Method for testing rock expansion force

An expansion force and rock technology, applied in the field of technical geotechnical engineering, can solve the problems of tediousness, inaccurate expansion force test, manual reading of the dial indicator degree error, etc., to improve accuracy, reduce human error, and ensure accurate sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

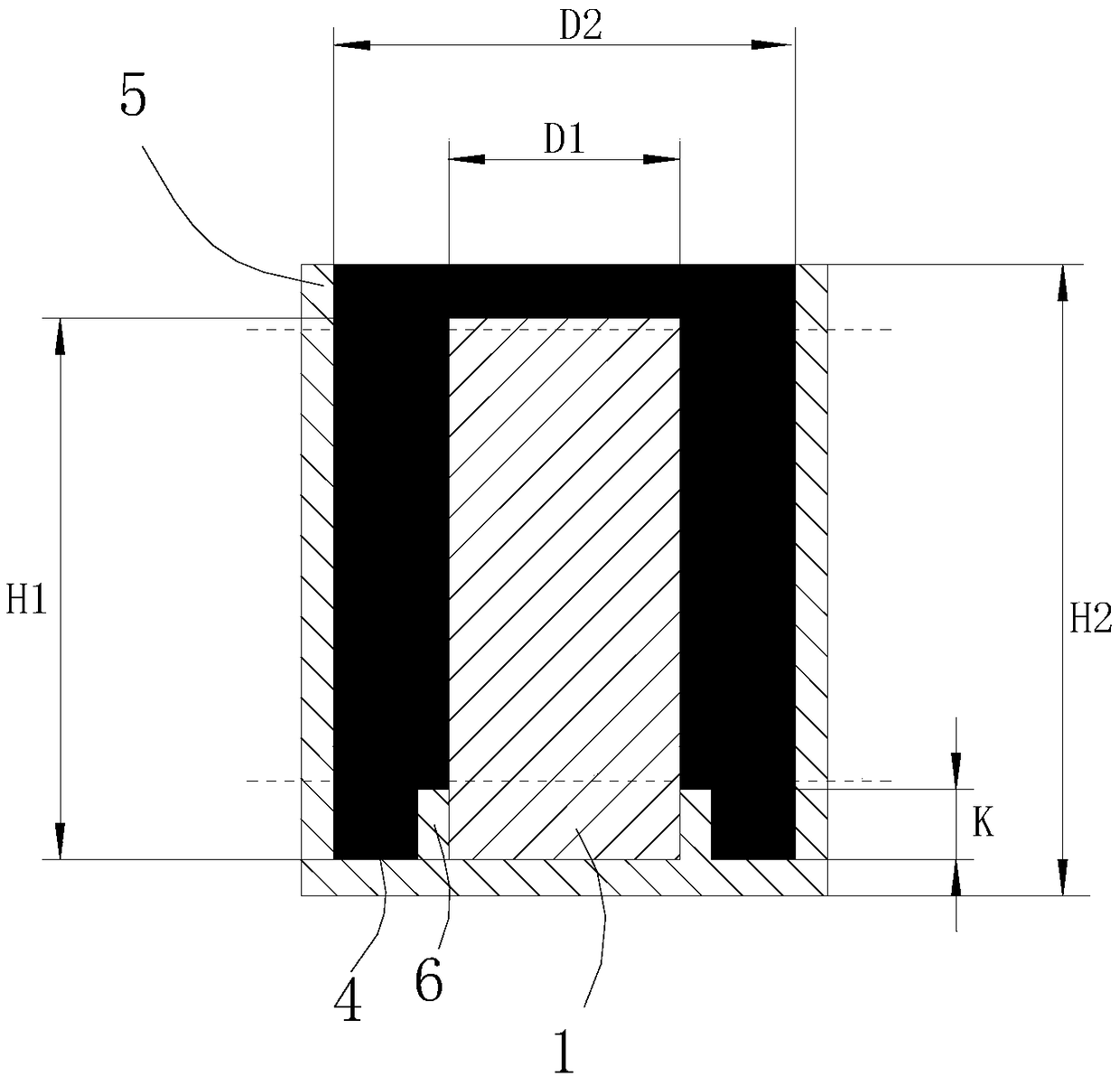

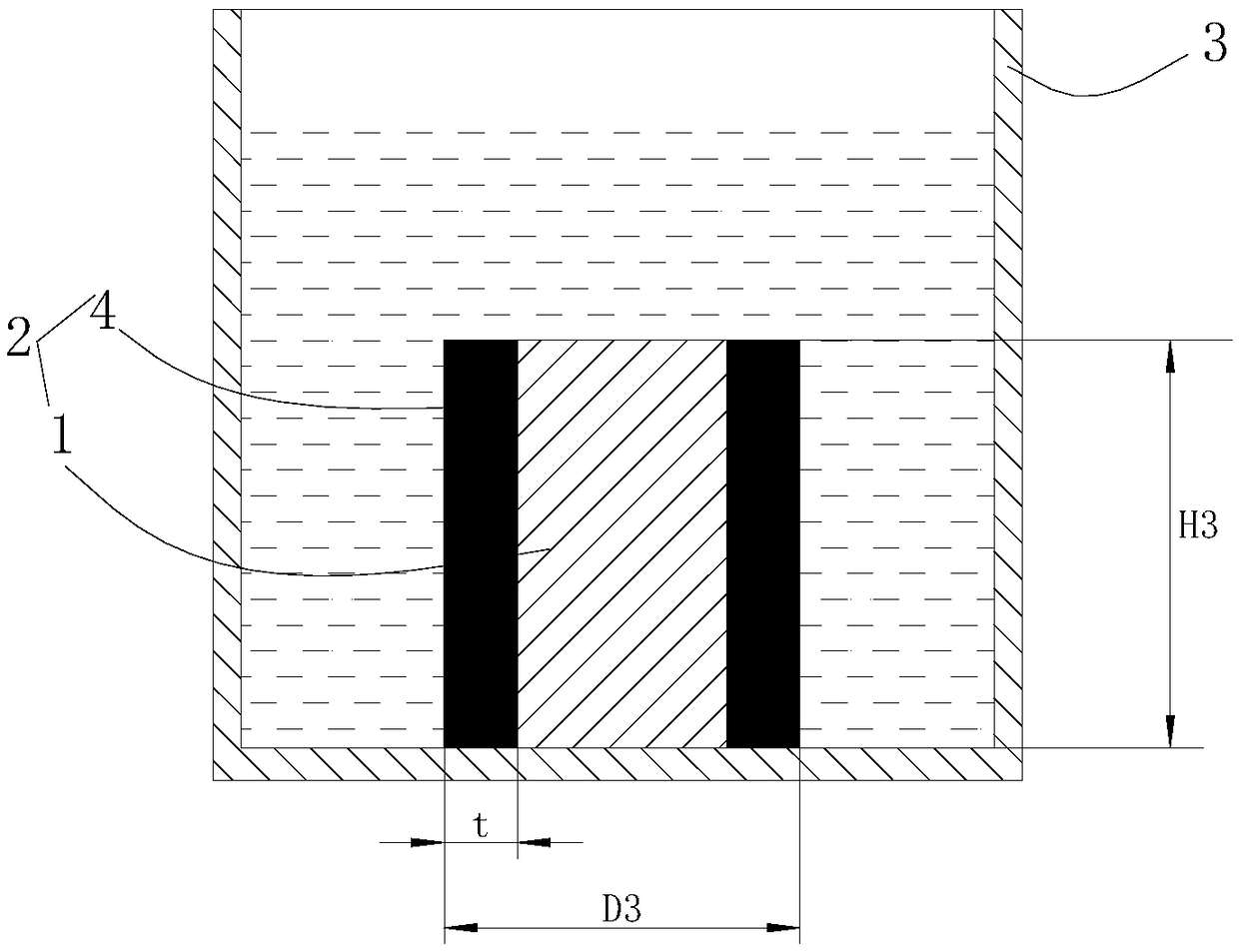

[0030] This embodiment relates to a method for testing rock expansion force, by figure 1 combine figure 2 As shown, the method includes the following steps:

[0031] S1, preprocessing, processing the rock into a cylindrical rock sample 1 with a diameter D1 of 25 mm and a height H1 of 60 mm;

[0032] S2, wrapping the adhesive layer 4 on the outer peripheral surface of the rock sample 1 to make the artificial rock core 2, and determine the elastic modulus E of the adhesive layer 4 by uniaxial mechanical testing;

[0033] S3, soaking the artificial rock core 2 with water, collecting relevant parameters of the adhesive layer 4 during the soaking process, and recording the hoop strain ε o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com