High-speed intelligent band sawing machine

An intelligent band sawing machine, high-speed technology, applied in the field of sawing machines, can solve the problems of inability to form a closed loop, few feed speed adjustment parameters, and inability to adjust the sawing speed in time, so as to achieve the effect of ensuring the sawing effect and the life of the sawing belt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

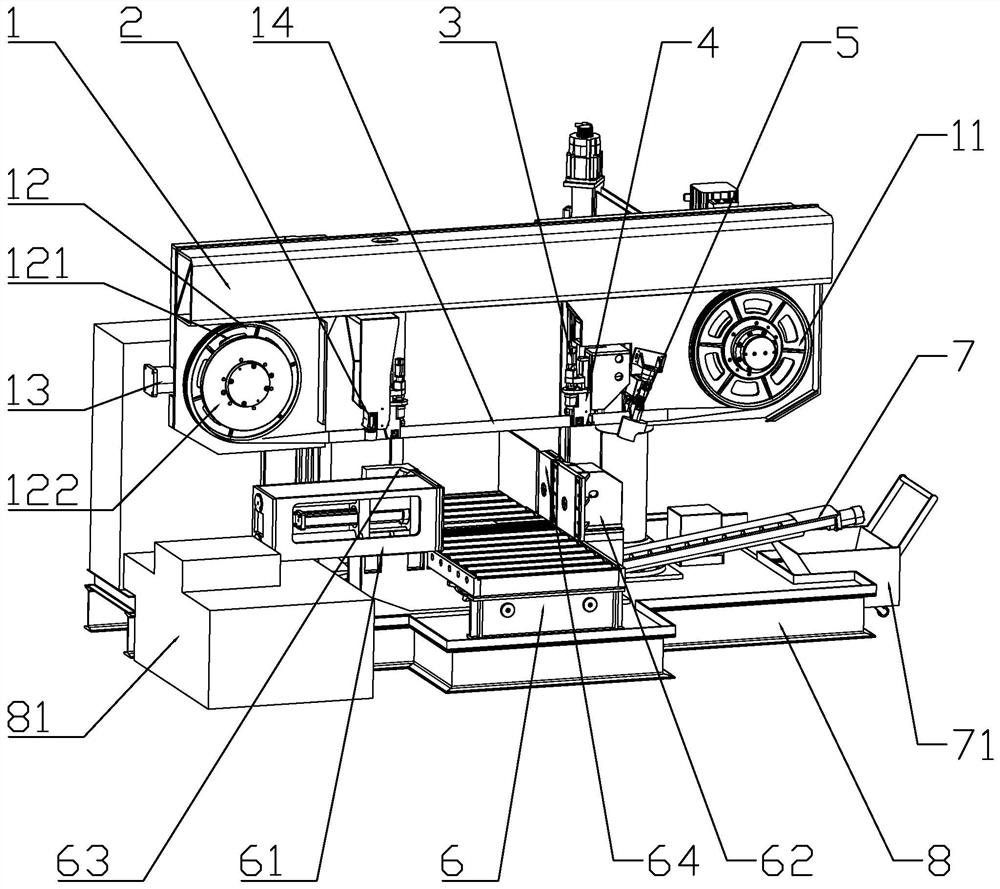

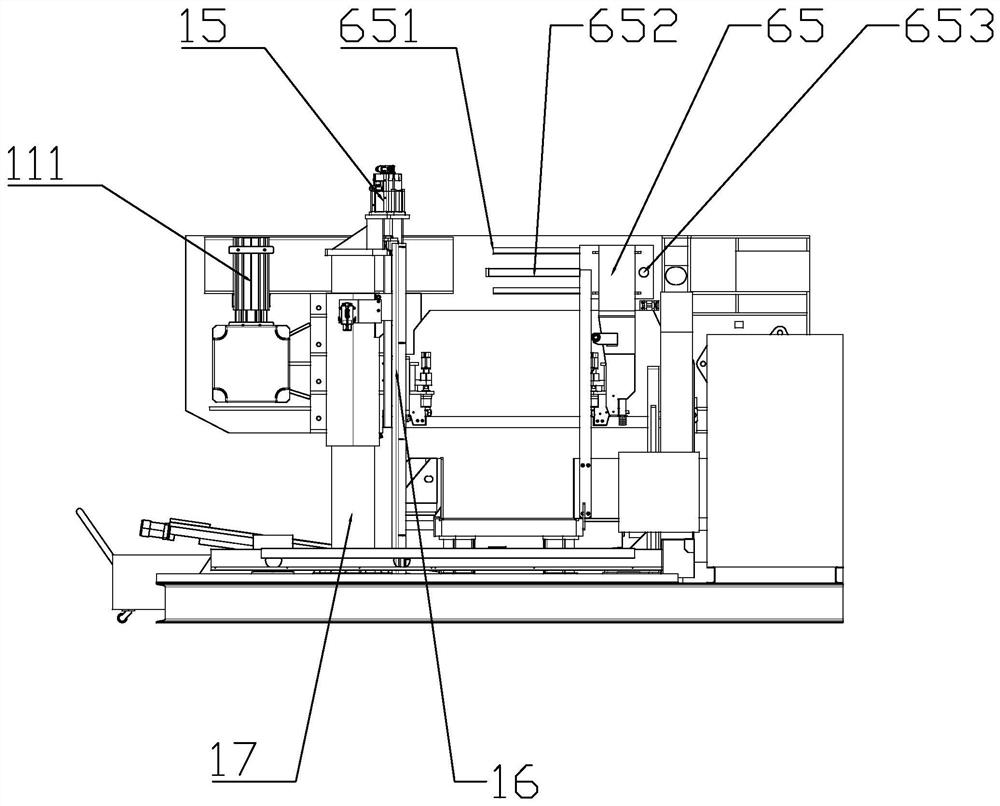

[0046] Such as figure 1 , figure 2 In the shown embodiment 1, a high-speed intelligent band sawing machine includes a base, a bed platform and a saw frame 1, the bed platform is arranged on the base, and is used to place and clamp transport materials, and the bed platform includes a feeding belt 6, respectively The front clamping device and the rear clamping device on the front side and the rear side of the saw band, the rear clamping device is slidably arranged on the bed platform along the feeding direction, and the front clamping device includes a front movable jaw 63 and a front movable jaw on both sides of the feeding belt. The front micro-movement jaw 64, the rear clamping device includes a rear movable jaw 61 and a rear micro-movement jaw 62 on both sides of the feeding belt, the rear movable jaw 61 and the rear micro-motion jaw 62 are connected at the bottom, and the front movable jaw 63 and the rear movable jaw 61 are slidably connected on the bed platform along the...

Embodiment 2

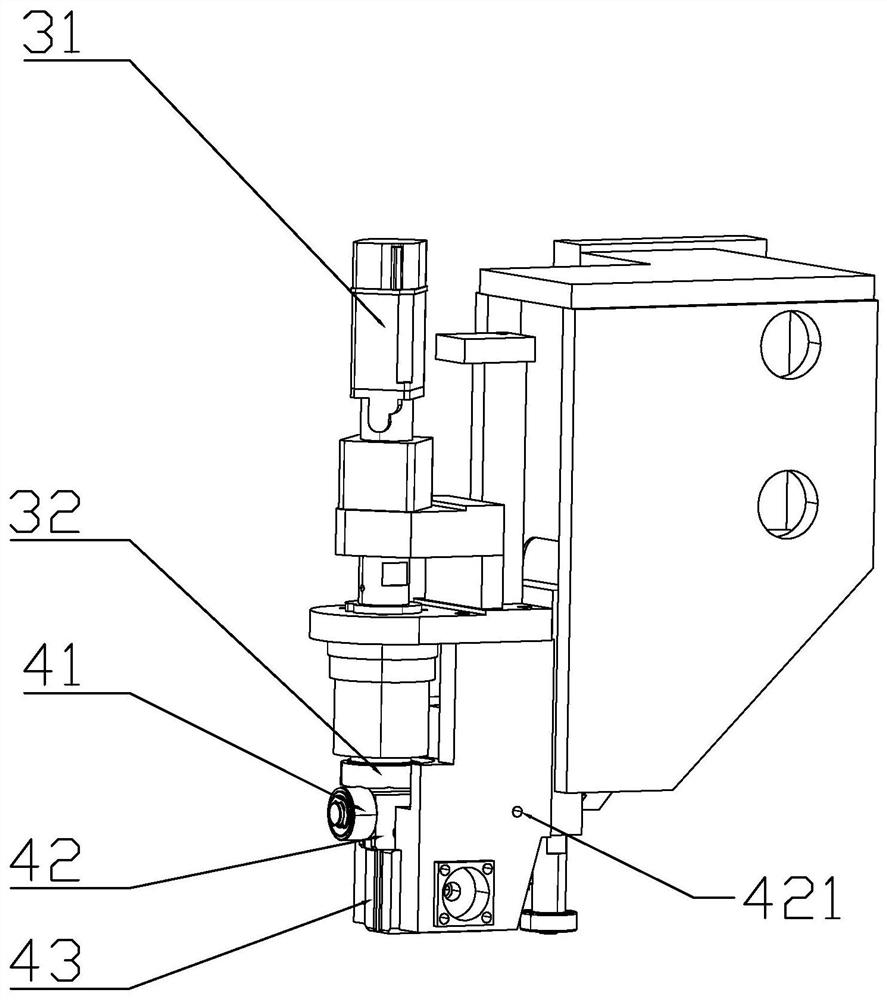

[0059] Such as Figure 8 In the shown embodiment 2, a high-speed intelligent band sawing machine has roughly the same structure as that of embodiment 1, the difference is that the lowest points of the two adjacent circular arc concave surfaces 323 are connected by a concave plane, A long concave surface 324 with both ends being circular arc surfaces is formed, and the long concave surface 324 extends along the circumferential direction.

[0060] After the pulse chip breaking device is started, the toggling surface drives the pulse bearing 41 to rotate. When the circular arc concave surface 323 of the toggling surface contacts the bearing, the end of the point pressing member 42 vibrates up and down at a certain frequency at the same time, pressing The back of the saw band makes the saw band vibrate up and down according to the frequency; when the long concave surface 324 of the toggle surface is rotated to contact with the bearing, the contact time between the long concave sur...

Embodiment 3

[0062] A high-speed intelligent band sawing machine, the structure of which is roughly the same as that of Embodiment 2, the difference is that an outwardly convex arc convex surface is provided between the arc concave surfaces 323, and the toggle surface extends circumferentially except for the long concave surface 324 wavy surface. When the bearing abuts against the wave surface, the saw band performs simple harmonic vibration, which increases the downward pressure range and enhances the chip breaking effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com