Mine filling material compression characteristic experiment device and experiment method thereof

An experimental device and compression characteristics technology, applied in the direction of measuring devices, analysis materials, strength characteristics, etc., can solve the problems of ignoring the friction effect, not suitable for tailings, and not considering the compression characteristics of cemented filling body, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

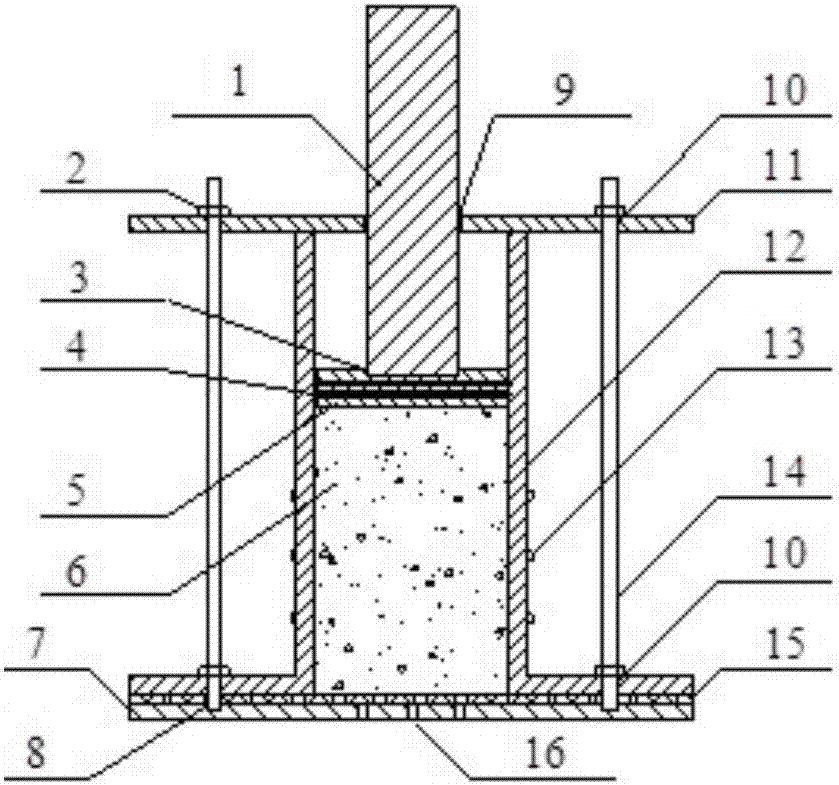

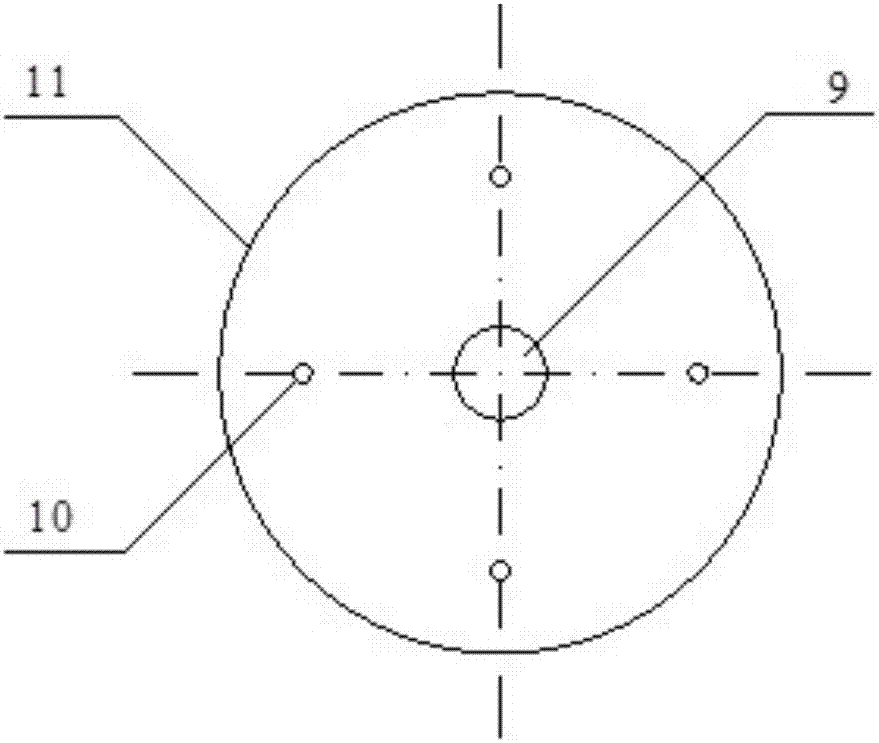

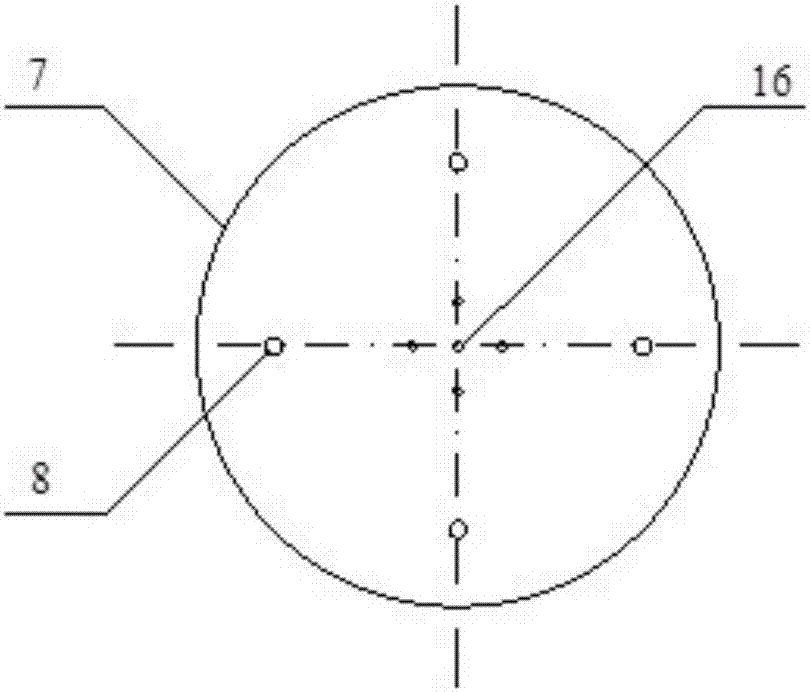

[0049] see Figure 1-6 , a mine filling material compression characteristic experiment device in the illustration is the preferred solution of the present invention, which specifically includes a circular pressure bearing column 1, a nut 2, a sealing ring 4, a piston 5, a bottom cover 7, a top cover 11, a belt chassis Steel cylinder 12, hoop strain gauge 13, screw rod 14, geotextile 15 and other components.

[0050] Wherein, the bottom cover 7, the top cover 11 and the steel cylinder 12 with a chassis form a cavity for filling the filling material 6, and the main body of the cavity is a cylindrical inner chamber with a steel cylinder 12 with a chassis, and the bottom of the steel cylinder 12 with a chassis and The bottom cover 7 is equipped with a bleeding structure to ensure the water discharge of the filling material during the compression process. The top is fixed to the top cover 11, and a piston 5 is installed in the inner cavity of the steel cylinder. The inner wall of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Hole depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com