Method and system for calculating extrusion stress of isotropic double-pipe concrete column

A technology of extrusion stress and concrete columns, applied in the direction of columns, pillars, pier columns, etc., can solve the problems of difficult research, measurement, and inability to pass direct tests, etc., and achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

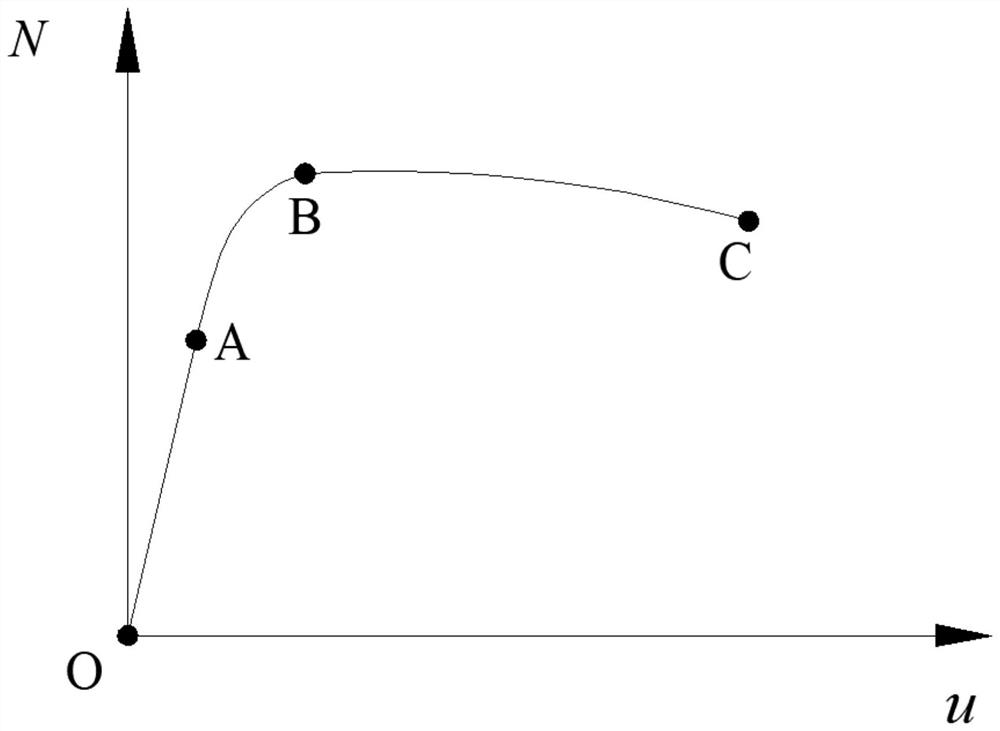

[0088] In order to study the axial compression performance of the dual steel pipe concrete column, the typical load - displacement curve of the dual steel pipe concrete column (eg figure 1 The shown is divided into three phases: the elastic phase (OA), the elastoplastic phase (AB), and the decline (BC). In the elastic phase (OA): At this stage, the load increases as the displacement increases. Regarding the location of a point, it is generally 0.70 to 0.85 times limit load. In the elastoplastic phase (ab): The load is no longer increased as the displacement increases. The slope of the load-displacement curve gradually decreases until a peak load is reached. In the decreased segment (BC), with the increase in displacement, the load is lowered. It is worth noting that as the curved coefficient increases, the decline may become gentle, and even the continuation of the load.

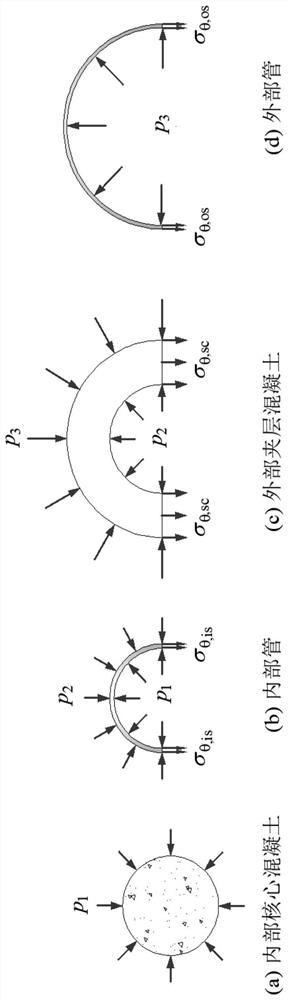

[0089] In the actual engineering, the components are generally in a state of elastic pressure. Analysis of th...

Embodiment 2

[0234] In this embodiment, it provides the method of extrusion stress calculation system described above, and the method described in can be achieved.

[0235] In this example, the isotropic dual-tube concrete column extrusion stress computing system includes parameter acquisition module, internal core concrete force deformation analysis module, internal tube force deformation analysis module, external interlayer concrete deformation analysis module, external The stress deformation analysis module, the extrusion stress analysis module, the calculation module, the image forming module, the input display module, and the control module.

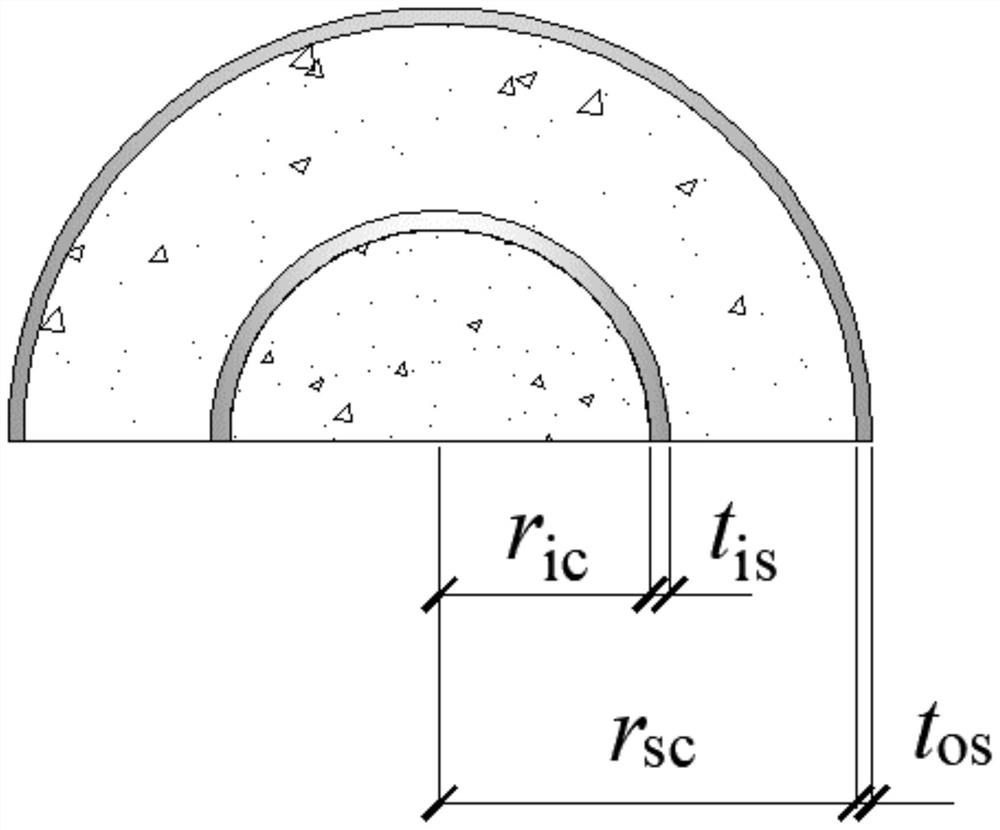

[0236] The parameter acquisition module is used to obtain the calculation parameters of the dual-tube concrete column, and the calculation parameters include: Poisson ratio, elastic modulus, internal pipe and external pipe of internal core concrete and exterior pipes, and Poisson, elastic modulus, Inner diameter, wall thickness, etc.

[0237] The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com