Controllable-pretension FBG (Fiber Bragg Grating) strain hoop gripper system

A fiber grating and holder technology, applied in the field of sensors, can solve the problems of inability to accurately measure the circumferential strain of the pipeline, the inability of the optical fiber to be tightened, and the inability of ordinary fiber grating strain hoop sensors to closely fit the pipeline, etc., to achieve suitable mass production, Wide range of applications, easy production and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

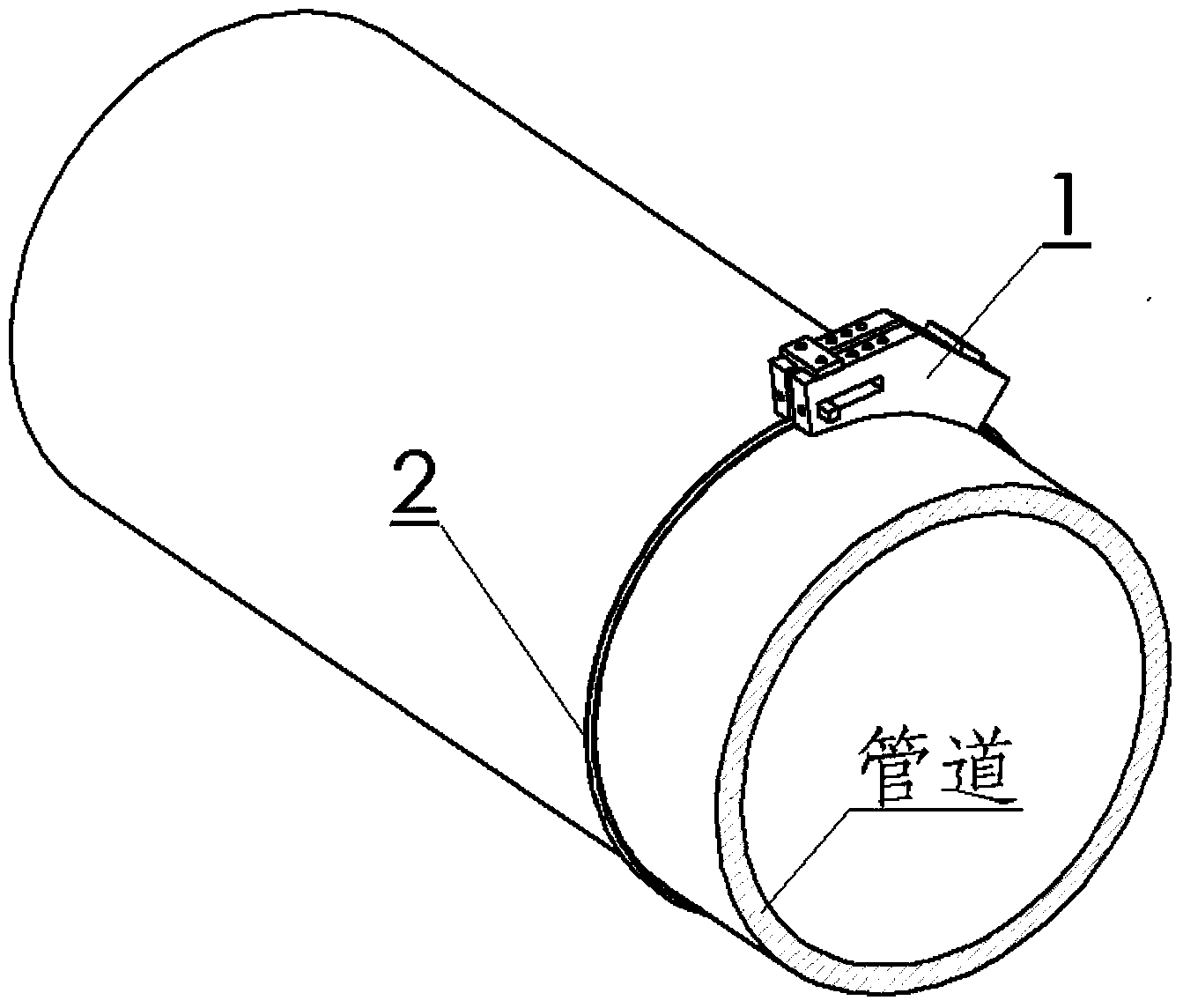

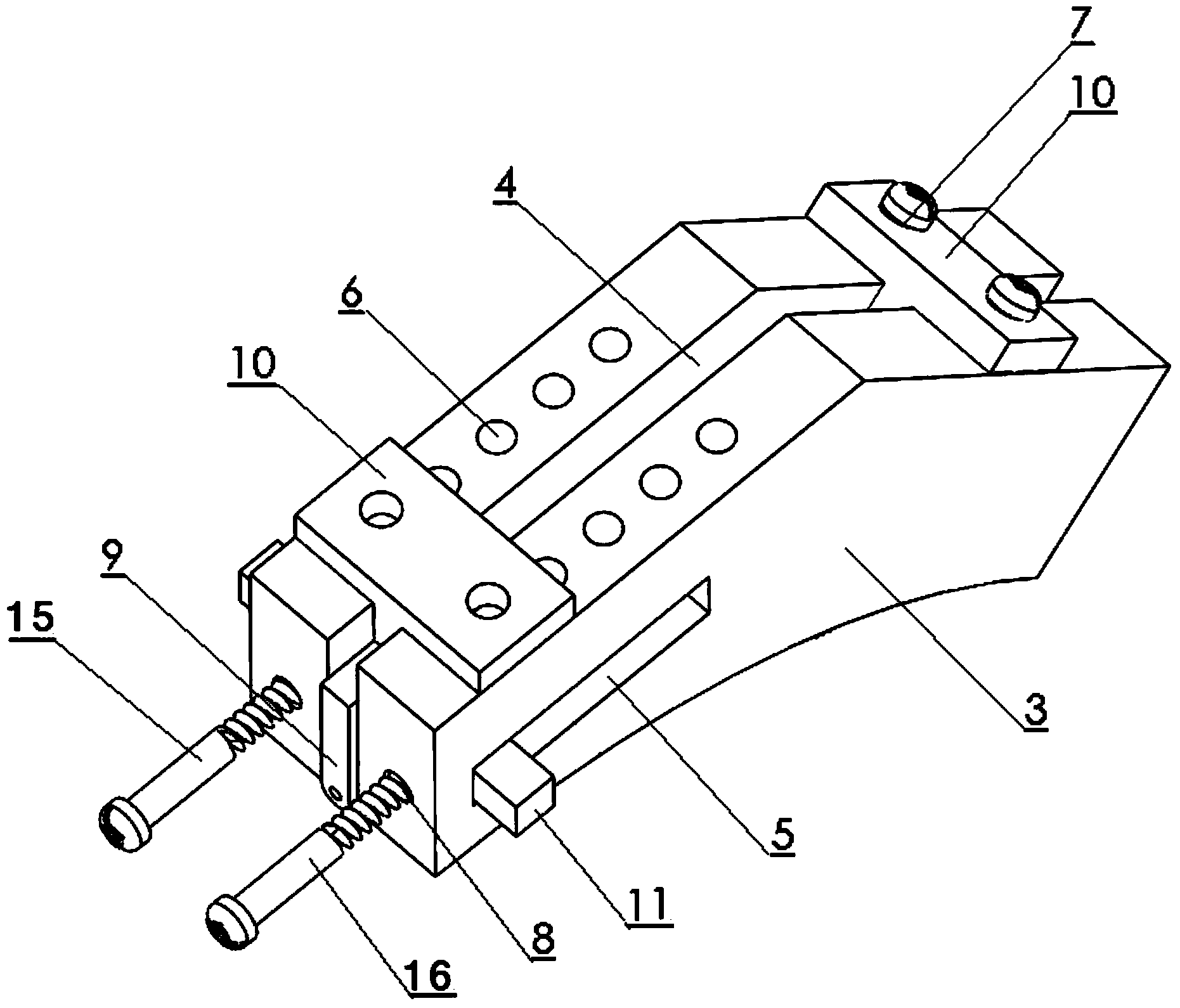

[0018] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

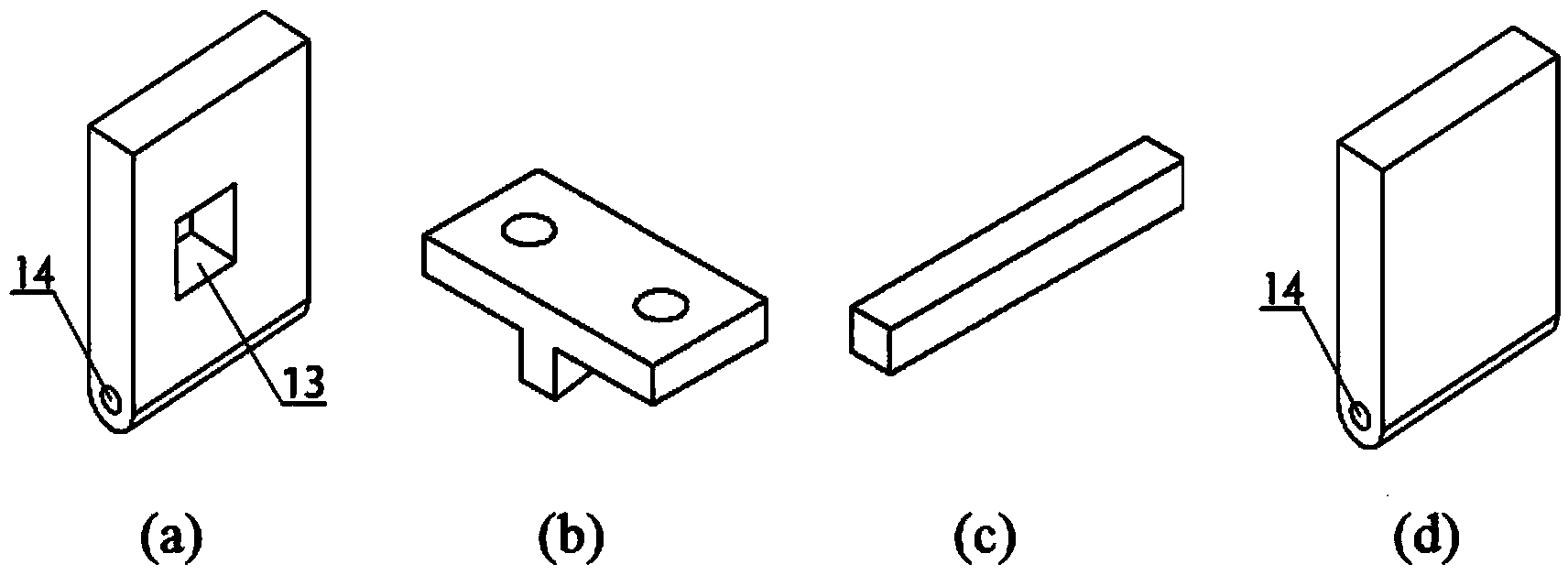

[0019] The contact surface between the holder support 3 and the pipe is arc-shaped, and the diameter of the arc is equal to the outer diameter of the pipe. There is a straight groove 4 along the long axis of the support. The axis of the groove bottom is tangent to the outer surface of the pipe; the left side of the axis of symmetry Open a rectangular slideway 5; open a pair of penetrating screw holes 8 at the left end of the holder support; open two rows of screw holes 6 on the left slope, and open a pair of fixing screw holes 7 on the right slope; when packaging the fiber grating sensor, Both ends of the optical fiber respectively pass through the optical fiber hole 14 at the lower end of the perforated slide 9 and the non-porous slide 12, and the prepared epoxy resin is filled into the optical fiber hole and waits ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com