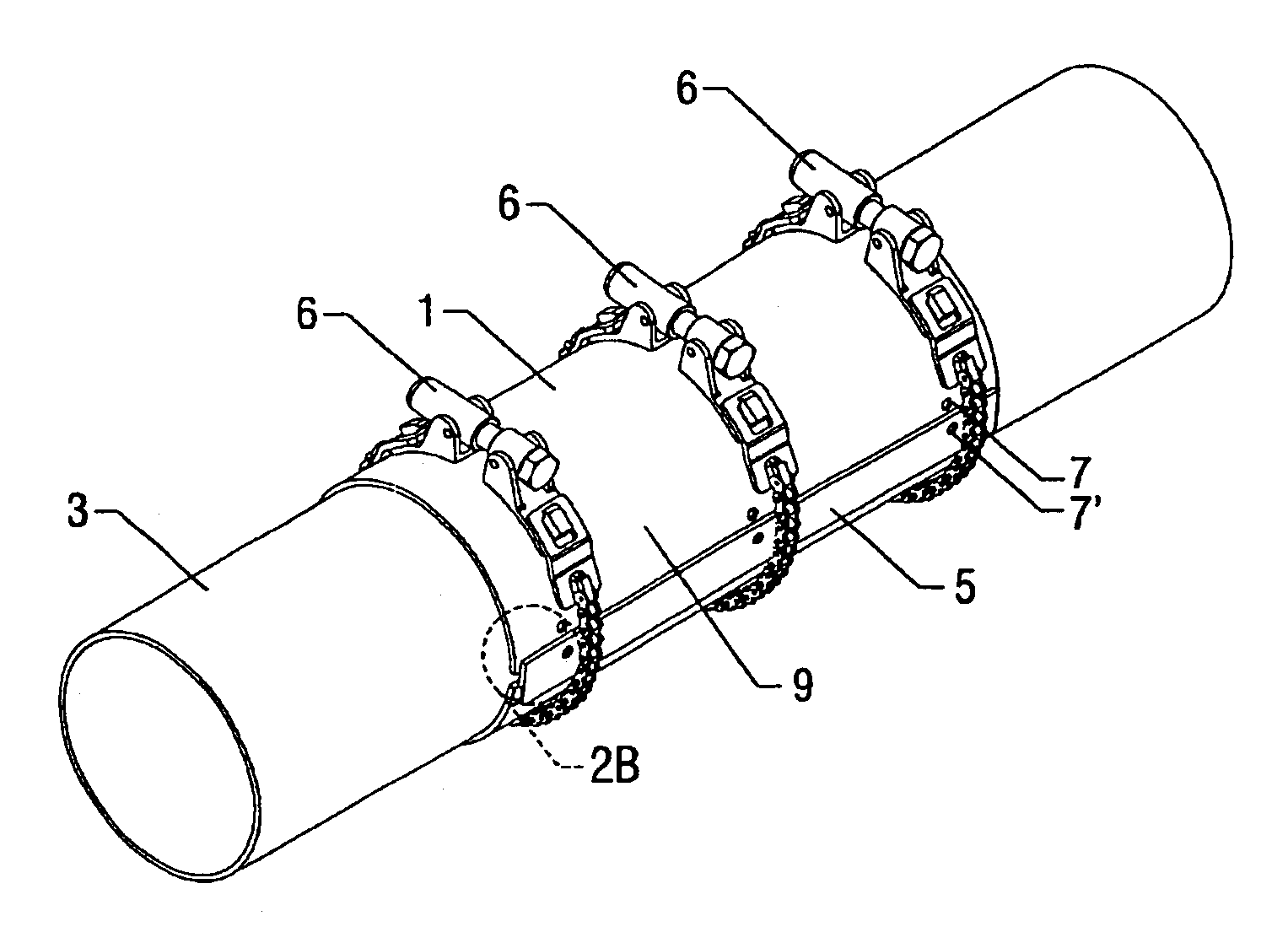

Compression pipe repairing and reinforcing methods

ActiveUS20040011415A1Sleeve/socket jointsFluid pressure sealed jointsEngineeringOperant conditioning

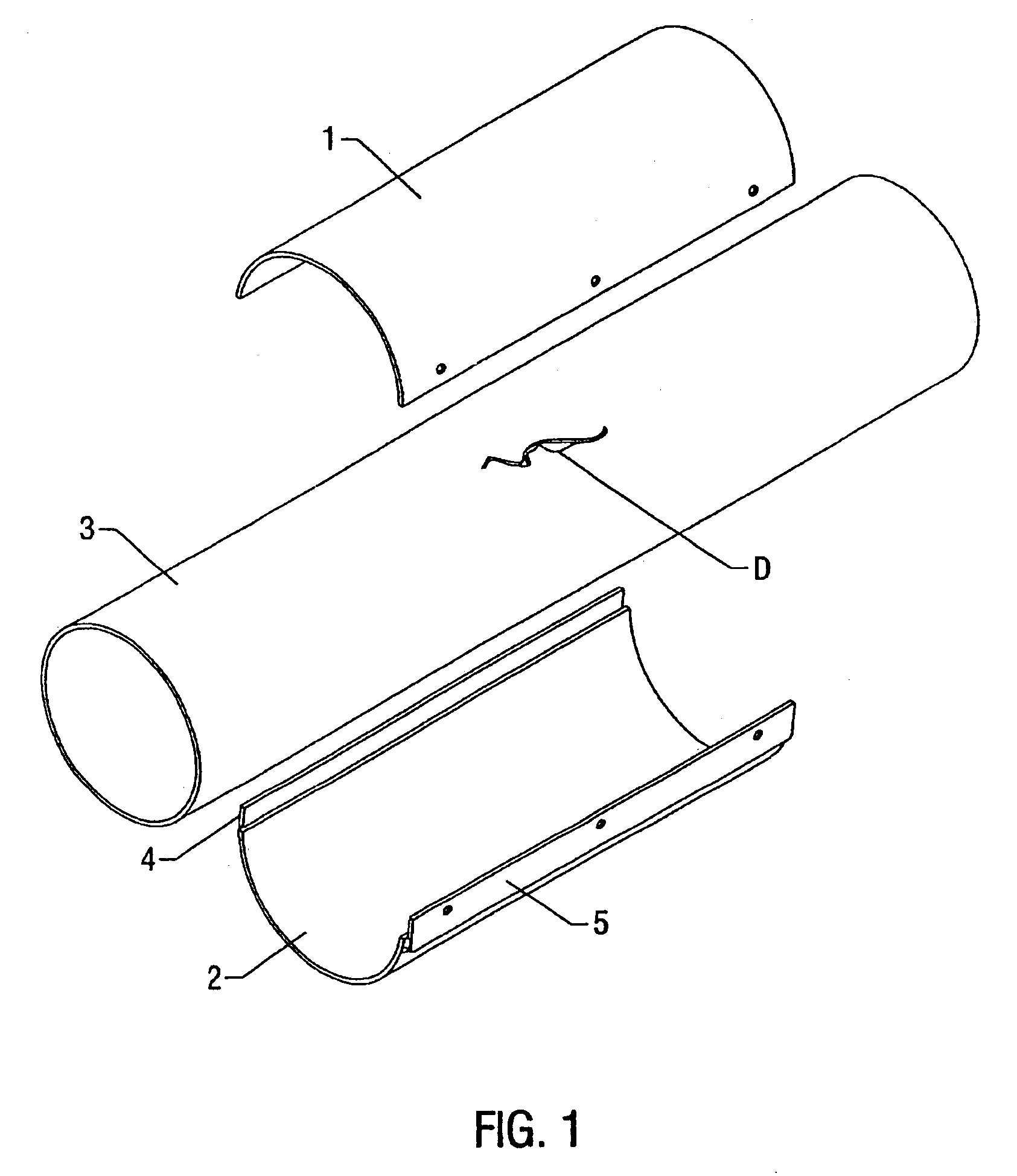

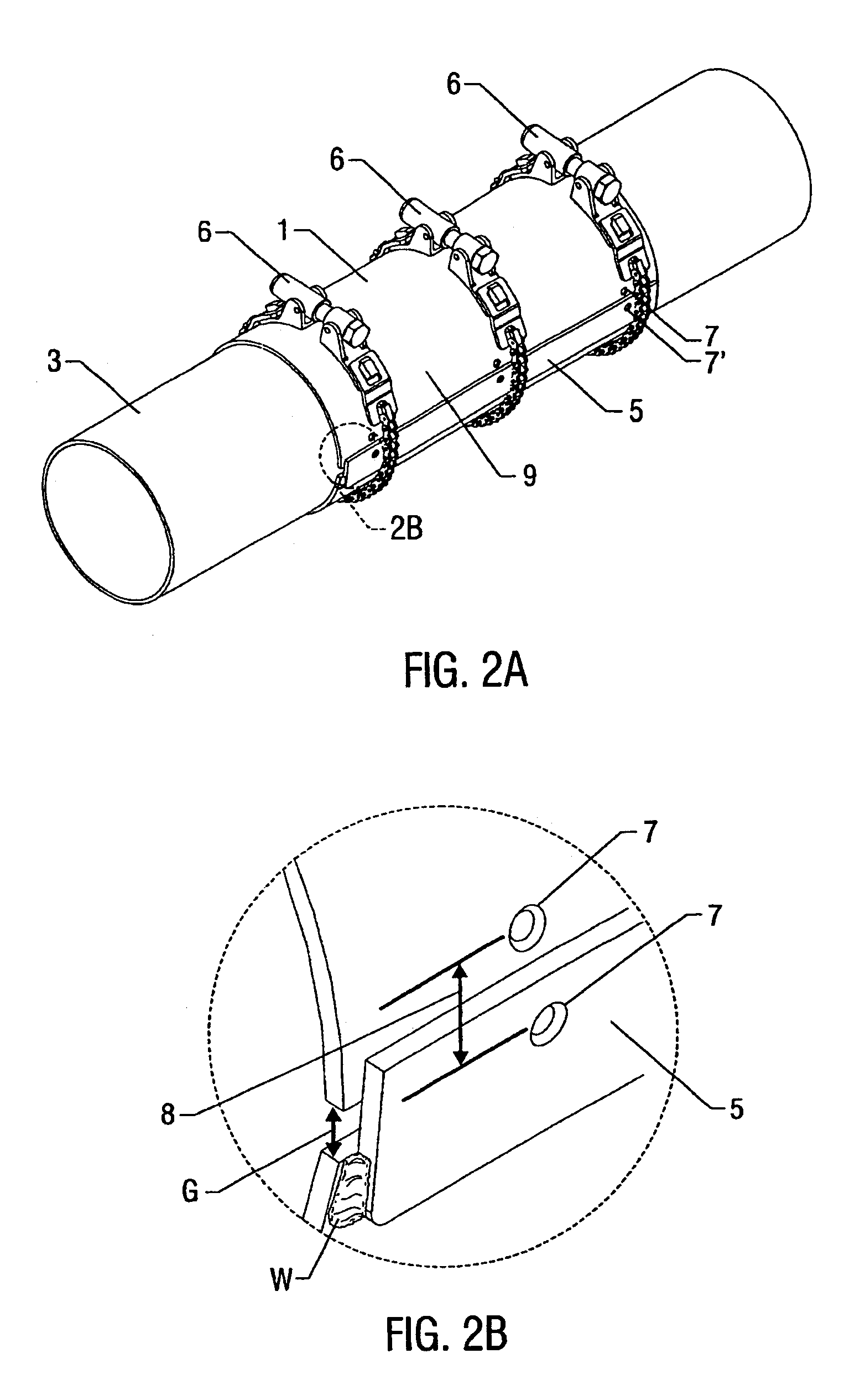

A method of repairing a section of pipe is described. The method includes applying a first split sleeve and a second split sleeve to the pipe section, functionally associating the first end of the first split sleeve with the first end of the second split sleeve, and applying a compressive force until the internal diameter of the pipe experiences compressive shear hoop strain. The method described produces substantially uniform compressive hoop strain along the length of the pipe section, and may exceed a predetermined value, such as 100 microstrain in compression, for example. The amount of force required may be calculated utilizing maximum operating conditions. The method described may produce an acceptable permanent repair by ensuring that the inner diameter of the section of pipe experiences compressive strain. Also described is a method of reinforcing a section of pipe utilizing these apparatus and methods.

Owner:BJ SERVICES CO

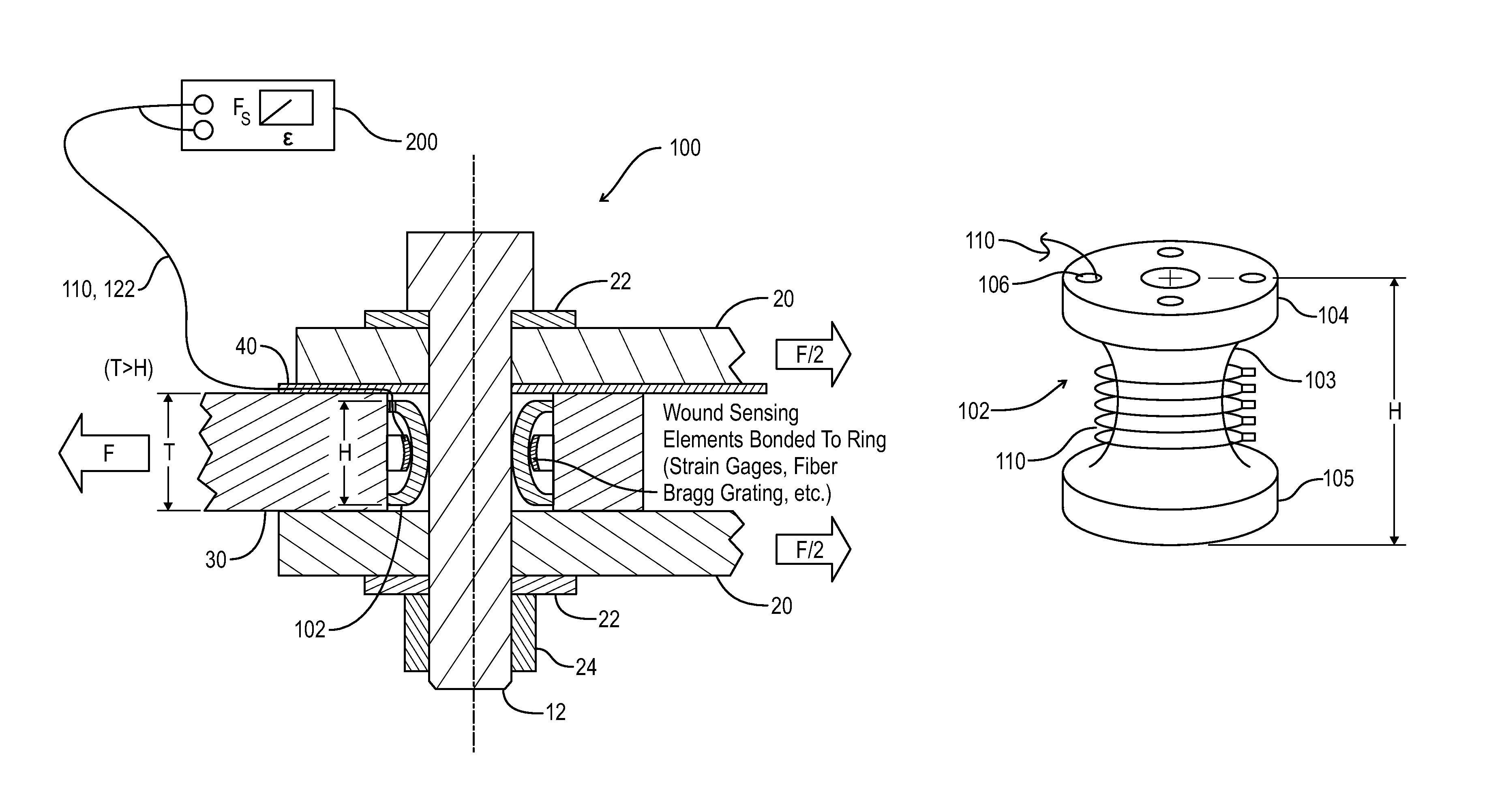

Bolt shear force sensor

ActiveUS9429485B1Measurement of torque/twisting force while tighteningForce measurement using piezo-electric devicesEngineeringForce sensor

A bolt shear force sensor for in-service monitoring is provided in which the sensor includes a deformable ring with channel-like cross-sections and a wire egress hole. The ring surrounds a bolt or fastener to be tested. The channel-like cross sections face exterior to a center of the ring. Strain sensing elements are mounted within the channel cross-sections as an outer circumference of the ring. The sensing elements capture hoop strain from surrounding plates of the operating system which holds the fastener. A signal conditioner operationally connected via wire conductors is used to convert strain sensing signals from the sensing elements to strain output. The strain outputs are then used in conjunction with a calibration curve of shear force versus strain to determine the magnitudes and directions of the resultant shear forces.

Owner:UNITED STATES OF AMERICA

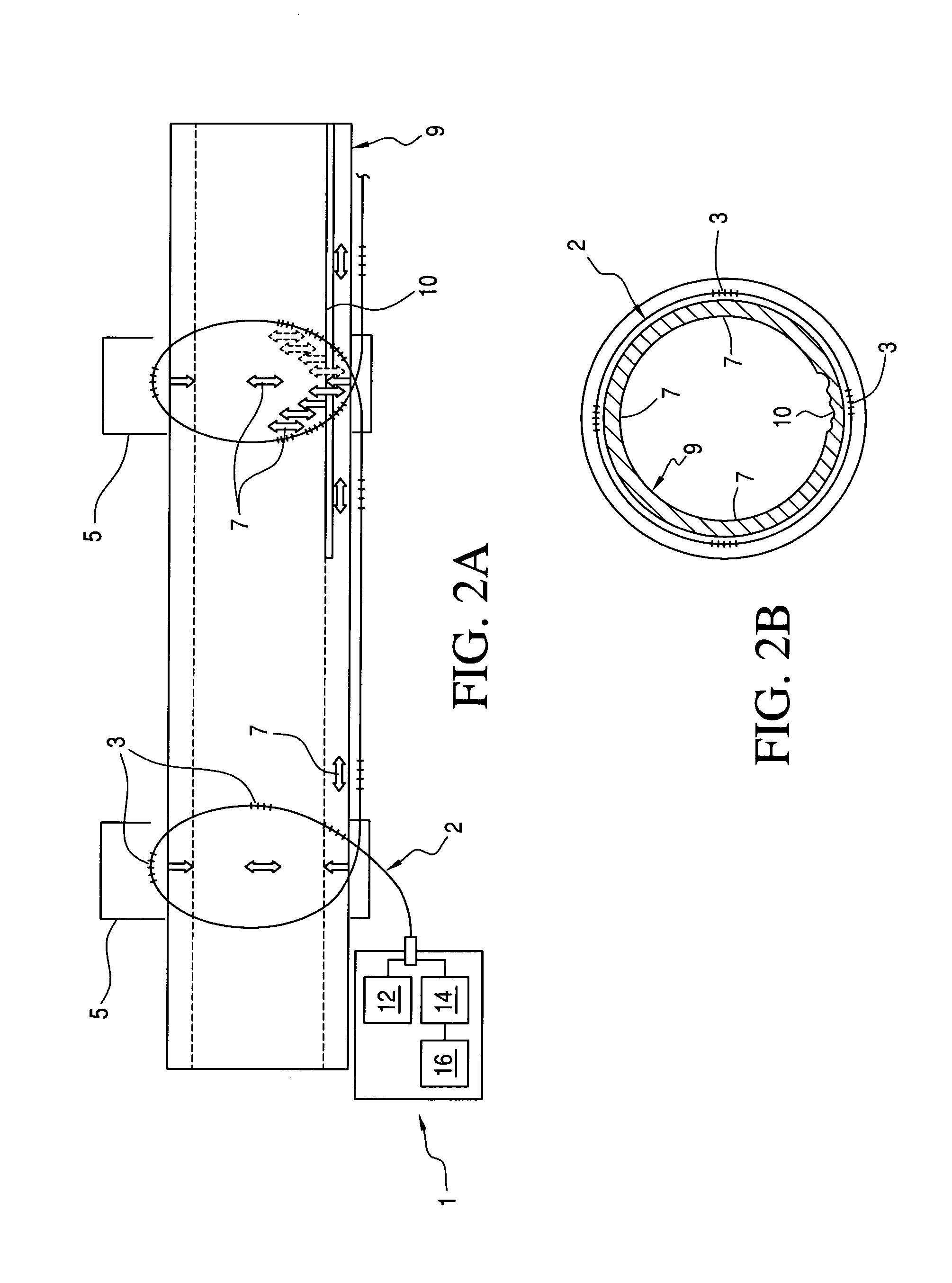

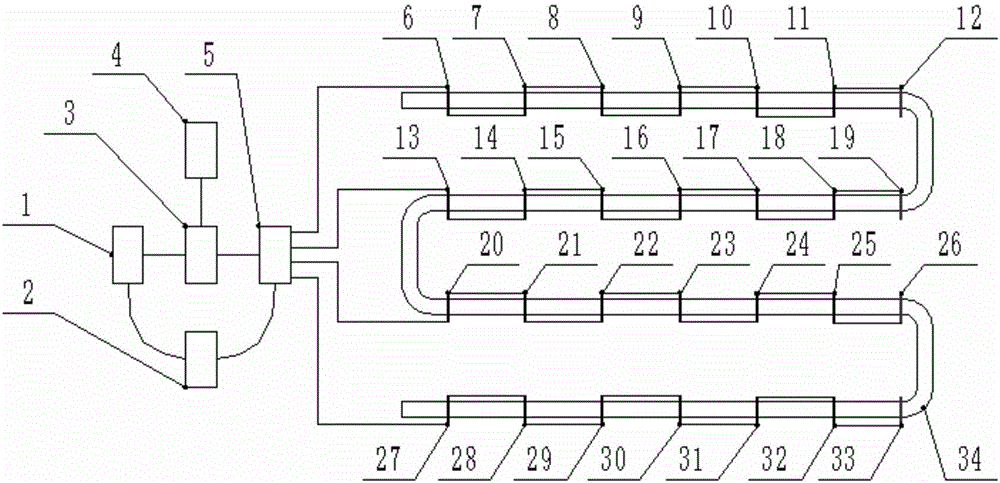

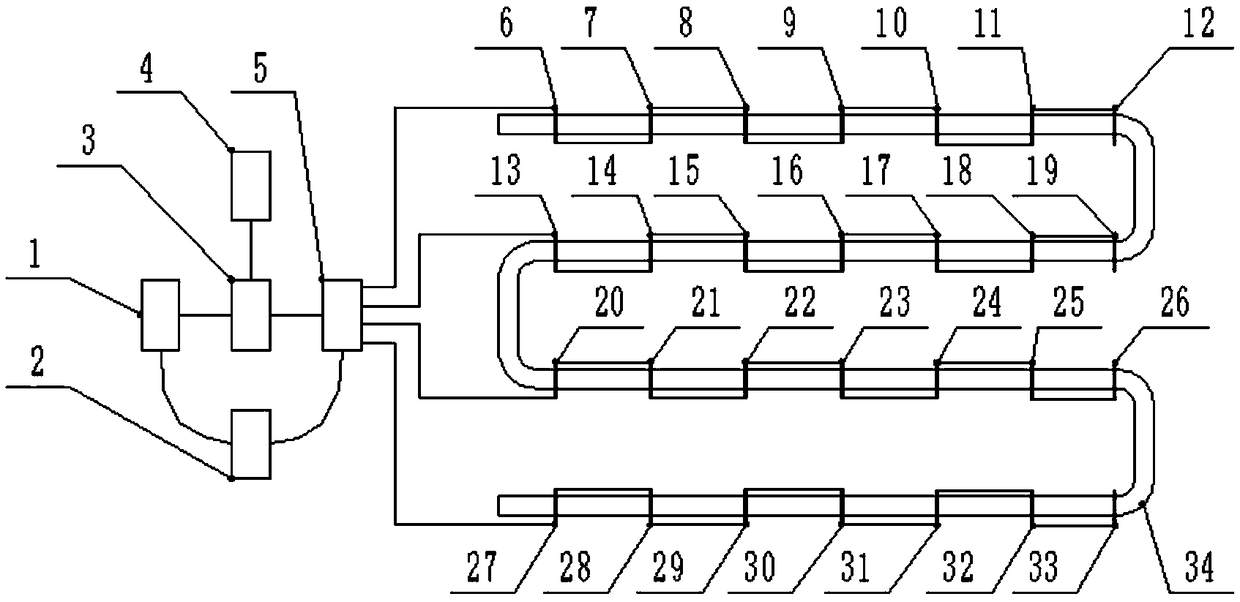

Pipeline leakage and corrosion online monitoring device and method based on optical fiber grating sensing

ActiveCN106764463ALeak real-time monitoringReal-time monitoring of leakagePipeline systemsGratingBeam splitting

The invention relates to a pipeline leakage and corrosion online monitoring device and method based on optical fiber grating sensing. The device comprises a beam splitting system, a demodulating system, a control system and optical fiber grating sensors which are fixed on the outer wall of a long straight pipeline and the outer wall of a bent pipe. The optical fiber grating sensors fixed on the outer wall of the long straight pipeline only have one optical fiber grating and are arranged axially at equal intervals, and judge whether the long straight pipeline leaks or not according to a change condition of detected hoop strain of the pipeline, find out the leak position and acquire uniform corrosion condition; and the optical fiber grating sensors fixed on the outer wall of the long straight pipeline are provided with a plurality of optical fiber gratings and the optical fiber gratings on the same optical fiber grating sensor are uniformly arranged along the circumference, and the optical fiber grating sensors judge non-uniform corrosion condition at the bent pipe according to a change condition of detected local hoop strain. The device is simple in structure, low in cost, convenient to mount and high in monitoring precision.

Owner:WUHAN UNIV OF TECH

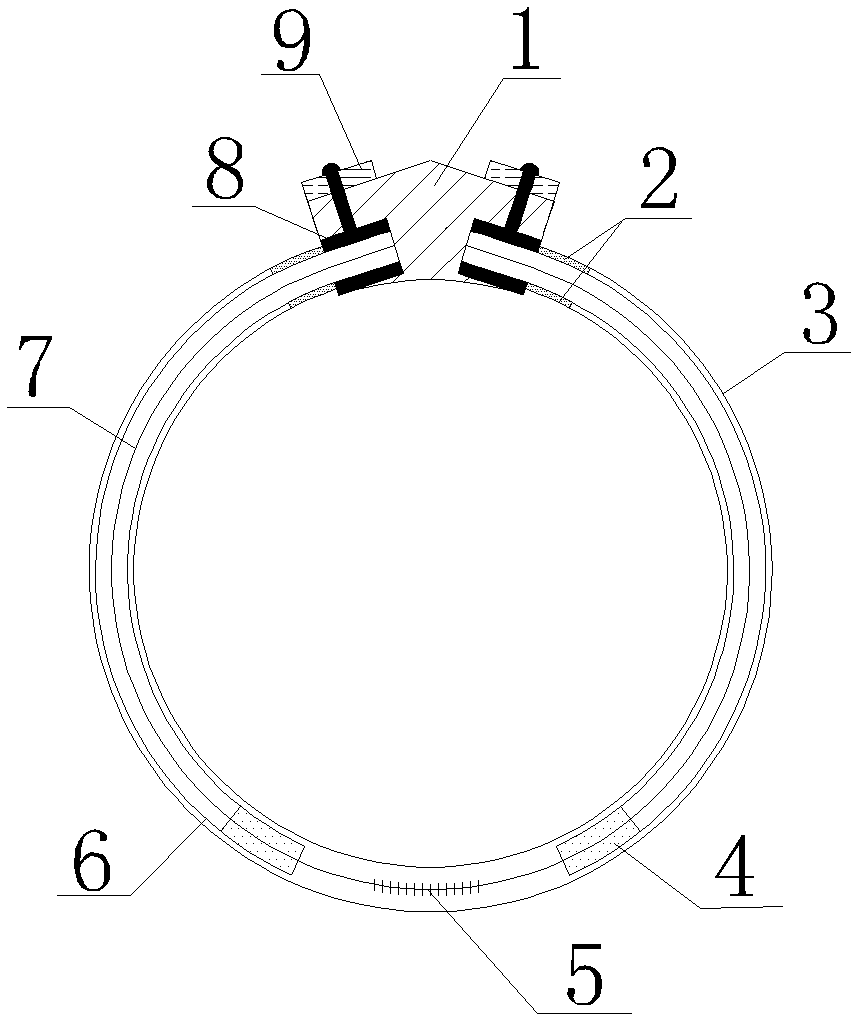

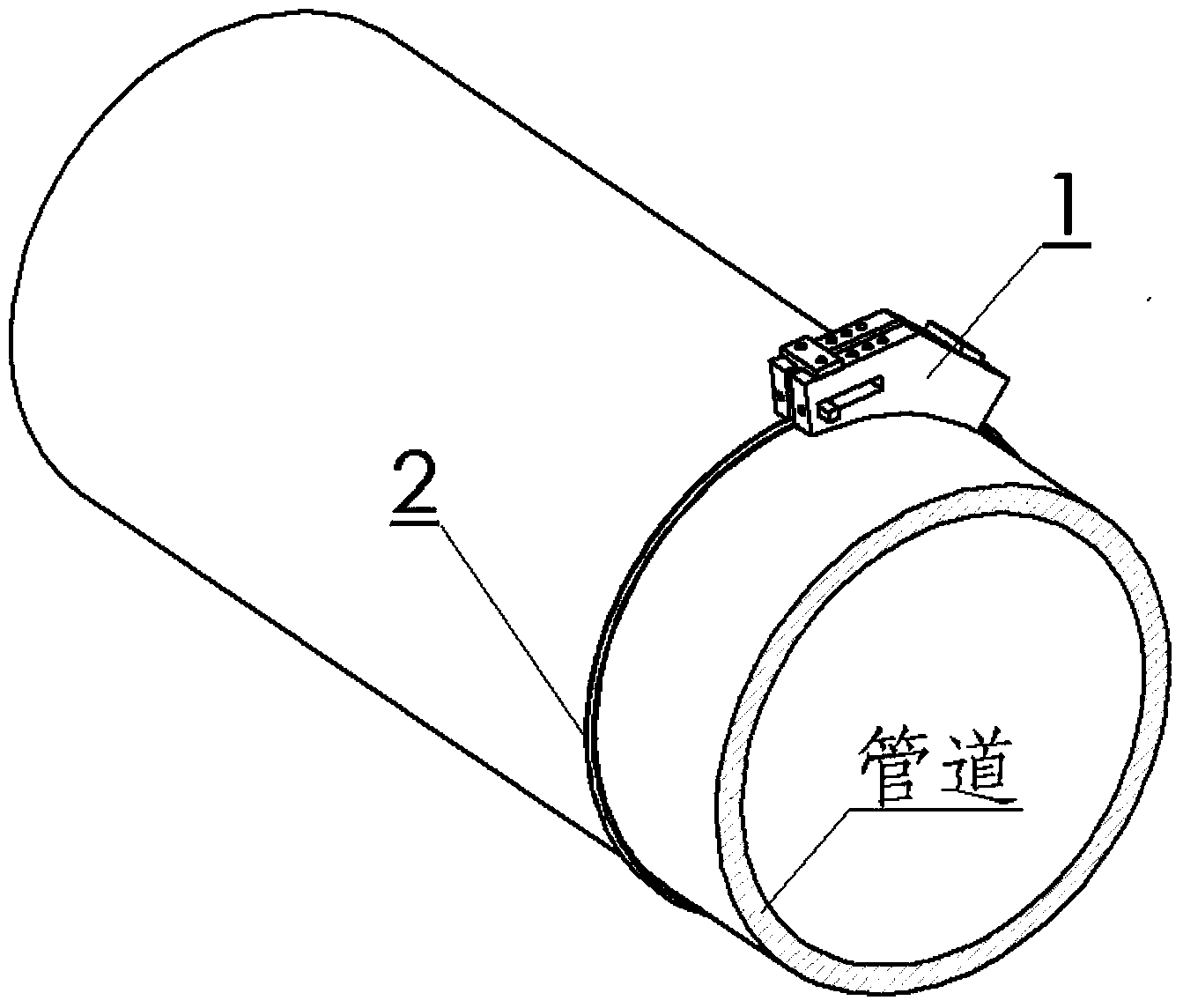

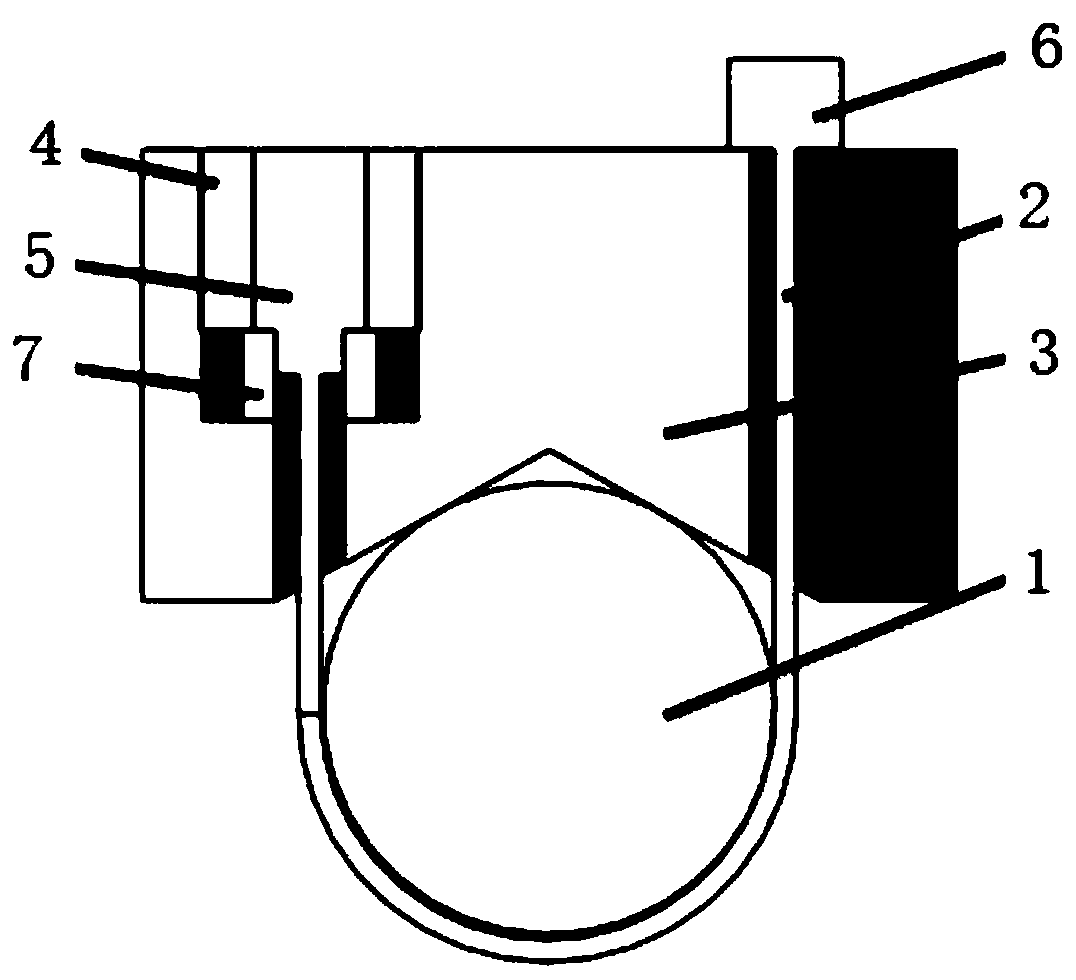

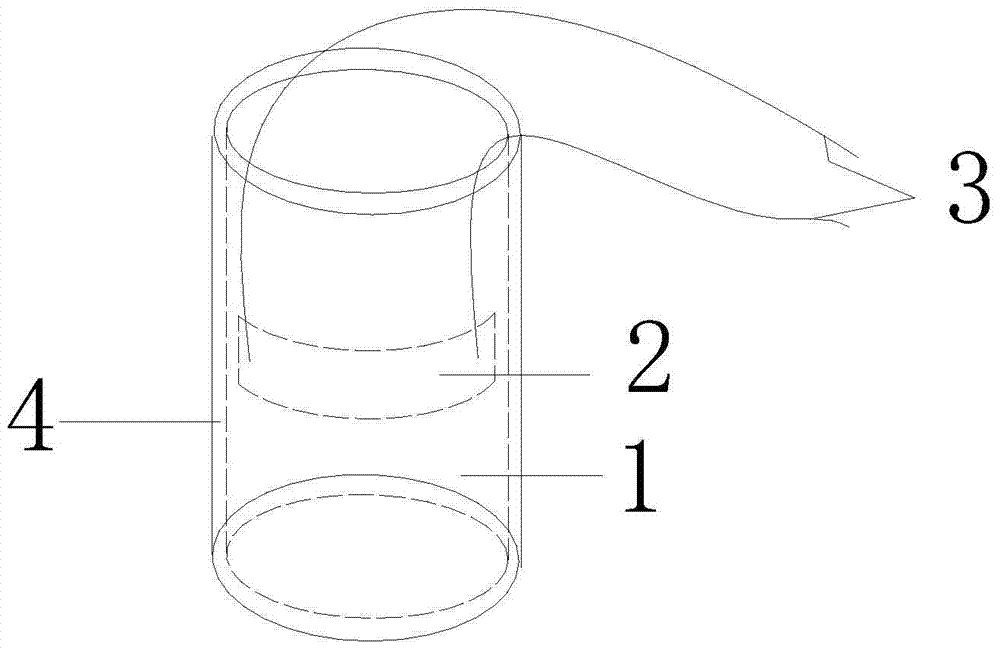

Strain hoop sensor used for measuring hoop strain of pipeline

InactiveCN102636128AHigh sensitivityUsing optical meansElectrical resistance and conductanceElectromagnetic interference

The invention discloses a strain hoop sensor used for measuring the hoop strain of a pipeline and belongs to the technical field of sensing. The strain hoop sensor is characterized by being packaged by a double-layer capillary steel pipe, wherein the strain hoop sensor packaged by a double-layer capillary steel pipe is tightly looped to the pipeline by virtue of a metal support and a clamping piece, and the capillary steel pipe is pasted to the outer wall of the pipeline by virtue of epoxy resin. The arc diameter of the contact surface of the metal support and the pipeline is equal to the external diameter of the pipeline, and the metal support is tightly contacted with the pipeline. The measuring sensitivity of the sensor can be adjusted by changing the sizes of elements of the sensor according to the actual requirements. The strain hoop sensor provided by the invention has the effects and advantages that the strain hoop sensor used for measuring the hoop strain of the pipeline can measure the hoop strain of the section of the pipeline, and has high sensitivity; and moreover, the strain hoop sensor can be used for overcoming the defects of small measuring scope, low precision, high possibility of influence caused by electromagnets, poor long-term stability and the like of a resistance strain gauge.

Owner:DALIAN UNIV OF TECH

Compression pipe repairing and reinforcing methods

A method of repairing a section of pipe is described. The method includes applying a first split sleeve and a second split sleeve to the pipe section, functionally associating the first end of the first split sleeve with the first end of the second split sleeve, and applying a compressive force until the internal diameter of the pipe experiences compressive shear hoop strain. The method described produces substantially uniform compressive hoop strain along the length of the pipe section, and may exceed a predetermined value, such as 100 microstrain in compression, for example. The amount of force required may be calculated utilizing maximum operating conditions. The method described may produce an acceptable permanent repair by ensuring that the inner diameter of the section of pipe experiences compressive strain. Also described is a method of reinforcing a section of pipe utilizing these apparatus and methods.

Owner:BJ SERVICES CO

System and method for uniform and localized wall thickness measurement using fiber optic sensors

ActiveUS8941821B2Accurately determineClean and high signal to noise ratioFluid pressure measurement by electric/magnetic elementsUsing optical meansRelative strainFiber Bragg grating

A system and method are provided for determining wall thickness of a structure such as a metallic pressurized pipe. The system includes an optical fiber having a plurality of Fiber Bragg Gratings (FBGs), and a mounting for securing the FBGs over discrete portions of the exterior surface of the pipe such that strain in the pressurized pipe wall is transmitted to the FBGs. The system further includes a light source and a light sensor coupled to an end of the optical fiber. The light sensor converts light reflected back from the FBGs into electrical signals that a digital processor converts into strain measurements. The FBGs are mounted around portions of the pipe expected to have significant metal loss as well as portions of the pipe expected to have negligible metal loss. The method includes at least one of comparing relative strains at locations with negligible metal loss to those with significant metal loss to accurately determine the thickness of the wall with metal loss; compensating for temperature effects by considering relative strains at areas of the pipe with and without metal loss; and measuring axial strain on the pipe with one or more of the FBGs to correct for at least one of bending and torsion effects on hoop strain.

Owner:SCHLUMBERGER TECH CORP

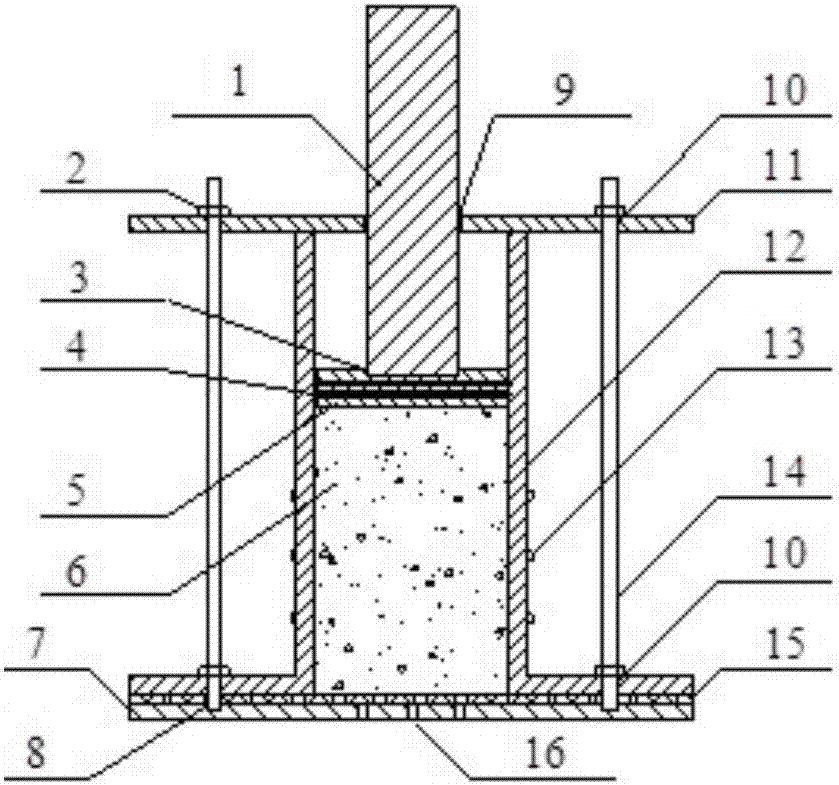

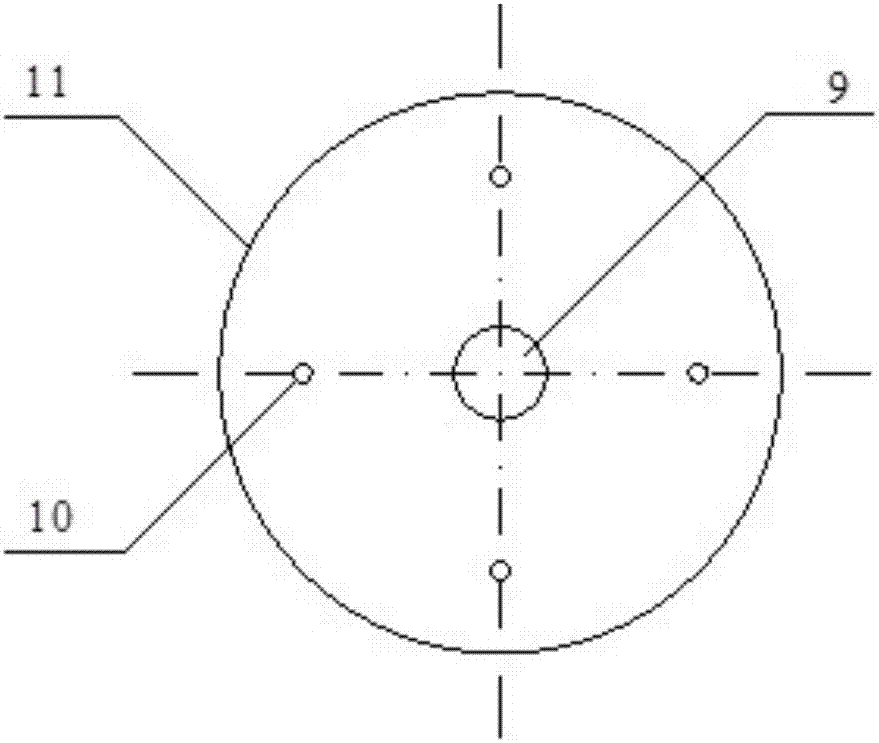

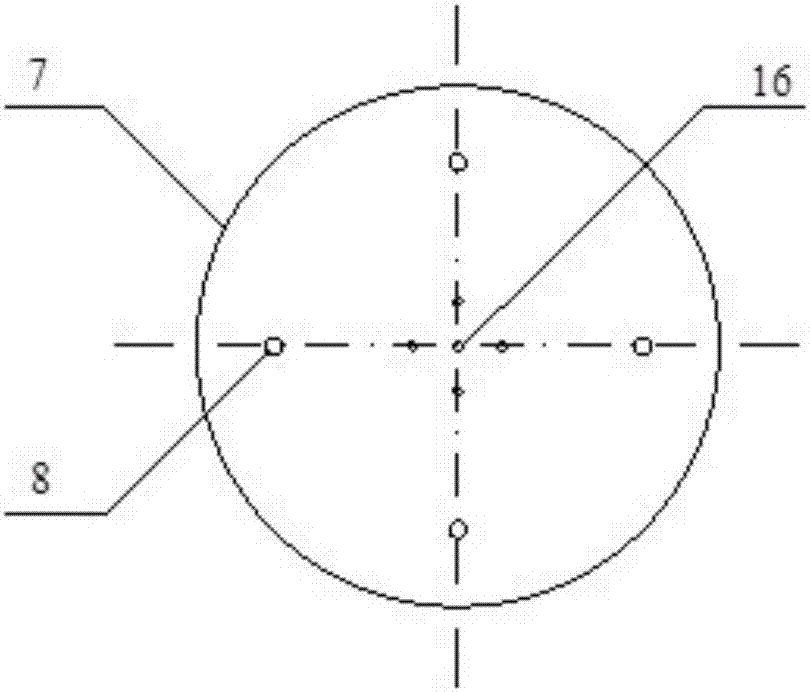

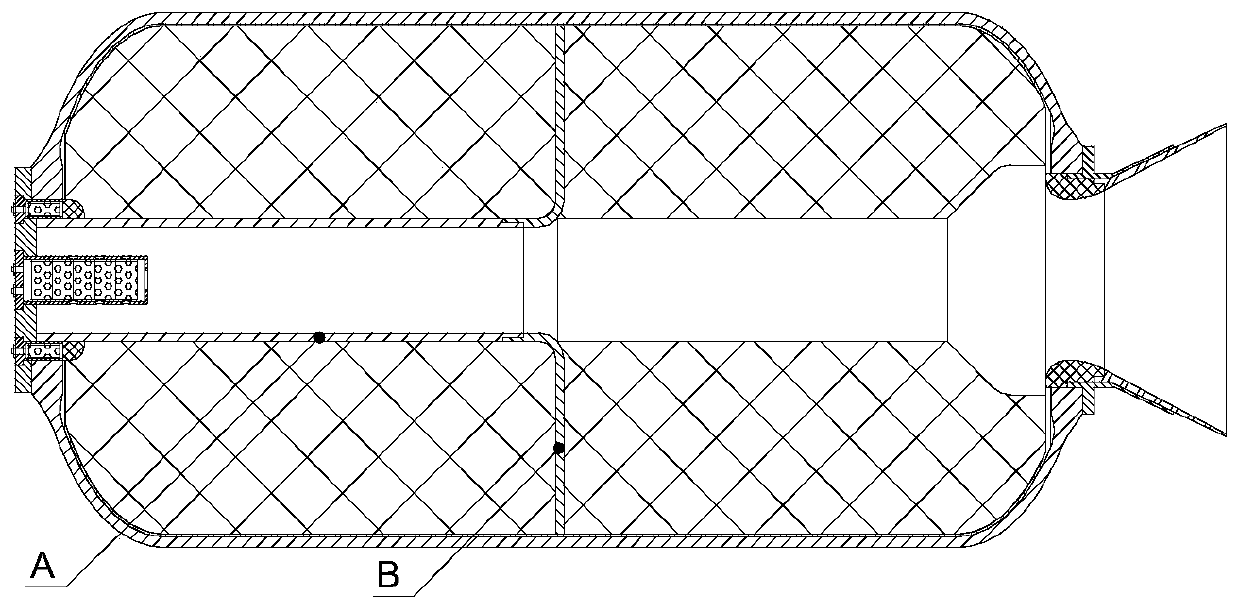

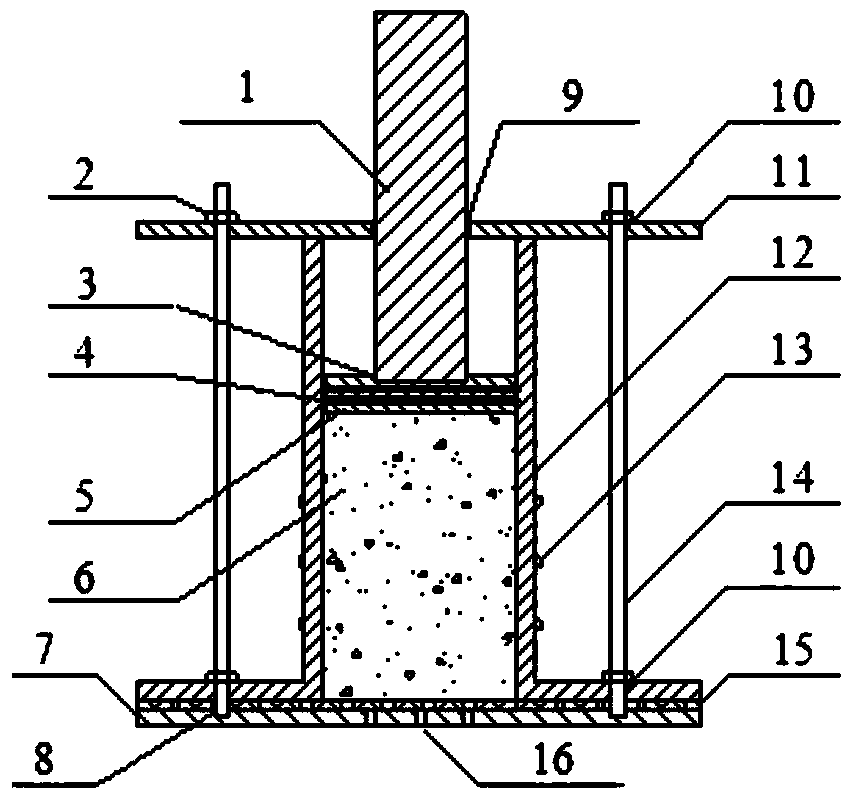

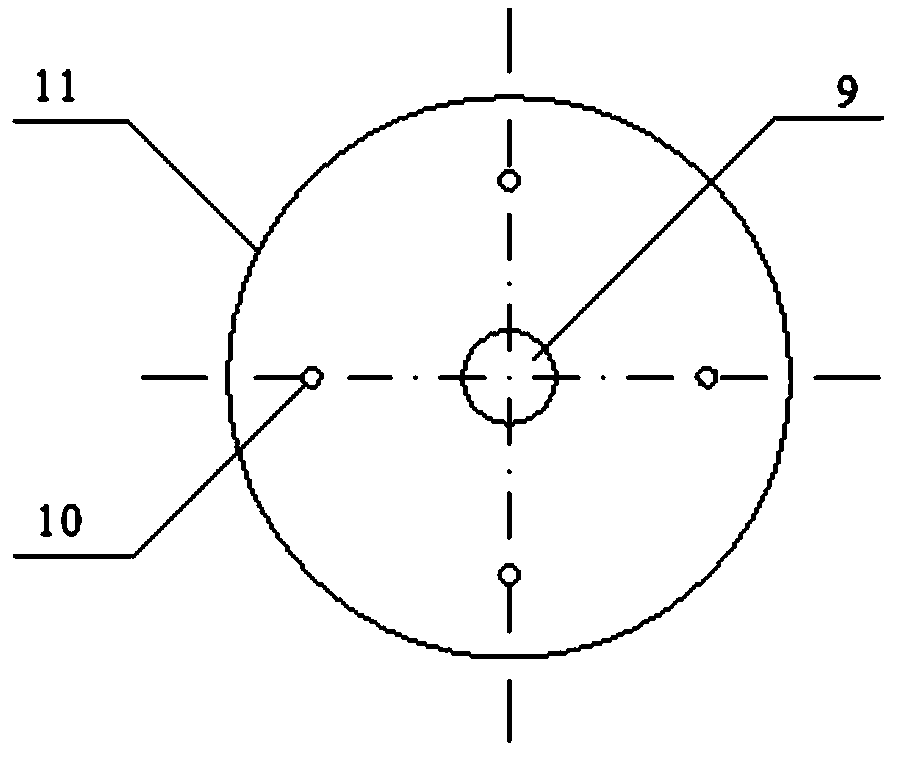

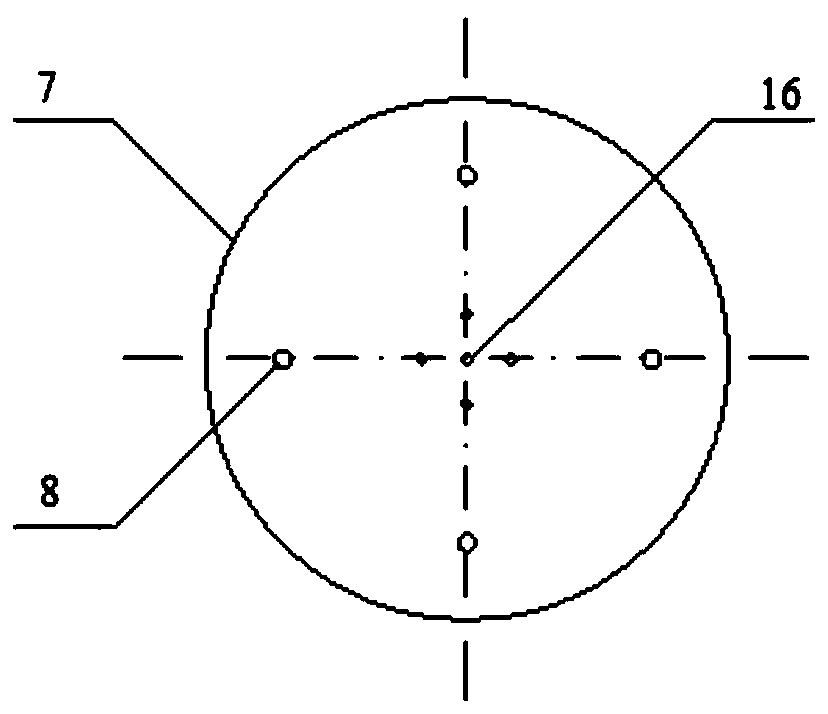

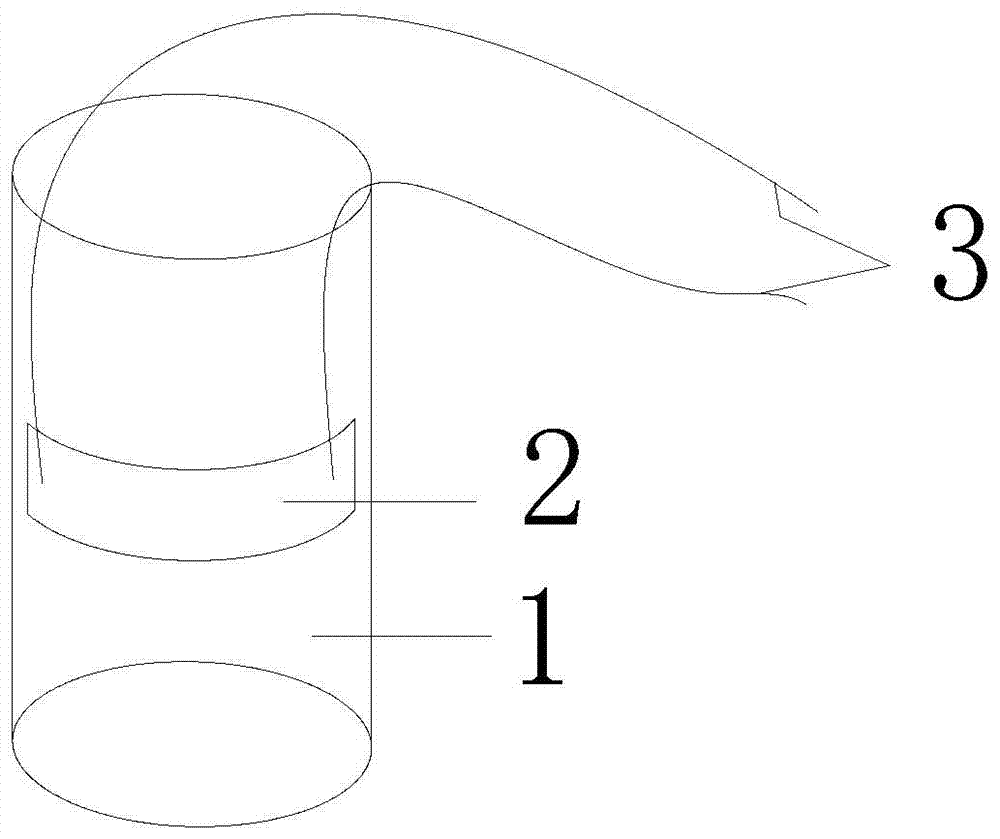

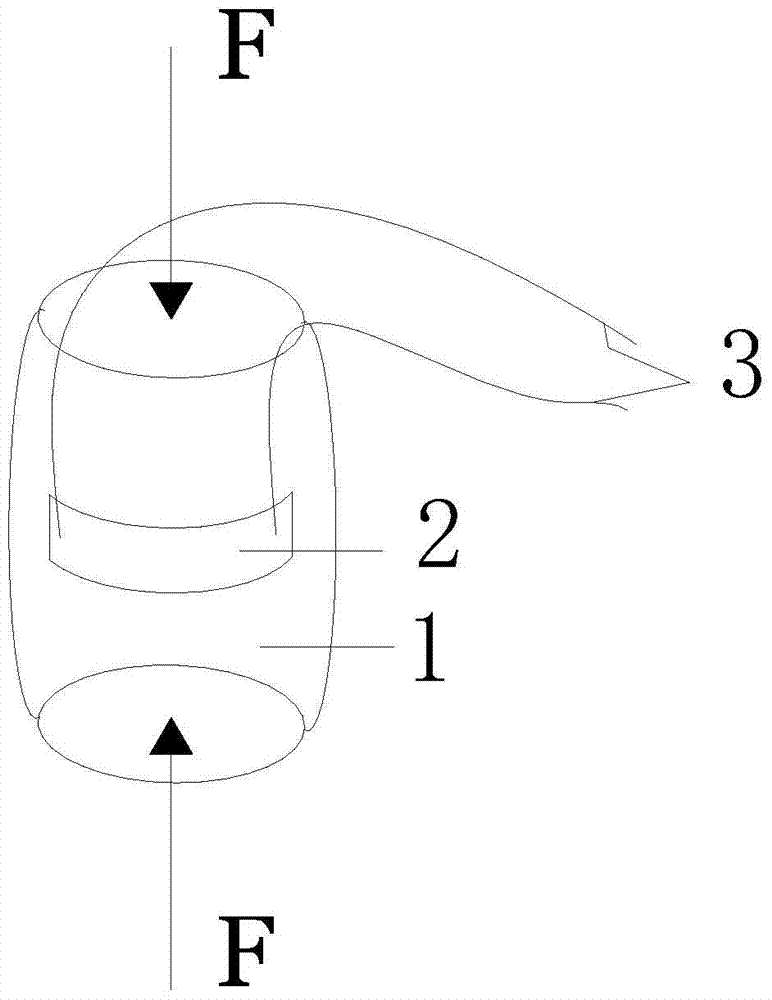

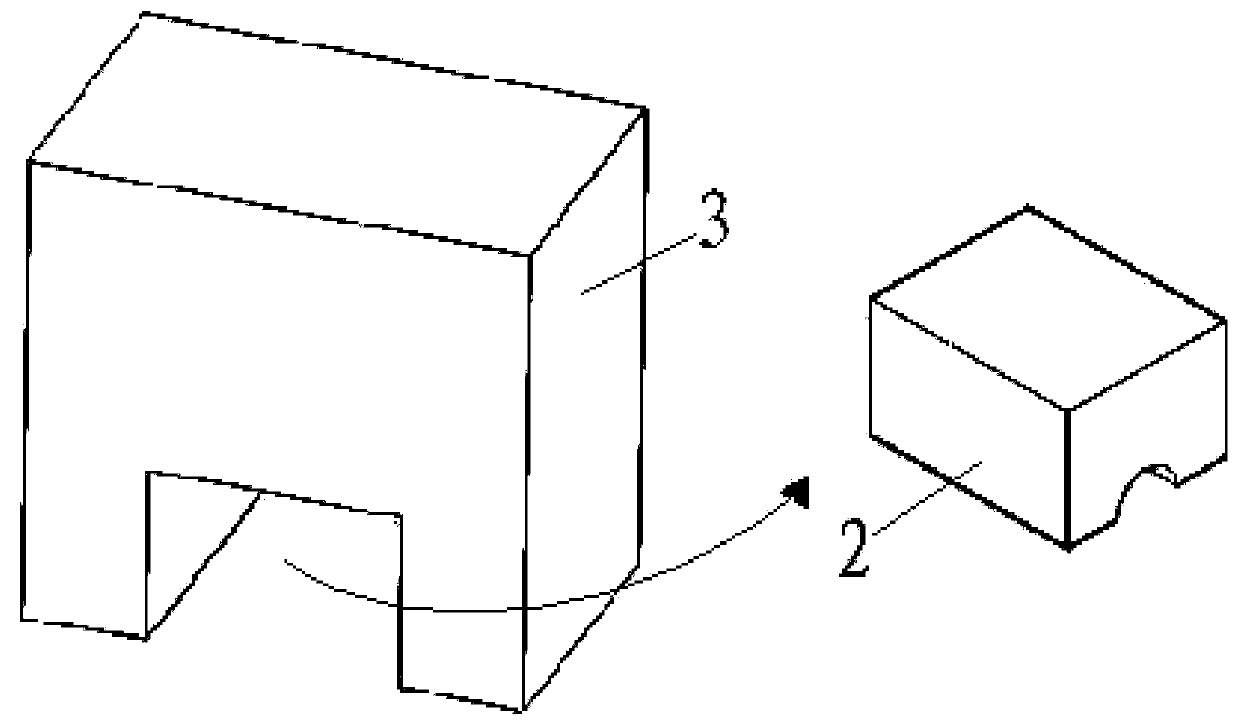

Mine filling material compression characteristic experiment device and experiment method thereof

ActiveCN107389449ASimple structureClosely connectedMaterial strength using tensile/compressive forcesFilling materialsEngineering

The invention discloses a mine filling material compression characteristic experiment device and an experiment method thereof. The experiment device is arranged on a pressure machine, and comprises a cavity for holding a filling material, wherein a bleeding structure is arranged at the bottom end of the cavity; the other end of the cavity is sealed through a slidable piston in the cavity; the bottom end of the cavity is arranged on a lower pressure-bearing plate of the pressure machine; a pressure-bearing column connected with the piston contacts an upper pressure-bearing plate of the pressure machine; an outer wall of the cavity is provided with a plurality of hoop strain foils at different axial positions in a pasting way; the hoop strain foils are connected with a statical strain indicator; a displacement sensor is also arranged between the upper pressure-bearing plate and the lower pressure-bearing plate of the pressure machine; the statical strain indicator and the displacement sensor are in signal connection with a computer connected with a pressure machine measuring system. The mine filling material compression characteristic experiment device provided by the invention can be used for monitoring compression amounts of the filling materials under different stresses and a strain level of an outer wall of a steel cylinder through the pressure machine measuring system, and is simple in structure, convenient to operate, and applicable to compression characteristic tests of dry filling bodies, water sand filling bodies, cemented filling bodies and other filling bodies.

Owner:CENT SOUTH UNIV

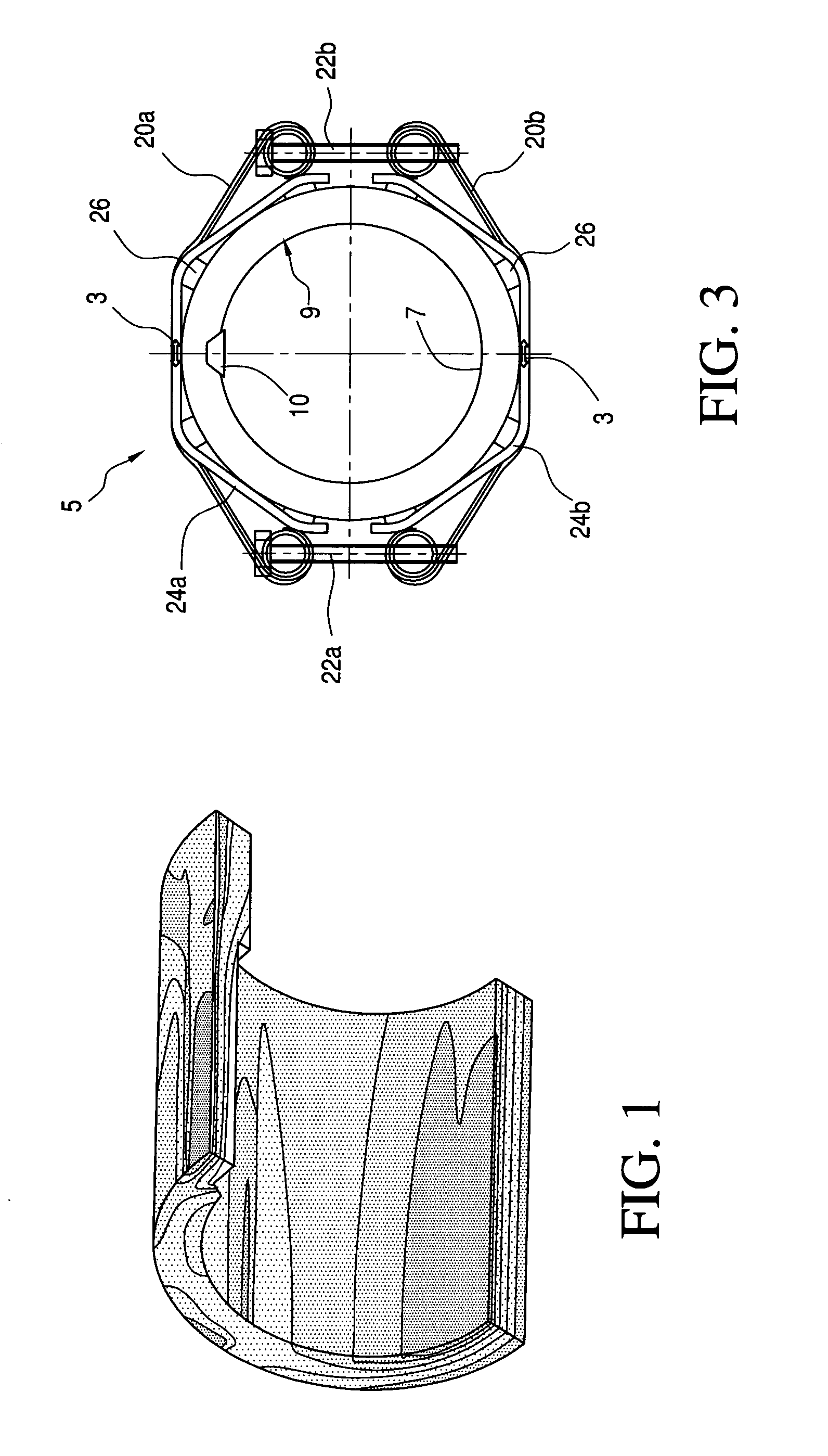

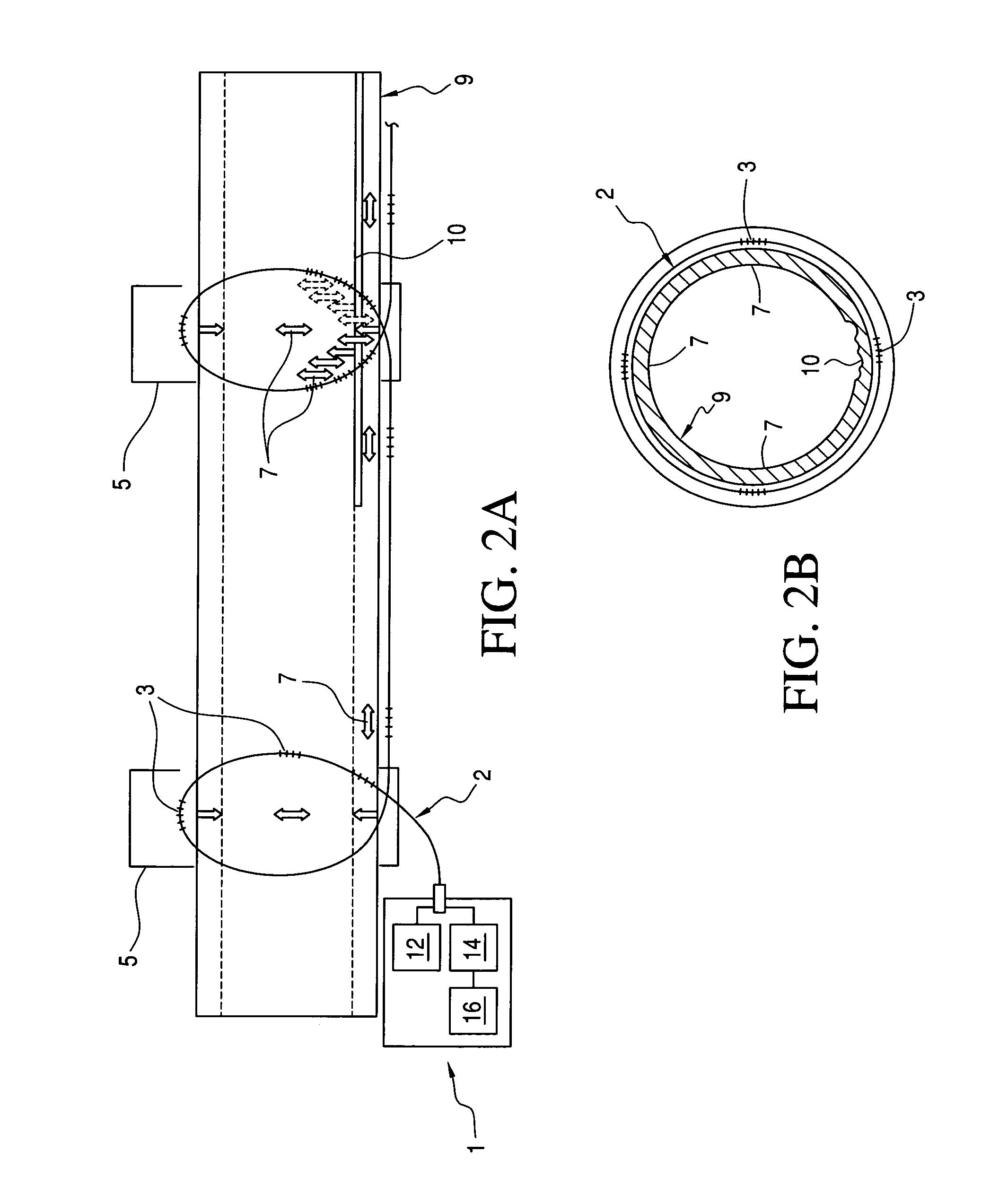

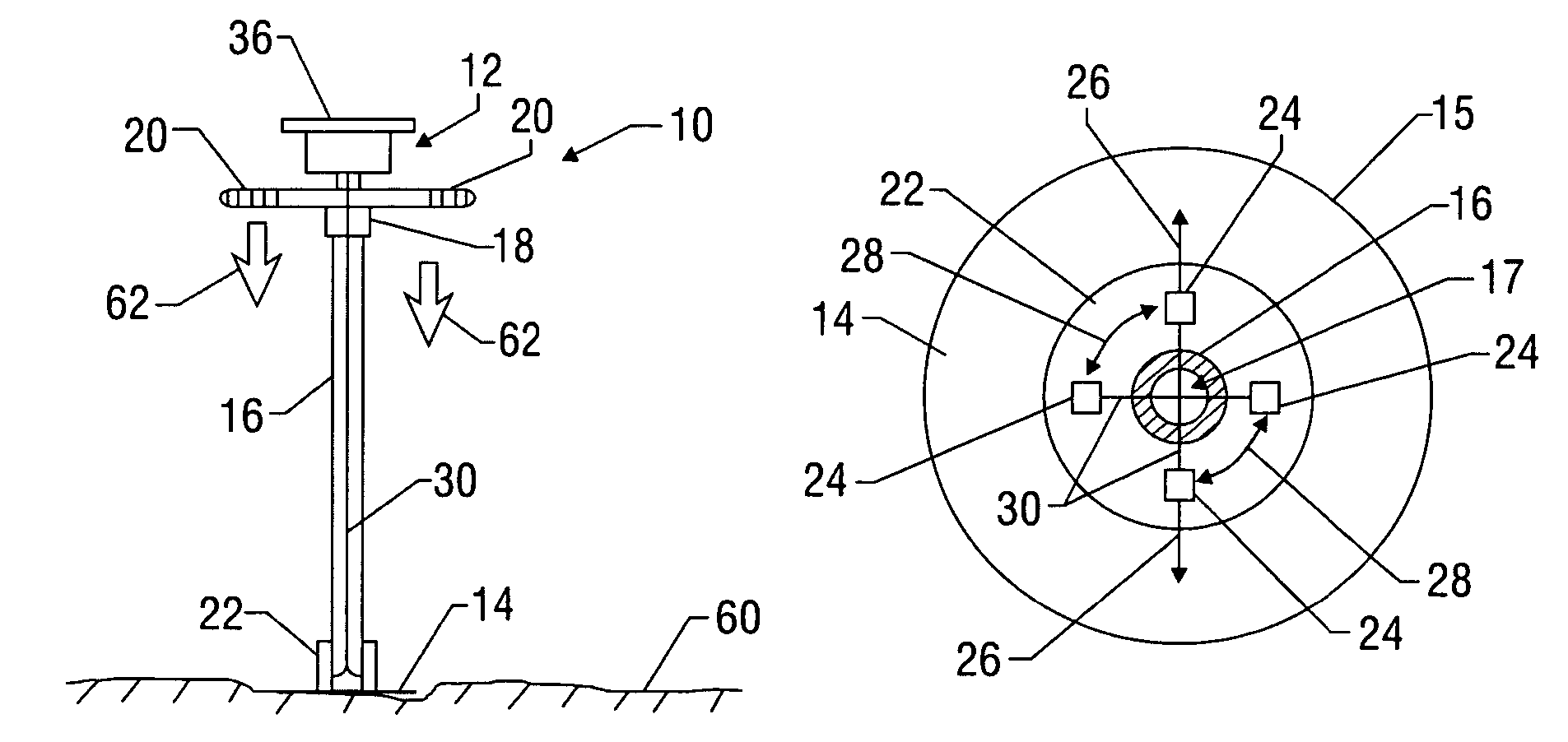

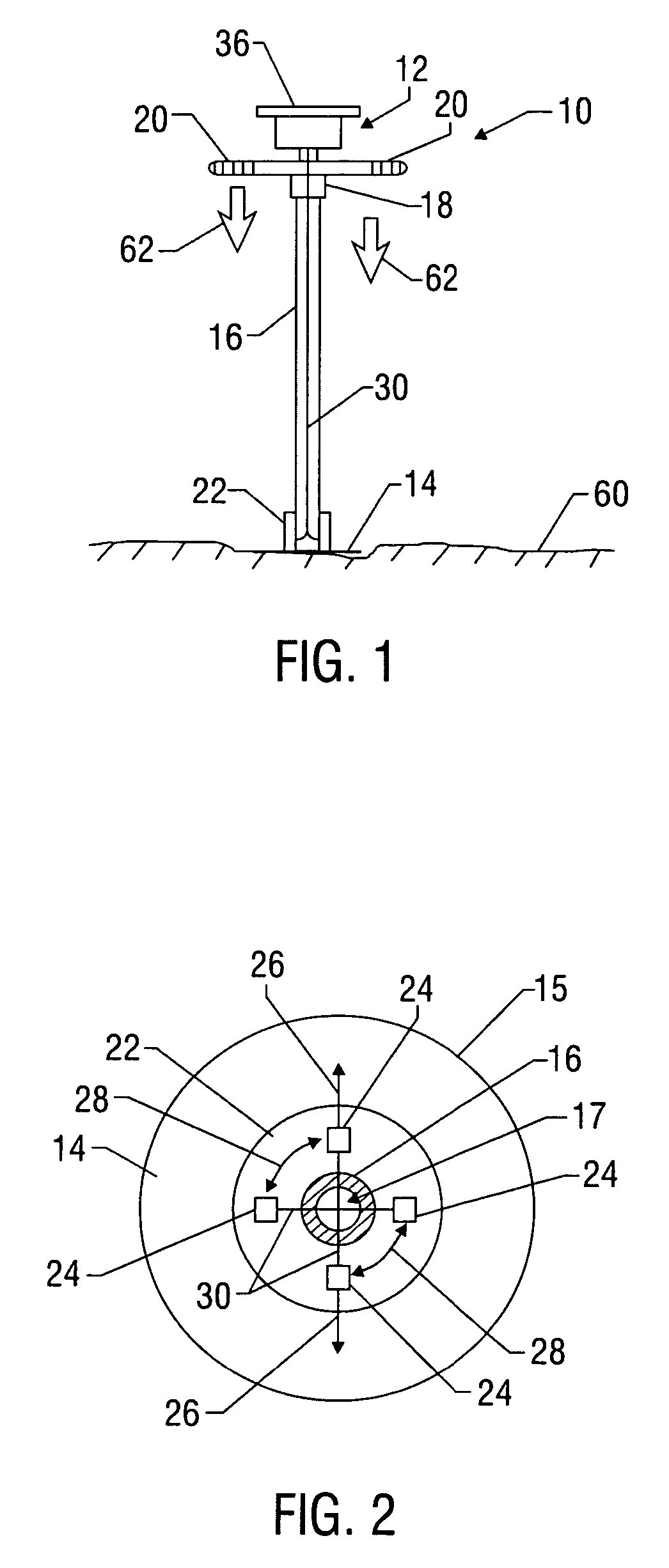

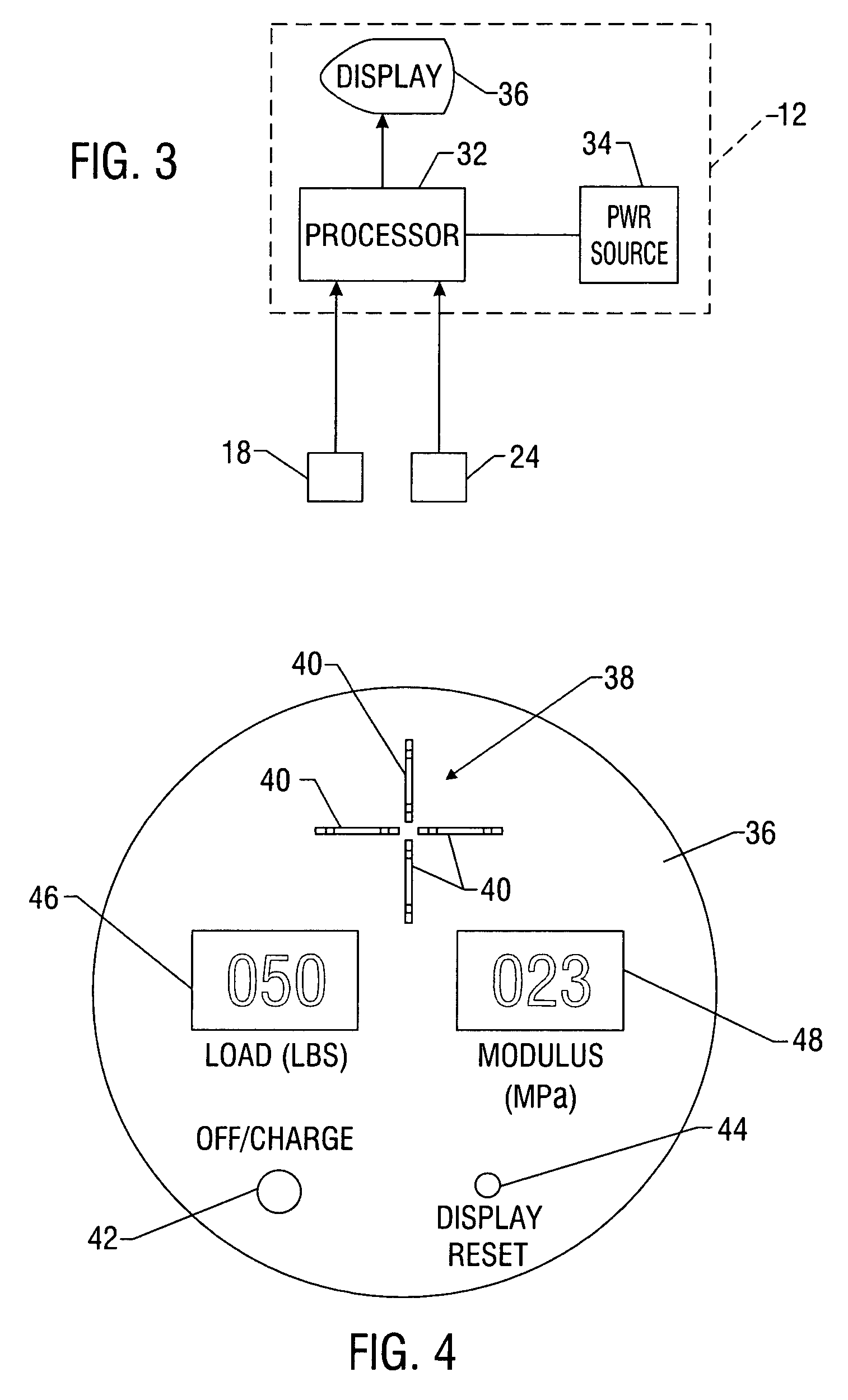

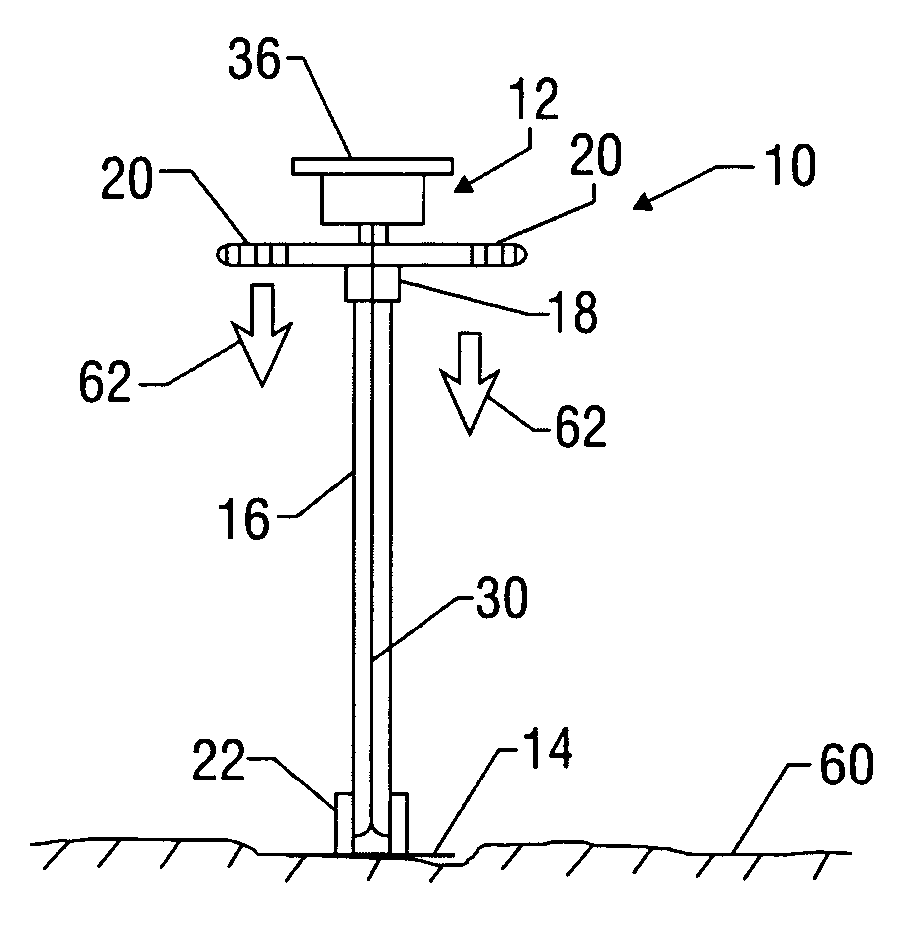

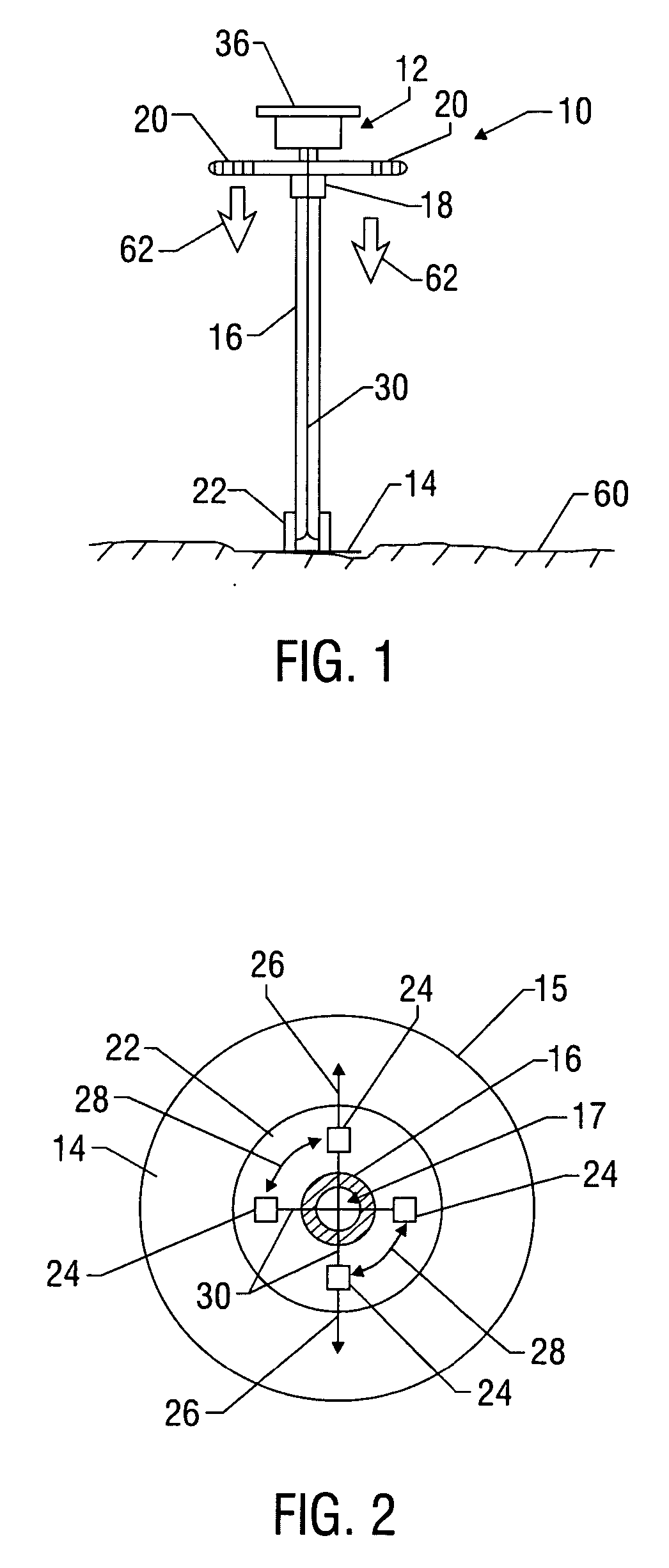

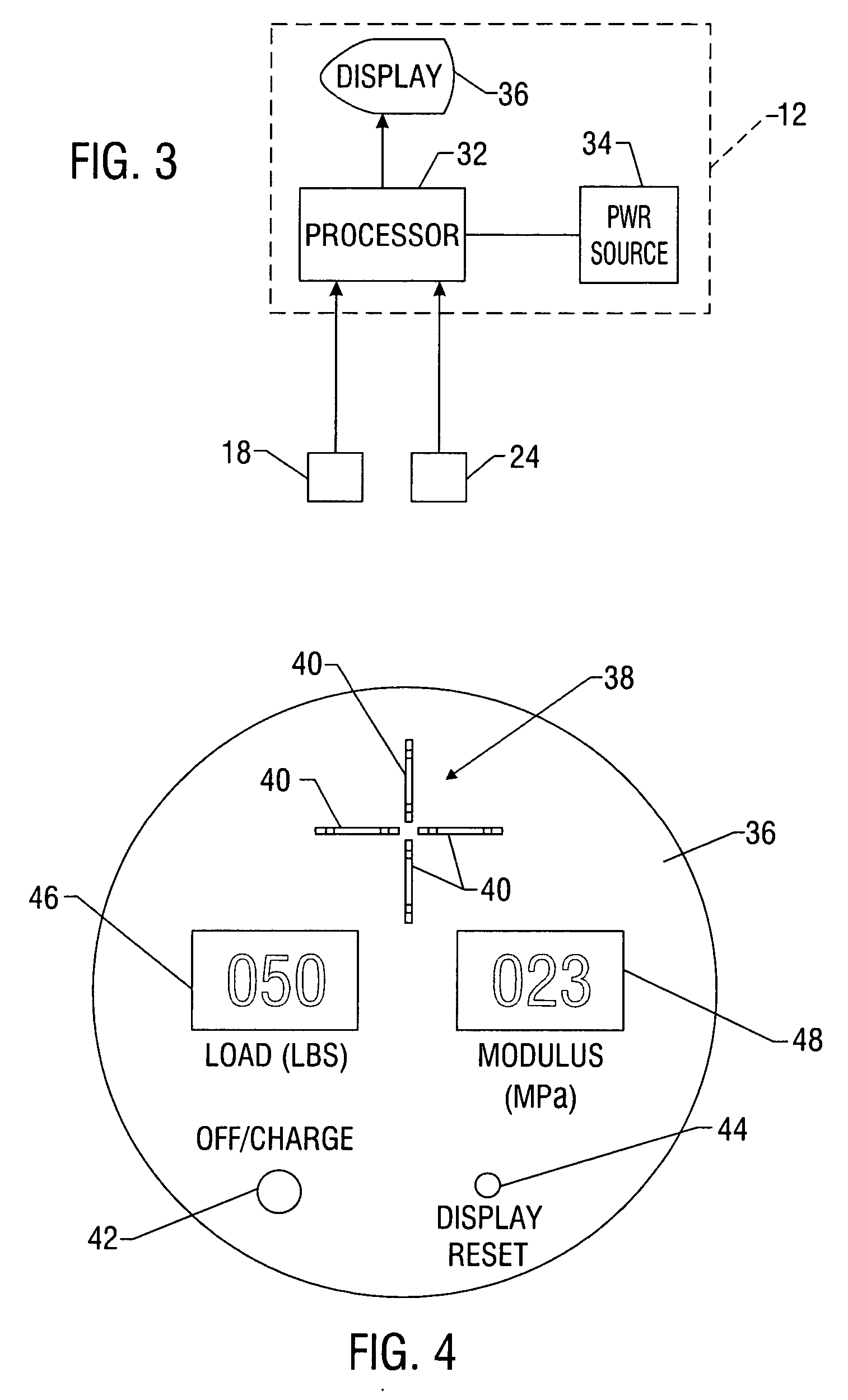

System and method for testing the compaction of soil

InactiveUS7299686B2The process is simple and effectiveMinimize damageEarth material testingAcceleration measurementEngineeringSoil surface

A device for determining soil compaction includes a control member fitted with one or more sensors that measure the response of the control member during co-action between the control member and a soil surface. In one embodiment, this response can be flexure as characterized by a measurable parameter such as strain. A measurement module in communication with the sensor or sensors determines a soil modulus for the soil based on the strain measurement from the sensor or sensors. In one arrangement, the control member includes one set of sensors that measure radial strain and another set of sensors that measures hoop strain. The device can also include a load sensor for measuring the load applied to the control member. In one embodiment the measurement module includes a processor that determines soil modulus based the strain measurements and the measured load.

Owner:TEXAS A&M UNIVERSITY

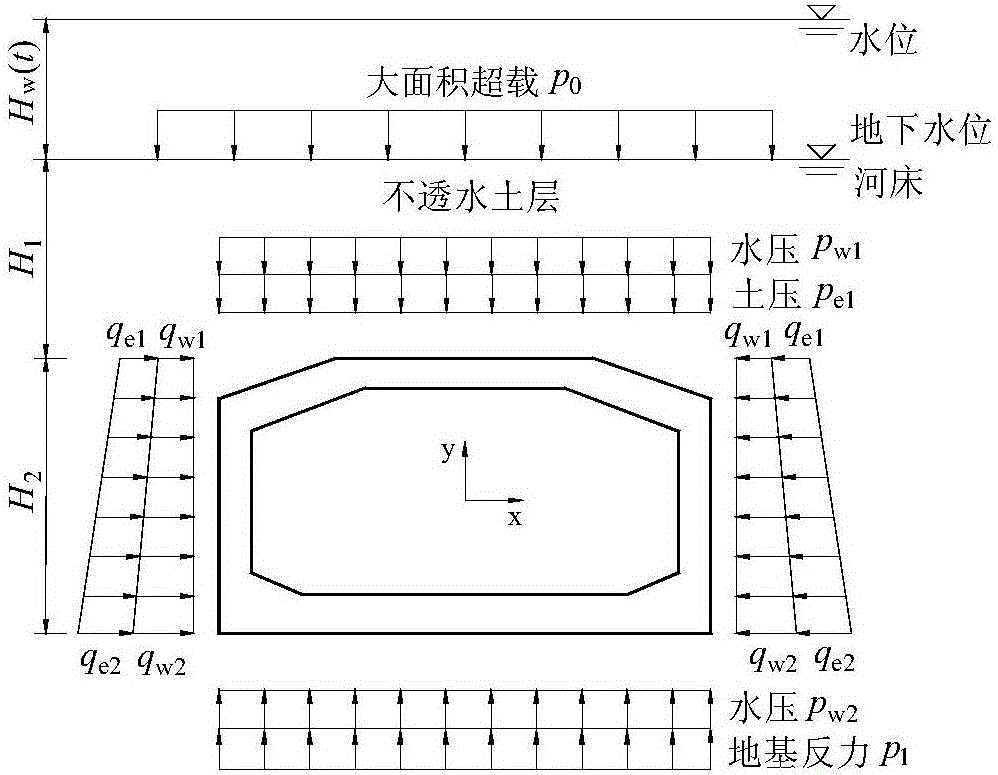

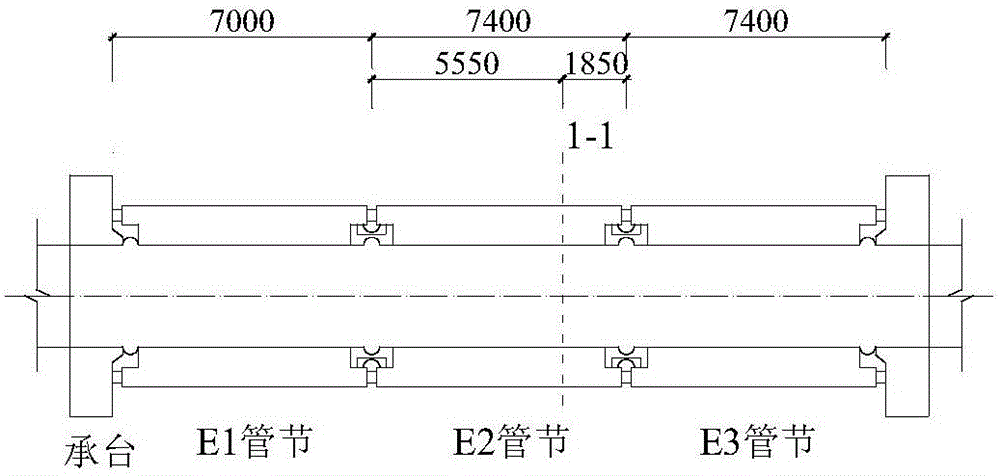

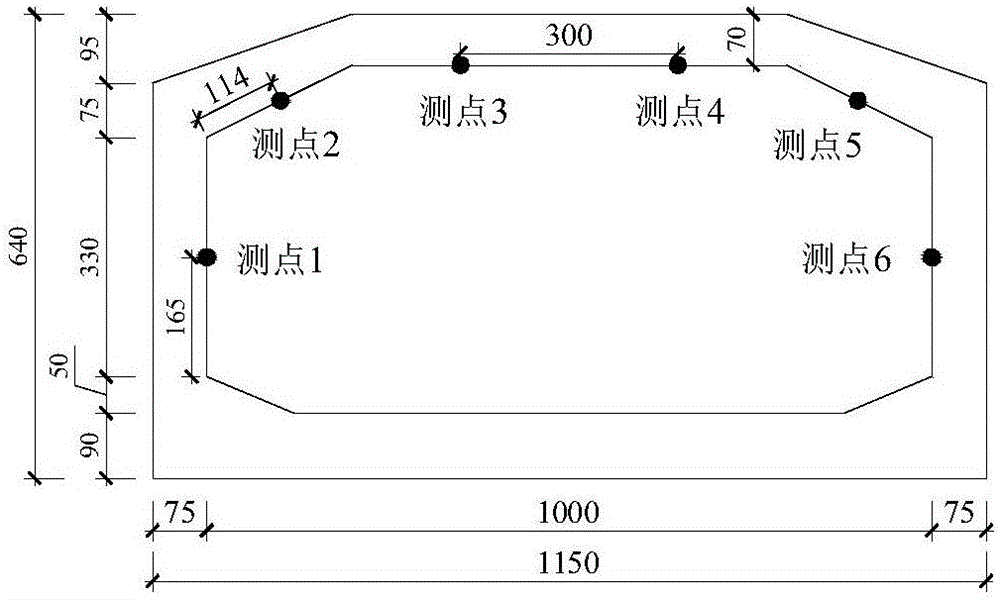

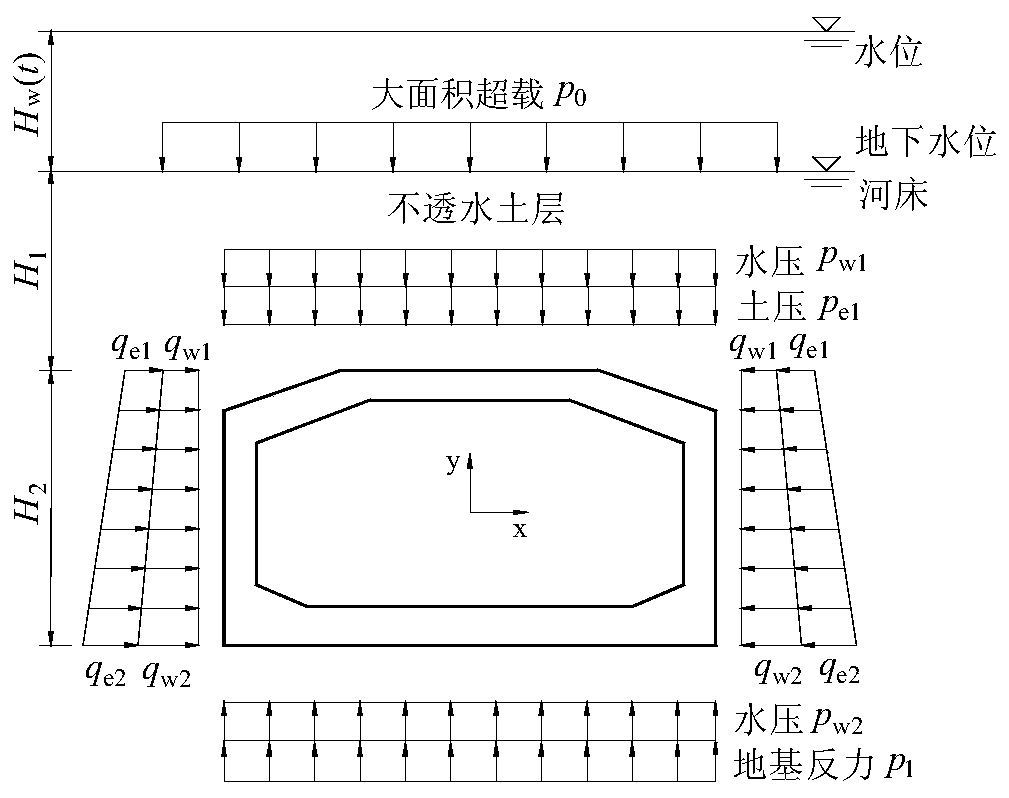

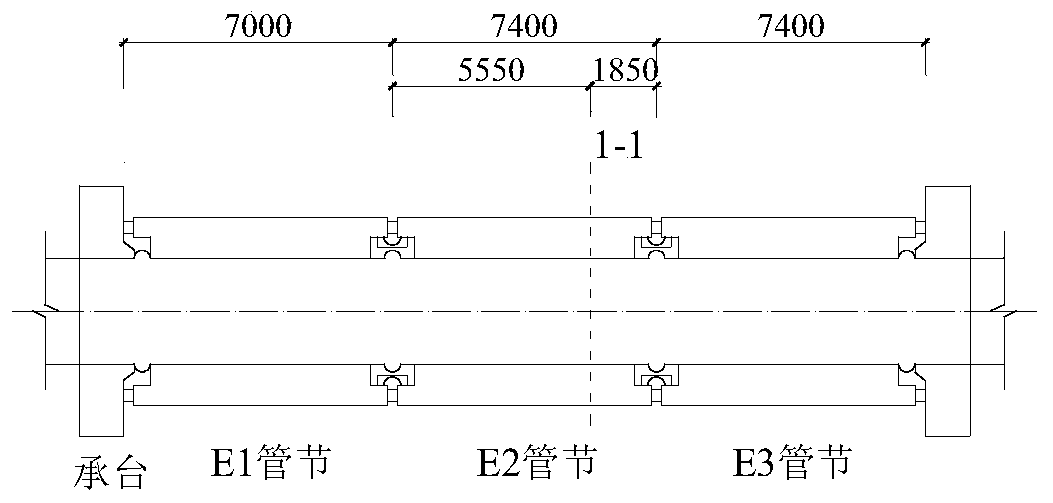

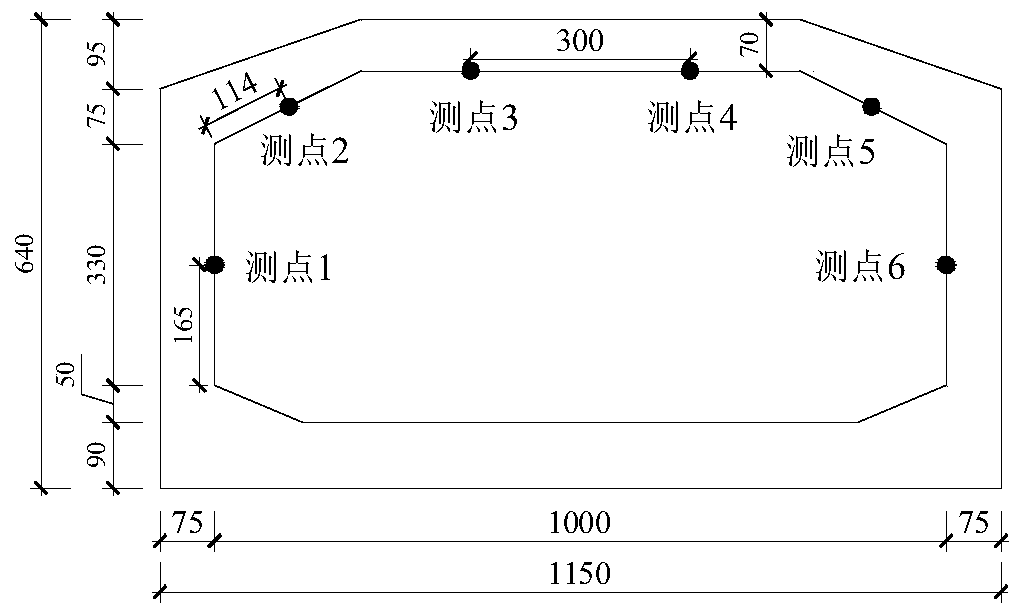

Calculation method of pipe joint hoop strain of tide load sinking pipe tunnel

ActiveCN106682267AStrong computing powerIncrease computing speedDesign optimisation/simulationSpecial data processing applicationsCross modelWater table

The invention provides a calculation method of a pipe joint hoop strain of a tide load sinking pipe tunnel. The method includes steps of, assuming a back silt layer on the pipe joint as an impervious bed, and regarding the change of the tide level as a large area load pO added on the impervious bed, wherein the location of an underground level is the top face of the impervious bed; not considering about influence of tide on the pipe joint structure, calculating water, soil pressure and subgrade reaction acted on the outer wall of the pipe joint; applying a winkler foundation module, regarding the loop strain calculation as the plane strain problem; analyzing the loop stress and deformation of the pipe joint structure by a load-structure method; through the calculation of cross model stress of the pipe joint, acquiring the relationship of the loop stress strain relationship of the pipe joint; finally, through calculation, acquiring the loop strain distribution of inner and outer walls of the pipe joint under one tide level and influence of the loop strain of every point of inner and outer walls of the pipe joint along with the change of the tide level. The calculation result can be used for predicting the loop strain of the pipe joint of the sinking pipe tunnel in operation stage, judging the part where may generate crack, and carrying out key monitoring and prevention.

Owner:ZHEJIANG UNIV CITY COLLEGE

Briaud compaction device

InactiveUS20050199045A1The process is simple and effectiveMinimize damageEarth material testingAcceleration measurementEngineeringSoil surface

A device for determining soil compaction includes a control member fitted with one or more sensors that measure the response of the control member during co-action between the control member and a soil surface. In one embodiment, this response can be flexure as characterized by a measurable parameter such as strain. A measurement module in communication with the sensor or sensors determines a soil modulus for the soil based on the strain measurement from the sensor or sensors. In one arrangement, the control member includes one set of sensors that measure radial strain and another set of sensors that measures hoop strain. The device can also include a load sensor for measuring the load applied to the control member. In one embodiment the measurement module includes a processor that determines soil modulus based the strain measurements and the measured load.

Owner:TEXAS A&M UNIVERSITY

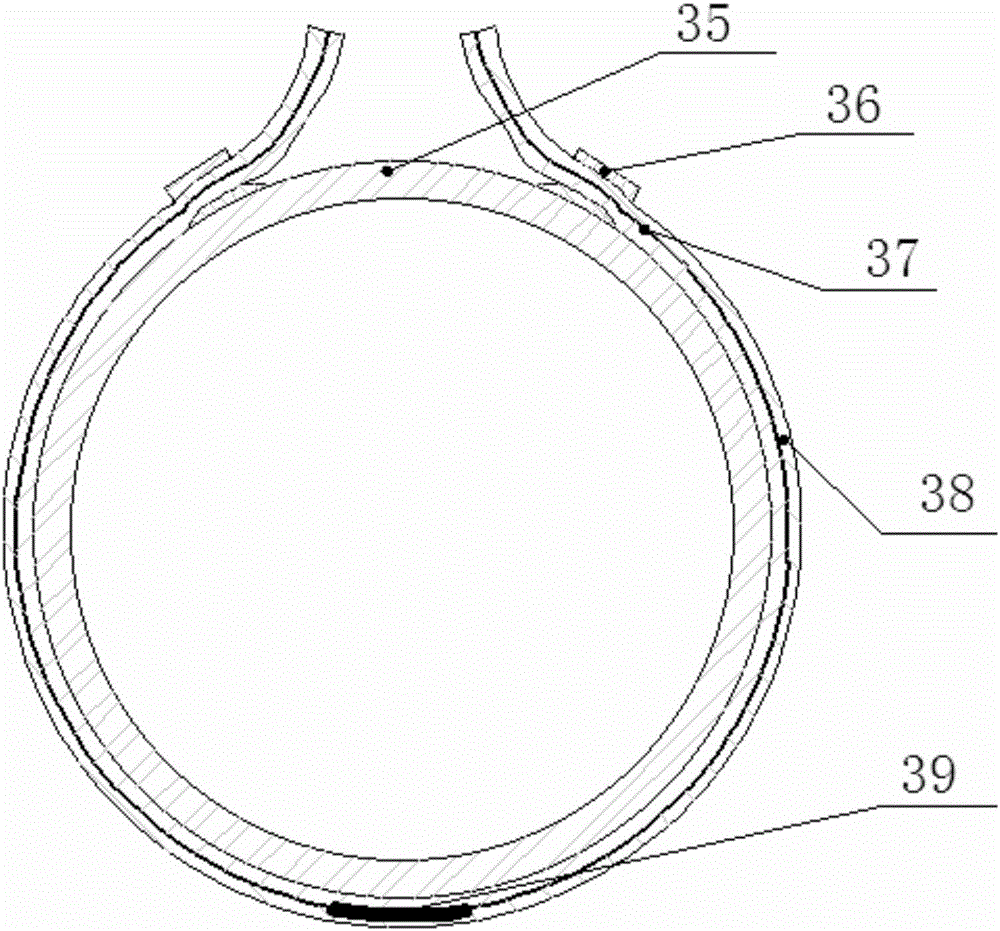

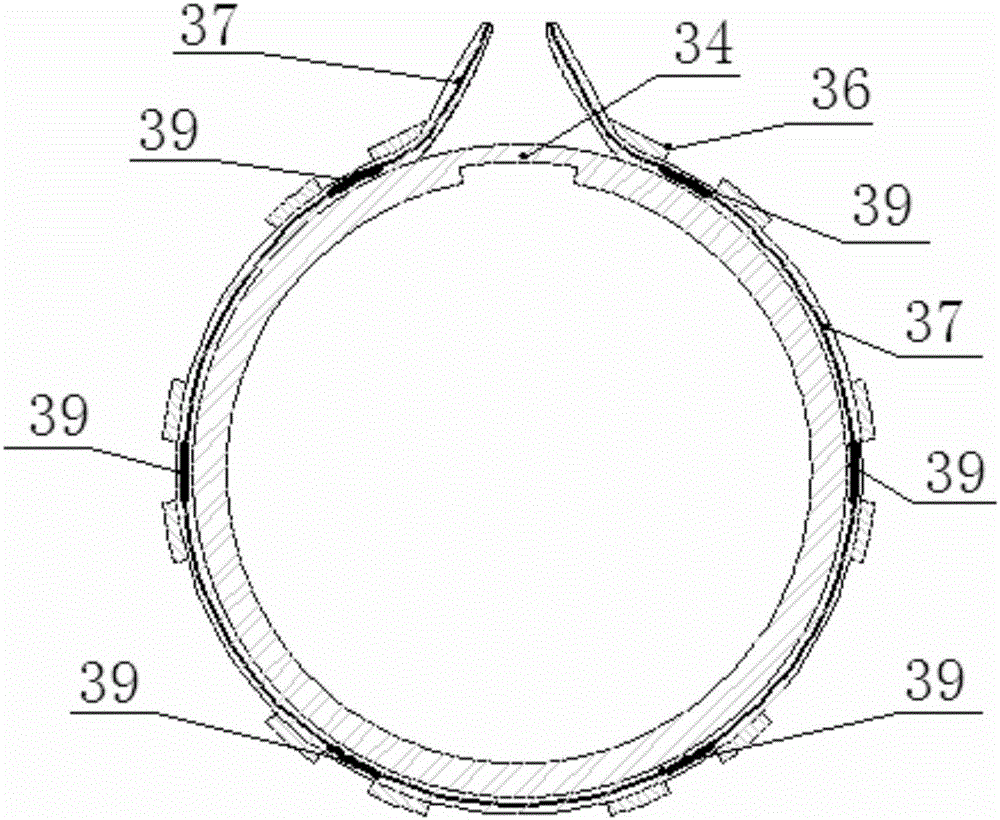

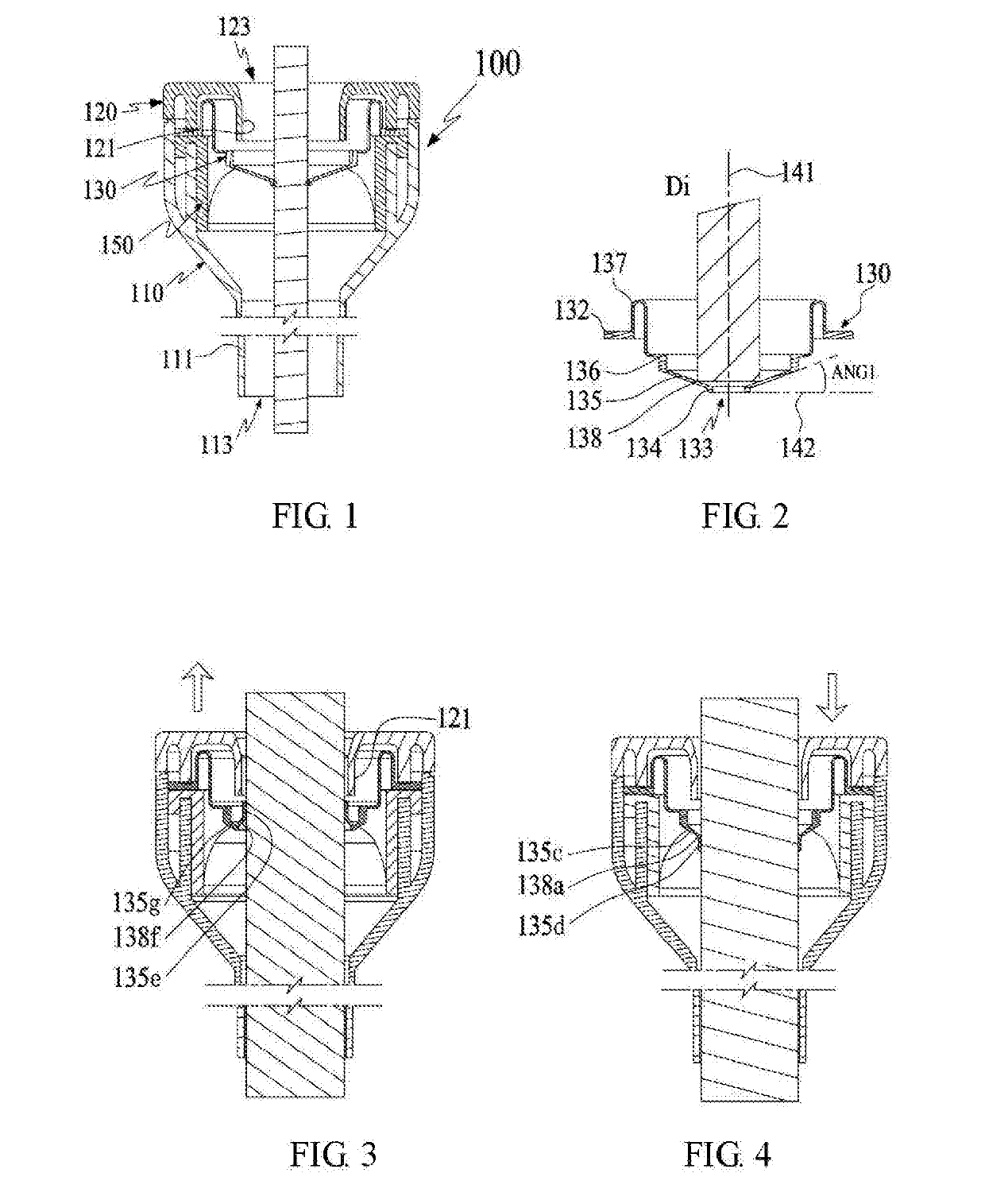

Pleated trocar seal membrane

InactiveUS20190142460A1Strengthen axial tensile stiffnessEnhance axial tensile stiffnessCannulasSurgical needlesTransverse planeEngineering

The invention discloses an improved pleated trocar seal membrane. Said seal membrane comprises a proximal opening, a distal aperture, and a sealing wall which extends from the distal aperture to the proximal opening, said distal aperture formed by a sealing lip for accommodating the inserted instrument and forming a gas-tight seal. Said sealing lip comprises a longitudinal axis and a transverse plane substantially perpendicular to said axis. Said sealing wall comprises a plurality of pleats extending laterally from the sealing lip. Each said pleat comprises a pleat peak, a pleat valley and a pleat wall extending there between. And the lip-adjacent area, the depth of the pleat wall gradually increases along the longitudinal axis; while outside the lip-adjacent area, the depth of which gradually decreases along the longitudinal axis. Said pleats enlarge hoop circumference, and reduce the cylinder hoop strain (stress) when a large diameter instrument is inserted, thereby reducing the hoop force and the frictional resistance.

Owner:5R MED TECH CHENGDU CO LTD

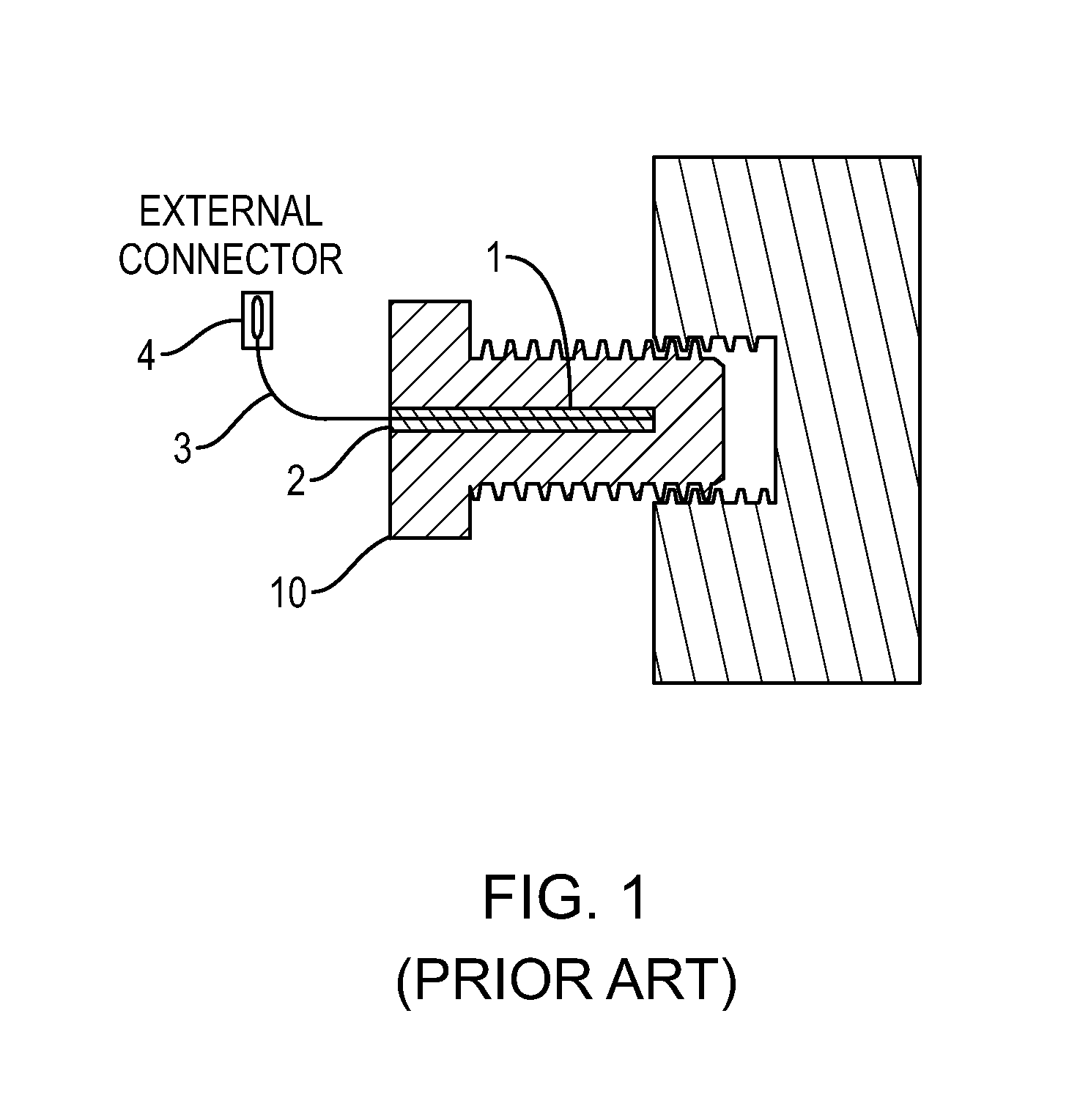

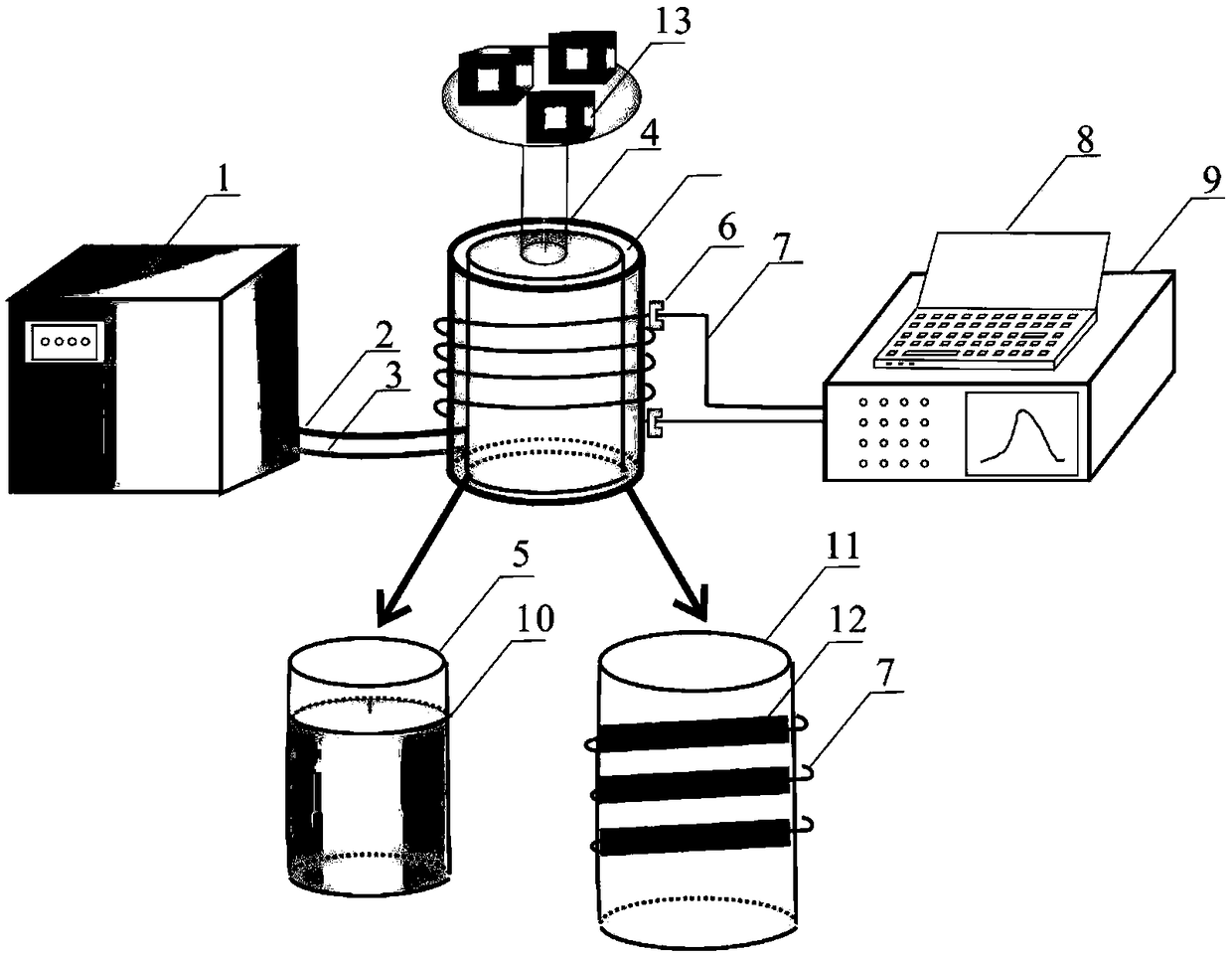

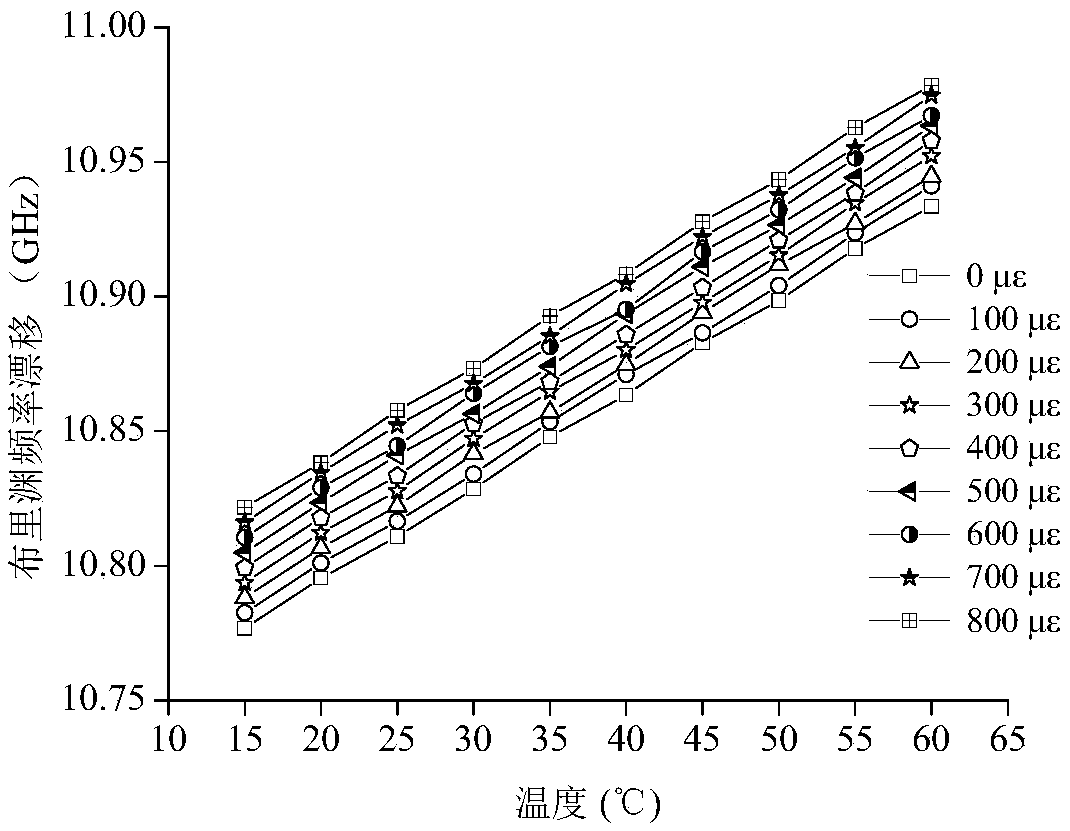

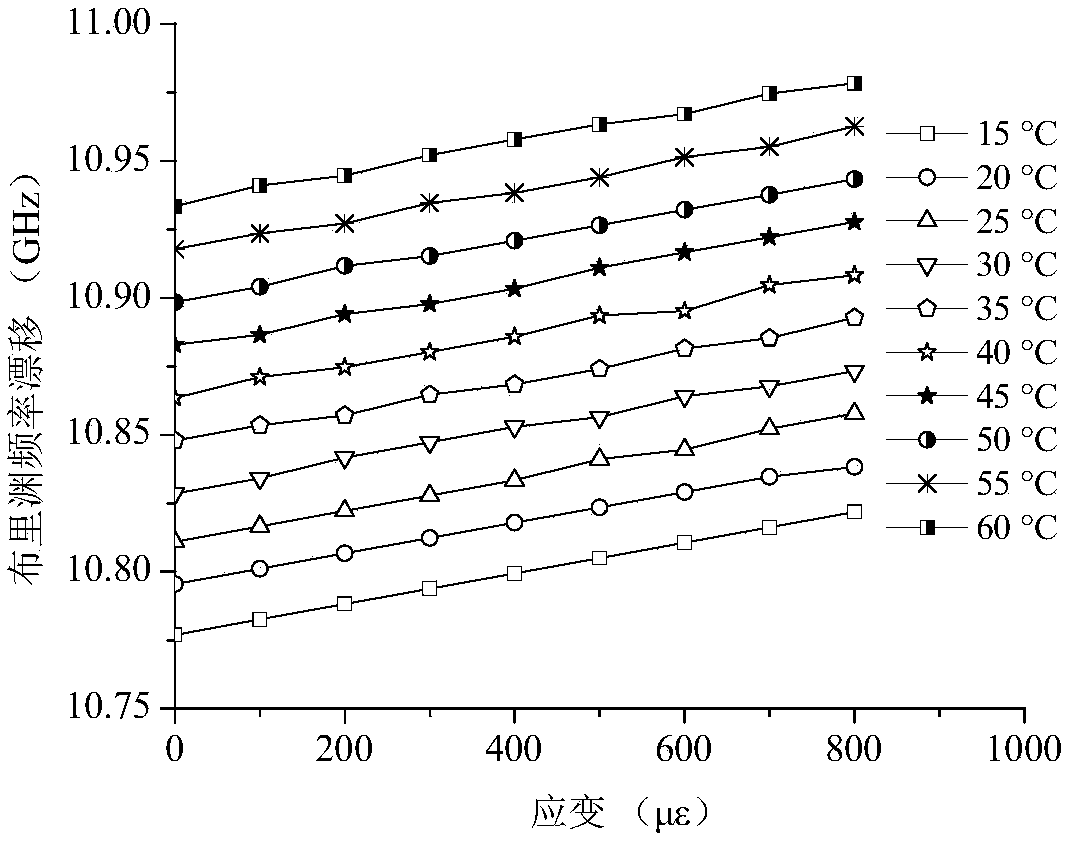

Synchronous calibration device and method for strain and temperature of distributed sensor fiber (cable)

ActiveCN109211325APromote water circulationHigh precisionMeasurement devicesTemperature controlFiber

The invention discloses a synchronous calibration device and method for strain and a temperature of a distributed sensor fiber (cable). The synchronous calibration method comprises the following stepsof uniformly winding fibers (cables) to be calibrated around an outer wall of a calibration barrel during calibrating a strain coefficient, gradually adding weights, calculating hoop strain of the calibration barrel under different loads according to elastic modulus of the calibration barrel and poisson ratio, reading spectrum information under each level of load by a fiber data demodulator, building a relation between the hoop strain and the spectrum information, and calibrating the strain coefficient; achieving control on a temperature of the calibration barrel by a temperature control boxduring calibrating a temperature coefficient, acquiring the spectrum information under different temperatures by the demodulator, and calibrating the temperature coefficient. By the synchronous calibration method, the strain coefficient and the temperature coefficient can be independently or synchronous calibrated, the strain generated by an external force effect and the influence of environmentaltemperature change on the spectrum information can be simultaneously determined, the cross effect between the strain and the influence is analyzed, and a calibration effect has high accuracy and is more confirm to an actual application condition.

Owner:NANJING UNIV

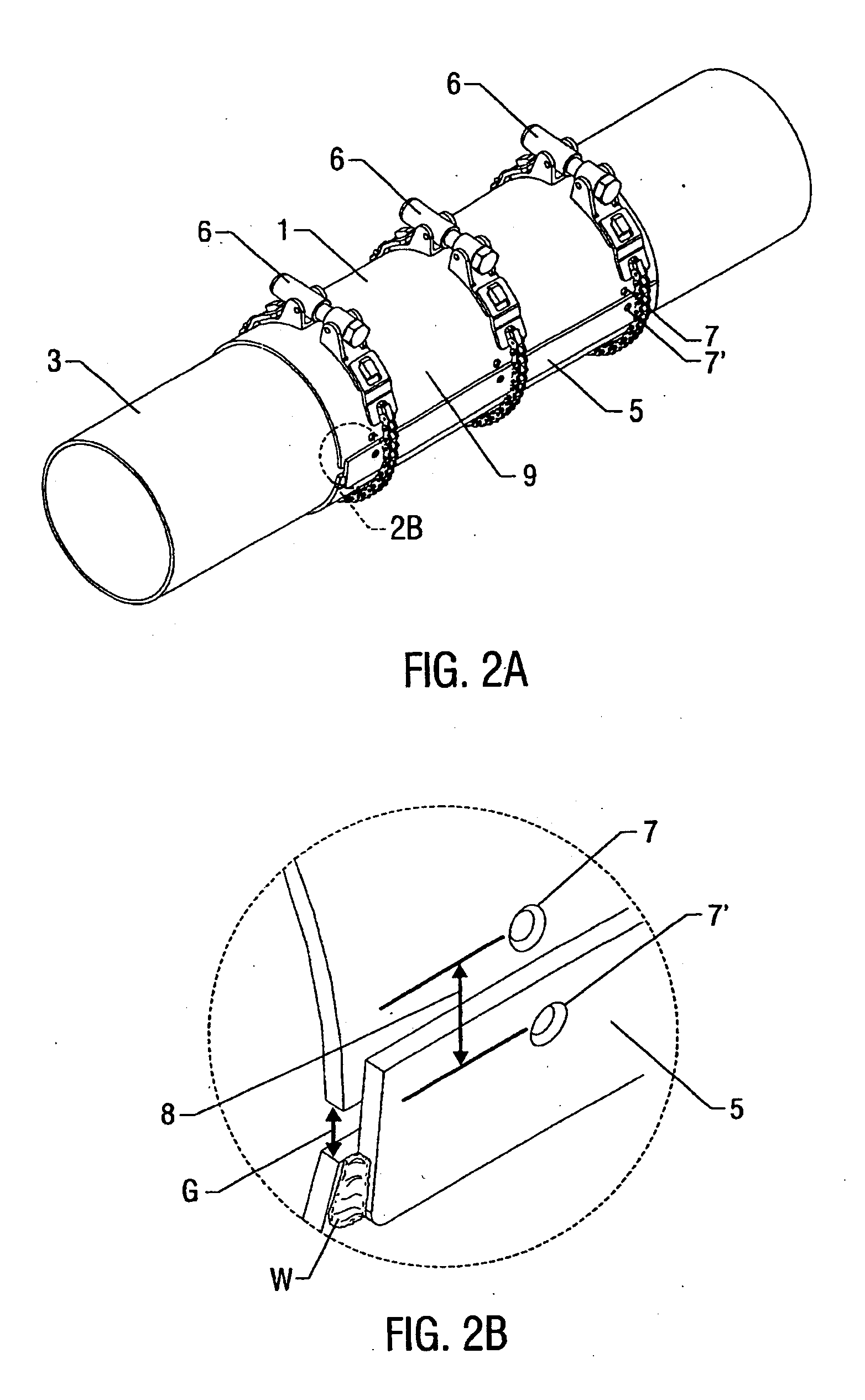

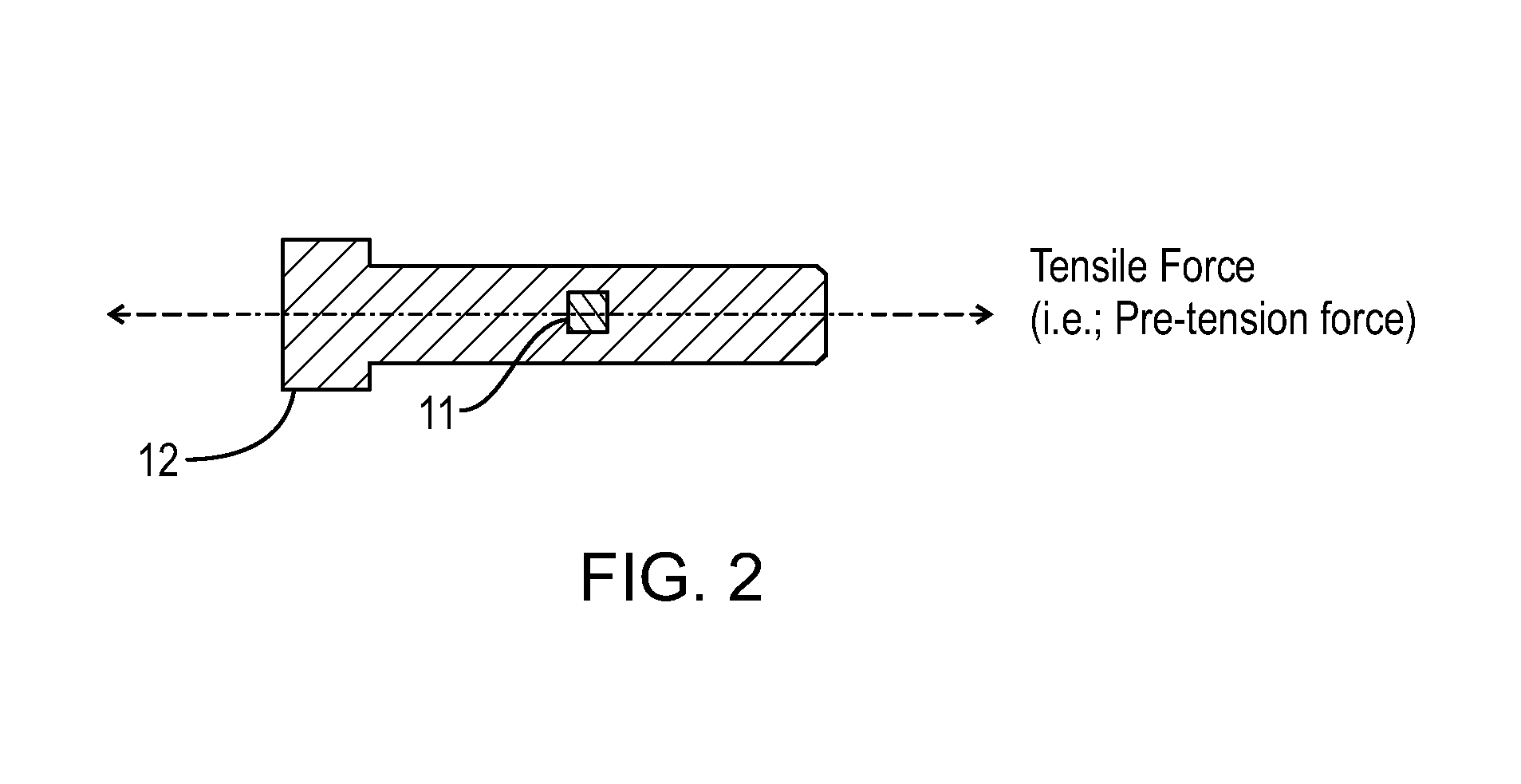

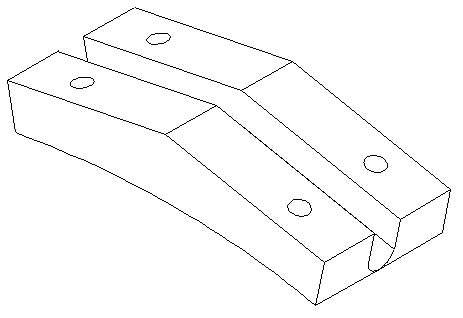

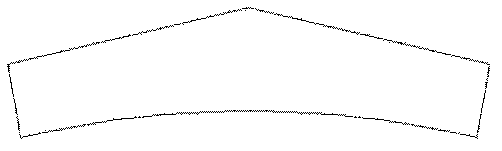

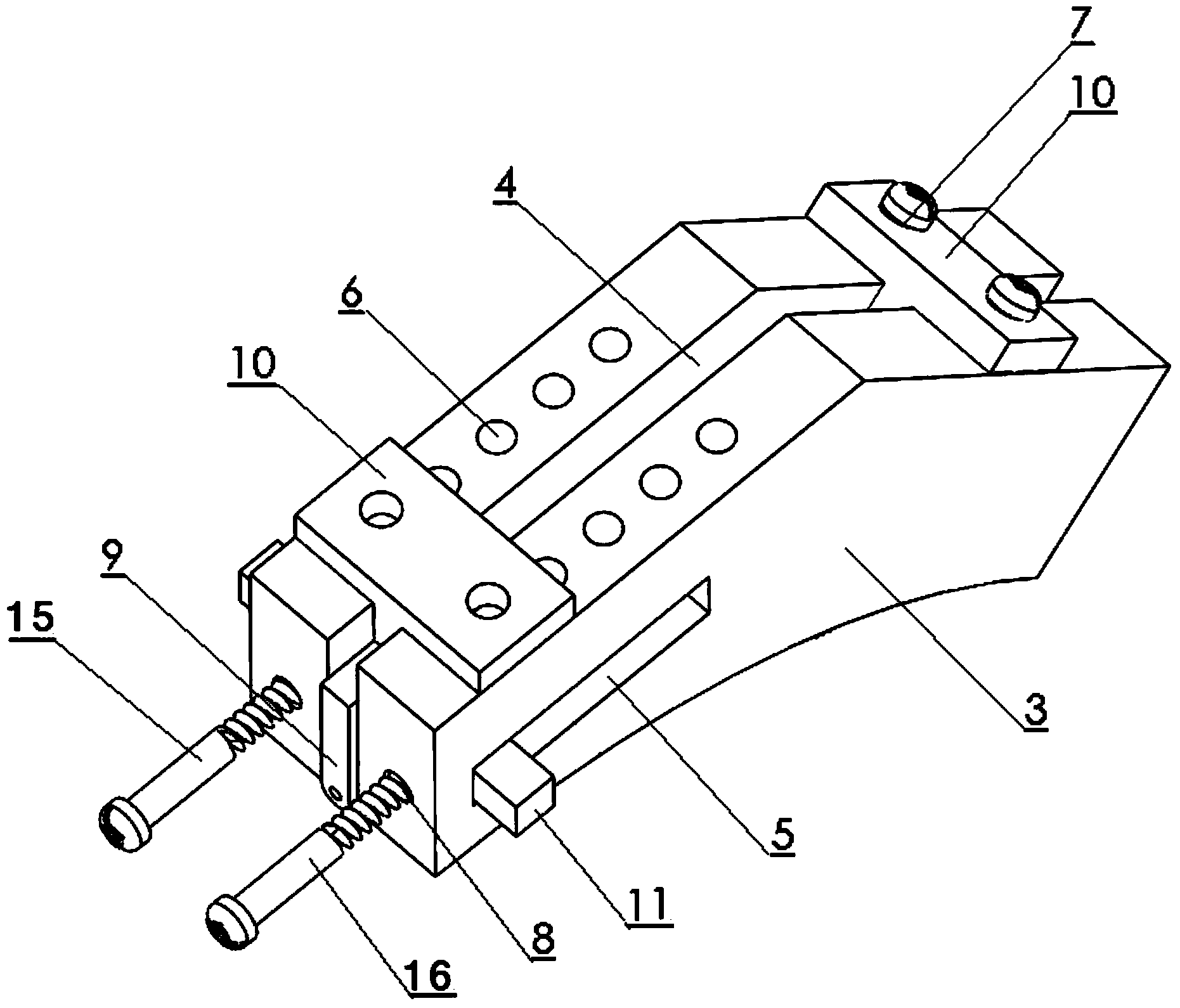

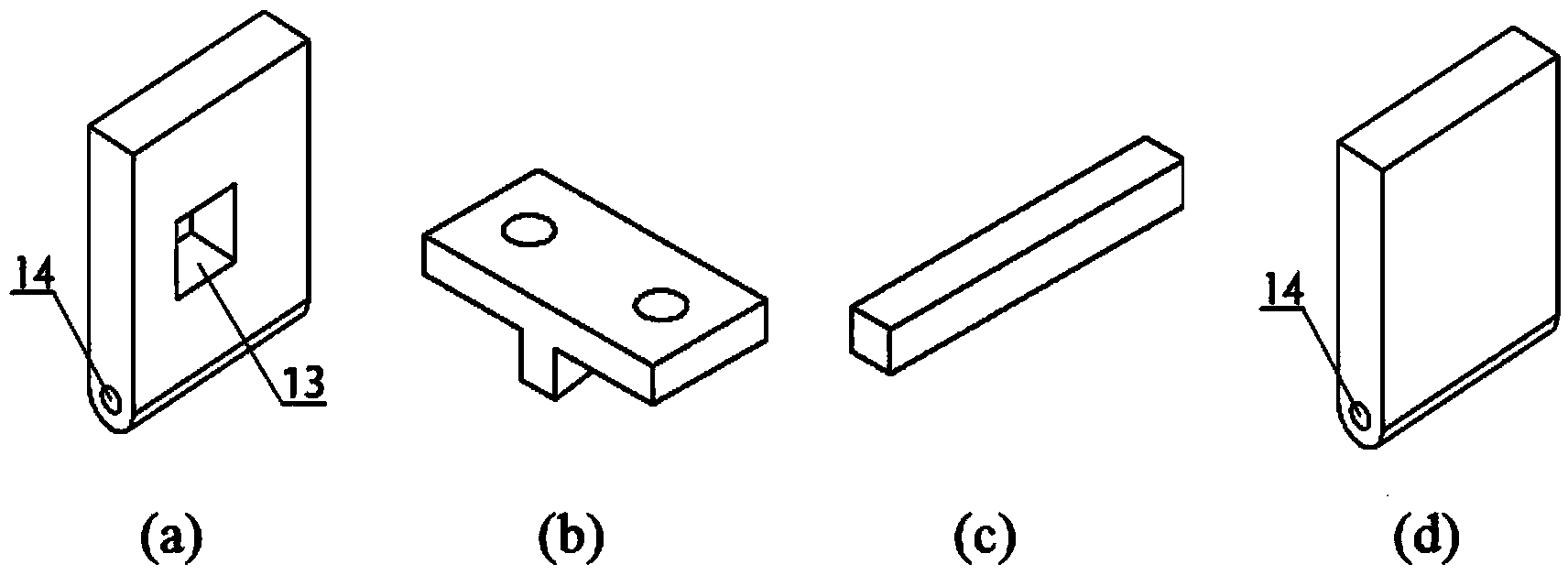

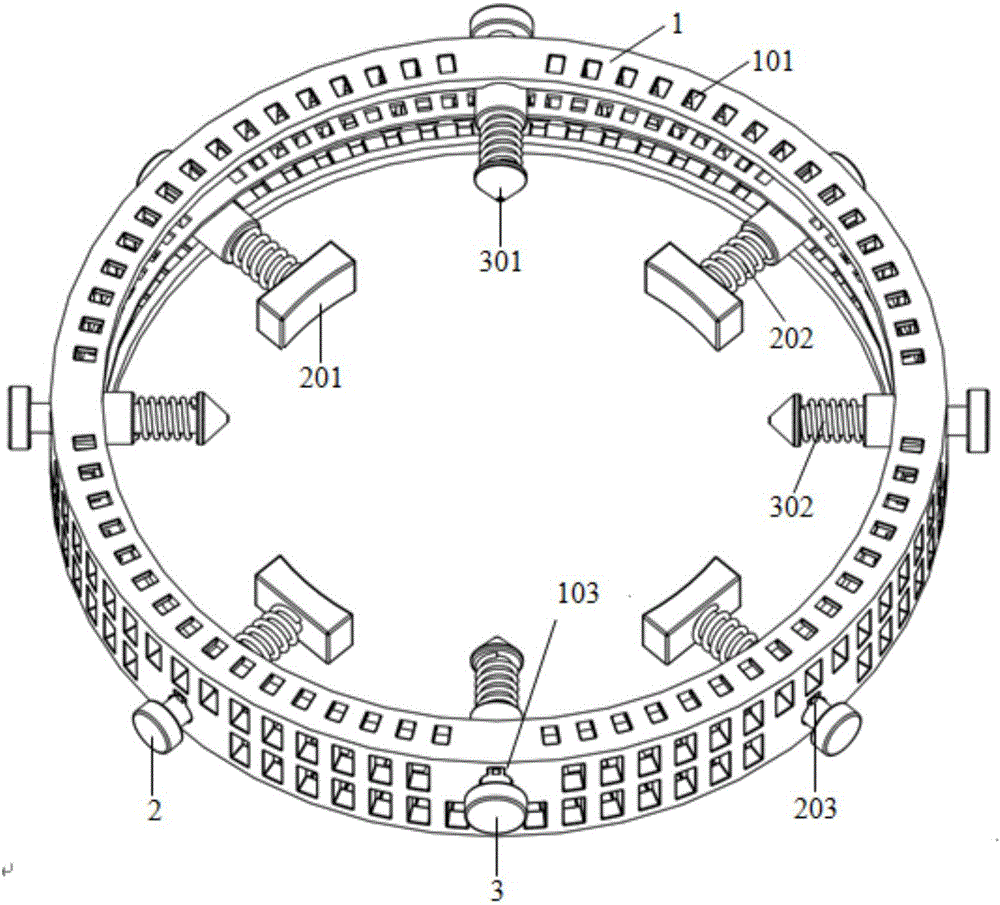

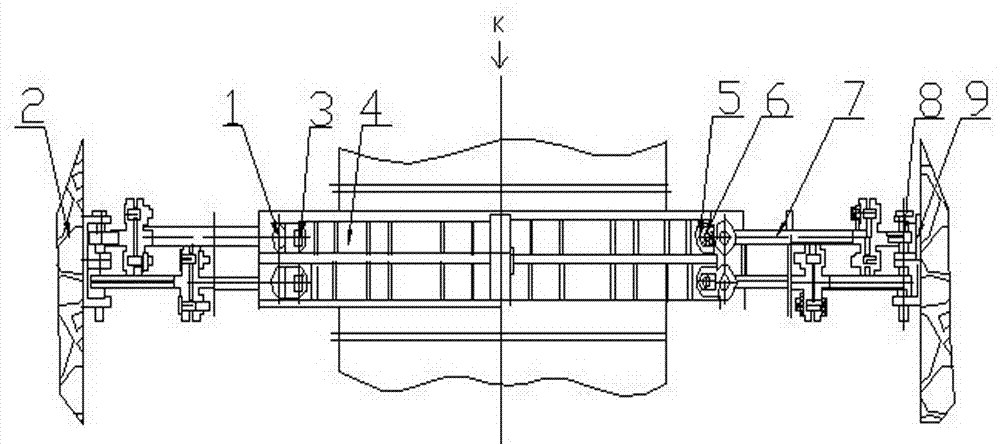

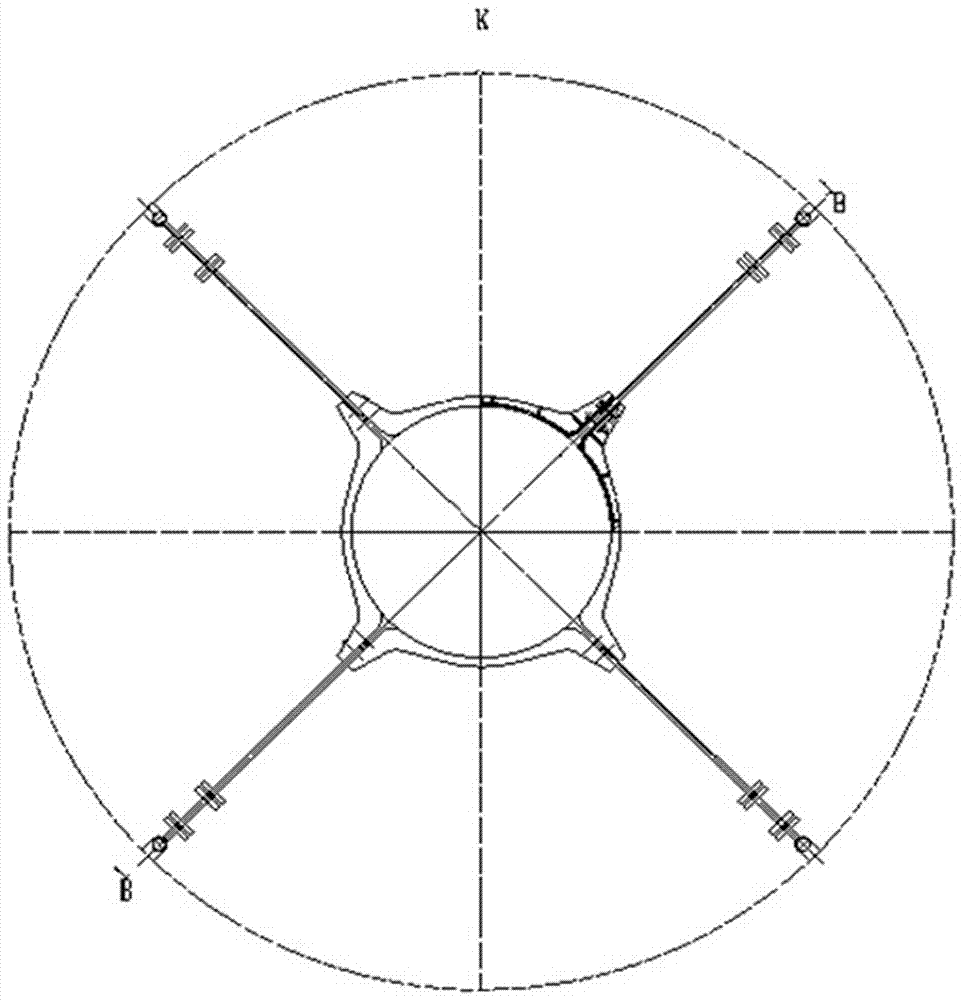

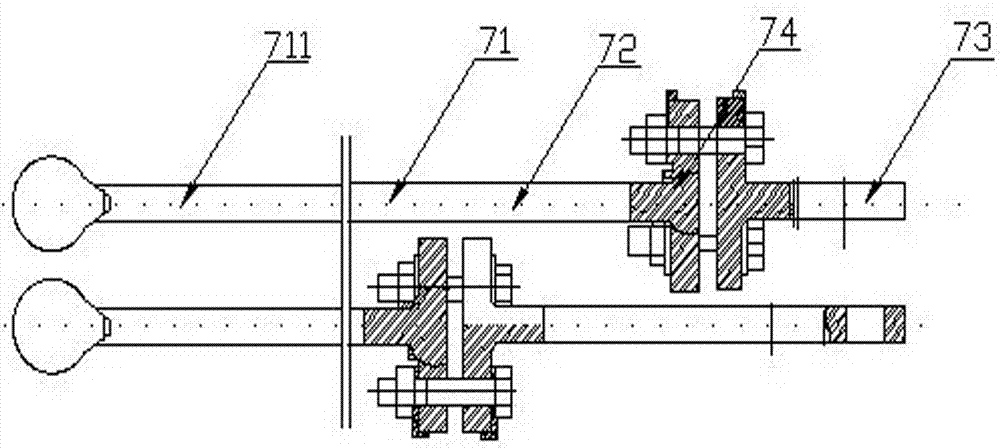

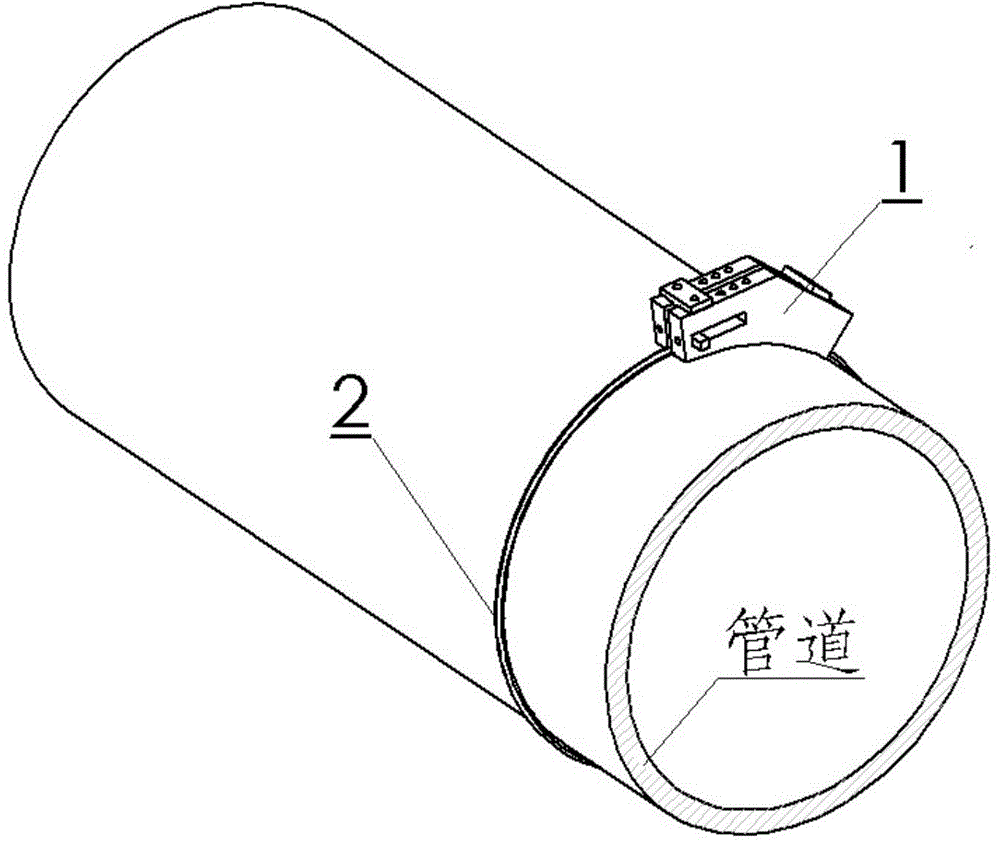

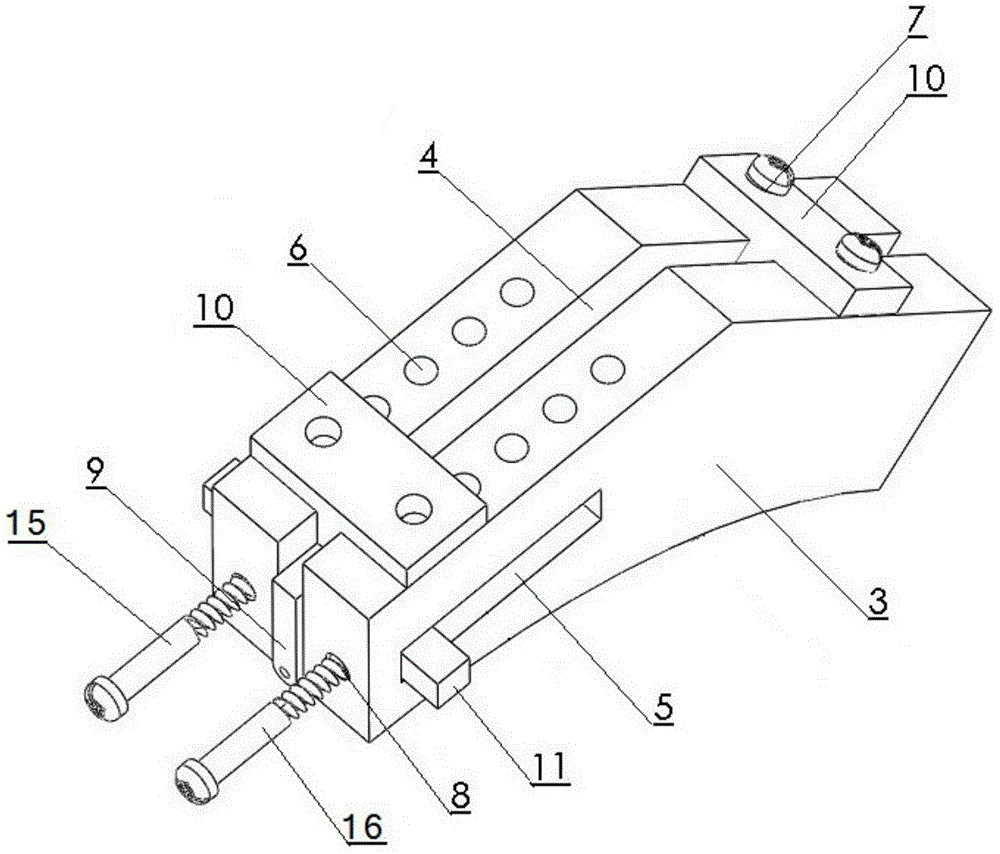

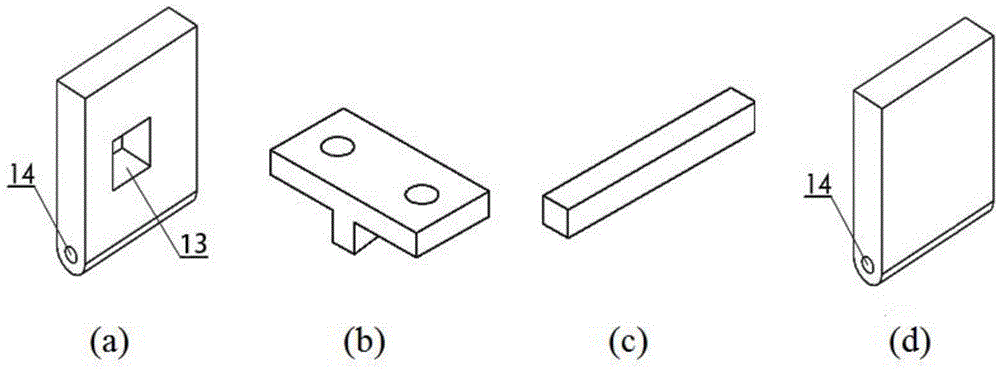

Controllable-pretension FBG (Fiber Bragg Grating) strain hoop gripper system

ActiveCN103867793ACan't solveSolve close pipe contactPipe supportsWork holdersGratingFiber Bragg grating

The invention discloses a controllable-pretension FBG (Fiber Bragg Grating) strain hoop gripper system, and belongs to the technical field of a sensor. The controllable-pretension FBG strain hoop gripper system is characterized by being applied to an FBG strain hoop sensor and being used for measuring hoop strain of a pipeline; the controllable-pretension FBG strain hoop gripper system has the key that a long-rod screw is screwed in the end part by penetrating through a screw hole so as to push a wedge to slide forwards, the increment of an FBG wave length is controlled according to the reading of an interrogator, the controllable pretension is realized, the sensor is tightly attached to the outer wall of the pipeline, and optical fibers at the inner part of the sensor can be always in an effective tension measuring state. The pretension-controllable FBG strain hoop gripper system disclosed by the invention has the beneficial effects that problems that the FBG strain hoop sensor cannot be in tight contact with the pipeline, and the hoop strain of the pipeline cannot be accurately measured are solved, the accuracy of the FBG strain hoop sensor is increased, and the pretension-controllable FBG strain hoop gripper system has the advantages that the pretension can be controlled, the manufacturing and the installing are simple and convenient, the mass production is suitable for being carried out, and the like.

Owner:DALIAN UNIV OF TECH

Method for testing rock expansion force

InactiveCN109186833AGuaranteed accuracyReduce human errorApparatus for force/torque/work measurementAdhesiveRock sample

The invention provides a method for testing a rock expansion force, comprising the following steps: S1, processing the rock into a rock sample; S2, wrapping an adhesive layer on the outer peripheral surface of the rock sample, and determining an elastic modulus E; S3, soaking an artificial core with water, and recording a hoop strain epsilon of the adhesive layer; and S4, taking the data obtainedin the S2 and S3 into the formula: sigma is equal to Eepsilon, and calculating the formula to obtain an expansion force sigma at the junction of the adhesive layer and the rock sample, wherein sigma is the expansion force of the rock sample. By processing a rock sample into an artificial core having an adhesive layer, pre-calculating the elastic modulus E of the adhesive layer, then soaking the artificial core with water, and obtaining the expansion force due to formula calculation by recording the hoop strain epsilon of the adhesive, the method for testing a rock expansion force provided by the invention greatly reduces personal errors and improves the accuracy of the test, compared with the traditional method of reading for many times by a vertical dial gauge.

Owner:SHIJIAZHUANG TIEDAO UNIV

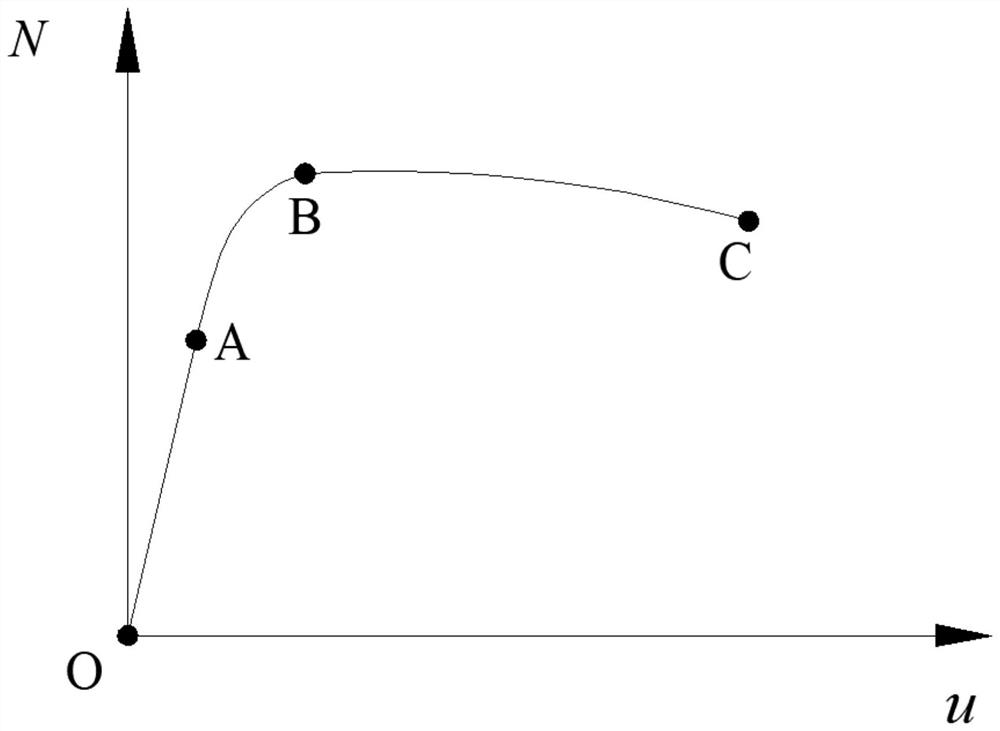

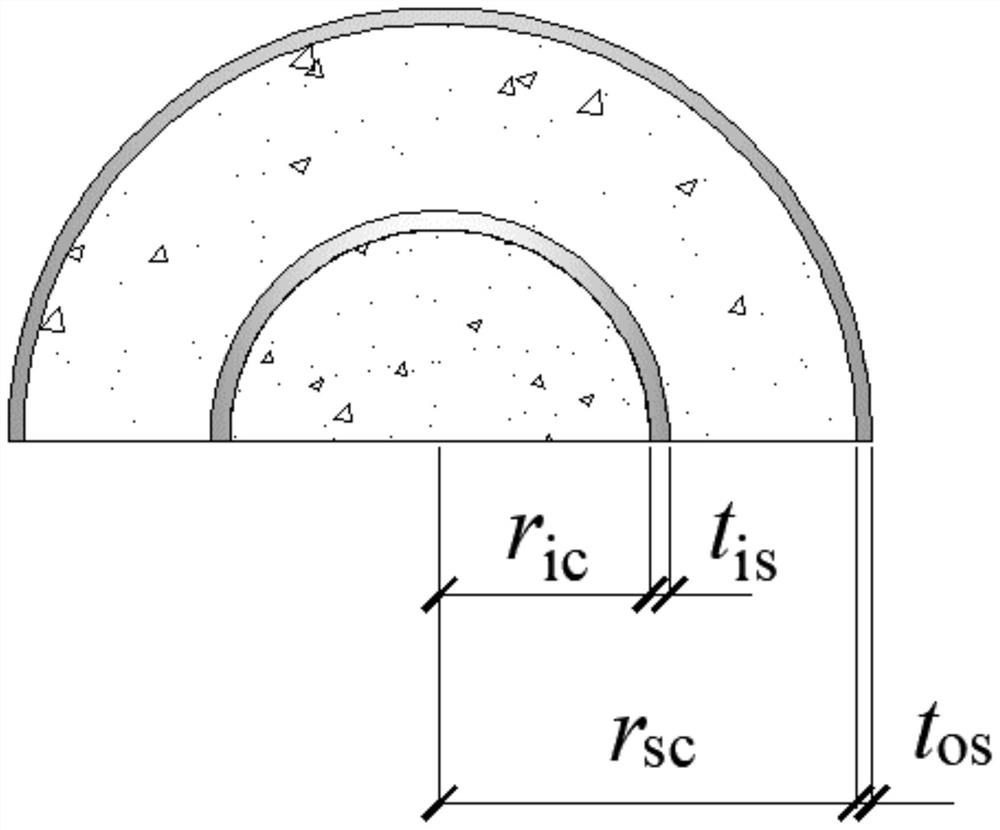

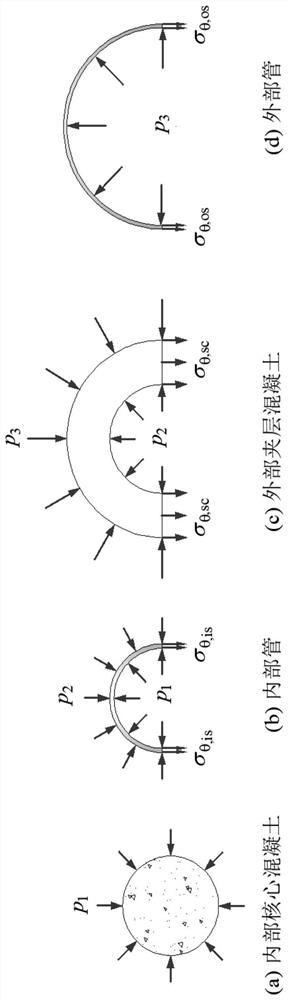

Method and system for calculating extrusion stress of isotropic double-pipe concrete column

The invention provides a method and system for calculating extrusion stress of an isotropic double-pipe concrete column, and the method comprises the steps: 1, obtaining calculation parameters of a double-pipe concrete column, including the Poisson's ratio and elastic modulus of internal core concrete and external interlayer concrete, and the Poisson's ratio, elastic modulus, inner diameter and wall thickness of an internal pipe and an external pipe; 2, establishing an extrusion stress relationship among all parts of the double-pipe concrete column; 3, substituting calculation parameters into the step 2 to obtain the extrusion stress between the parts; 4, based on the calculation parameters and the result obtained through solving in the step 3, obtaining the annular and radial strain of the inner core concrete, the annular stress and the annular strain of the inner pipe, the radial and annular stress of the outer interlayer concrete changing along the thickness and the radial and annular strain of the outer interlayer concrete changing along the thickness, the circumferential strain of the inner side and the outer side of the outer interlayer concrete and the circumferential stress and the circumferential strain of the outer pipe.

Owner:WUHAN UNIV

Radial deformation measuring device based on LVDT sensor

PendingCN110375638AHigh precisionWidely applicable to radial small deformation measurementElectrical/magnetic solid deformation measurementElectrical/magnetic diameter measurementsEngineeringHoop strain

The invention discloses a radial deformation measuring device based on an LVDT sensor. The device comprises an auxiliary tooling and a sensor device. The sensor device comprises a flexible iron wire,an LVDT coil, an LVDT core, a spring and a bolt. A sample is fixed between the flexible iron wire and the auxiliary tooling, one end of the flexible iron wire is connected to a bolt and is fixed on one side of the auxiliary tooling, the other end of the flexible iron wire is sequentially connected to the spring and the LVDT core in series and passes through the LVDT coil, and the LVDT coil is fixed to the other side of the auxiliary tooling. The device is simple to assemble, the radial deformation value can be effectively amplified, the measurement accuracy is improved, and the hoop strain ismeasured without affecting an explosive test.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

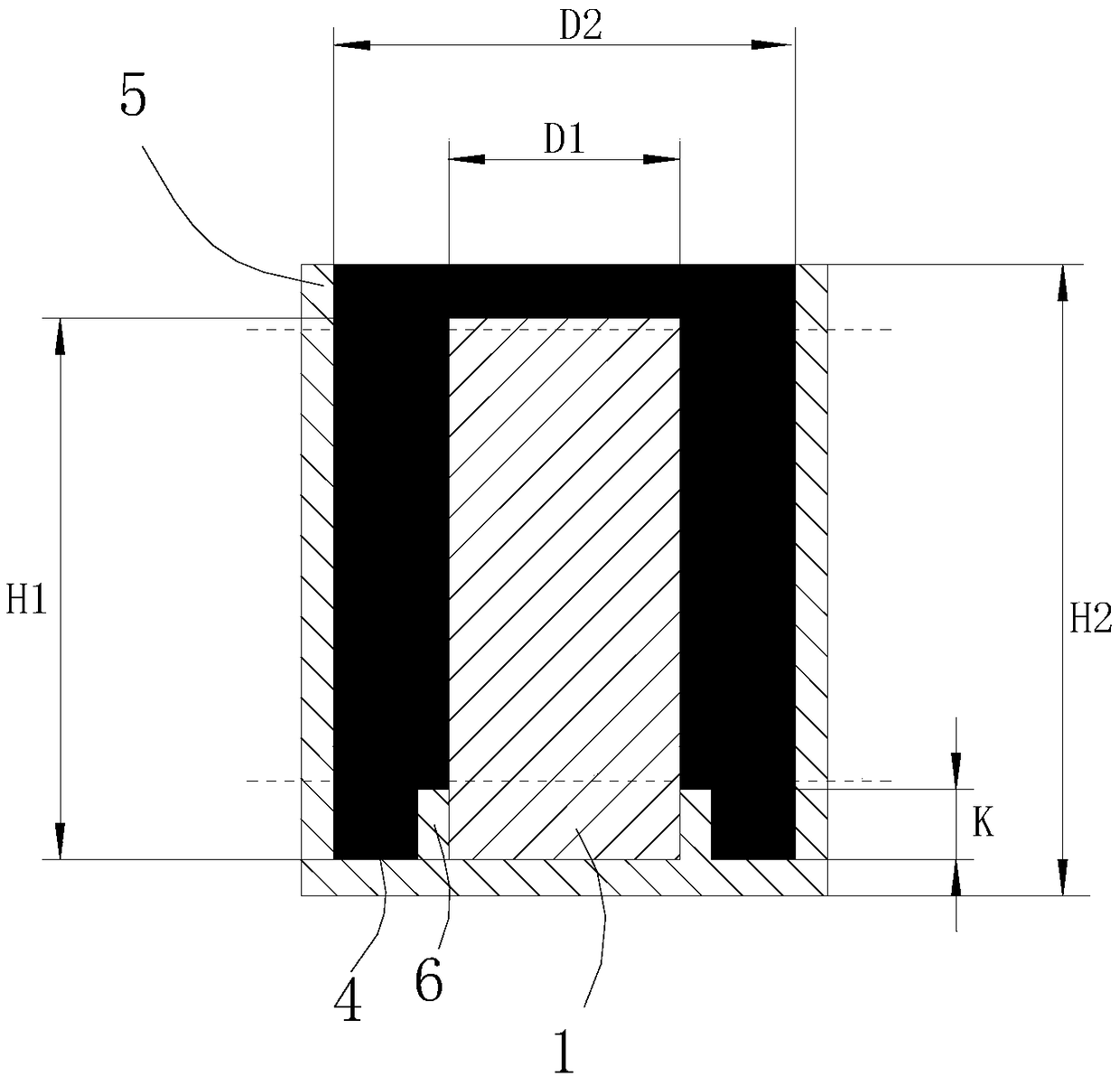

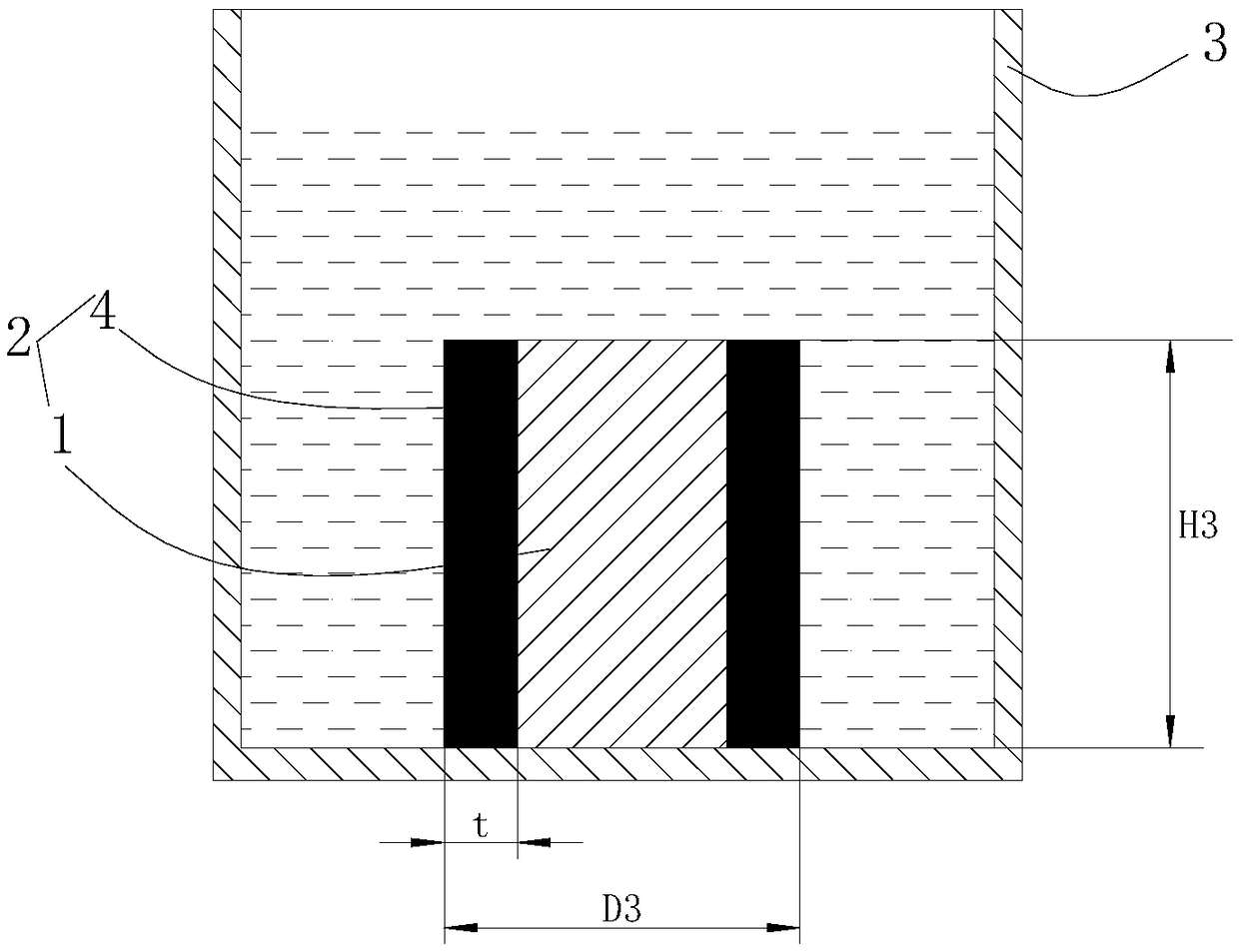

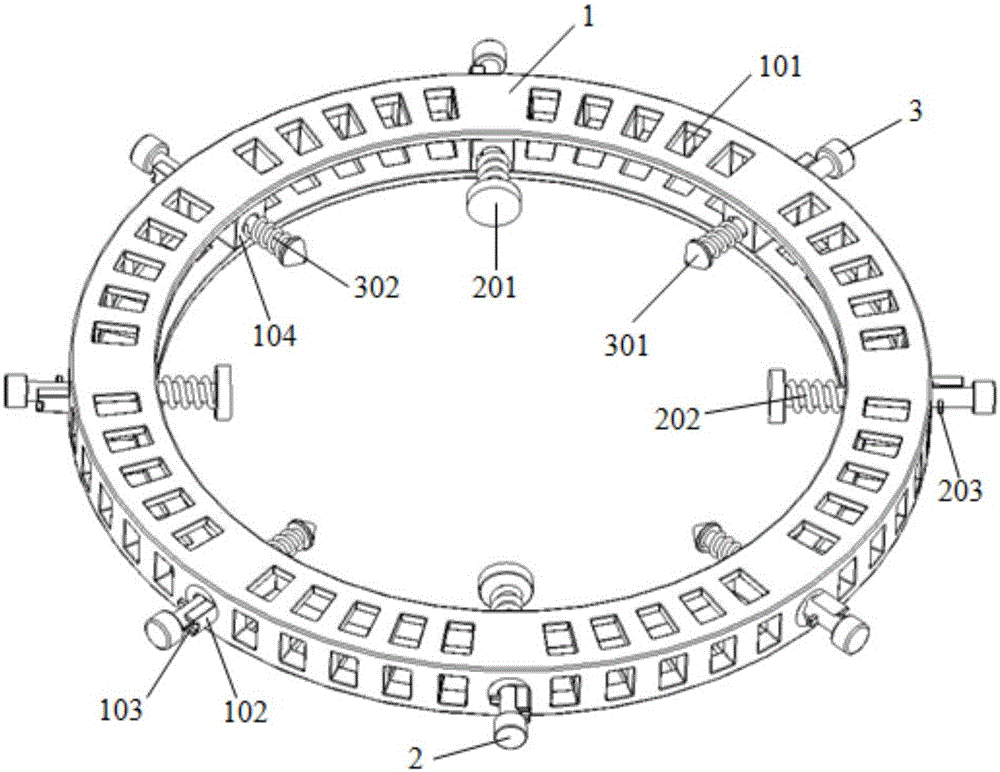

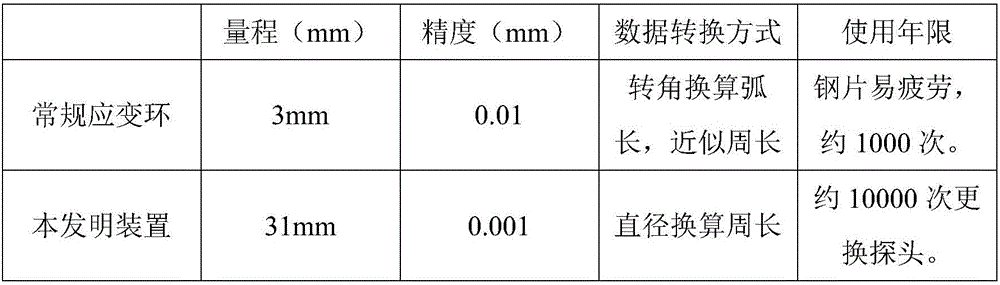

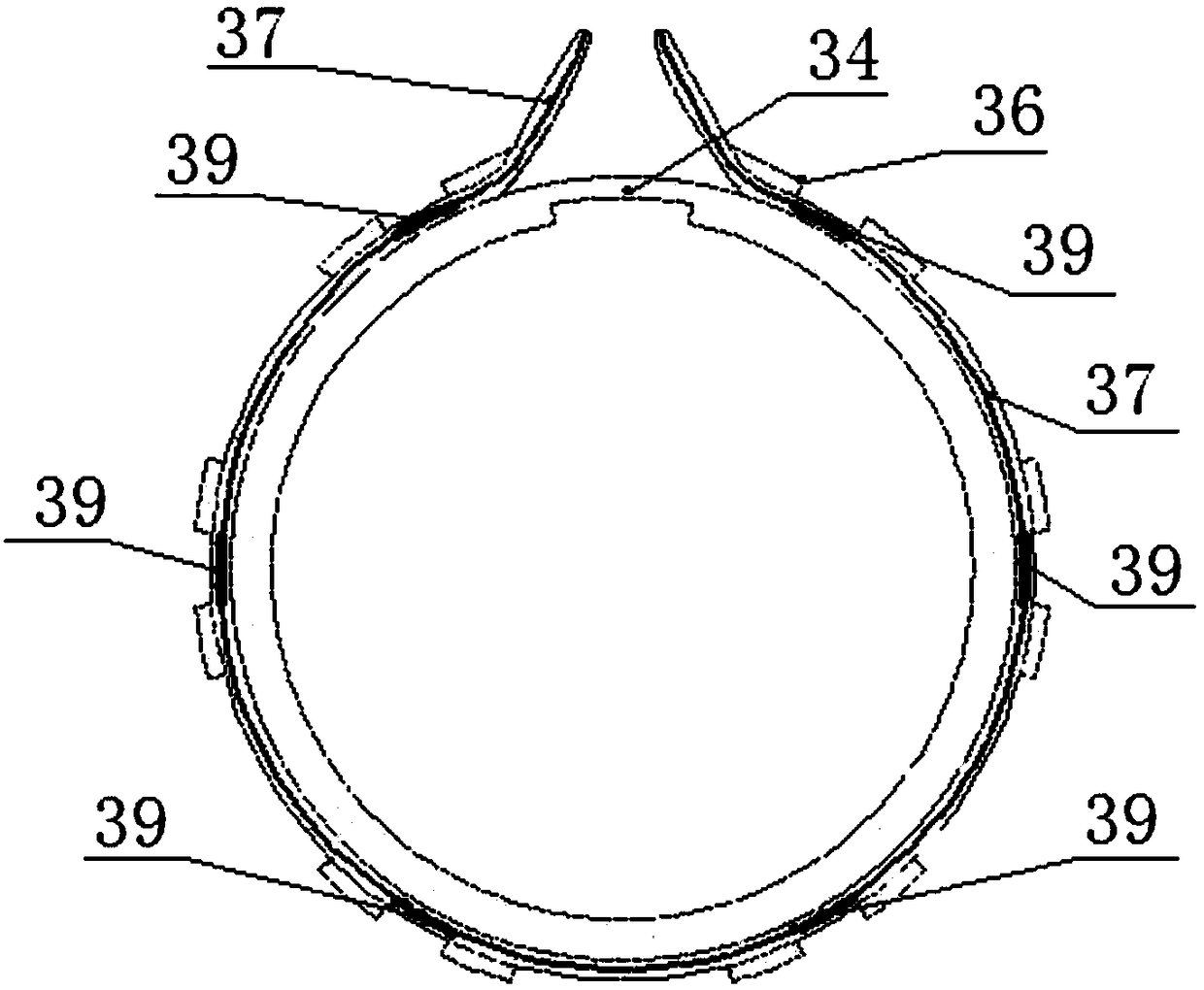

Follow-up multi-point contact type hoop strain measurement device

ActiveCN106500652ASimple structureSolution to short lifeMeasurement devicesMeasurement deviceContact type

The present invention provides a follow-up multi-point contact type hoop strain measurement device. The device comprises a connecting ring, a fixing device and an LVDT sensor. A plurality of mounting members are evenly distributed to pass through the sidewall of the connecting ring, wherein the mounting members are square and are provided with circular through holes. The fixing device and the LVDT sensor are alternately arranged in the through holes through connecting pieces. The fixing device comprises a fixing rod having the telescopic function, and end caps arranged at the two ends of the fixing rod, wherein one end cap in contact with a sample at the center of the connecting ring is an arc-shaped end cap. The arc shape of the arc-shaped end cap is matched with the outer periphery of the sample. A fixing device spring is sleeved onto the fixing rod. The two ends of the spring of the fixing device are respectively fixed onto the arc-shaped end cap and the mounting members. The probe of the LVDT sensor is arranged towards the sample. A sensor spring is sleeved onto the fixing rod of the LVDT sensor. The two ends of the sensor spring are respectively fixed on a probe base and the mounting members.

Owner:HOHAI UNIV

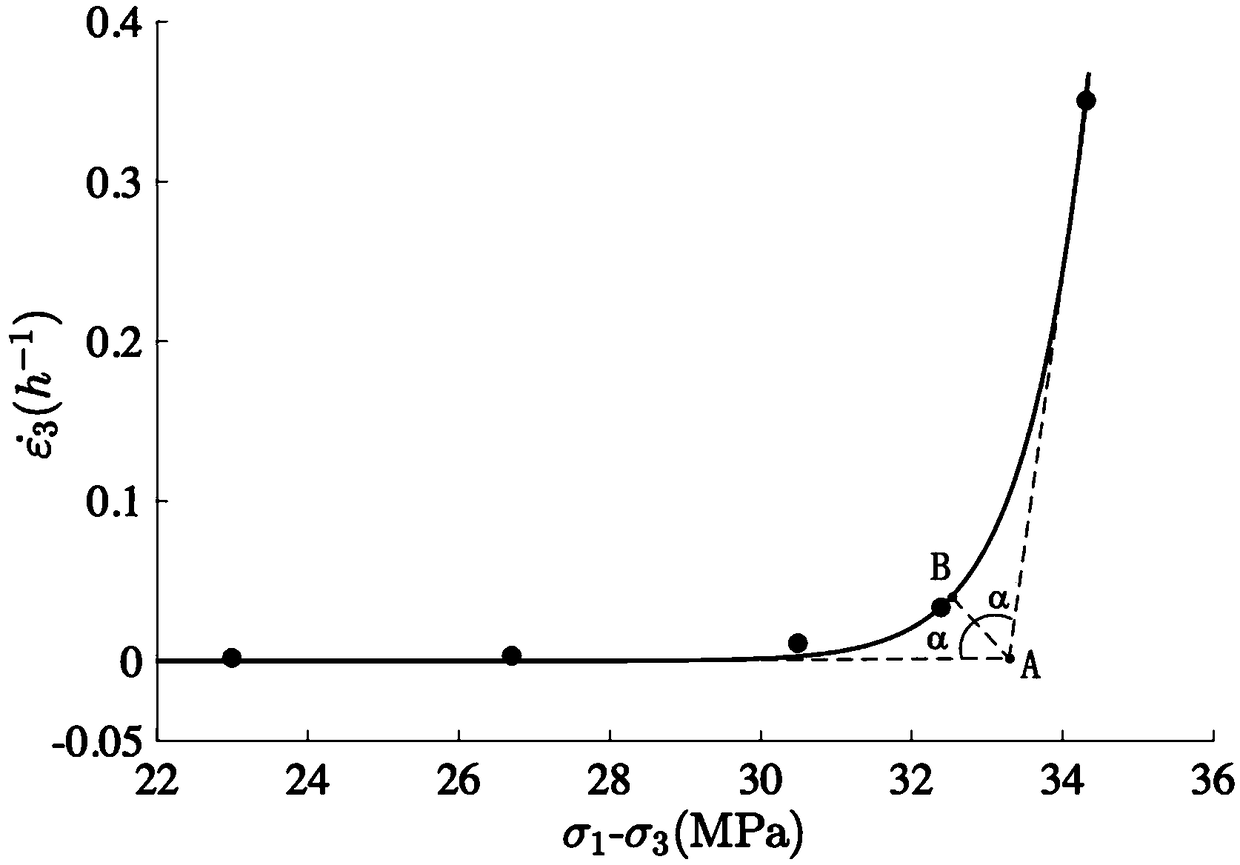

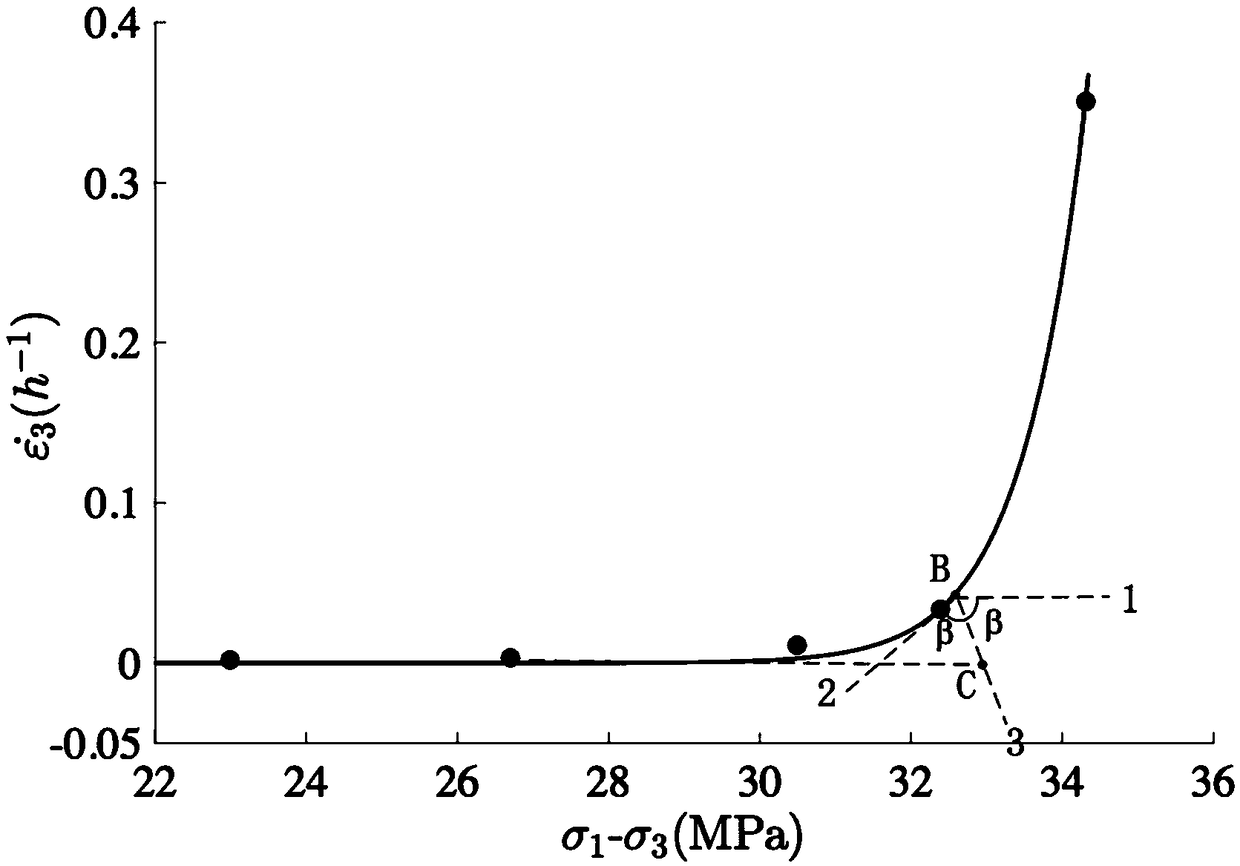

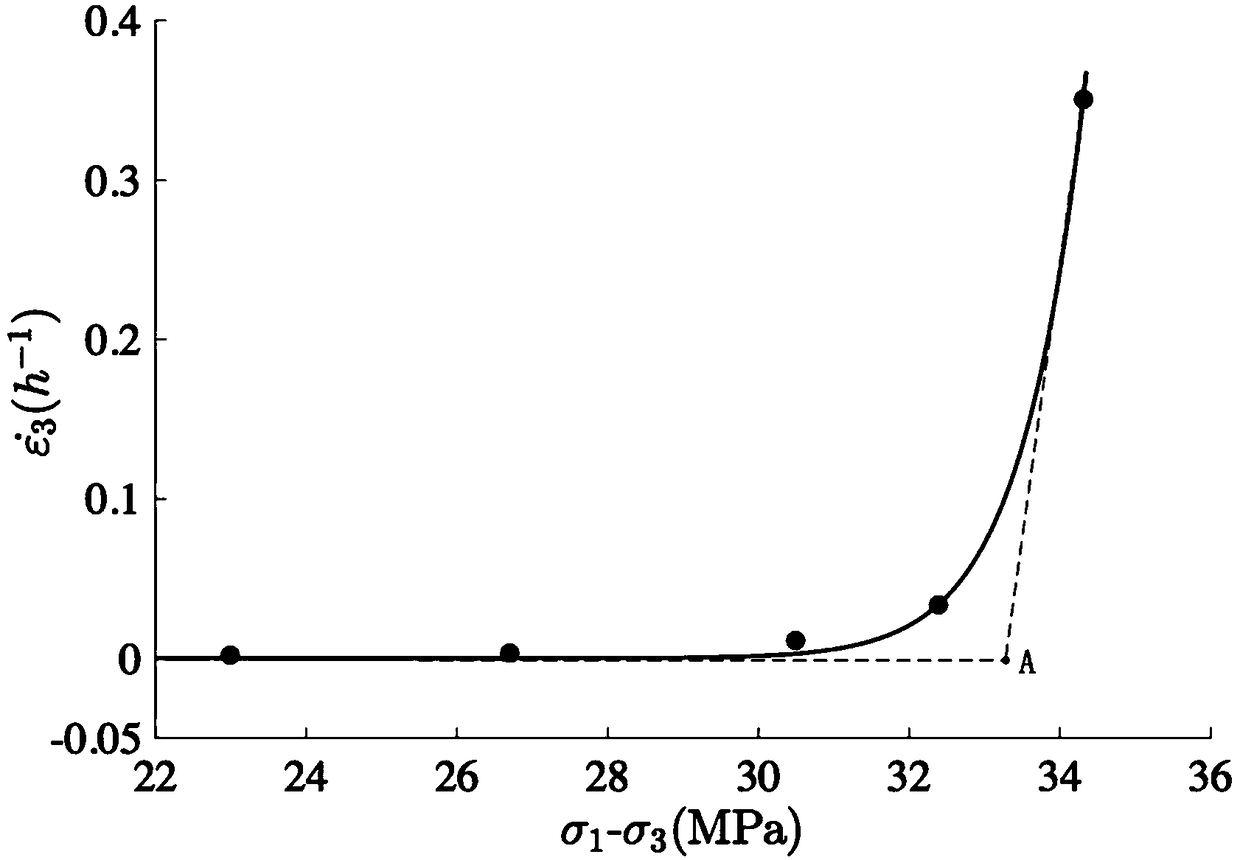

A method for determining long-term rock strength parameters based on the Casa Grande method

ActiveCN106908324BReduce mistakesSelect clearMaterial strength using tensile/compressive forcesRock engineeringStress level

The present invention discloses a rock long-term strength parameter determination method based on a Casagrande method. The rock long-term strength parameter determination method comprises: drawing a steady-state hoop strain rate-stress level relationship curve according to triaxial creep test results, extending the upper straight section and the lower straight section of the steady-state hoop strain rate-stress level relationship curve to form an angle, making the angular bisector of the angle, making the angular bisector and the steady-state hoop strain rate-stress level relationship curve intersect at a first intersection point, determining the first intersection point as the inflection point of the steady-state hoop strain rate-stress level relationship curve, and obtaining the rock long-term strength parameter based on a Casagrande method so as to achieve the purposes of exact selection of the curve intersection point and substantial reduction of the data error. According to the present invention, the method is simple and effective, and the disadvantages of unclear defined inflection point, high error and the like of the traditional rock long-term strength parameter determination method are effectively improved, wherein the long-term strength parameter determined by the method of the present invention is moderate, can be used for the rock engineering long-term stability analysis, and provides reference for the construction and the long-term operation of the project.

Owner:HOHAI UNIV

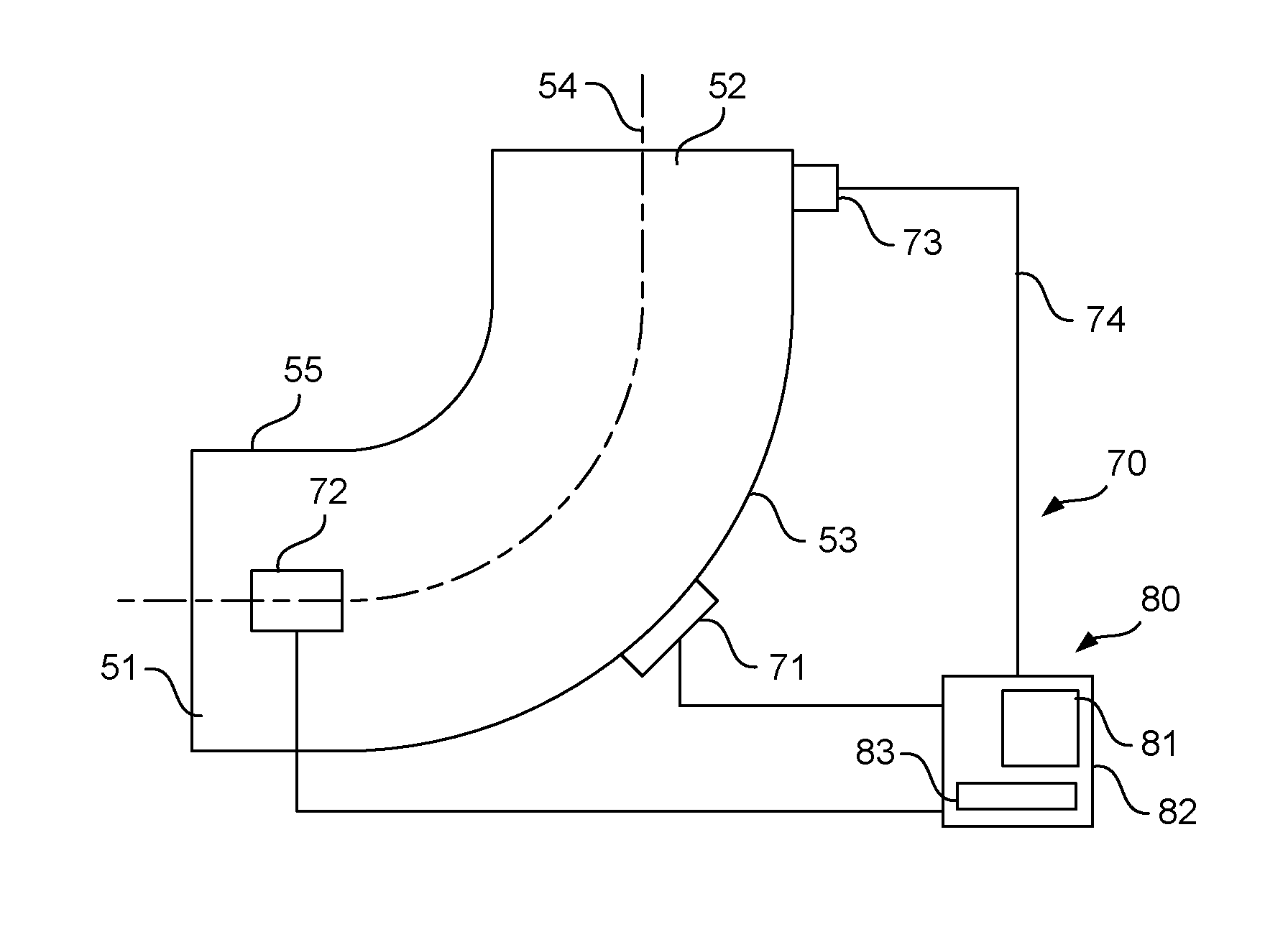

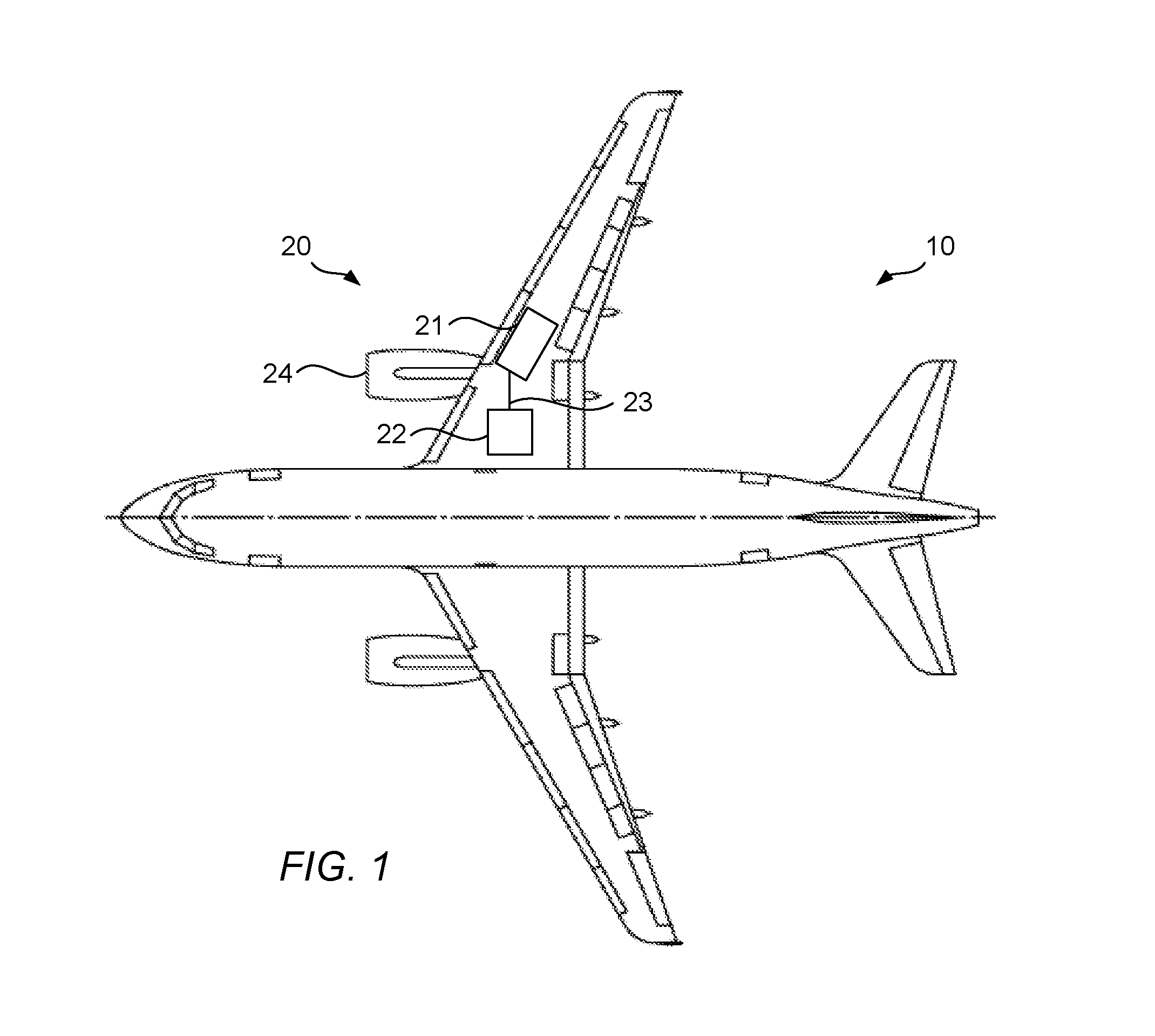

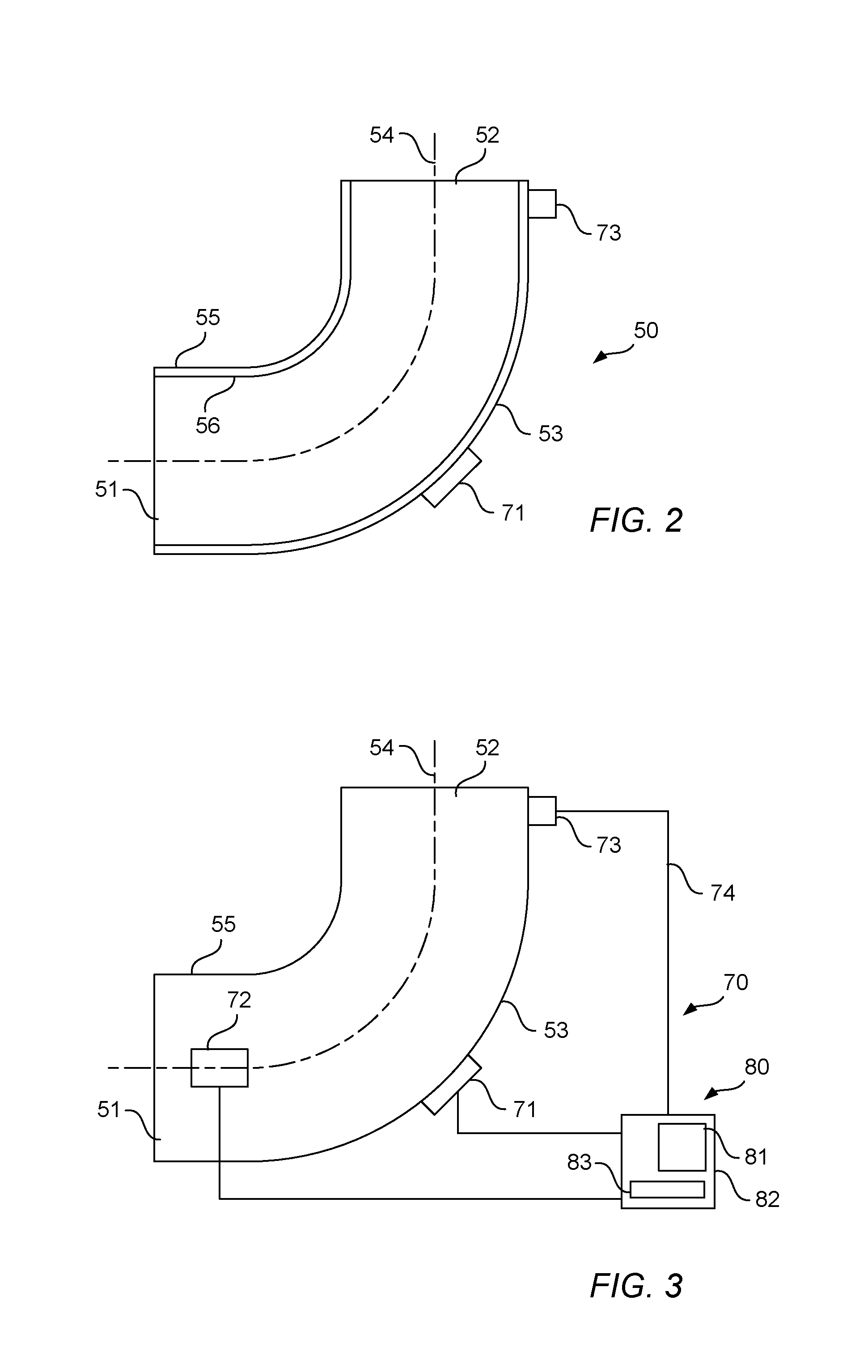

Metering apparatus for and method of determining a characteristic of a fluid flowing through a pipe

Owner:AIRBUS OPERATIONS LTD

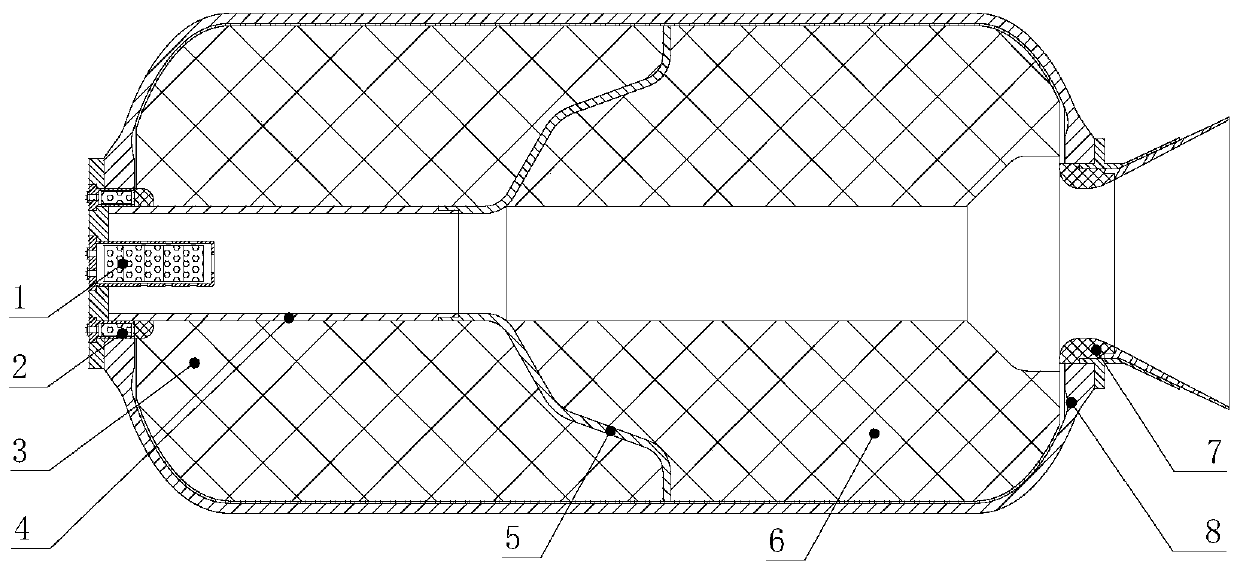

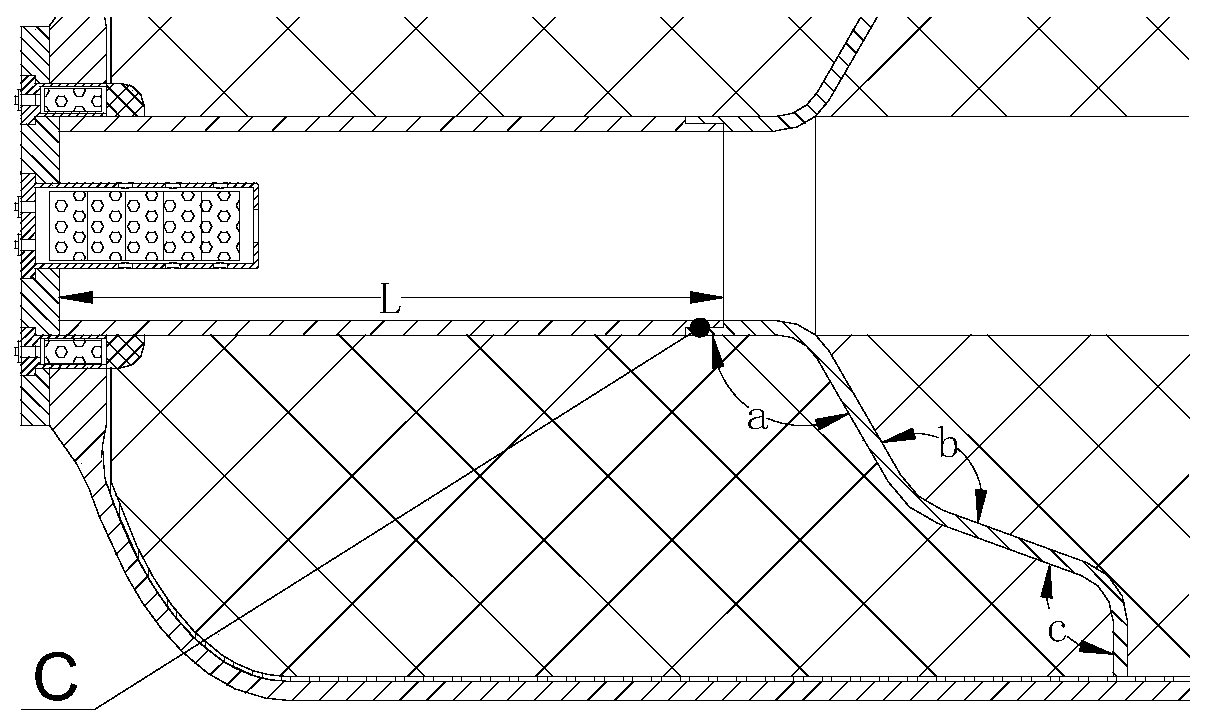

Interlayer structure for reducing interlayer strain of double-pulse solid engine

The invention discloses an interlayer structure for reducing interlayer strain of a double-pulse solid engine. The interlayer structure separates a grain into I pulse grains and II pulse grains, the interlayer structure comprises an axial interlayer and a radial interlayer, the radial interlayer is wrapped on the inner circumferential surface of the II pulse grain, the tail part of the radial interlayer is overlapped on the inner side of the head part of the axial interlayer, the axial interlayer is transited from the head part arc to the tail part, and the axial interlayer is wrapped on the opposite end surfaces of the II pulse grain and the I pulse grain. According to the interlayer structure, the hoop strain of the radial interlayer can be reduced, so that the strain of the interlayer of the double-pulse solid engine is reduced.

Owner:XIAN AEROSPACE PROPULSION TECH INST

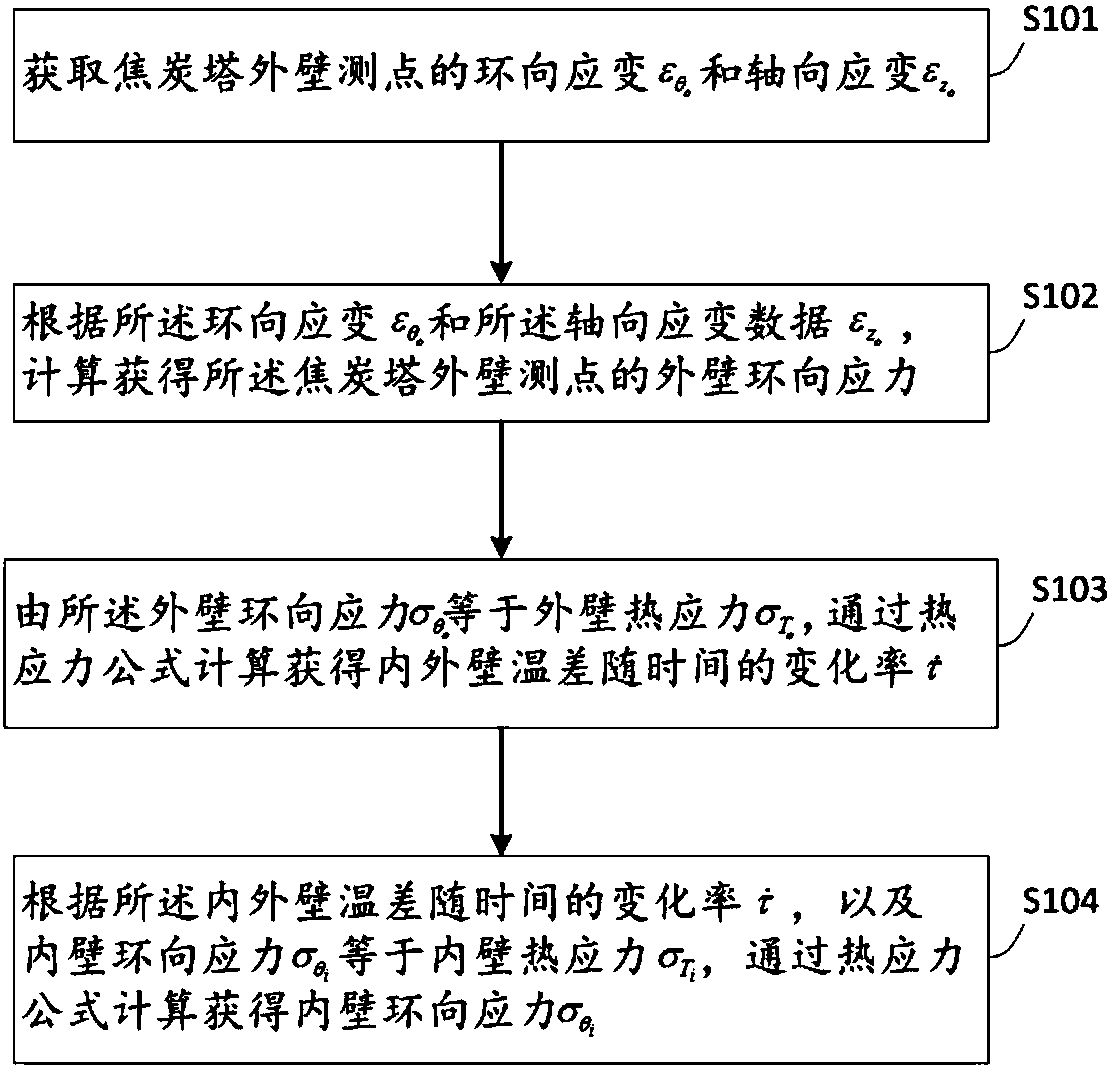

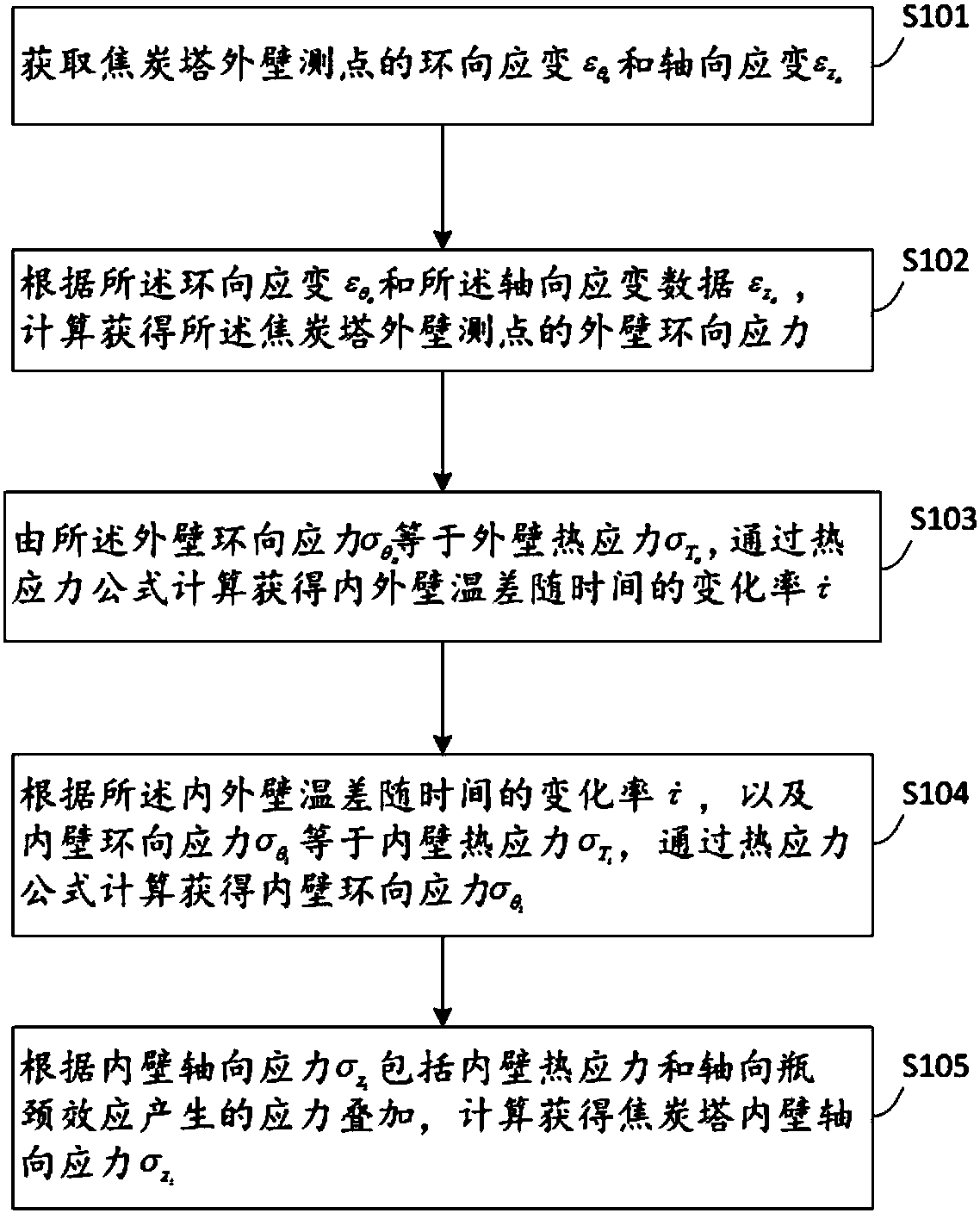

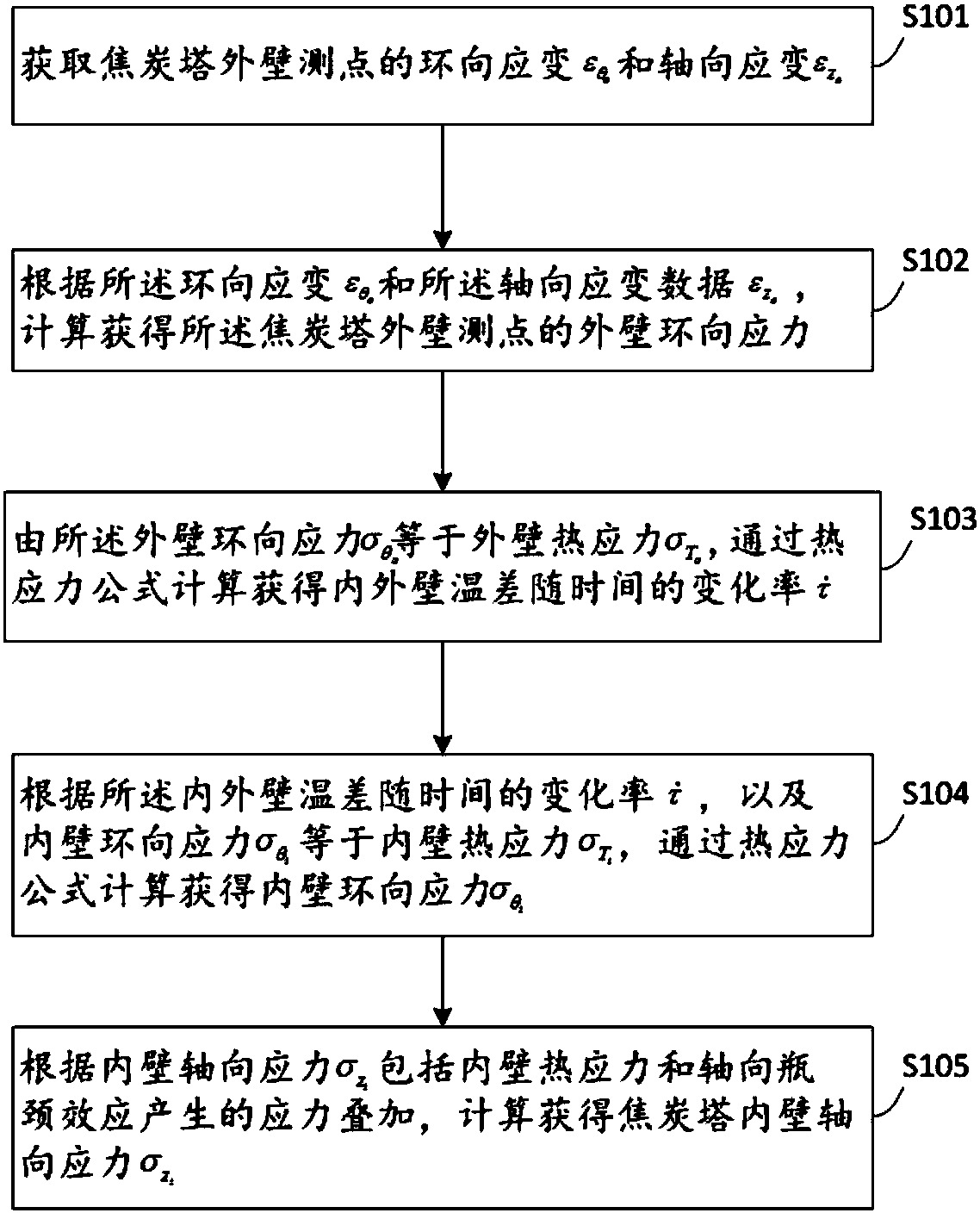

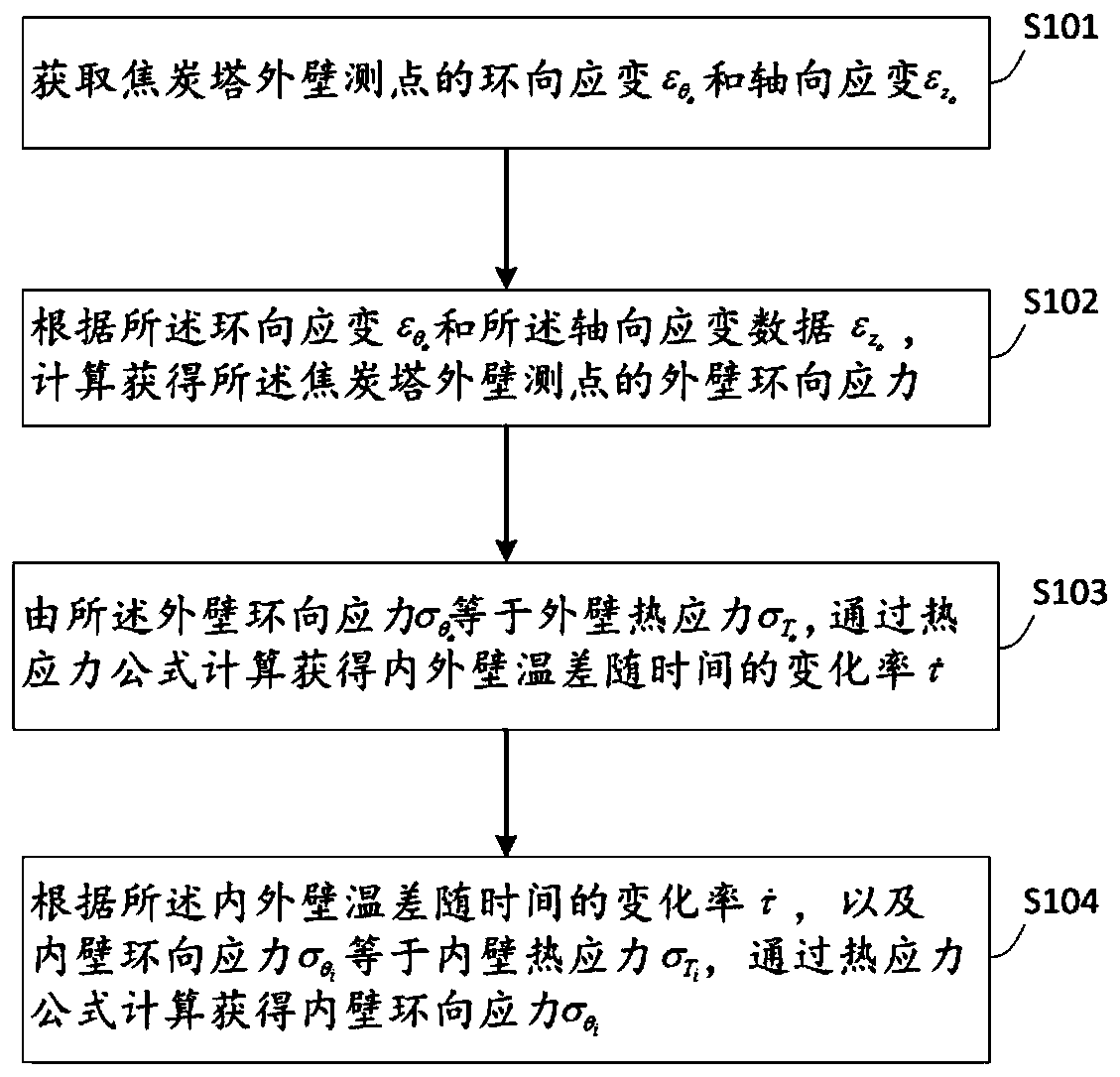

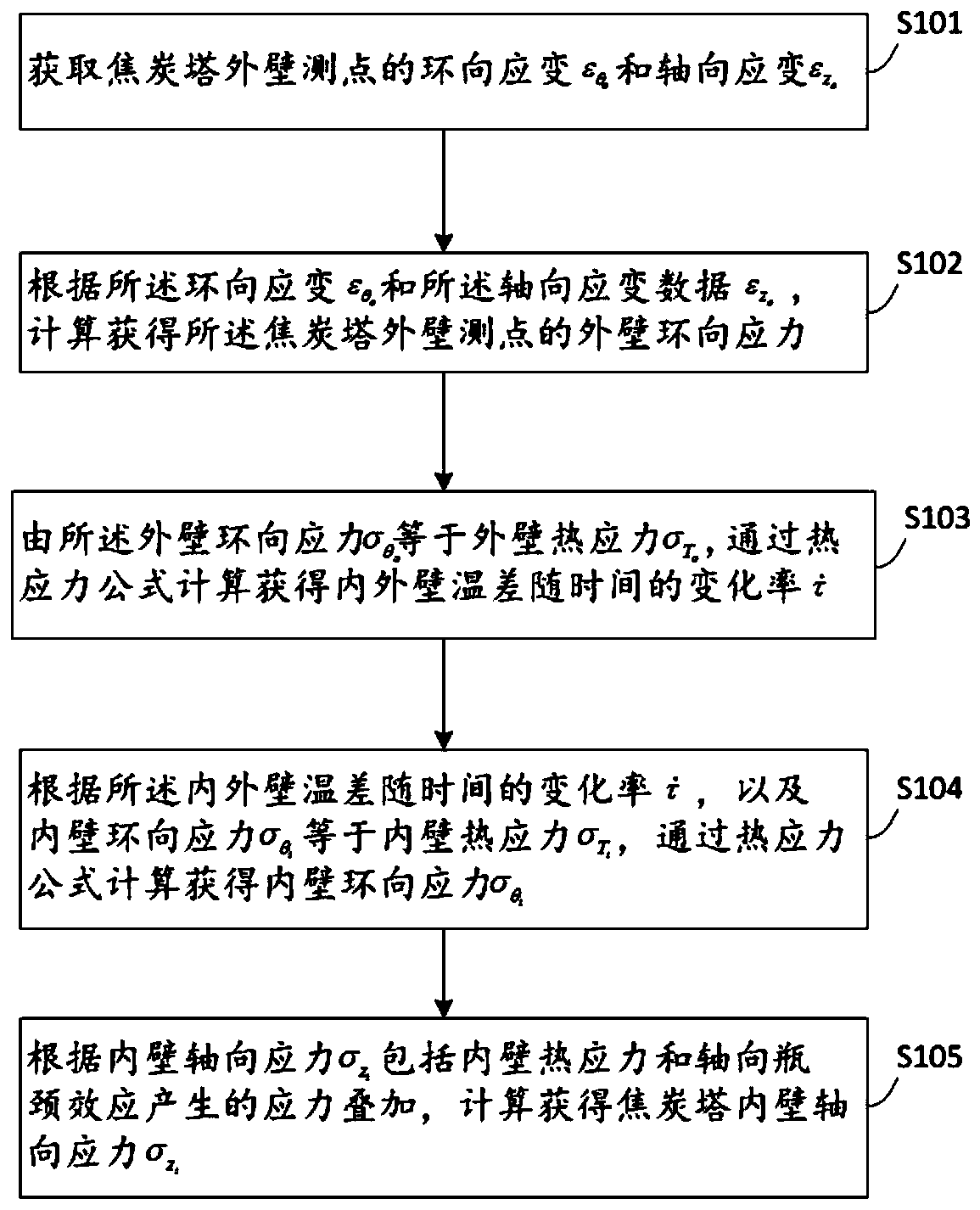

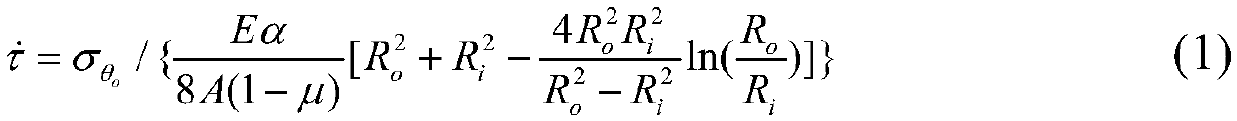

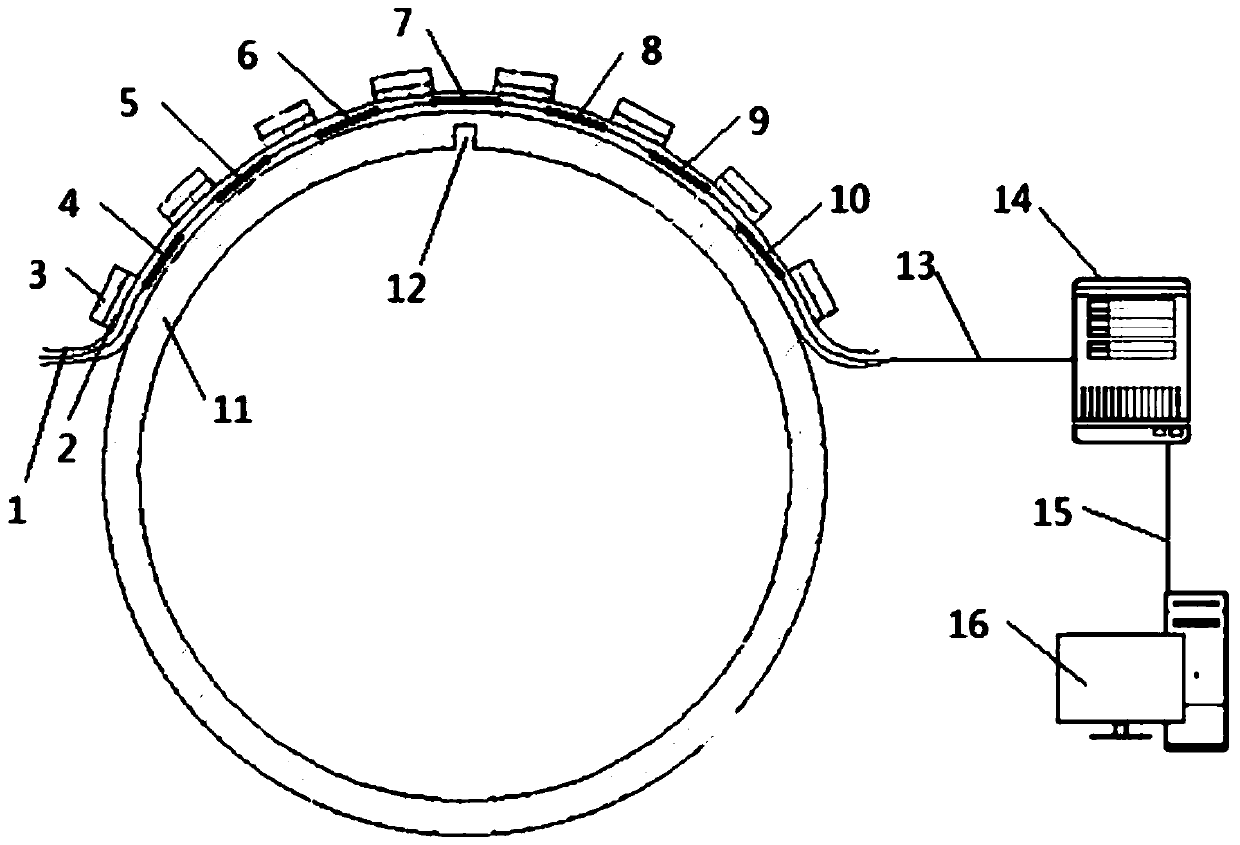

Coke tower inner wall stress calculation method

ActiveCN107063541ANo damageReduce monitoring costsApparatus for force/torque/work measurementMeasurement pointTemperature difference

The invention discloses a coke tower inner wall stress calculation method. The method comprises steps: hoop strain epsilon(theta)o and axial strain epsilon(z)o data of an outer wall measurement point on the coke tower are acquired; according to the hoop strain epsilon(theta)o and axial strain epsilon(z)o data, the outer wall hoop stress sigma(theta)o of the outer wall measurement point on the coke tower is calculated and acquired; the outer wall hoop stress sigma(theta)o is equal to outer wall thermal stress sigmaTo, the change rate capped tau of a temperature difference between the inner wall and the outer wall along with time is calculated and acquired through a thermal stress formula; according to the change rate capped tau of the temperature difference between the inner wall and the outer wall along with the time and the inner wall hoop stress sigma(theta)i equal to the inner wall thermal stress sigmaTi, the inner wall hoop stress sigma(theta)i is calculated and acquired through the thermal stress formula. The coke tower inner wall stress calculation method is high in precision and low in cost.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST +1

A Calculation Method for Circumferential Strain of Immersed Tunnel Tube Section Under Tidal Load

ActiveCN106682267BStrong computing powerIncrease computing speedDesign optimisation/simulationSpecial data processing applicationsCross modelEngineering

Owner:合肥龙智机电科技有限公司

An experimental device and experimental method for compression characteristics of mine filling materials

ActiveCN107389449BSimple structureClosely connectedMaterial strength using tensile/compressive forcesExperimental methodsFilling materials

The invention discloses a mine filling material compression characteristic experiment device and an experiment method thereof. The experiment device is arranged on a pressure machine, and comprises a cavity for holding a filling material, wherein a bleeding structure is arranged at the bottom end of the cavity; the other end of the cavity is sealed through a slidable piston in the cavity; the bottom end of the cavity is arranged on a lower pressure-bearing plate of the pressure machine; a pressure-bearing column connected with the piston contacts an upper pressure-bearing plate of the pressure machine; an outer wall of the cavity is provided with a plurality of hoop strain foils at different axial positions in a pasting way; the hoop strain foils are connected with a statical strain indicator; a displacement sensor is also arranged between the upper pressure-bearing plate and the lower pressure-bearing plate of the pressure machine; the statical strain indicator and the displacement sensor are in signal connection with a computer connected with a pressure machine measuring system. The mine filling material compression characteristic experiment device provided by the invention can be used for monitoring compression amounts of the filling materials under different stresses and a strain level of an outer wall of a steel cylinder through the pressure machine measuring system, and is simple in structure, convenient to operate, and applicable to compression characteristic tests of dry filling bodies, water sand filling bodies, cemented filling bodies and other filling bodies.

Owner:CENT SOUTH UNIV

A hoop and beam type support device for reactor pressure vessel

ActiveCN106384608BEliminates flex swing problemsEasy maintenanceNuclear energy generationContainmentReactor pressure vesselShock resistance

The invention discloses a linear support device for a hoop tension beam for a reactor pressure vessel, which comprises a concrete foundation, a hoop surrounding the upper part of the pressure vessel, and at least two sets of transverse tension beams relatively arranged on the periphery of the pressure vessel. One end of the beam is connected with the hoop, and the other end is connected with the concrete foundation. The invention adopts hoops, cross-tension beams, connecting pins and other structures. The hoops surround the upper outer surface of the pressure vessel. One end of the cross-tension beam is connected to the hoop, and the other end is fixed in the concrete foundation of the reactor pit. It is connected with the hoop through connecting pins, while supporting the reactor pressure device, it can decompose the lateral stress of the pressure vessel during operation, eliminate the flexible swing of the vessel, and enhance the shock resistance of the reactor pressure vessel.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Cylindrical hoop strain earth pressure sensor and measurement method

ActiveCN105115634BInheritedAccurate readingForce measurementElectrical resistance and conductanceCircumferential strain

The present invention relates to the field of earth pressure detection, in particular to a cylindrical body circumferential strain earth pressure sensor and a measurement method, the earth pressure sensor includes a cylindrical elastic induction body, a resistance strain gauge, a strain gauge lead wire and a housing, the cylindrical The elastic induction body adopts a cylindrical elastic entity composed of elastic base materials. The cylindrical elastic induction body is added with a structure to increase the compressive modulus. This structure is integrally formed with the cylindrical elastic induction body. The structure includes inner bars and stirrups. The ribs are arranged inside the cylindrical elastic induction body, and the stirrups are installed circumferentially on the upper side or the lower side surface of the cylindrical elastic induction body of the resistance strain gauge. By changing the shape, size and density of the internal ribs, the compressive modulus of the cylindrical elastic sensor is changed to improve the measurement accuracy.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

A Fiber Bragg Grating Strain Hoop Holder System with Controllable Pretension

ActiveCN103867793BHigh measurement accuracyEnsure consistencyPipe supportsWork holdersGratingFiber Bragg grating

The invention discloses a controllable-pretension FBG (Fiber Bragg Grating) strain hoop gripper system, and belongs to the technical field of a sensor. The controllable-pretension FBG strain hoop gripper system is characterized by being applied to an FBG strain hoop sensor and being used for measuring hoop strain of a pipeline; the controllable-pretension FBG strain hoop gripper system has the key that a long-rod screw is screwed in the end part by penetrating through a screw hole so as to push a wedge to slide forwards, the increment of an FBG wave length is controlled according to the reading of an interrogator, the controllable pretension is realized, the sensor is tightly attached to the outer wall of the pipeline, and optical fibers at the inner part of the sensor can be always in an effective tension measuring state. The pretension-controllable FBG strain hoop gripper system disclosed by the invention has the beneficial effects that problems that the FBG strain hoop sensor cannot be in tight contact with the pipeline, and the hoop strain of the pipeline cannot be accurately measured are solved, the accuracy of the FBG strain hoop sensor is increased, and the pretension-controllable FBG strain hoop gripper system has the advantages that the pretension can be controlled, the manufacturing and the installing are simple and convenient, the mass production is suitable for being carried out, and the like.

Owner:DALIAN UNIV OF TECH

Calculation method of inner wall stress of coke tower

ActiveCN107063541BNo damageReduce monitoring costsApparatus for force/torque/work measurementMeasurement pointTemperature difference

The invention discloses a coke tower inner wall stress calculation method. The method comprises steps: hoop strain epsilon(theta)o and axial strain epsilon(z)o data of an outer wall measurement point on the coke tower are acquired; according to the hoop strain epsilon(theta)o and axial strain epsilon(z)o data, the outer wall hoop stress sigma(theta)o of the outer wall measurement point on the coke tower is calculated and acquired; the outer wall hoop stress sigma(theta)o is equal to outer wall thermal stress sigmaTo, the change rate capped tau of a temperature difference between the inner wall and the outer wall along with time is calculated and acquired through a thermal stress formula; according to the change rate capped tau of the temperature difference between the inner wall and the outer wall along with the time and the inner wall hoop stress sigma(theta)i equal to the inner wall thermal stress sigmaTi, the inner wall hoop stress sigma(theta)i is calculated and acquired through the thermal stress formula. The coke tower inner wall stress calculation method is high in precision and low in cost.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST +1

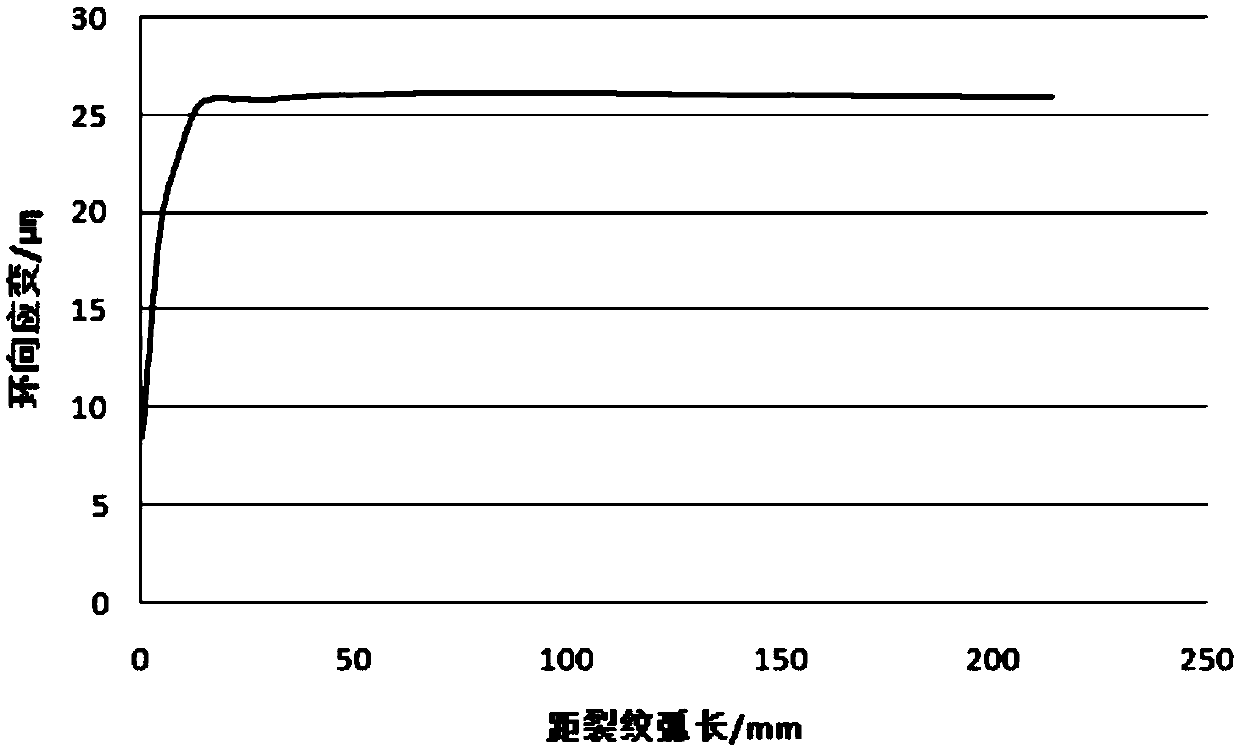

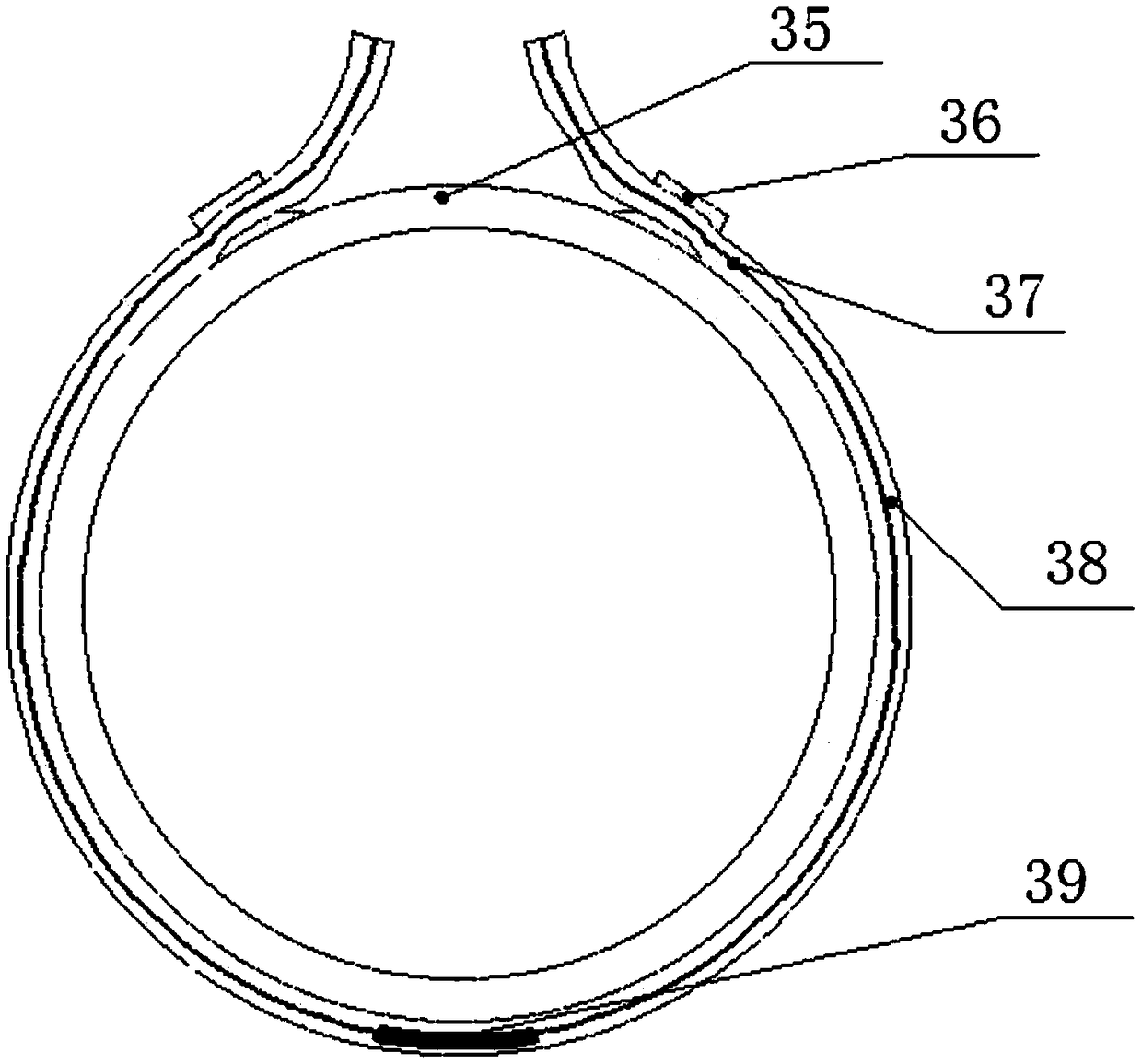

A device and method for detecting longitudinal cracks in pipelines based on fiber grating sensing

ActiveCN106705854BPrecise positioningReduce testing costsPipeline systemsUsing optical meansFiberData processing system

The invention relates to a pipeline longitudinal crack detection device and method based on fiber grating sensing. A fiber grating array sensor is arranged on the periphery of an outer wall of a pipeline, and comprises an optical fiber and fiber gratings equally distributed on the optical fiber; the fiber grating array sensor is pre-stretched so as to be clamped and fixed on the outer wall of the pipeline through a magnet, and demodulates a local hoop strain measured by each fiber grating so as to transmit to a data processing unit; the hoop strains of a pipeline with a longitudinal crack are symmetrically distributed by adopting the crack as a center; the local hoop strain at the crack part is the smallest; in a section of area close to the crack, the local hoop strains are increased along the increase of the distance away from the crack; in a section of area far away from the crack, the local hoop strains approach to a constant number; the data processing unit finds out the smallest local hoop strain according to the changing situation of the hoop strains so as to determine a position of the longitudinal crack of the pipeline. According to the pipeline longitudinal crack detection device and the method based on fiber grating sensing provided by the invention, the accurate positioning of the crack is realized, and the fiber grating array sensor is convenient to disassemble and utilize.

Owner:WUHAN UNIV OF TECH

An on-line monitoring device and method for pipeline leakage and corrosion based on fiber Bragg grating sensing

ActiveCN106764463BLeak real-time monitoringReal-time monitoring of leakagePipeline systemsGratingControl system

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com