A device and method for detecting longitudinal cracks in pipelines based on fiber grating sensing

A fiber grating and longitudinal crack technology, applied in the direction of measuring devices, optical devices, pipeline systems, etc., can solve problems such as troublesome installation, inability to accurately measure the specific position of pipeline cracks, difficulty in moving and reusing, etc., to reduce The effect of cost detection, accurate positioning, and work efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

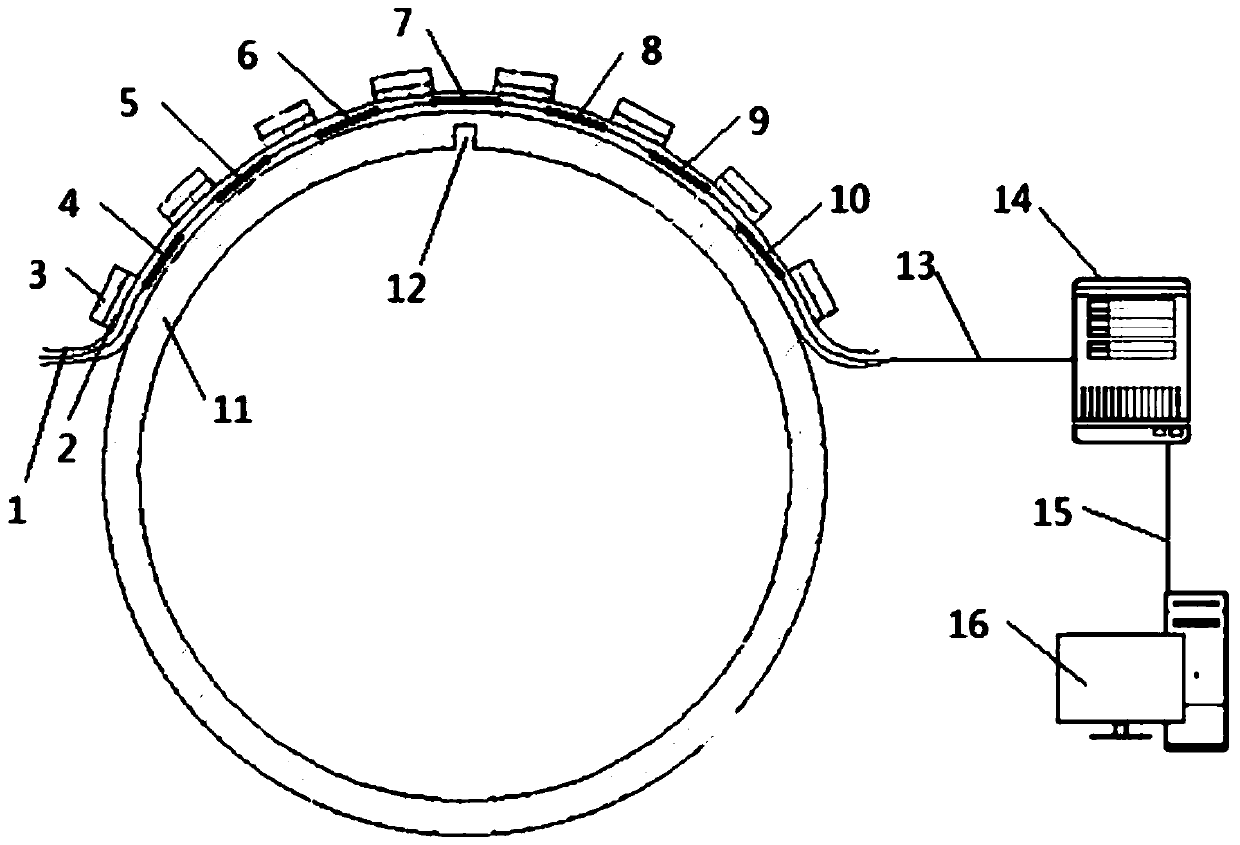

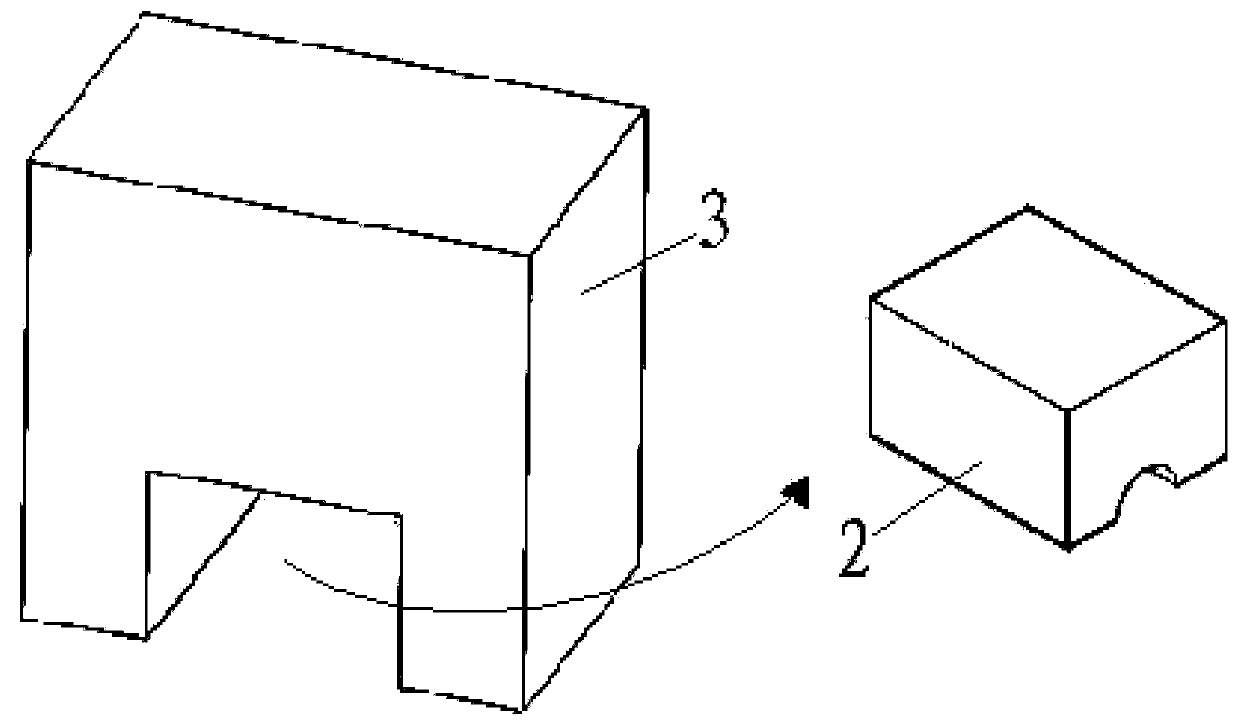

[0021] Such as figure 1 As shown, a pipeline longitudinal crack detection device based on fiber Bragg grating sensing includes a fiber grating array sensor, a fiber grating demodulator 14 and a data processing system 16 connected in sequence. The fiber grating array sensor is arranged along the outer wall of the pipeline 11 circumferentially, The fiber grating array sensor comprises a packaged optical fiber 1 and fiber gratings equidistantly distributed on the optical fiber 1 (in this embodiment, 7 fiber gratings are set, and the specific number can be selected according to the actual situation, not only 7 fiber gratings can be used. 1), the fiber grating array sensor is clamped and fixed on the outer wall of the pipeline 11 by the magnet 3 after being pre-stretched. The magnet 3 is located at the interval between adjacent fiber gratings and outside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com