Calculation method of inner wall stress of coke tower

A coke tower and stress technology, which is applied in the calculation of the inner wall stress of the coke tower, can solve problems such as difficult stress calculations, and achieve the effect of reducing monitoring costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

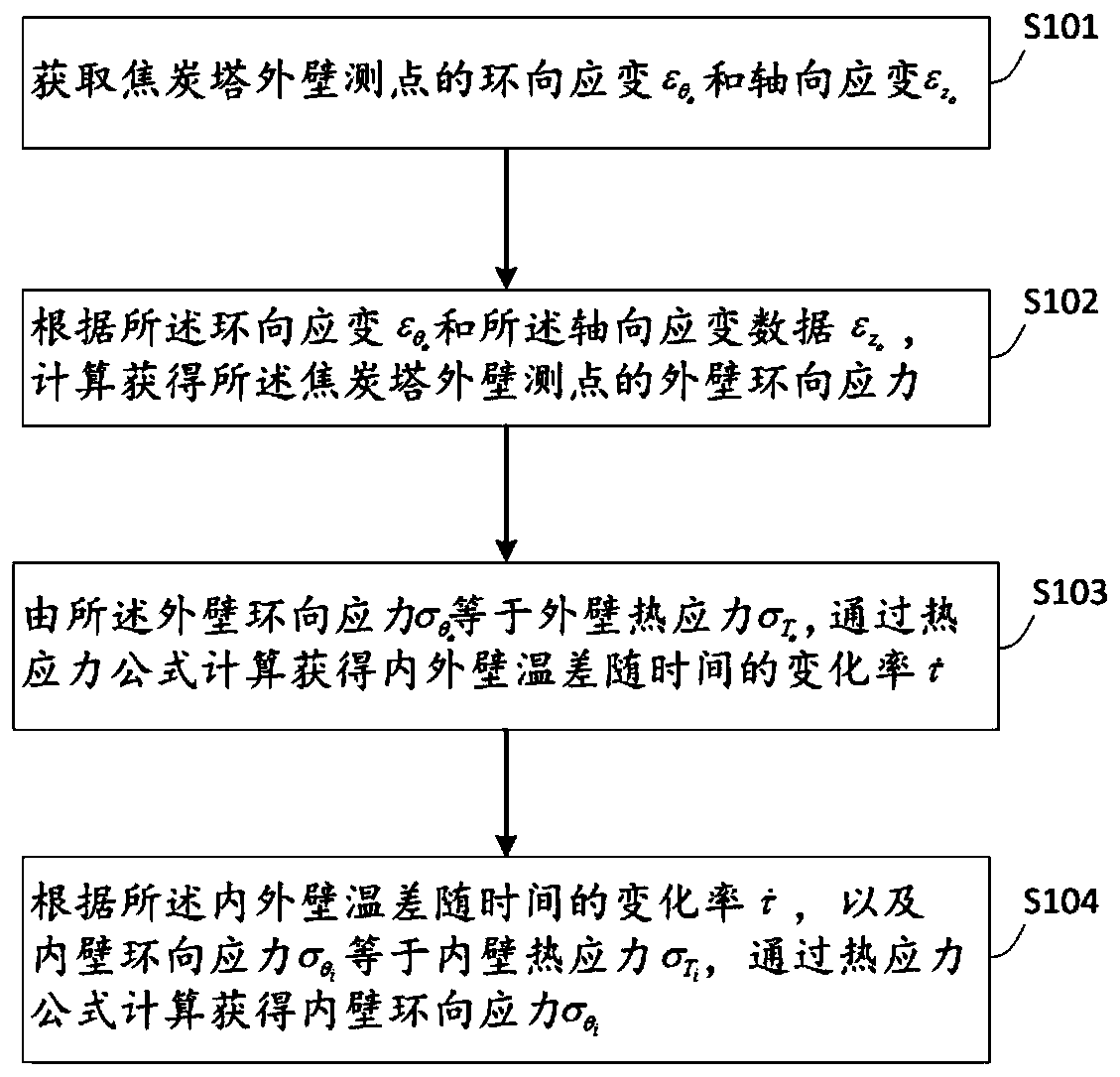

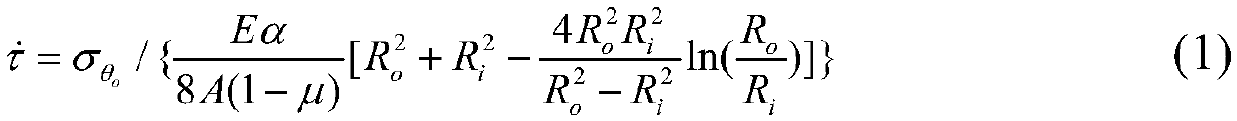

[0026] combine figure 1 , the calculation method of the inner wall stress of the coke tower in this embodiment includes the following steps:

[0027] S101: Obtain the hoop strain of the measuring points on the outer wall of the coke tower and axial strain

[0028] In this step, a high-temperature-resistant strain gauge is installed at the measurement points on the outer wall of the coke drum, and each measurement point is equipped with a high-temperature-resistant strain gauge in the axial and circumferential directions, and each high-temperature-resistant strain gauge is connected to a measurement channel of the strain gauge. The strain gauge collects the hoop strain of the coke tower measuring point through the high temperature resistant strain gauge and axial strain data.

[0029] S102: According to the hoop strain and the axial strain Data, calculate and obtain the outer wall hoop stress of the outer wall measuring point of the coke tower

[0030] This step...

Embodiment 2

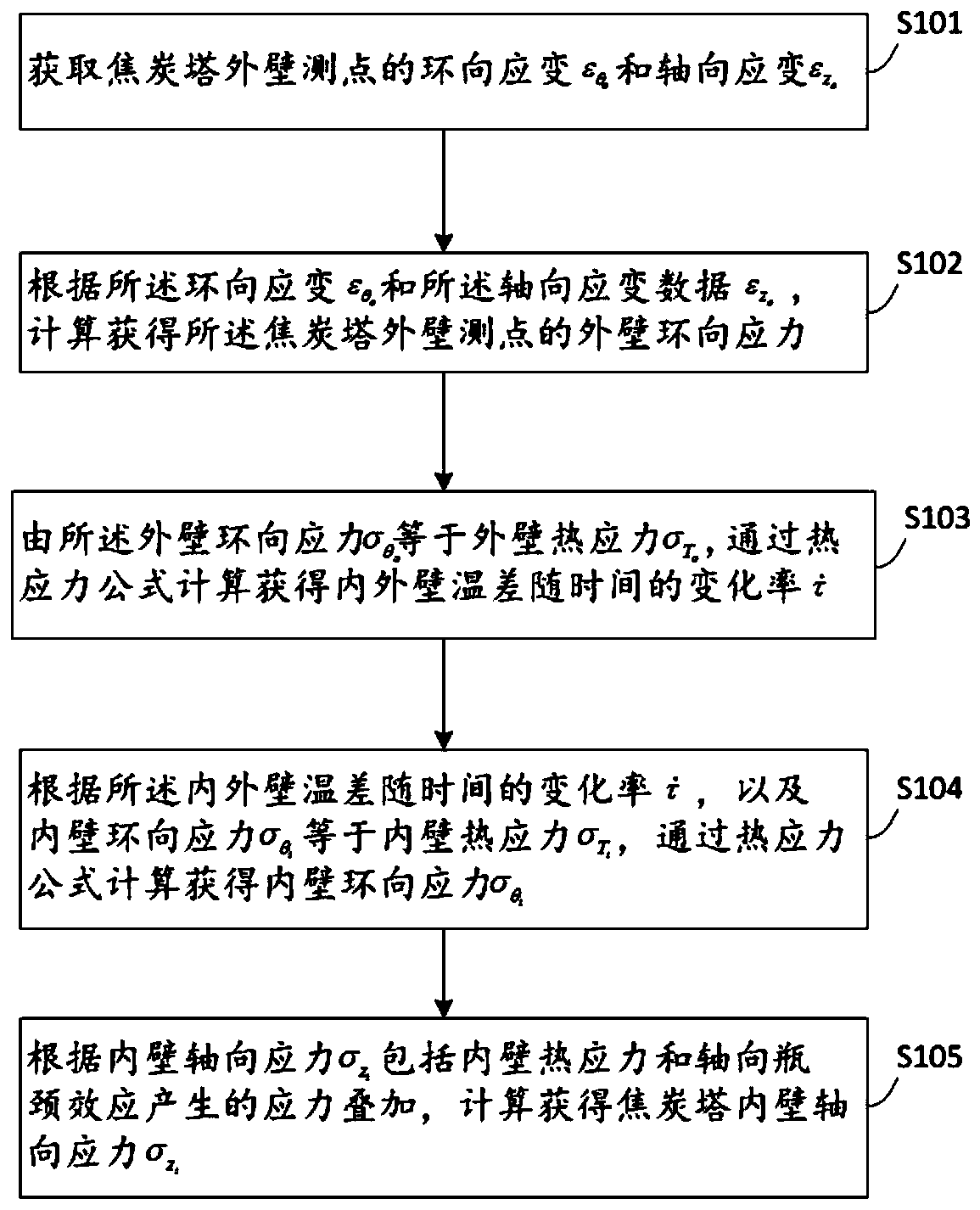

[0043] see figure 2 , this embodiment is based on Embodiment 1, the difference is that step S105 is also included.

[0044] S105, according to the axial stress of the inner wall Including the thermal stress on the inner wall and the stress superposition caused by the axial bottleneck effect, the axial stress on the inner wall of the coke drum is calculated

[0045] In this step, the axial stress on the inner wall is expressed as roll out

[0046]

[0047] in, is the axial stress on the outer wall, Stress due to axial bottleneck effect.

Embodiment 3

[0049] The method for calculating the stress of the inner wall of the coke tower provided in this example is based on the method in Example 2. The initial whole is in a uniform temperature field (120°C), and then the inner wall is directly cooled to room temperature (30°C), and its transient temperature field and thermoelastic field. The parameters of the material 15CrMo of the coke tower are shown in Table 1.

[0050] Table 1 Geometric parameters and material parameters

[0051]

[0052] The method for calculating the inner wall stress of the coke drum provided in this example has a very high precision in estimating the inner wall stress of the coke drum, and the relative error is less than 3.7%, which is now verified by finite element simulation. The numerical simulation of the thermoelastic field of a thin-walled cylinder with open ends is carried out by using the finite element method. The whole cylinder is initially in a uniform temperature field (120°C), and then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com